Efficient cross-flow wind wheel

A cross-flow wind rotor, high-efficiency technology, applied in the components of the pumping device for elastic fluid, non-variable-capacity pump, noise suppression, etc. weight issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

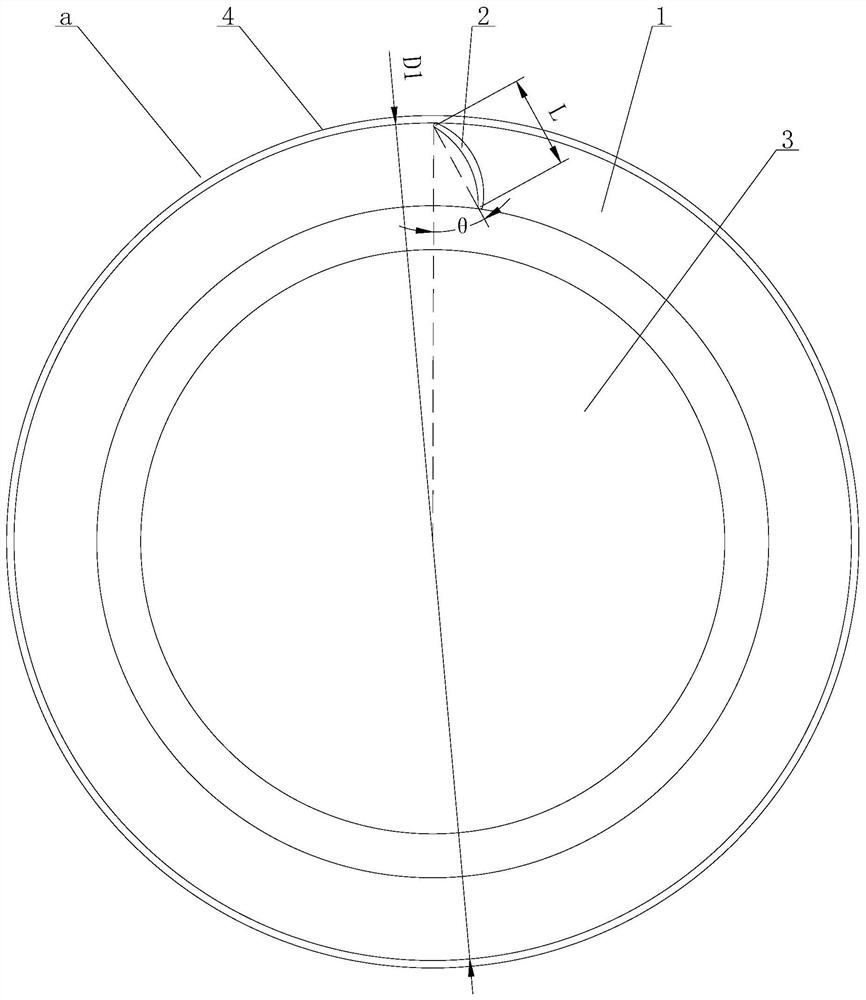

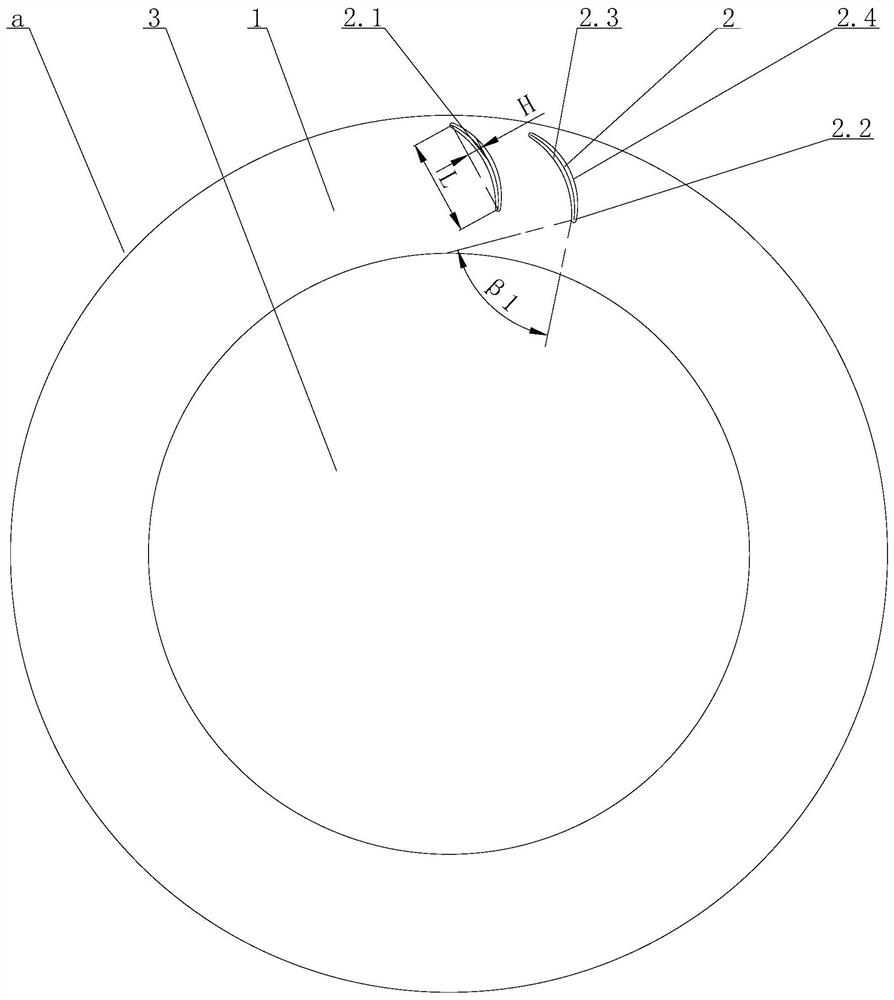

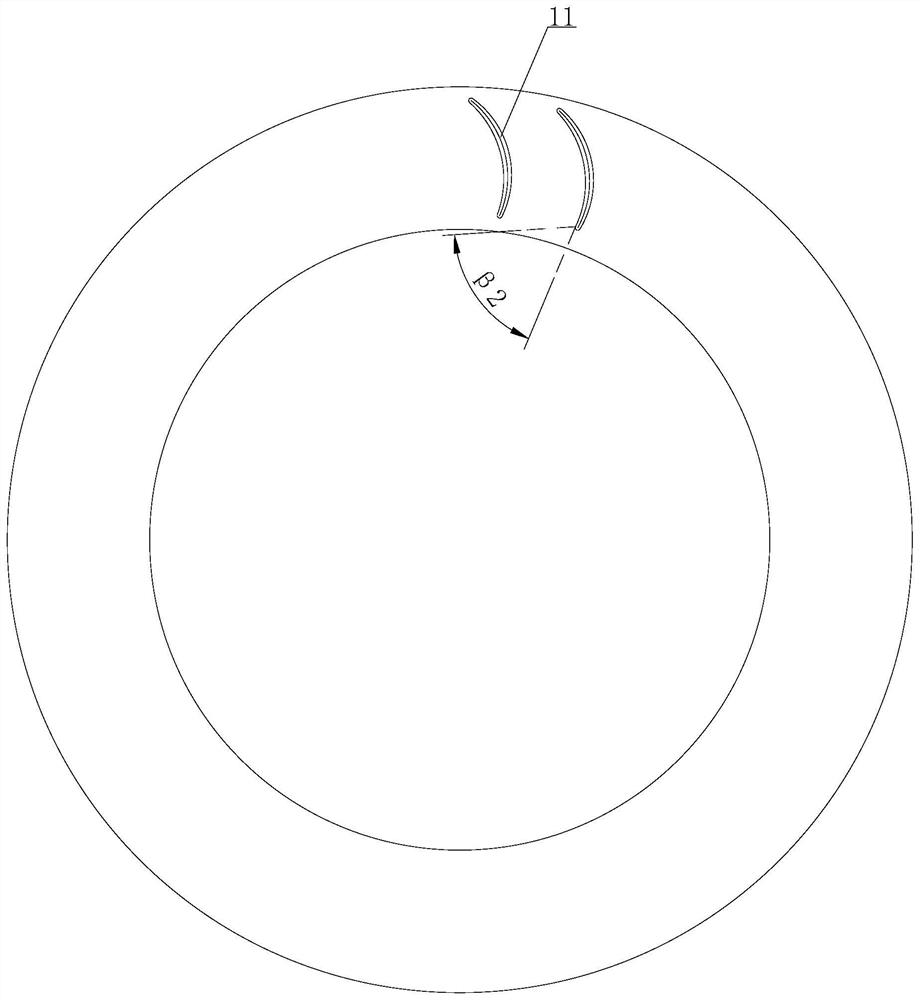

[0016] see Figure 1-Figure 2 , the high-efficiency cross-flow wind wheel includes at least one middle-section wind blade a, the middle-section wind blade a includes a middle plate 1, and a plurality of blades 2 are annularly arranged on the peripheral side of the middle plate 1. The blades 2 are short-chord blades, and the effective The outer diameter (i.e. the diameter of the tangential circle of the end arcs of all blades 2 close to the outside of the blade) is D1, the chord length of the blade 2 (i.e. the length of the common tangent line of the arcs at both ends of the blade 2) is L, 0.095<L / D1<0.115, This design makes the length of the blade 2 shorter, which is beneficial to reduce the weight of the blade 2, thereby reducing the weight of the wind rotor, and effectively increases the distance between the blade 2 and the hub 3, and the inclination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com