Bypass type double-throat passive vectoring sprayer nozzle

A technology of vector nozzle and double throat, which is applied in the field of bypass double throat passive vector nozzle to achieve the effect of small flow loss and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

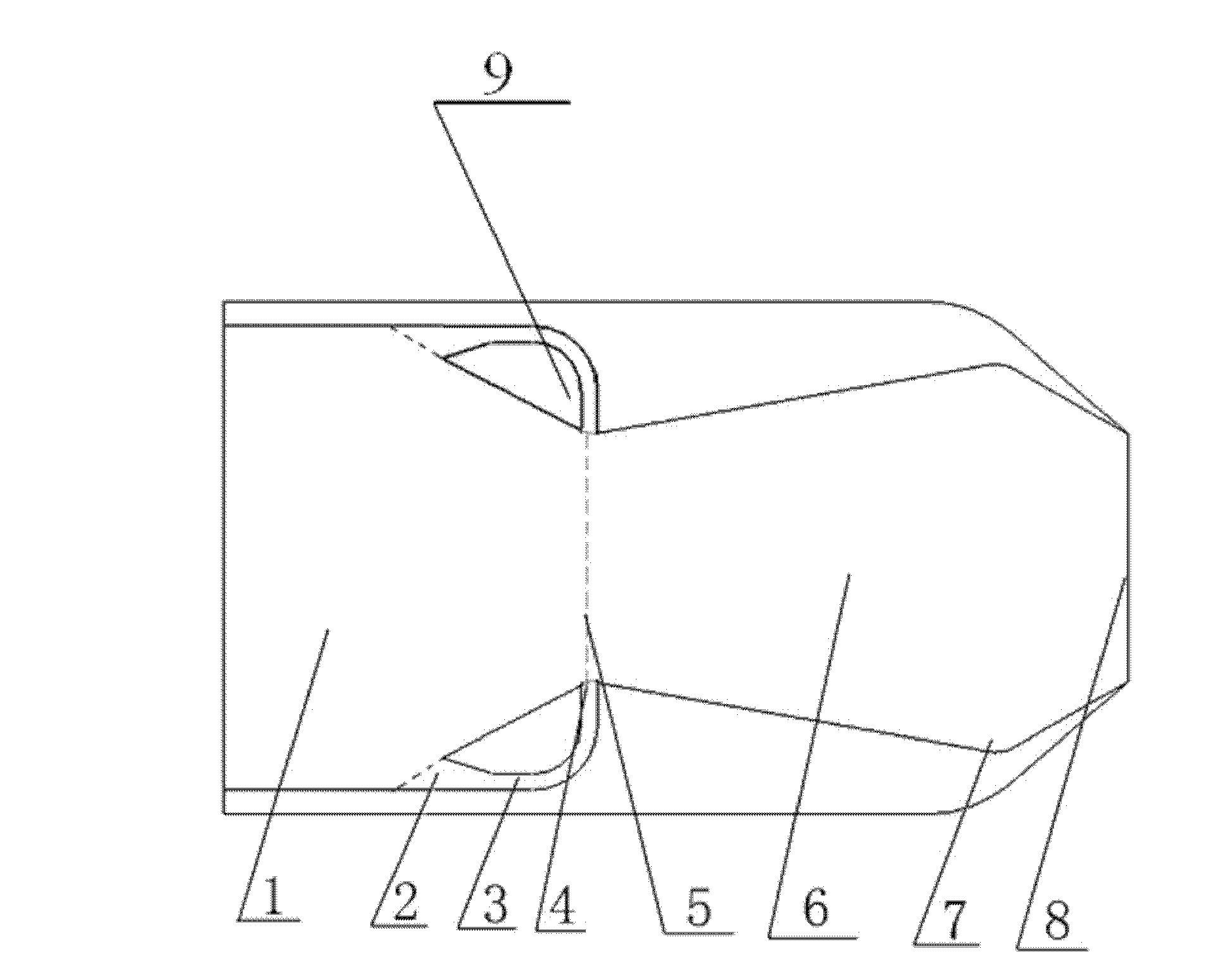

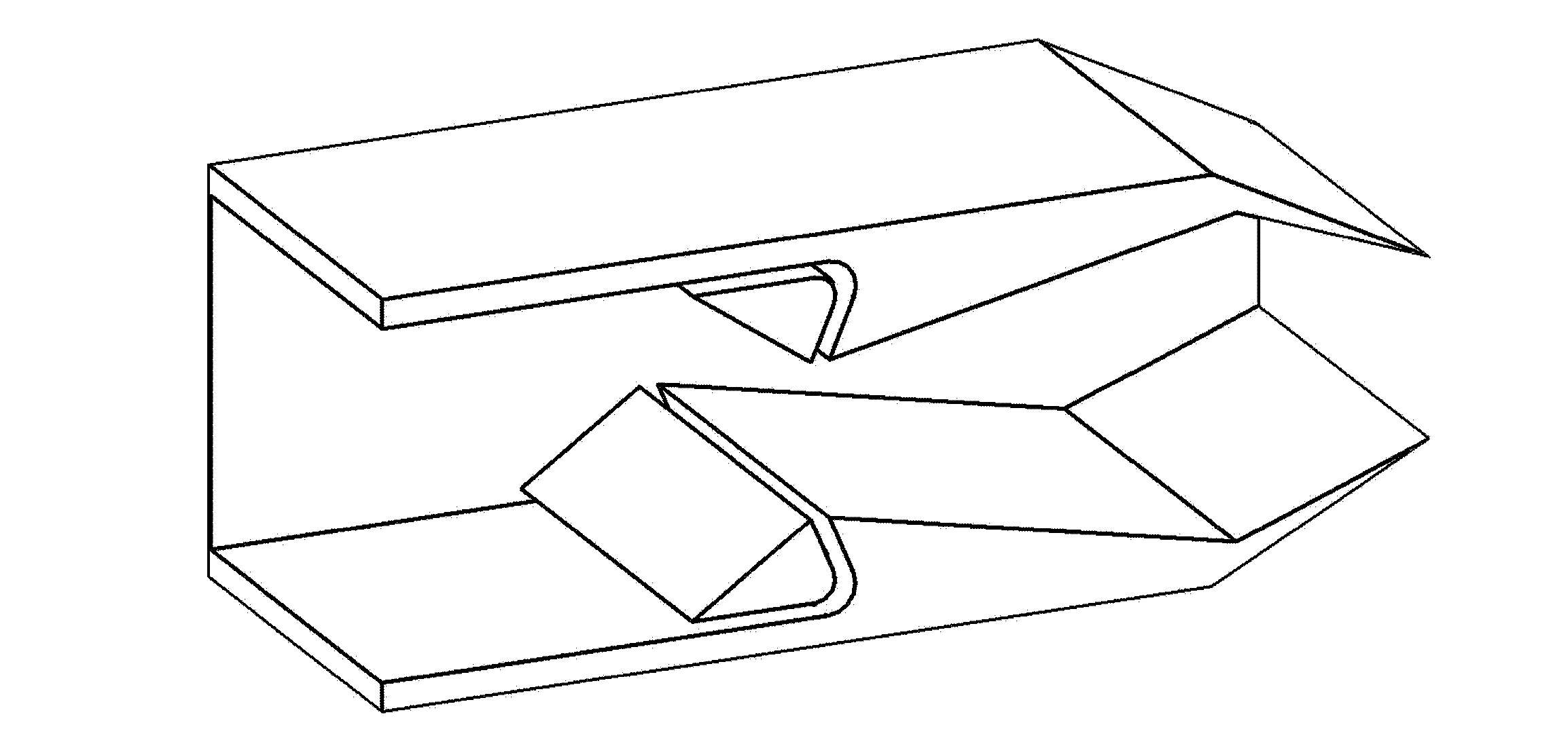

[0019] like figure 1 and figure 2 As shown, it is a schematic diagram of the structure of the present invention applied to the dual-throat nozzle. The present invention adds a bypass channel system to the existing dual-throat nozzle, which is the present invention. The bypass type double-throat passive vector nozzle includes a nozzle body, and the inner flow path of the nozzle body includes a converging section at the front of the throat, a throat, an expanding and converging section at the front of the second throat, Throat cavity and two throats, the converging section at the front of the throat is provided with a bypass channel adjacent to a throat, and the bypass channel is formed by a bypass projection transversely arranged in the inner flow channel of the nozzle body, The two end faces of the bypass projection perpendicular to the axis of the nozzle body are respectively welded and fixed to the inner channel of the nozzle body; the inlet of the bypass channel is arrang...

Embodiment 2

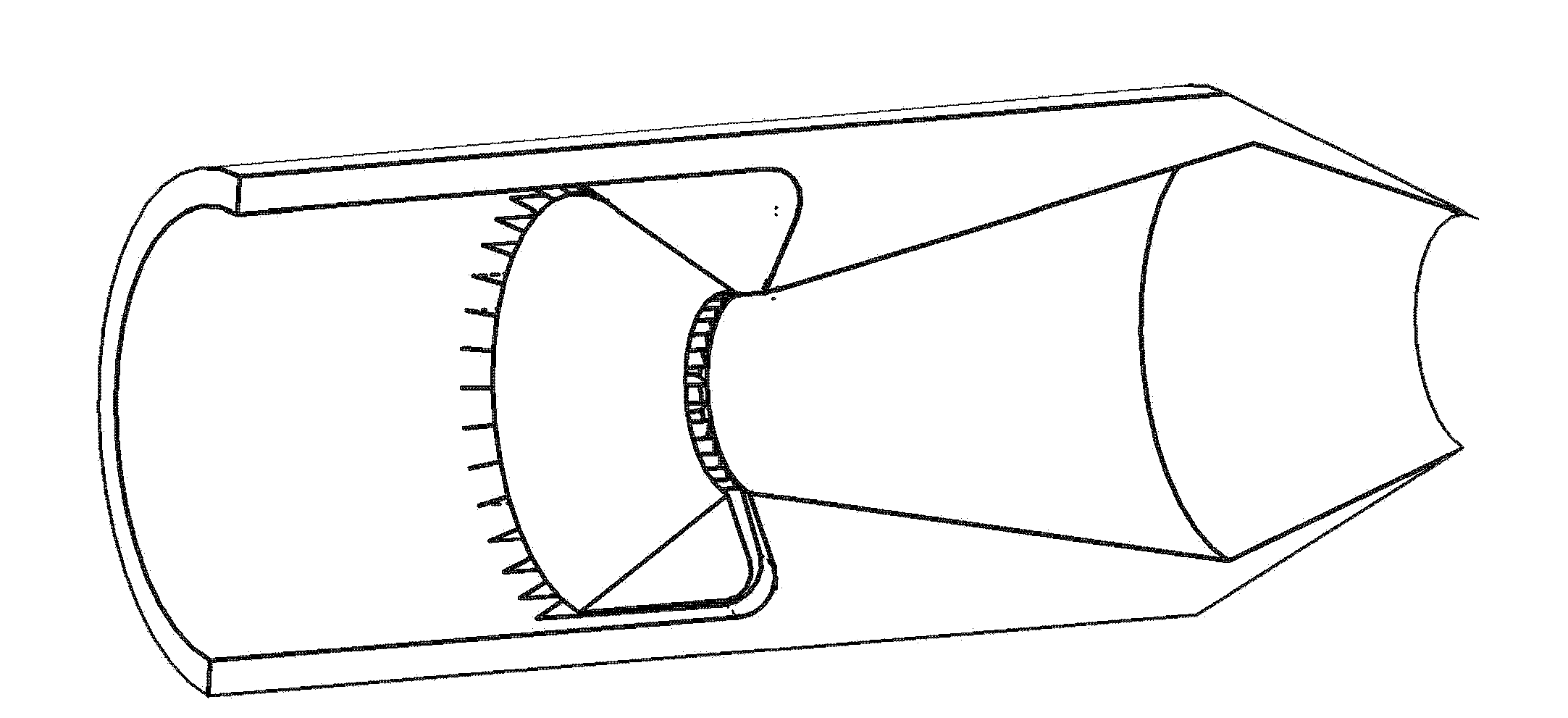

[0024] like figure 1 and 3 As shown, it is a structural schematic diagram of the present invention applied to an axisymmetric double-throat nozzle. The present invention adds a bypass passage system to the existing axisymmetric double-throat nozzle. The installation position, the height of the inlet of the bypass channel, the height and width of the outlet of the bypass channel, and the axial length of the bypass channel are all consistent with those in Embodiment 1. Only the way of forming the bypass channel in this embodiment is different from that in Embodiment 1. details as follows:

[0025] The present invention forms a bypass passage by arranging a bypass projection at a position close to a throat in the flow passage of the nozzle body. The interior of the bypass projection is provided with a flow passage along the axis, and the outer edge of the bypass projection is uniform in the circumferential direction. The protruding ribs are arranged, and the protruding ribs ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com