Portable blower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

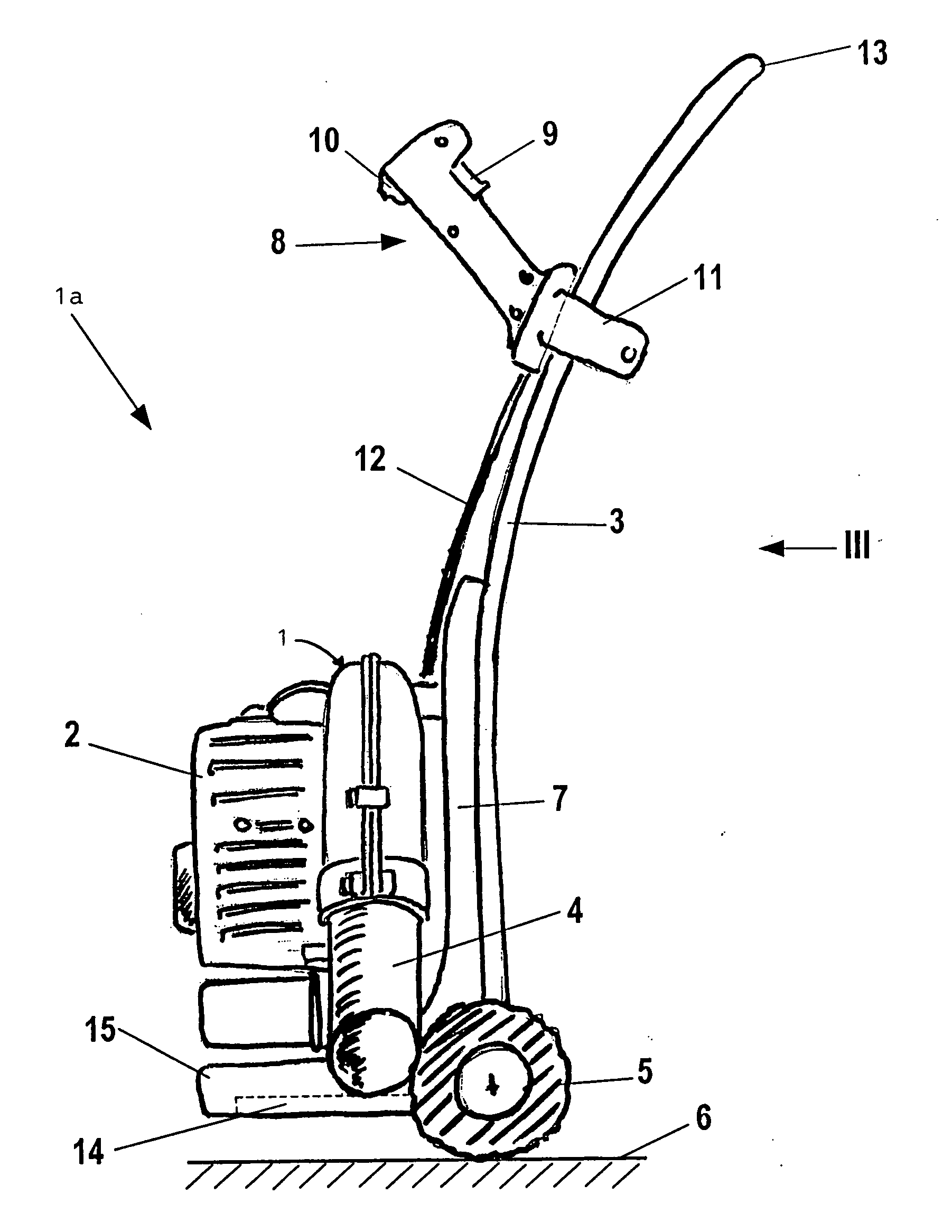

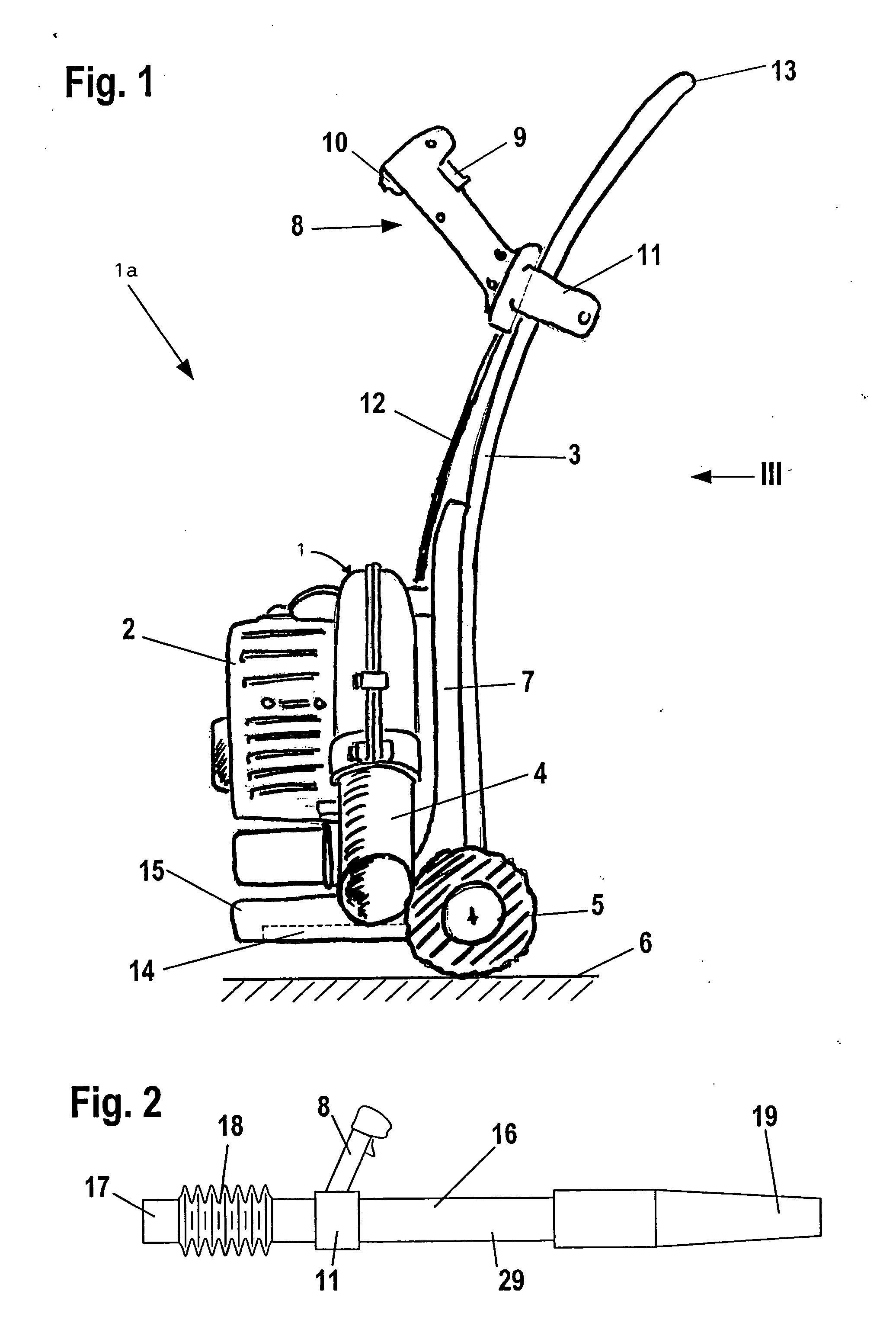

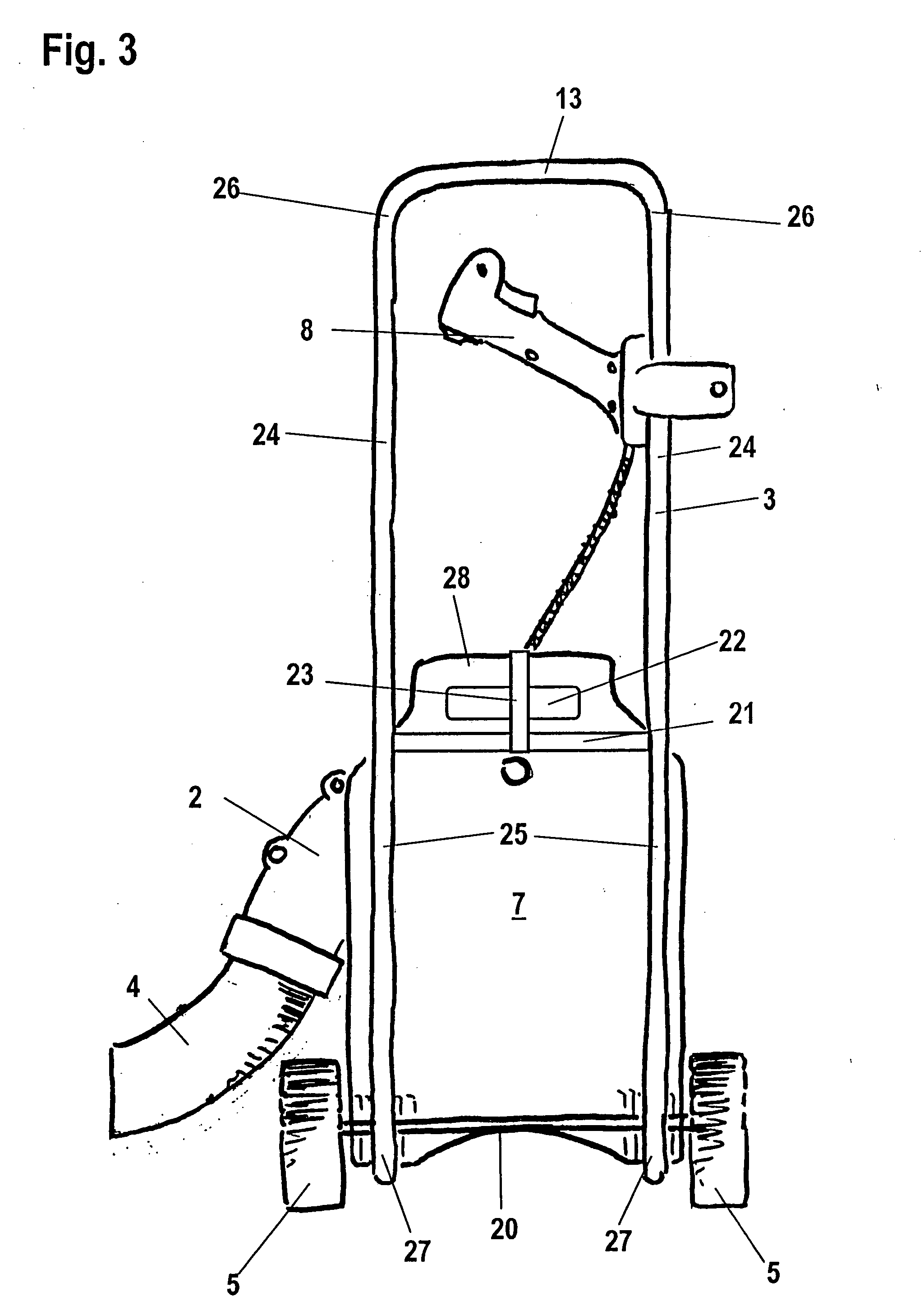

[0015] The blower unit 1 shown in FIG. 1 includes a housing 2 in which an internal combustion engine is mounted. The internal combustion engine is usually a two-stroke engine and drives a blower wheel which generates an air flow through a discharge pipe 4. The discharge pipe 4 is configured as a short pipe-shaped stub and terminates at a small spacing above the ground 6. The housing 2 of the blower unit 1 includes a back-carrier plate 7 which is configured as a separate component and is tightly connected to the housing 2. A base section 15 is formed on the back-carrier plate 7 at the end of the plate facing toward the ground 6. The base section 15 extends approximately perpendicularly to the back-carrier plate 7. An operator-controlled unit 8 is provided for operating the blower arrangement 1a which includes a moveable rack 3. The operator-controlled unit 8 includes a throttle lever 9 and a switch 10. The switch 10 can be a selector switch for adjusting different modes of operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com