Design method of fuel injection system for scramjet engine

A fuel injection system, scramjet technology, applied in computing, special data processing applications, instruments, etc., can solve the lack of understanding of the internal flow field of the combustion chamber, the lack of information transmission and feedback mechanisms, and the difficulty of flow at the outlet of the hypersonic intake port. and other problems, to achieve the effect of strengthening the degree of integrated design, enhancing the fuel injection and blending ability, and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

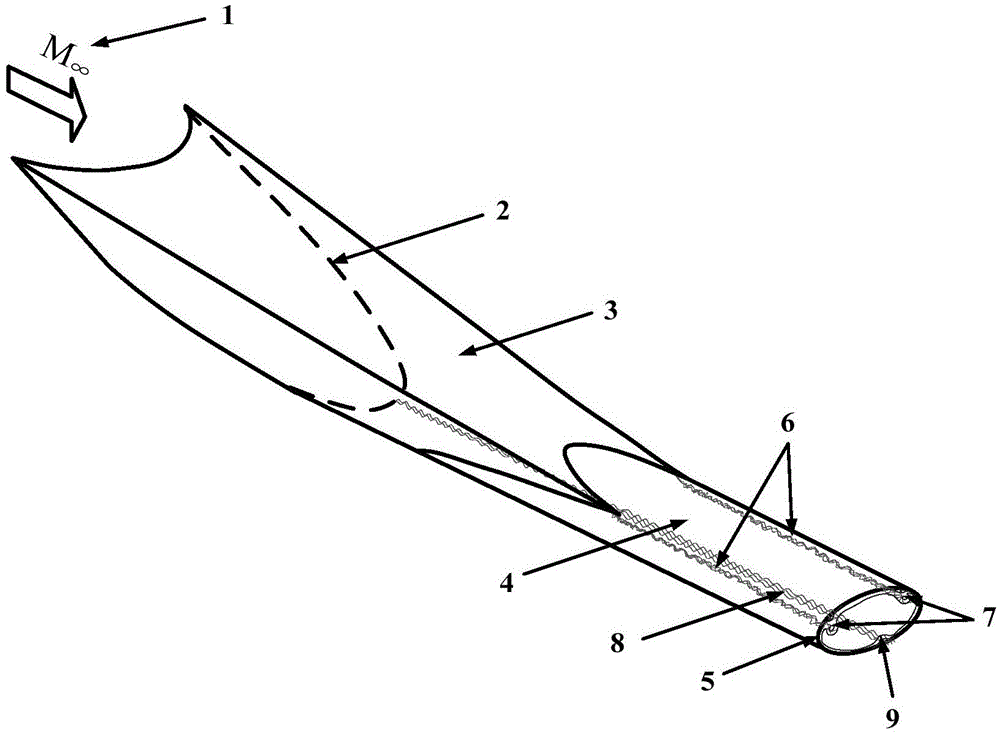

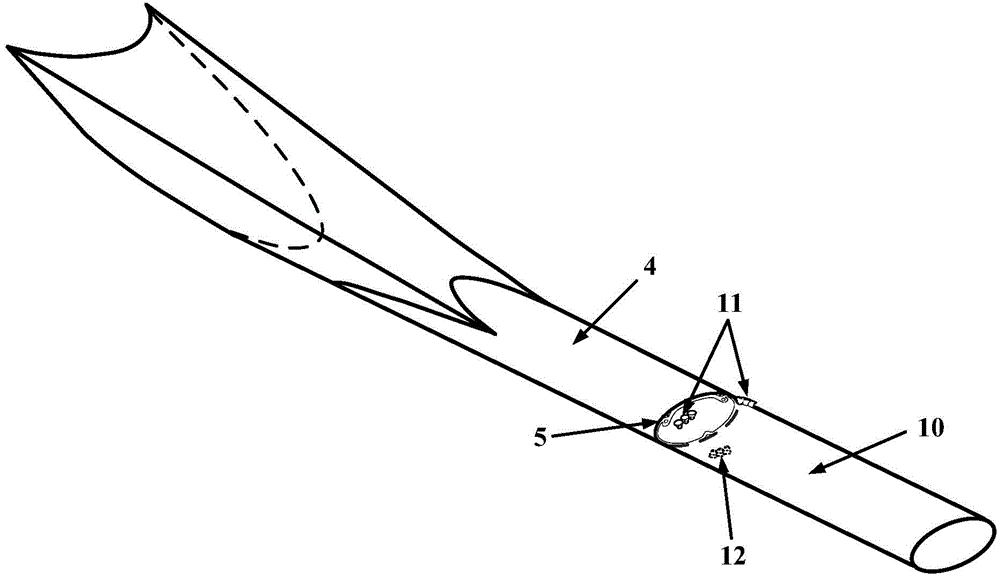

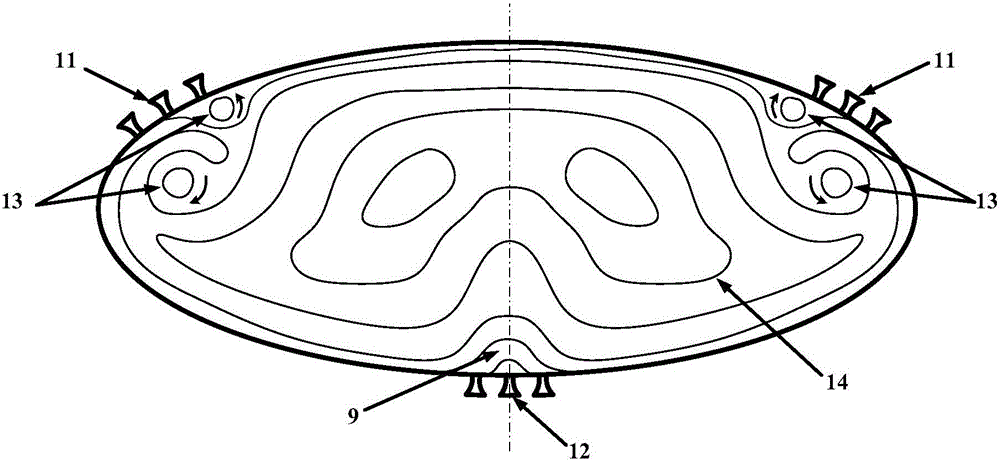

[0041] The outlet of the three-dimensional internal waverider hypersonic inlet is an ellipse with a long-to-short axis ratio of 2.5, and the inlet is similar to a V shape. There is an equal-area connection between the upstream intake port and the downstream combustion chamber, and there is no gradual or sudden transition of the geometric area. There are obvious corner vortex characteristics and low-energy / low-speed areas in the upper left corner and bottom of the intake port, respectively, and propagate to the downstream combustion chamber (such as figure 1 ). There are 3 nozzles evenly distributed in the circumferential direction in the upper left corner and the bottom of the combustion chamber (such as figure 2 and 4 ). The cross-sectional flow field at the outlet of its intake port is as follows: image 3 As shown, the fuel blending effect is obvious.

Embodiment 2

[0043] The outlet of the hypersonic three-dimensional internal waverider inlet is an ellipse with a major and minor axis ratio of 2.5, and the inlet shape is similar to a V shape. There is an equal-area connection between the upstream intake port and the downstream combustion chamber, and there is no gradual or sudden transition of the geometric area. There are obvious corner vortex characteristics and low-energy / low-speed areas in the upper left corner and bottom of the intake port, respectively, and propagate to the downstream combustion chamber (such as figure 1 ). 5 nozzles (eg Figure 5 and 7 ). The cross-sectional flow field at the outlet of its intake port is as follows: Image 6 As shown, the fuel blending effect is obvious.

Embodiment 3

[0045] The outlet of the hypersonic three-dimensional internal waverider inlet is an ellipse with a major and minor axis ratio of 2.5, and the inlet shape is similar to a V shape. There is an equal-area connection between the upstream intake port and the downstream combustion chamber, and there is no gradual or sudden transition of the geometric area. There are obvious corner vortex characteristics and low-energy / low-speed areas in the upper left corner and bottom of the intake port, respectively, and propagate to the downstream combustion chamber (such as figure 1 ). At the upper left corner and the bottom of the combustion chamber, three nozzles are distributed in the shape of a "pin" along the flow path of the corner vortex and the low energy / low velocity region respectively (such as Figure 8 and 10 ). The cross-sectional flow field at the outlet of its intake port is as follows: Figure 9 As shown, the fuel blending effect is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com