Patents

Literature

44 results about "Overall pressure ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In aeronautical engineering, overall pressure ratio, or overall compression ratio, is the ratio of the stagnation pressure as measured at the front and rear of the compressor of a gas turbine engine. The terms compression ratio and pressure ratio are used interchangeably. Overall compression ratio also means the overall cycle pressure ratio which includes intake ram.

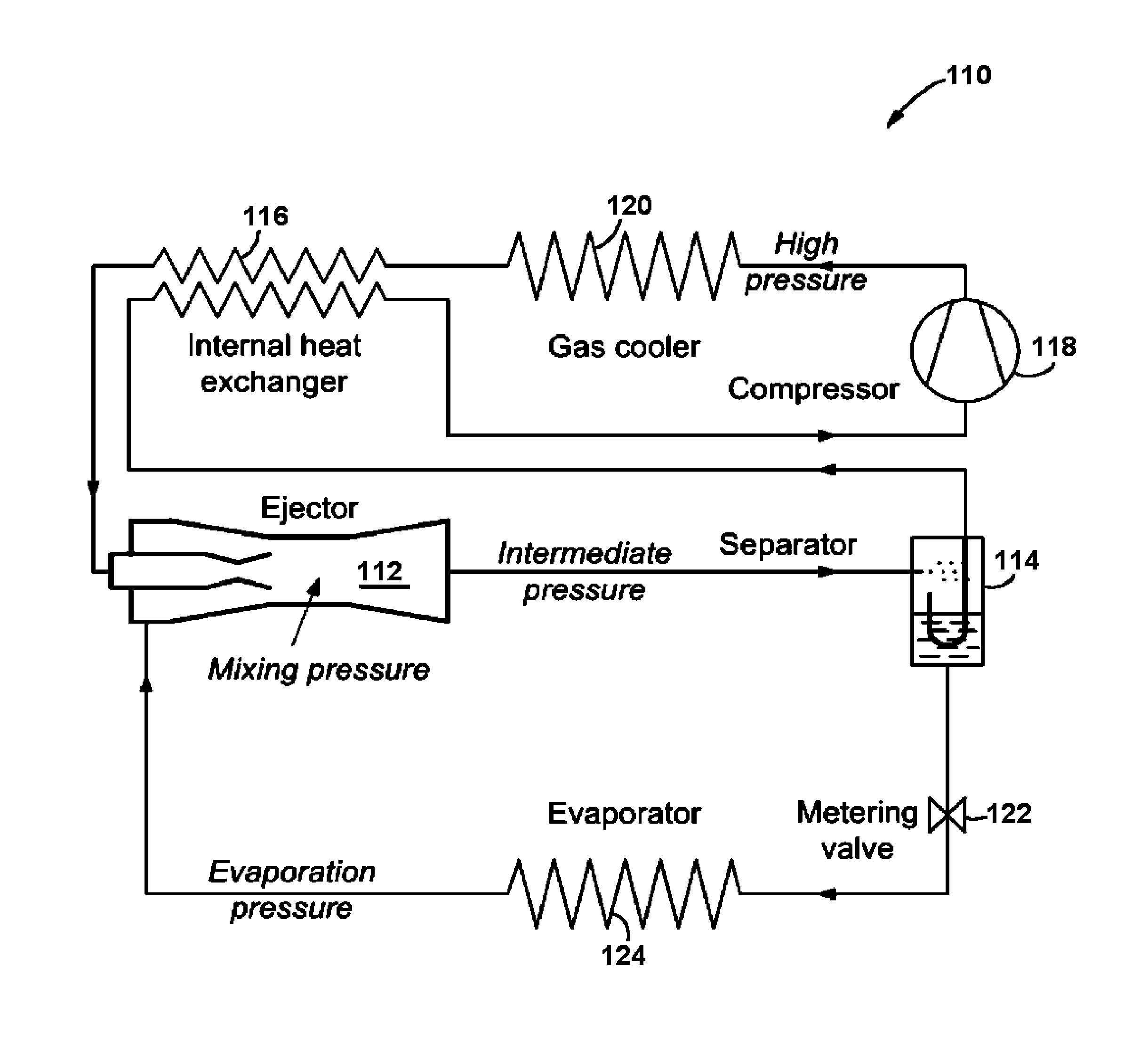

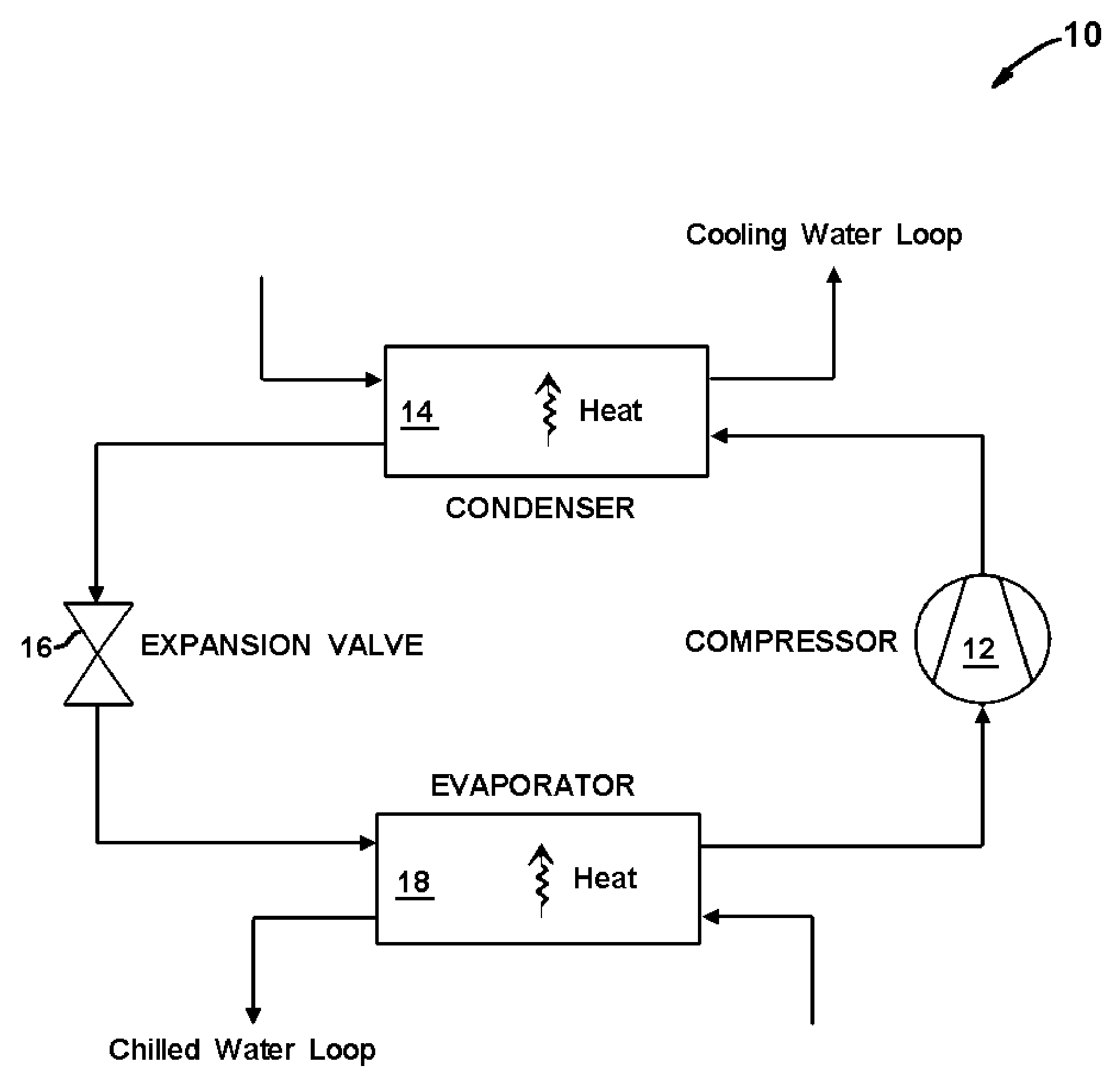

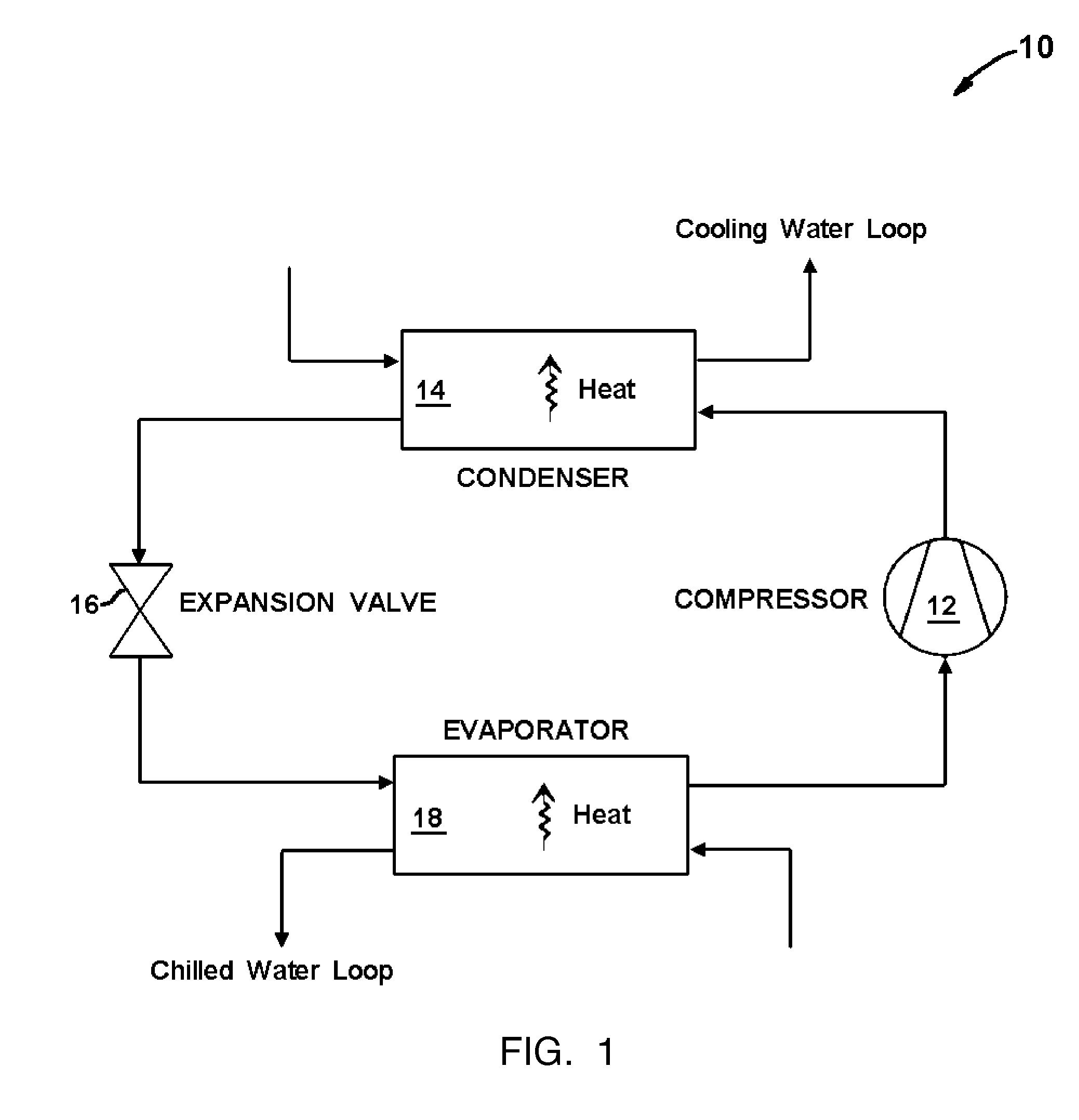

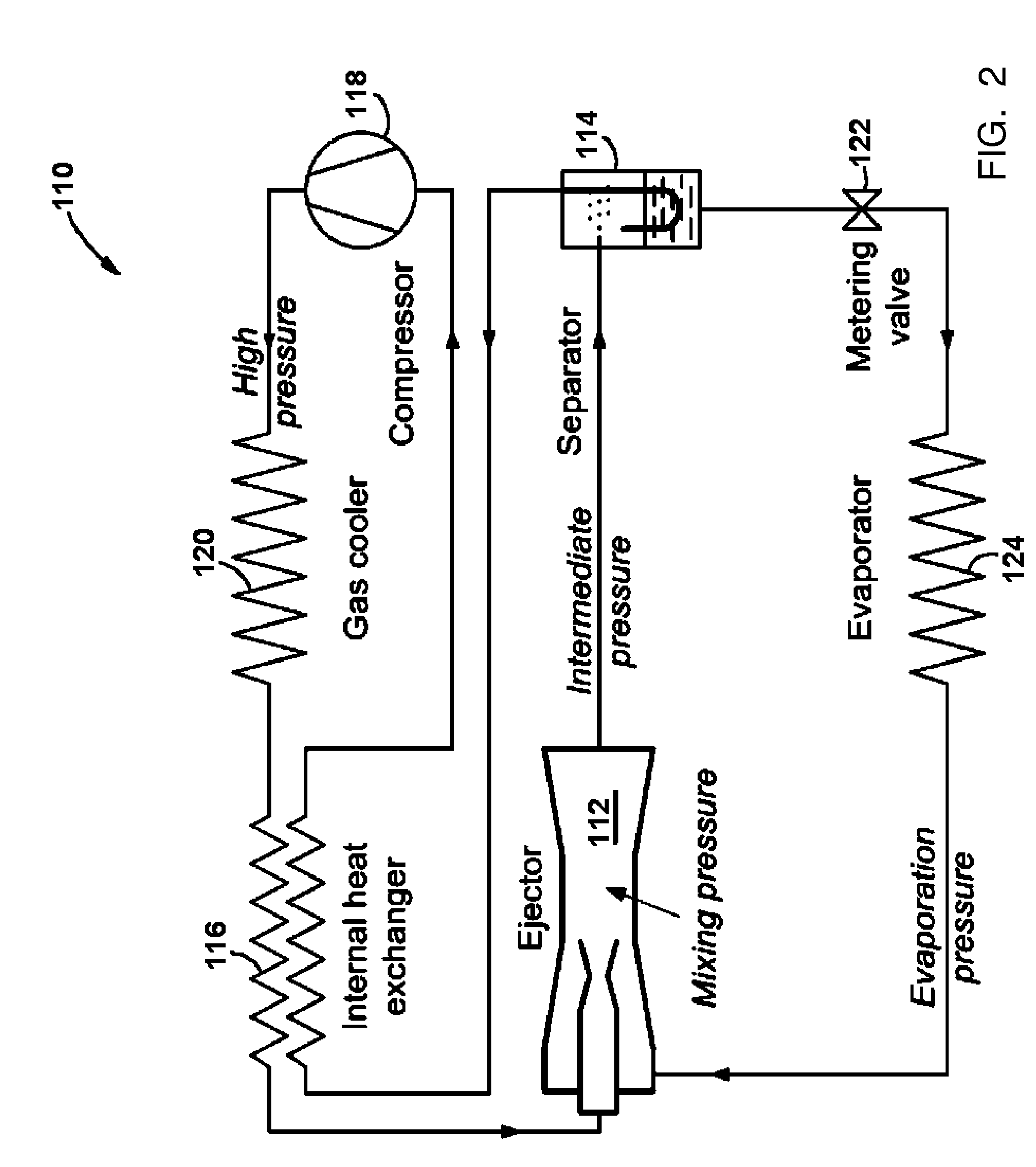

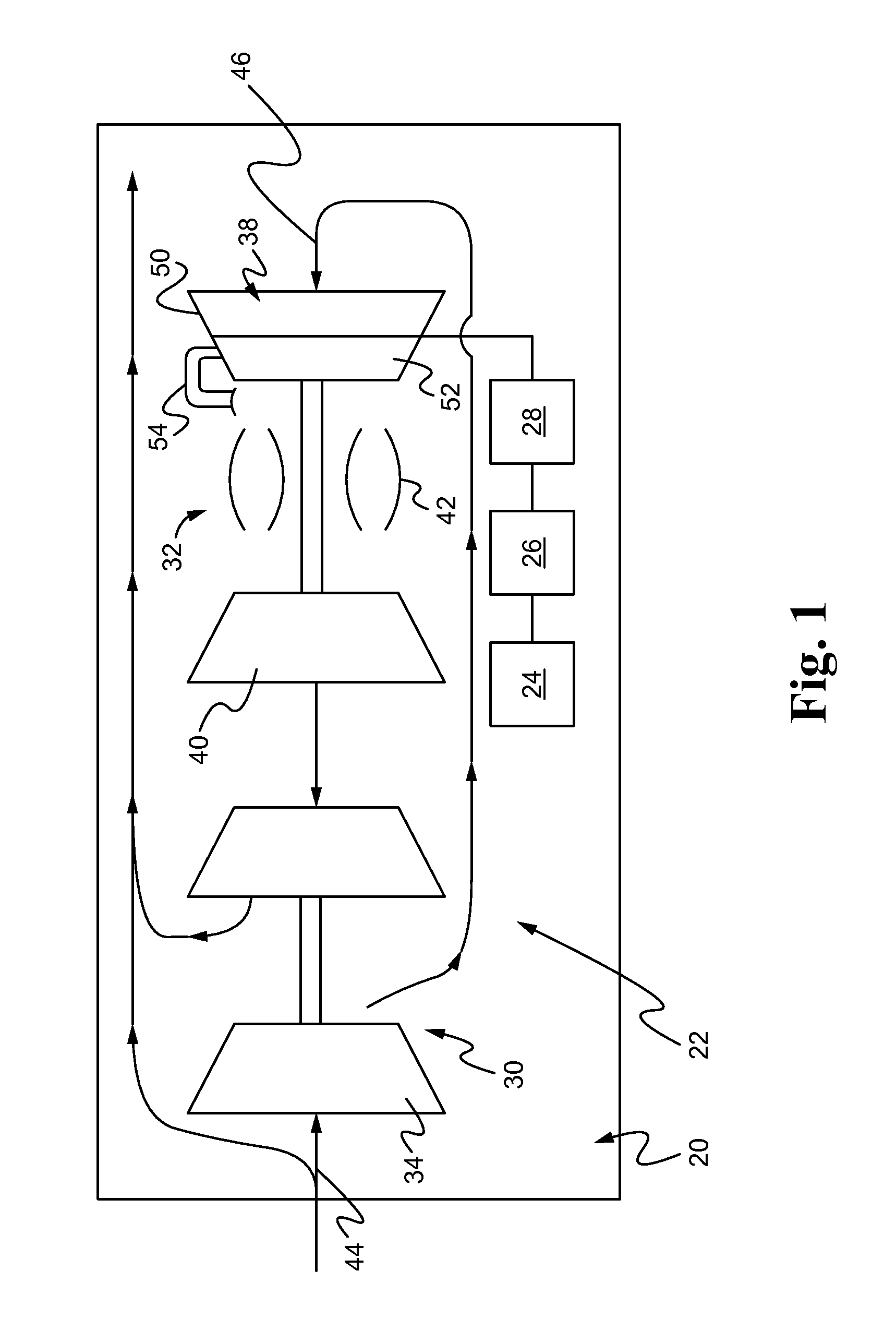

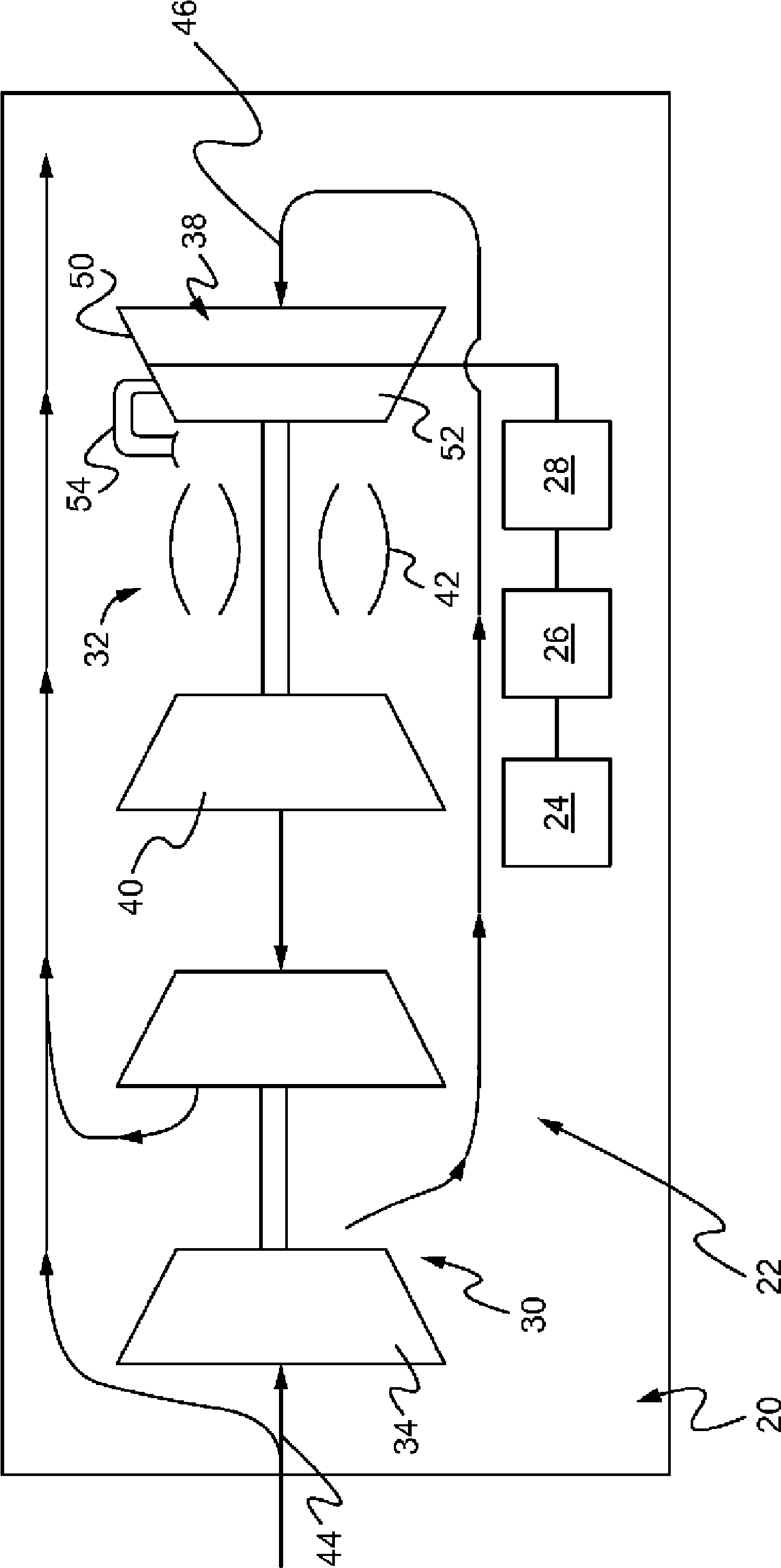

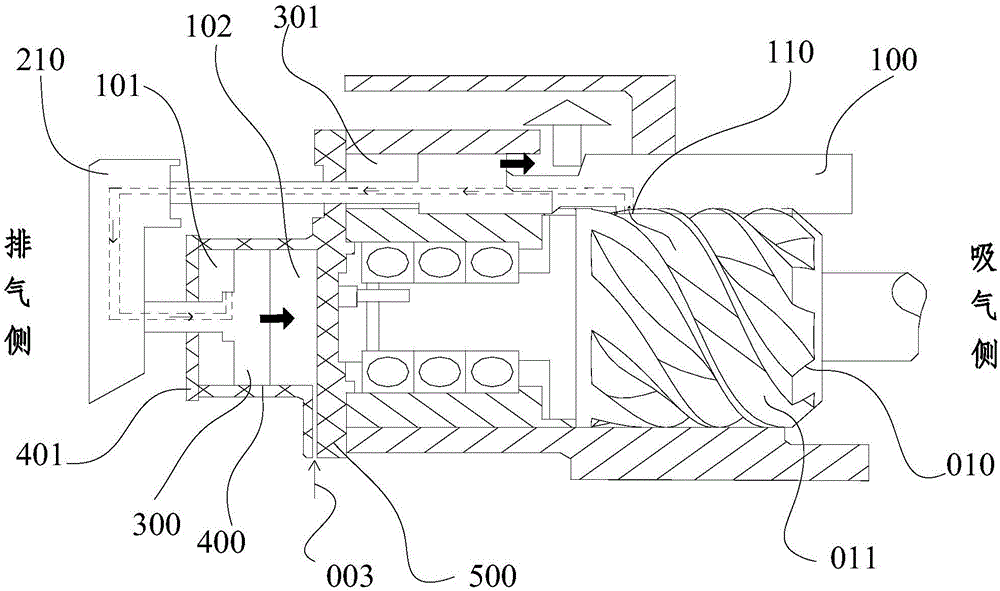

High efficiency r744 refrigeration system and cycle

InactiveUS20100313582A1Reduce compressionImprove cycle efficiencyCompression machines with non-reversible cycleFluid circulation arrangementEngineeringHigh pressure

A high efficiency R744 air conditioning and refrigeration system and cycle comprises a vapor compressor and two independent ejectors operatively connected to high and low-pressure sides of the compressor, respectively. The two ejectors reduce the overall pressure ratio of the mechanical vapor compressor resulting in dramatically increased thermodynamic cycle efficiency. As one example of its potential applications for residential, commercial or industrial uses, a 150 ton capacity of a water-cooled chiller designed in accordance with the present invention is predicted to provide the power consumption as low as 0.47 kW / ton, when operated in accordance with the cooling methods of the present invention, which corresponds to 7.47 of Coefficient of Performance (COP).

Owner:R & D DYNAMICS

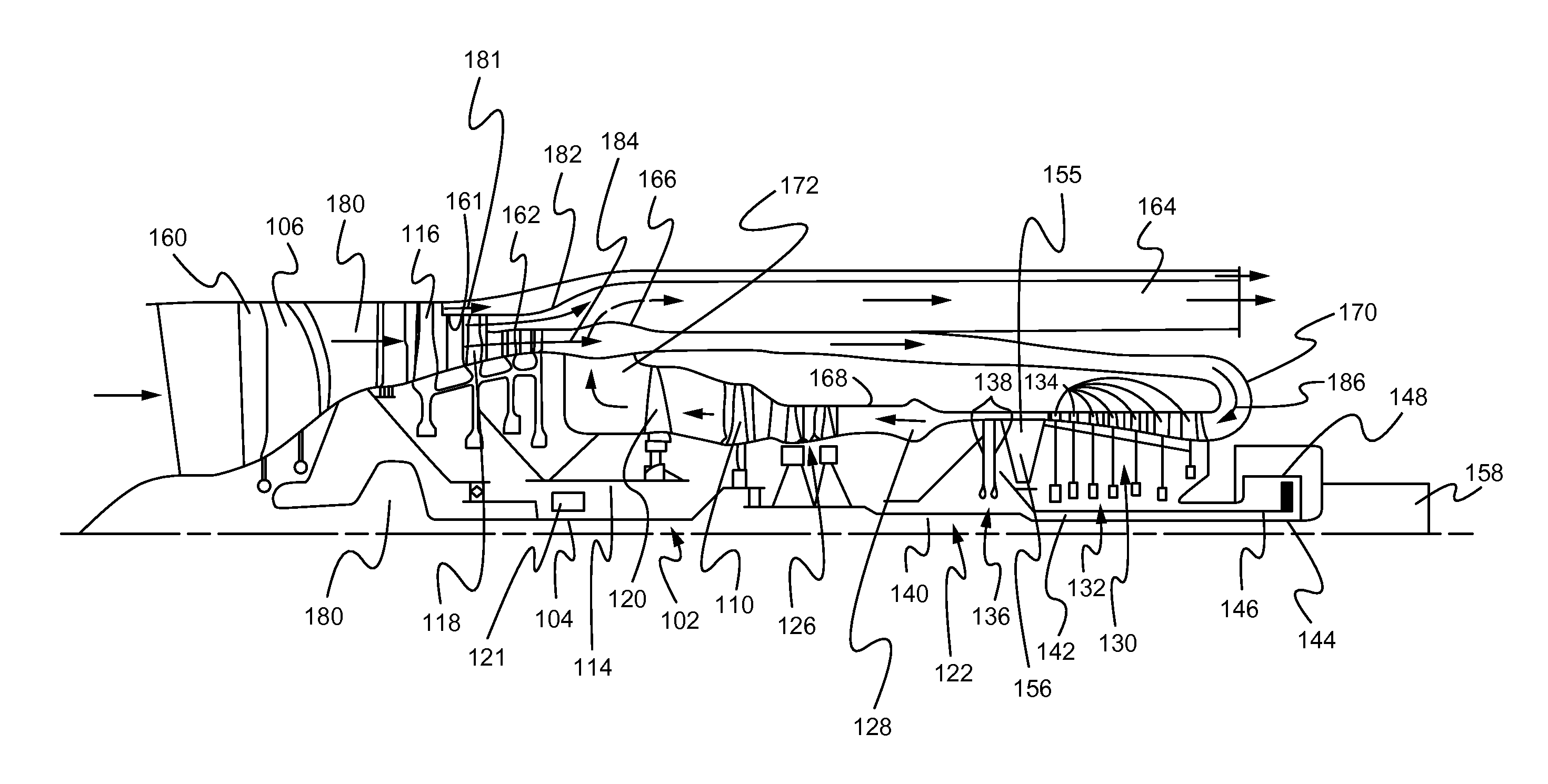

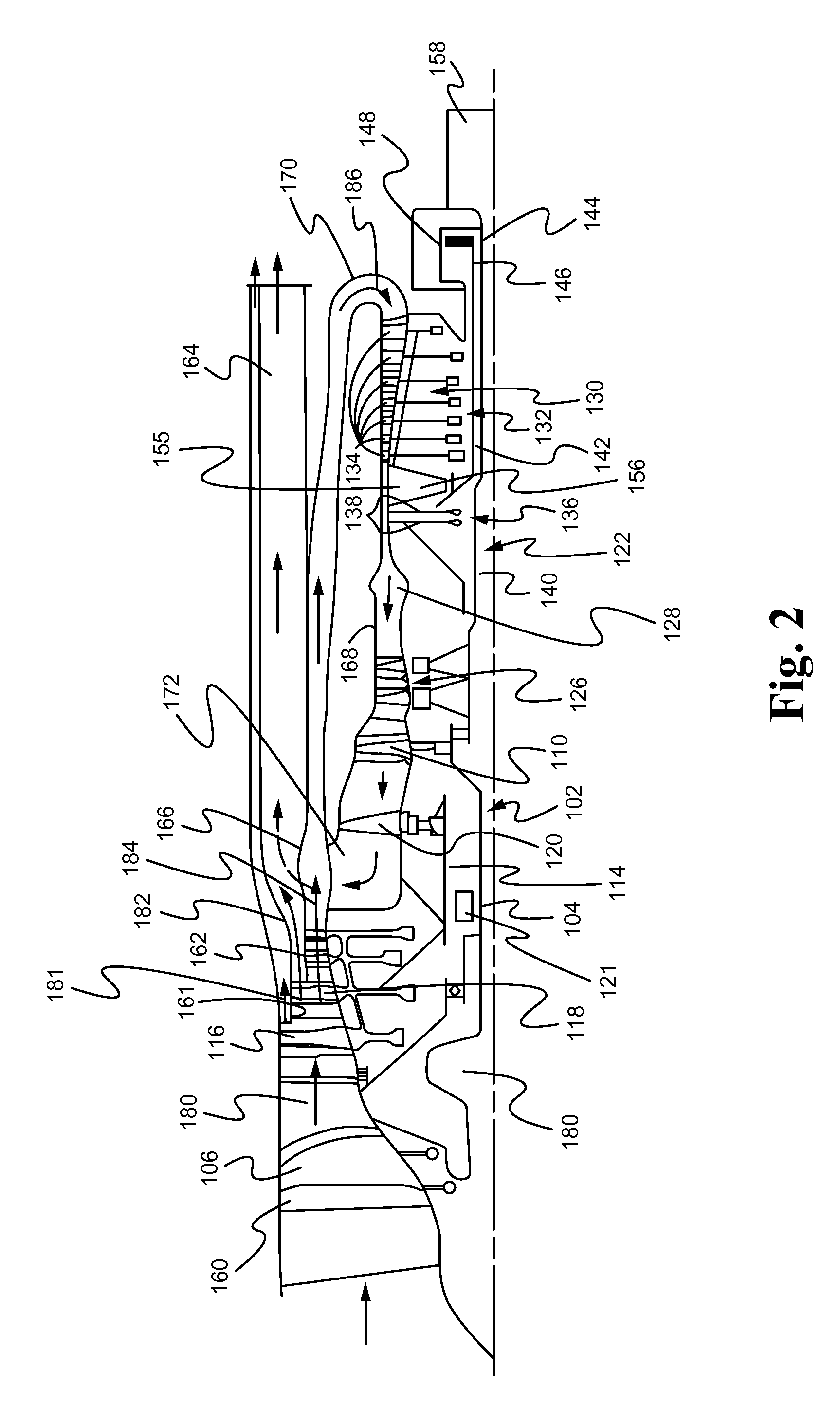

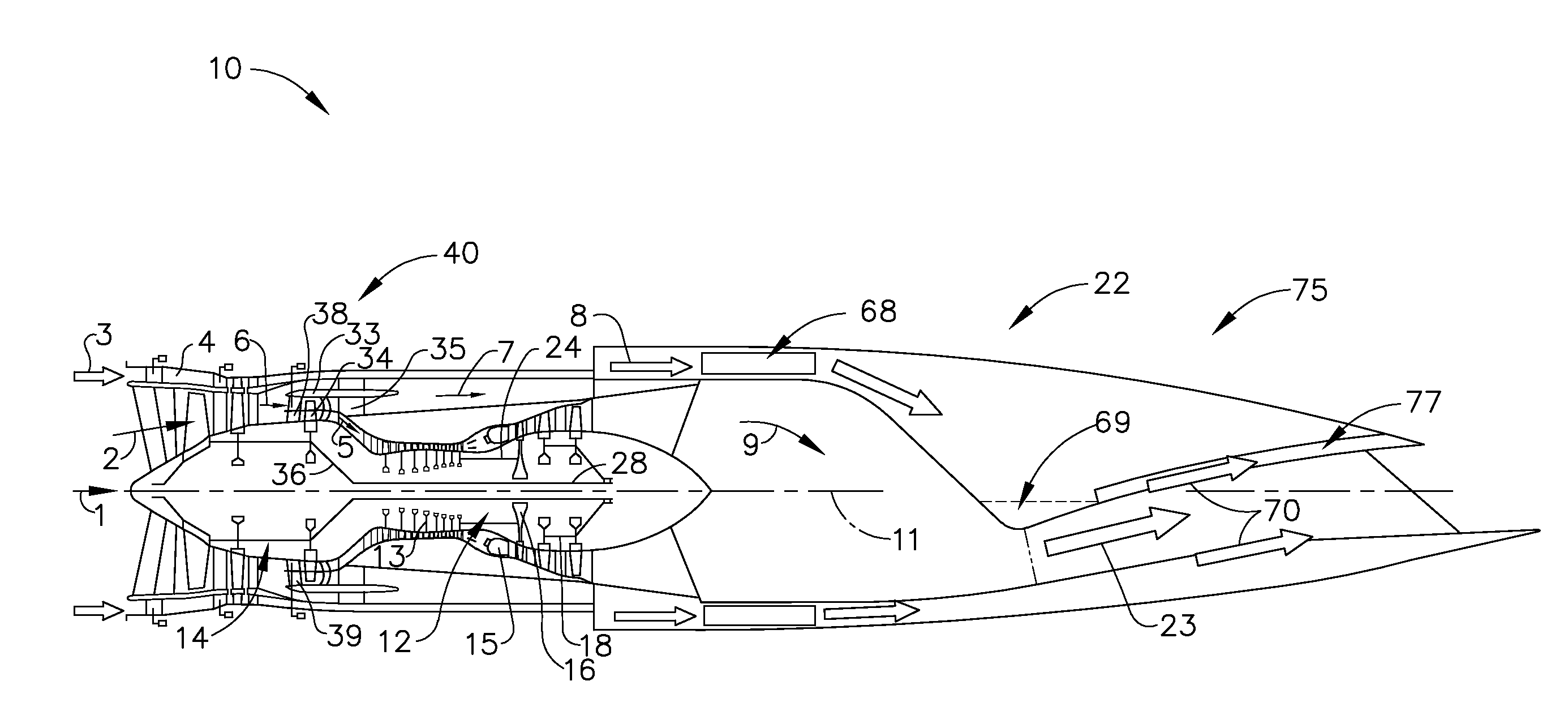

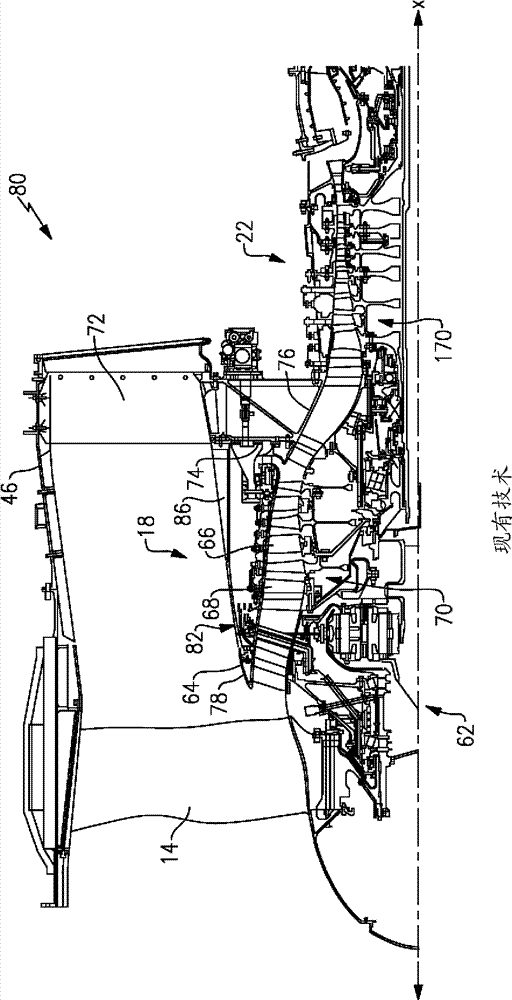

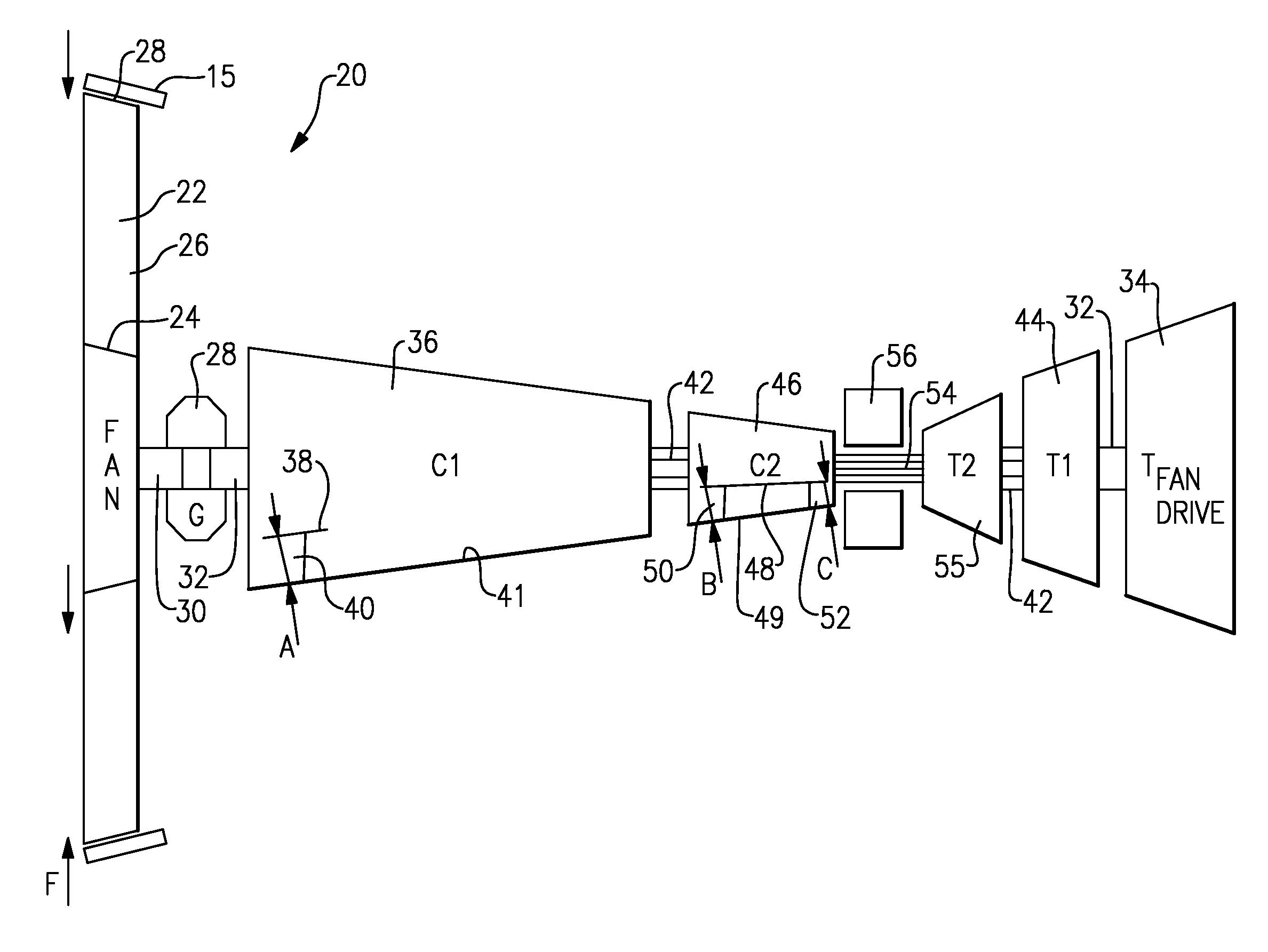

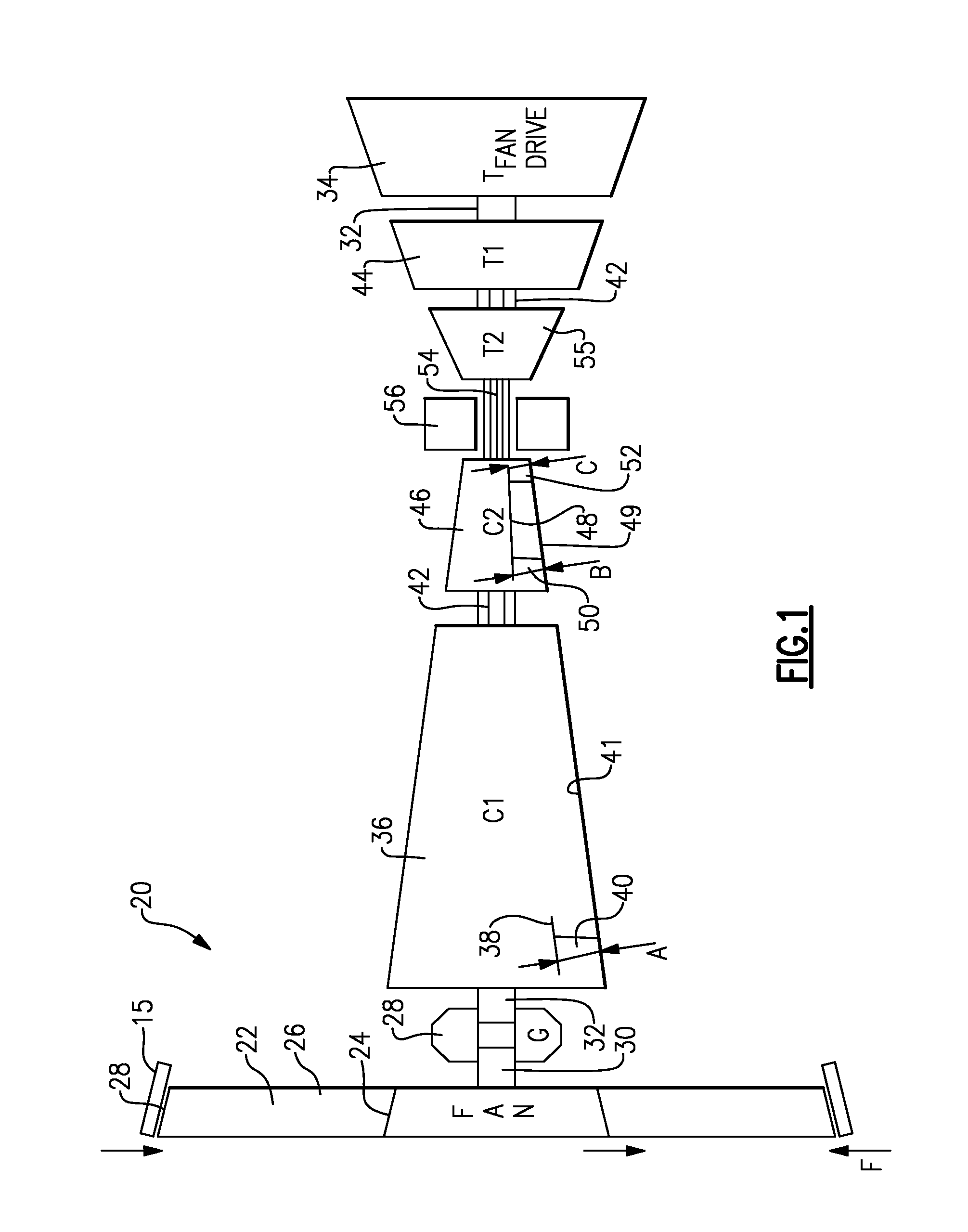

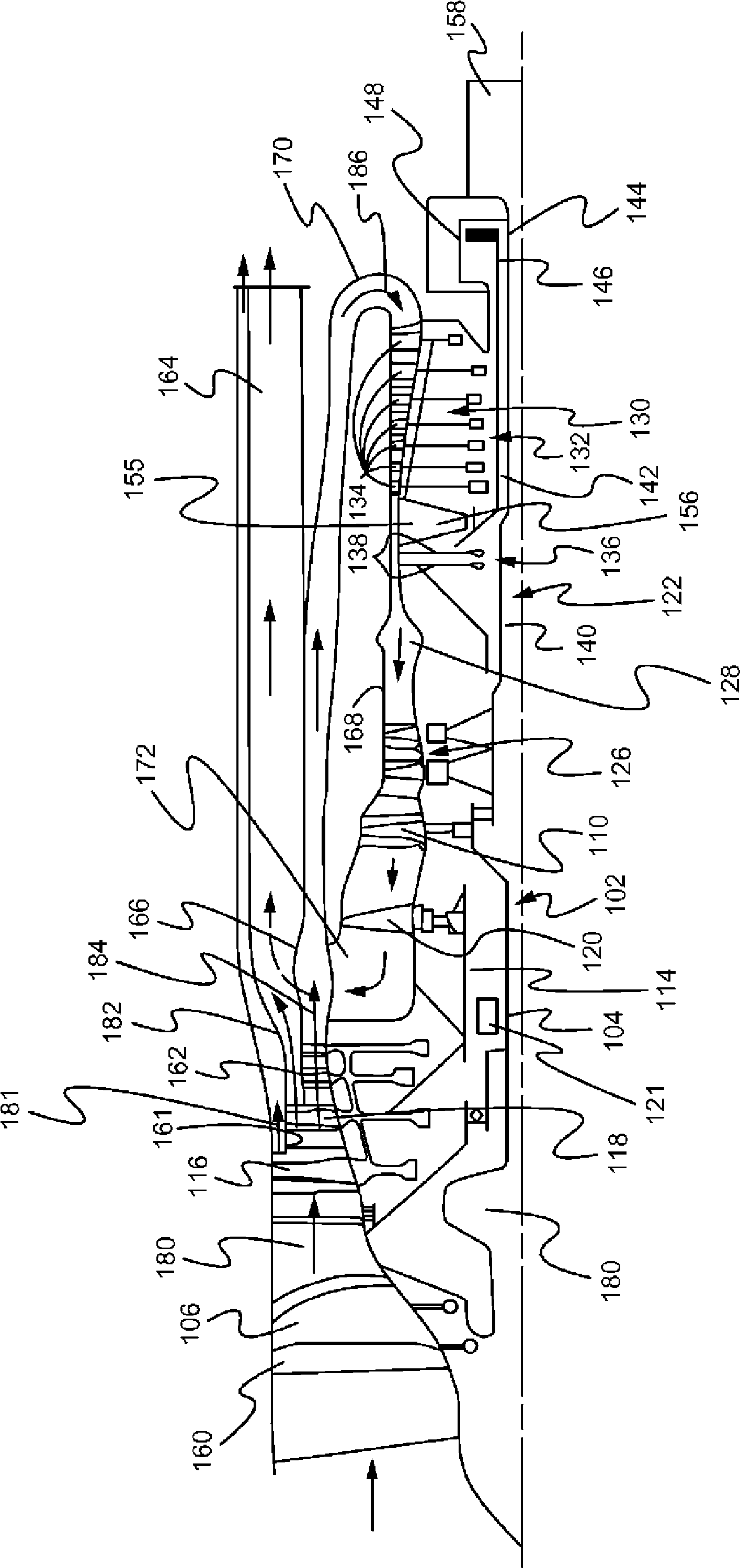

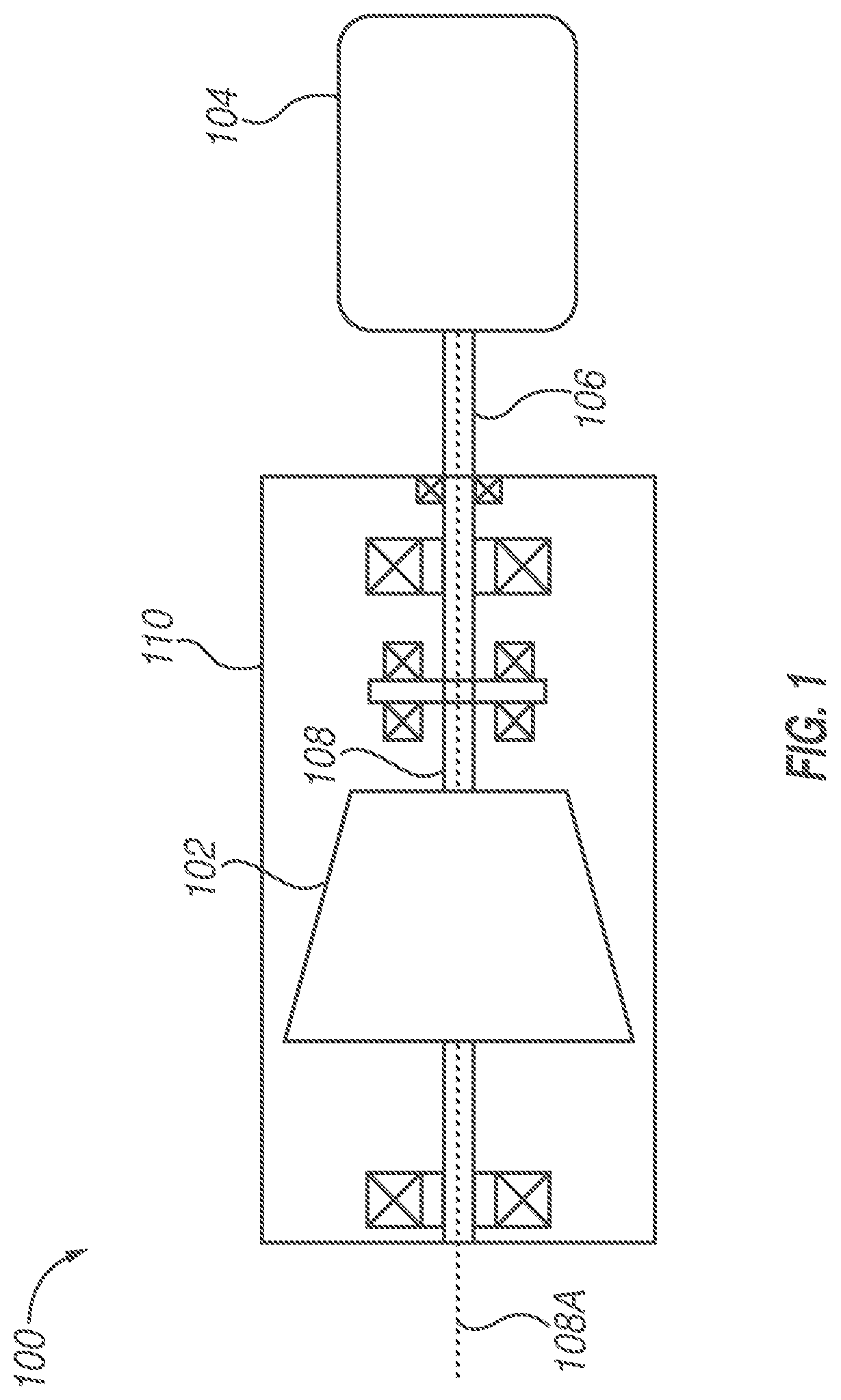

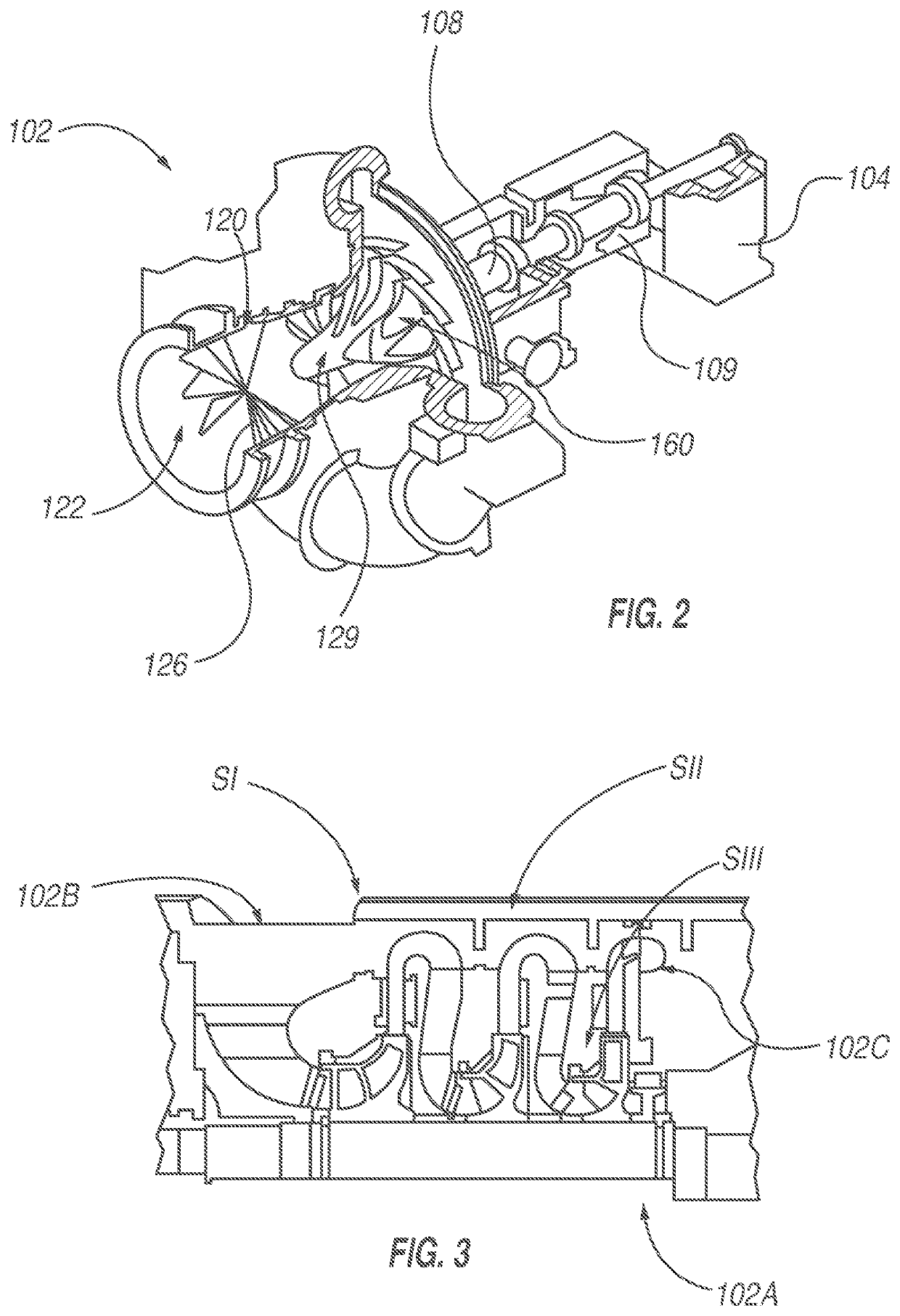

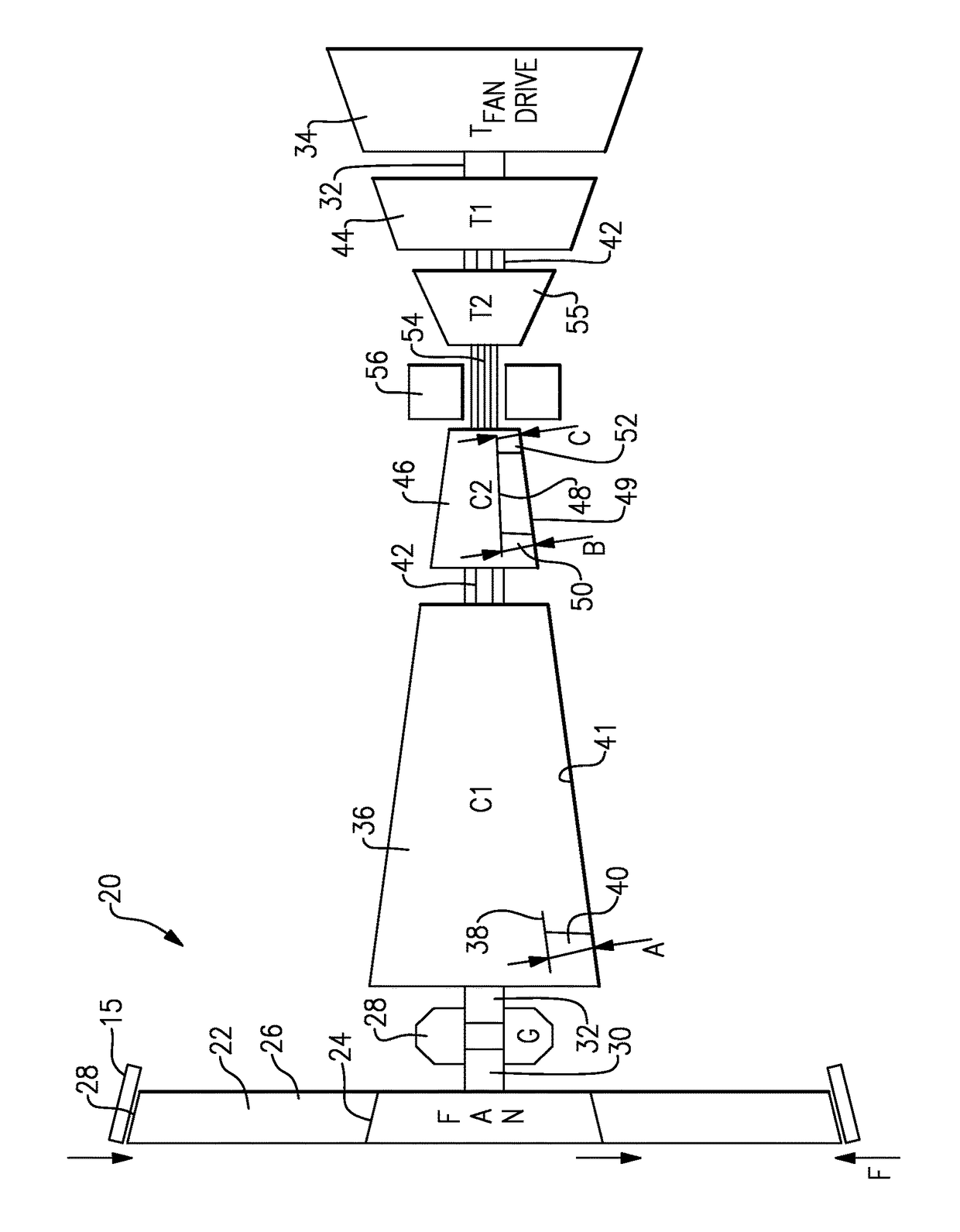

Gas Turbine Engine with Variable Overall Pressure Ratio

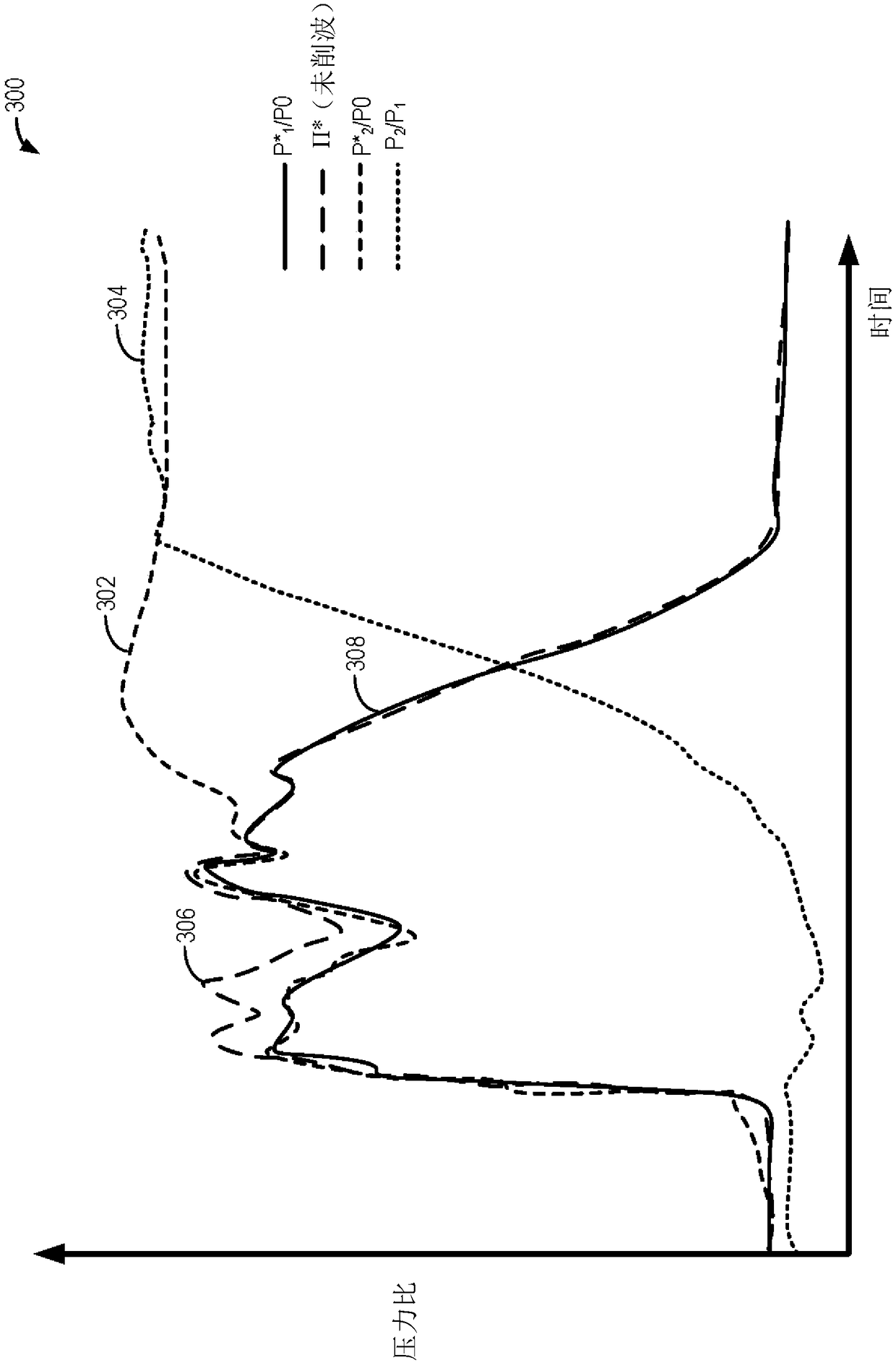

A gas turbine engine has a variable overall pressure rate (“OPR”). The engine includes a high pressure compressor having at least a primary stage having a set of primary rotors and a secondary stage having a set of secondary rotors. A clutch is provided to selectively engage the secondary rotors with the primary rotors. Engagement of the clutch may be controlled based on the vehicle travel mode, such as disengaging during a takeoff mode to reduce turbine entry temperature and engaging during a loiter mode to increase OPR.

Owner:RTX CORP +1

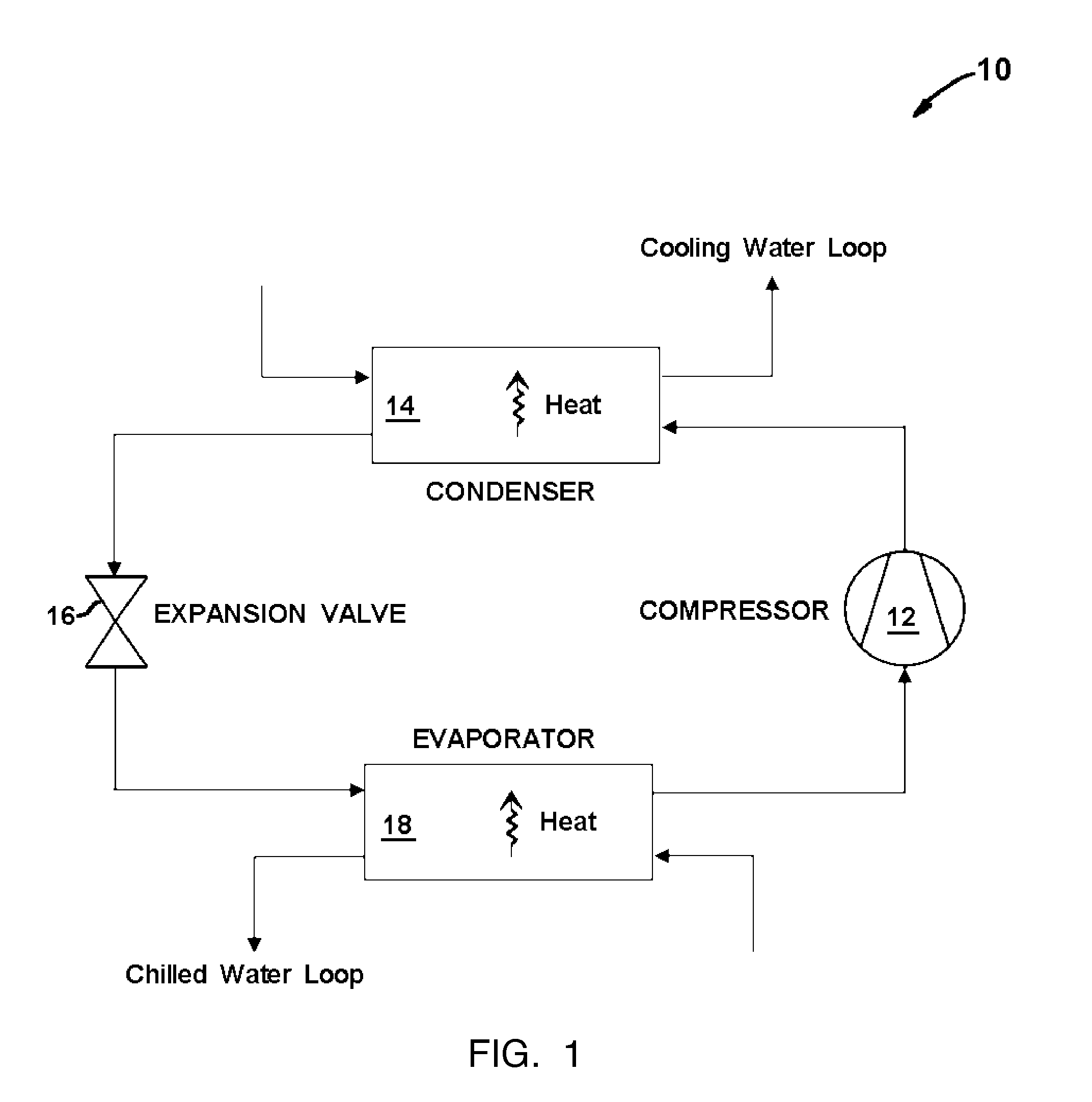

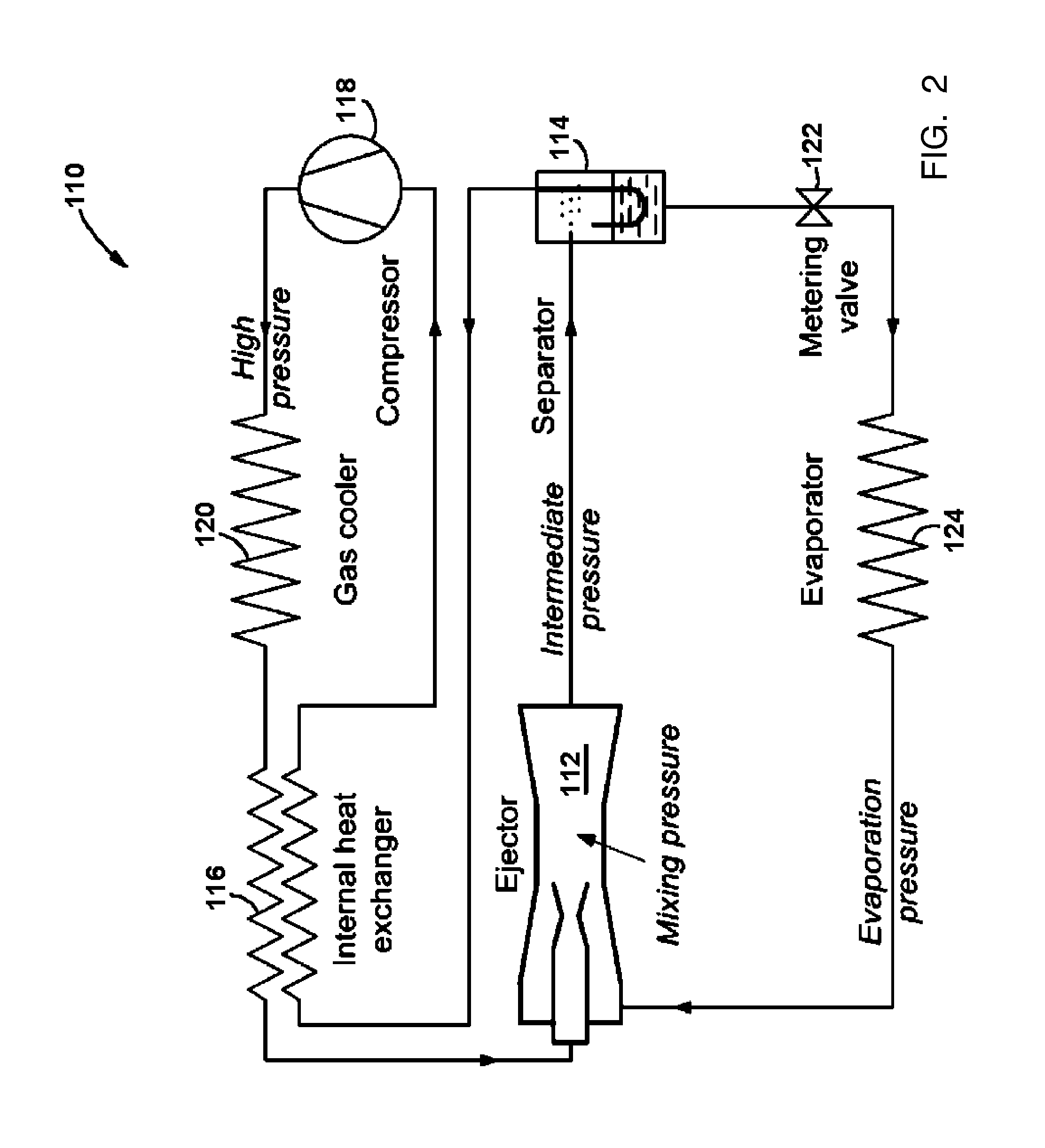

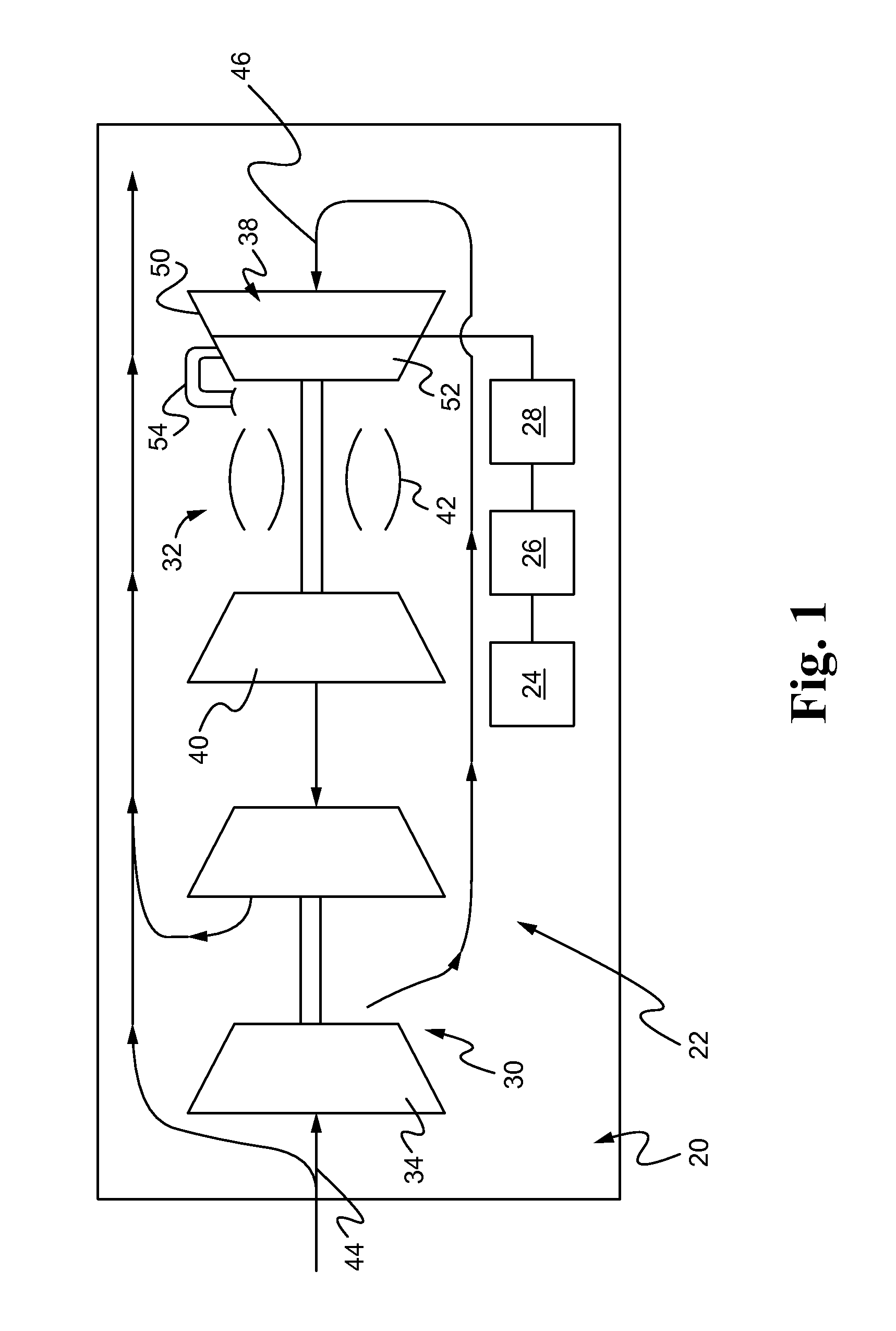

High efficiency refrigeration system and cycle

InactiveUS20120234026A1Reduce compressionImprove cycle efficiencyCompression machines with non-reversible cycleCompression machines with cascade operationEngineeringAir conditioning

A high efficiency air conditioning and refrigeration system and cycle comprises a vapor compressor and two independent ejectors operatively connected to high and low-pressure sides of the compressor, respectively. The two ejectors reduce the overall pressure ratio of the mechanical vapor compressor resulting in dramatically increased thermodynamic cycle efficiency. As one example of its potential applications for residential, commercial or industrial uses, a 150 ton capacity of a water-cooled chiller designed in accordance with the present invention is predicted to provide the power consumption as low as 0.47 kW / ton, when operated in accordance with the cooling methods of the present invention, which corresponds to 7.47 of Coefficient of Performance (COP).

Owner:R & D DYNAMICS

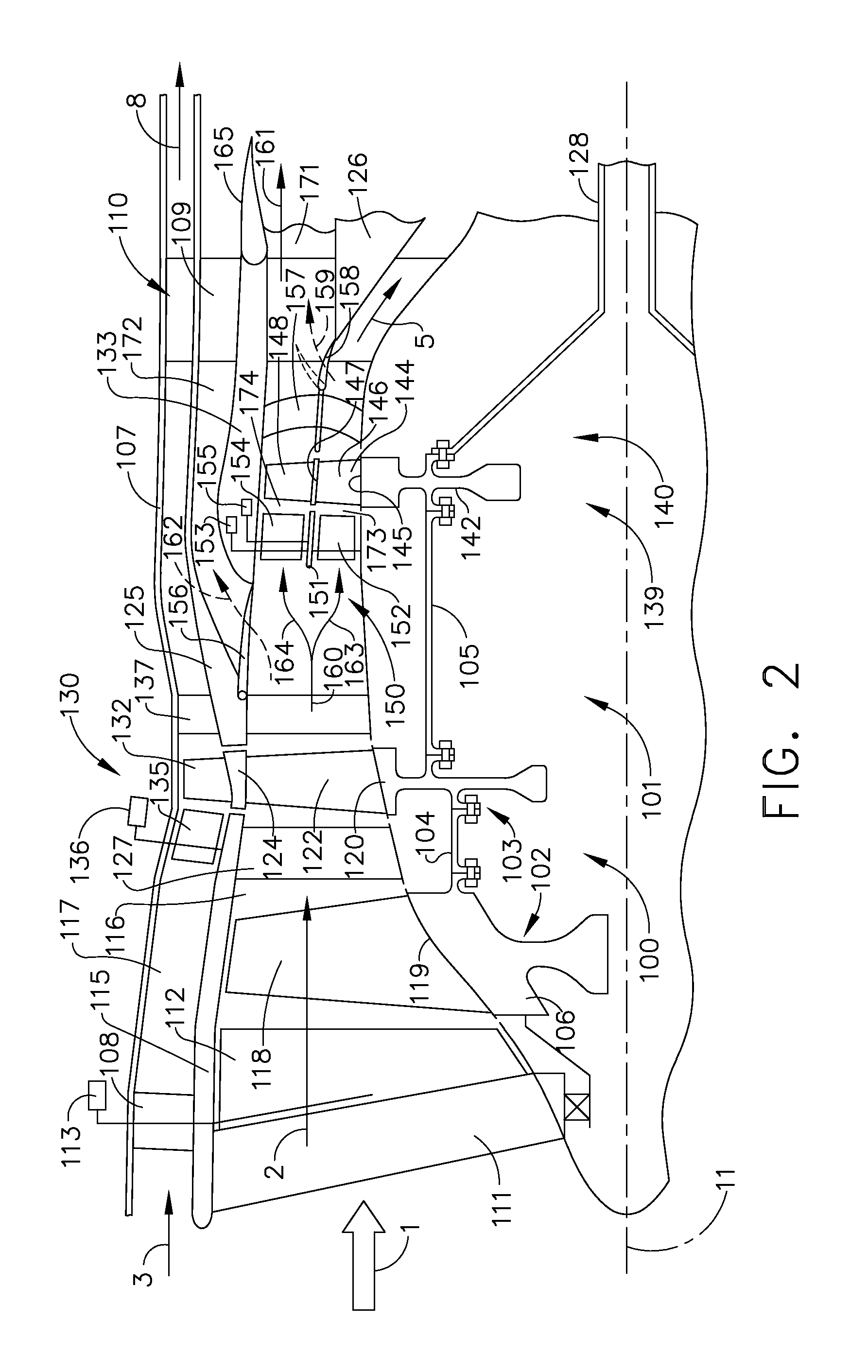

Method of operating a convertible fan engine

InactiveUS20110167784A1Reduce trafficCosmonautic vehiclesCosmonautic propulsion system apparatusEngineeringTurbine

A method of operating a gas turbine engine is disclosed having the steps of directing a flow of air to a front fan stage at a selected fan flow rate, fan speed and front fan stage pressure ratio corresponding to a selected first operating power level, pressurizing a portion of the flow from the front fan stage in a aft fan rotor to a first tip pressure ratio to generate a first overall fan pressure ratio, selecting a second operating power level that is lower than the first operating power level and reducing the flow in the aft fan rotor and pressurizing to a second tip pressure ratio to generate a second overall pressure ratio that is substantially lower than the first overall fan pressure ratio while the flow rate in the front fan stage is held substantially constant.

Owner:GENERAL ELECTRIC CO

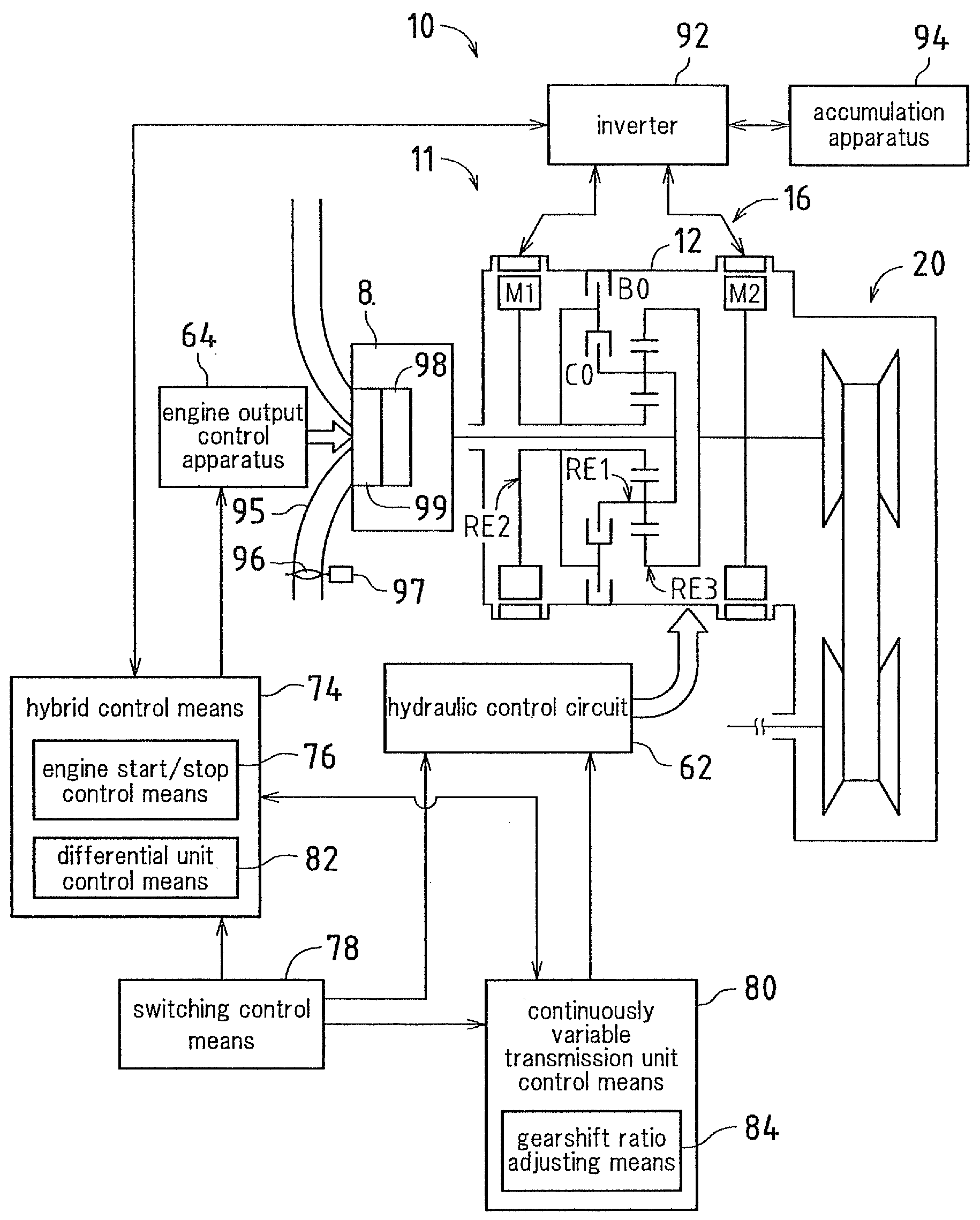

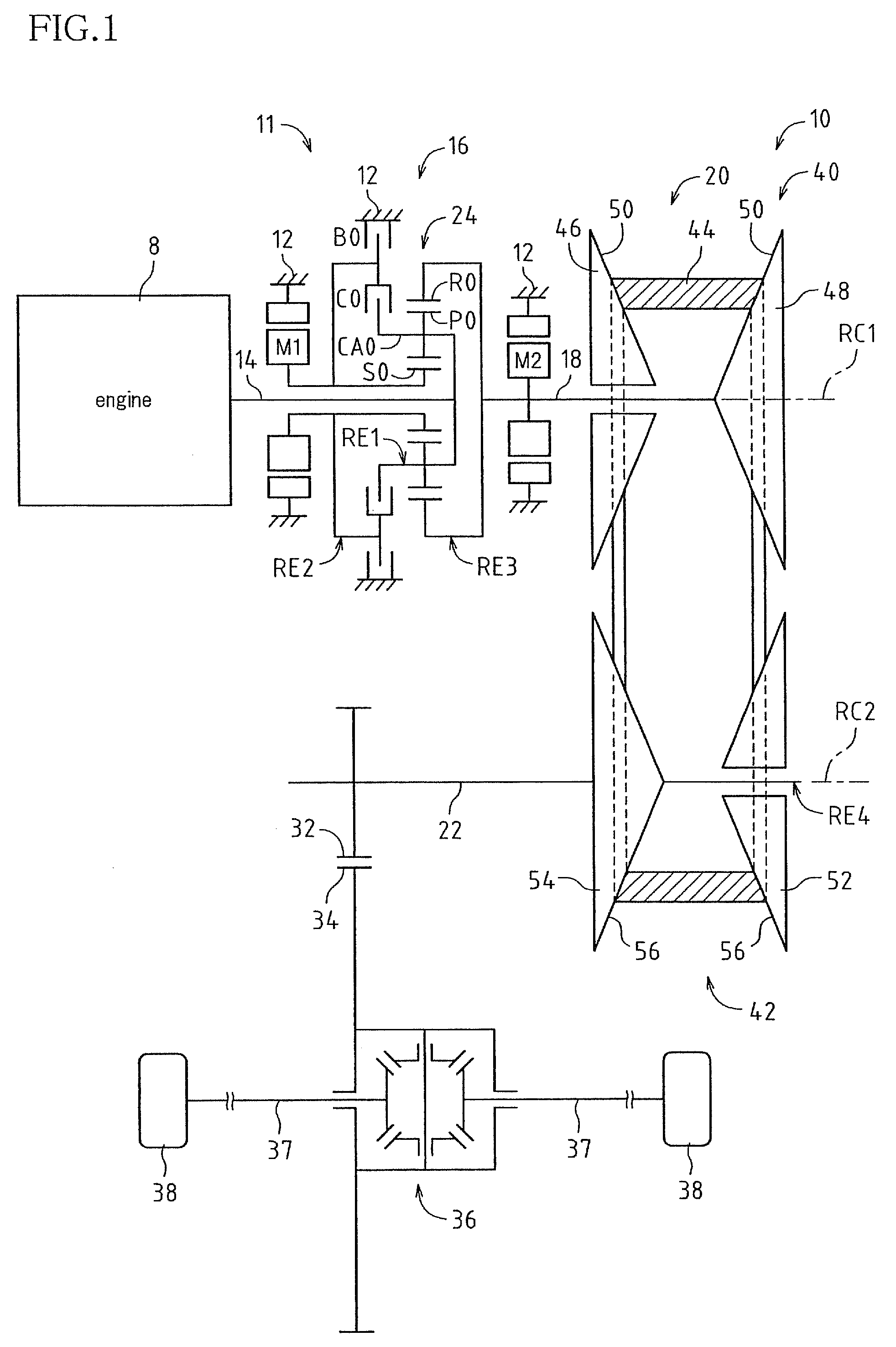

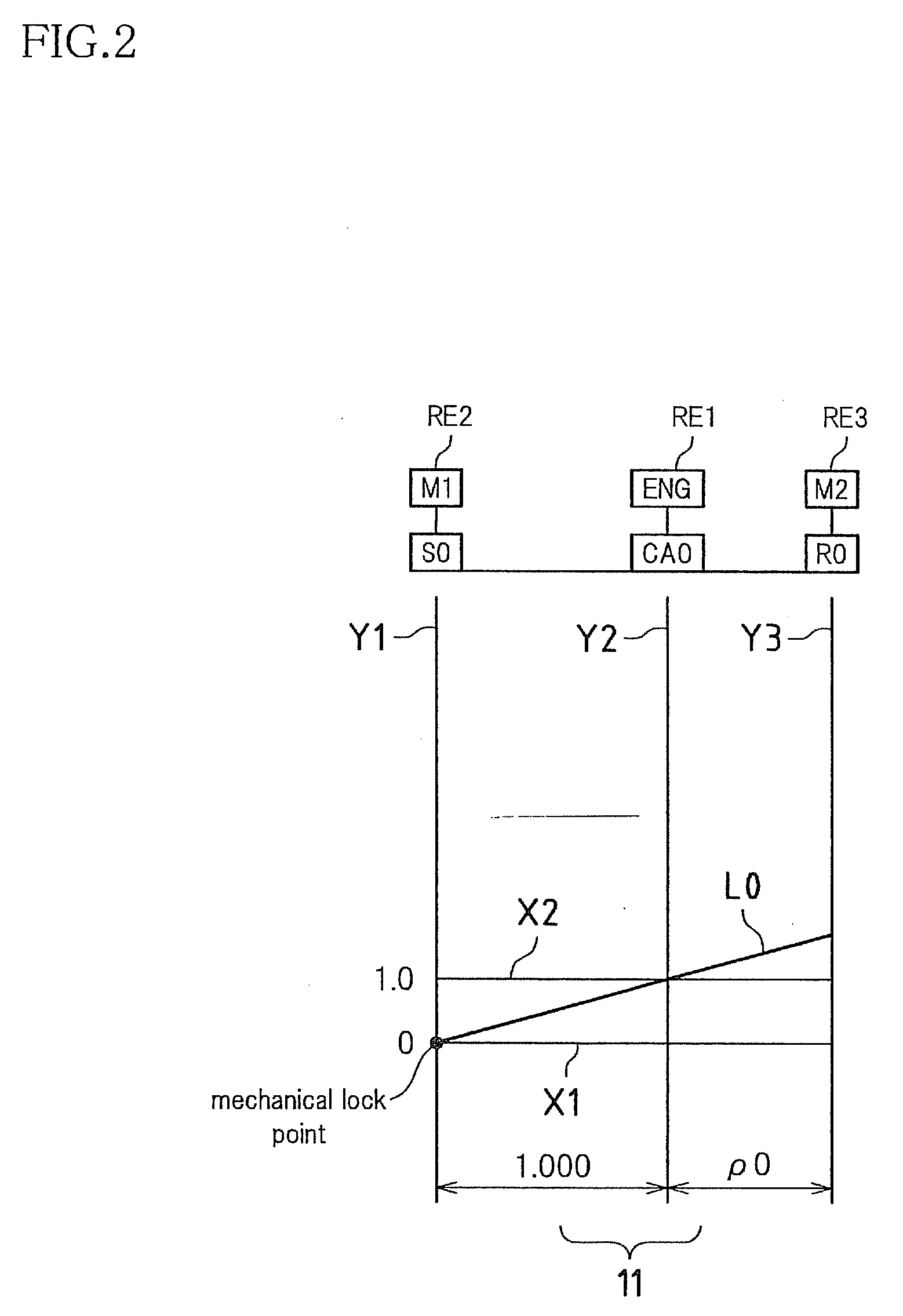

Control apparatus of vehicle drive apparatus

ActiveUS20090209382A1Improve drivabilityHybrid vehiclesVehicle sub-unit featuresControl theoryGear ratio

Owner:TOYOTA JIDOSHA KK

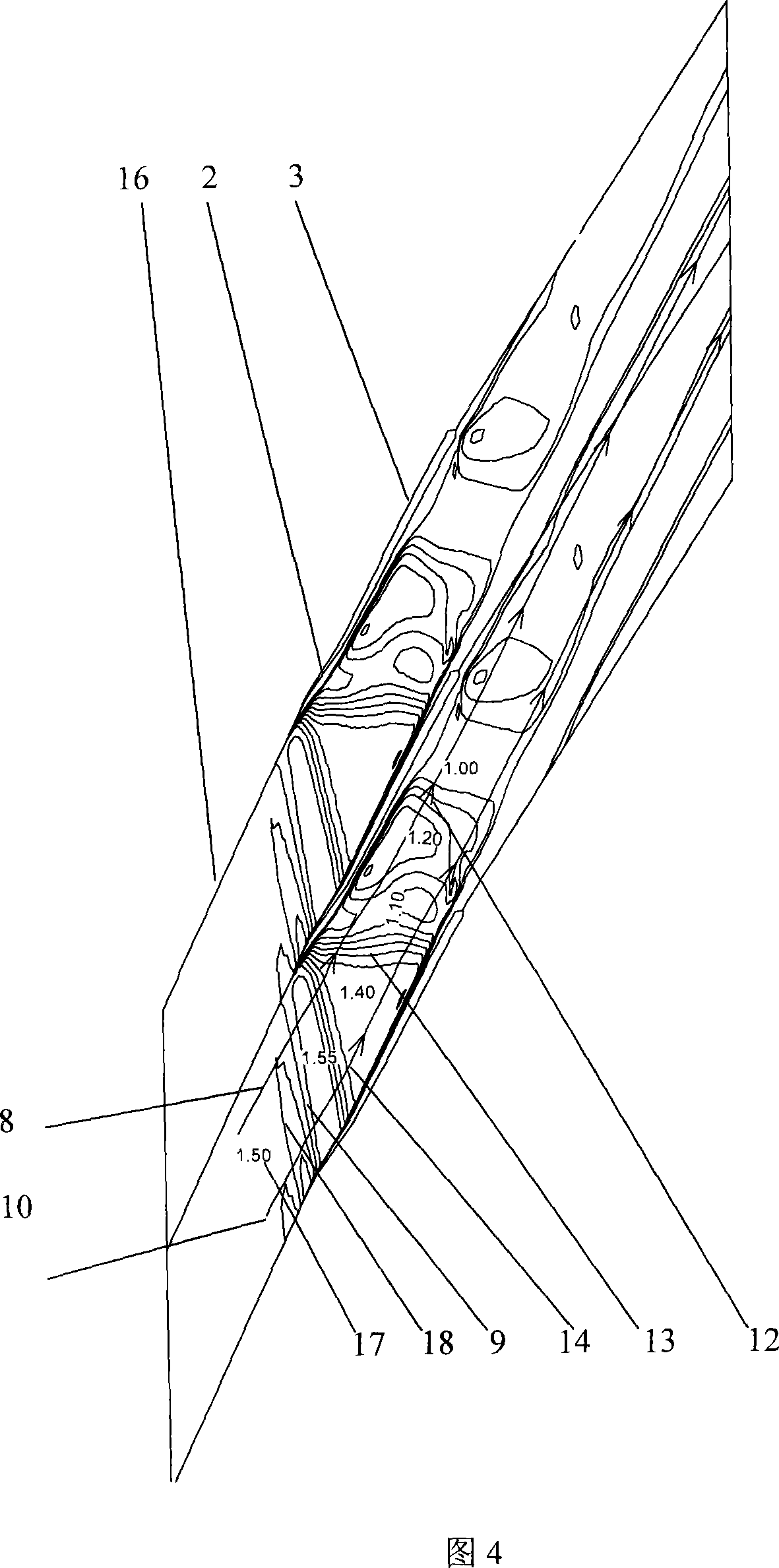

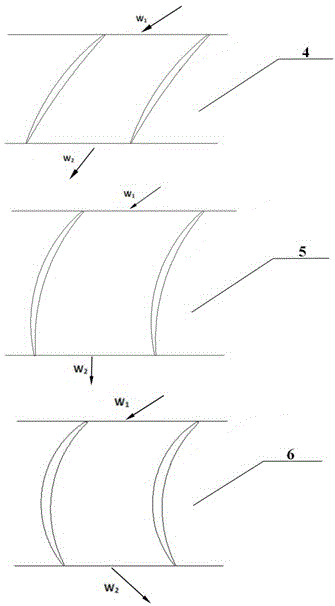

Ultrasound profile applied to aerial engine fan/compressor rotor and design method thereof

InactiveCN101182784AGood off-design performanceIncrease pressureBlade accessoriesMachines/enginesImpellerSuction stress

The present invention relates to an ultrasonic blade and a design method applied to aeroengine fans or aerocompressor rotors, pertaining to the art of impeller mechanical technology. The blade is characterized in that the small part of the blade on the front edge is S-shape and the large rear at the rear is flat and the thickness of the blade gradually increased from front to back; the ultrasonic air current flows into a grid formed by the blade, produces an expansion wave in the entrance of the grid, consequently forms an oblique shock wave in the transition from the S-shaped suction surface of the blade to the flat section intersected with the front edge of the adjacent blade, then produces a reflection shock wave and reproduces a local shock wave near the exit of the grid. The design method of the blade includes the following process: the front part is confirmed to be S-shaped and the rear part is divided by a straight medial camber line; the thickness distribution of the blade, which gradually increases from front to back, is confirmed; the surface mold of the blade is confirmed according to the medial camber line and the thickness distribution of the blade. The blade provided by the present invention can effectively reduce the flowing loss, increase the rim power of the rotor and improve the overall pressure ratio.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

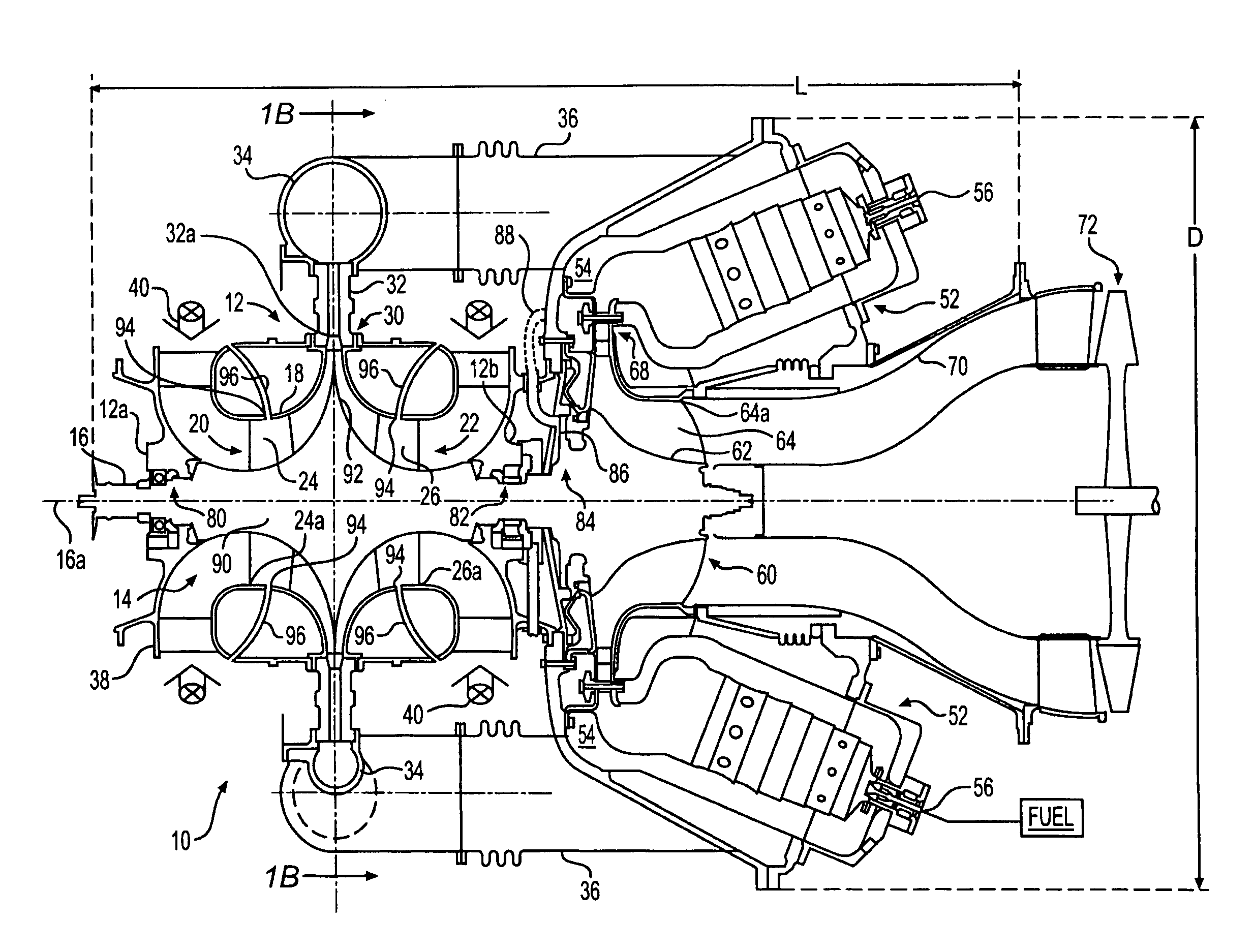

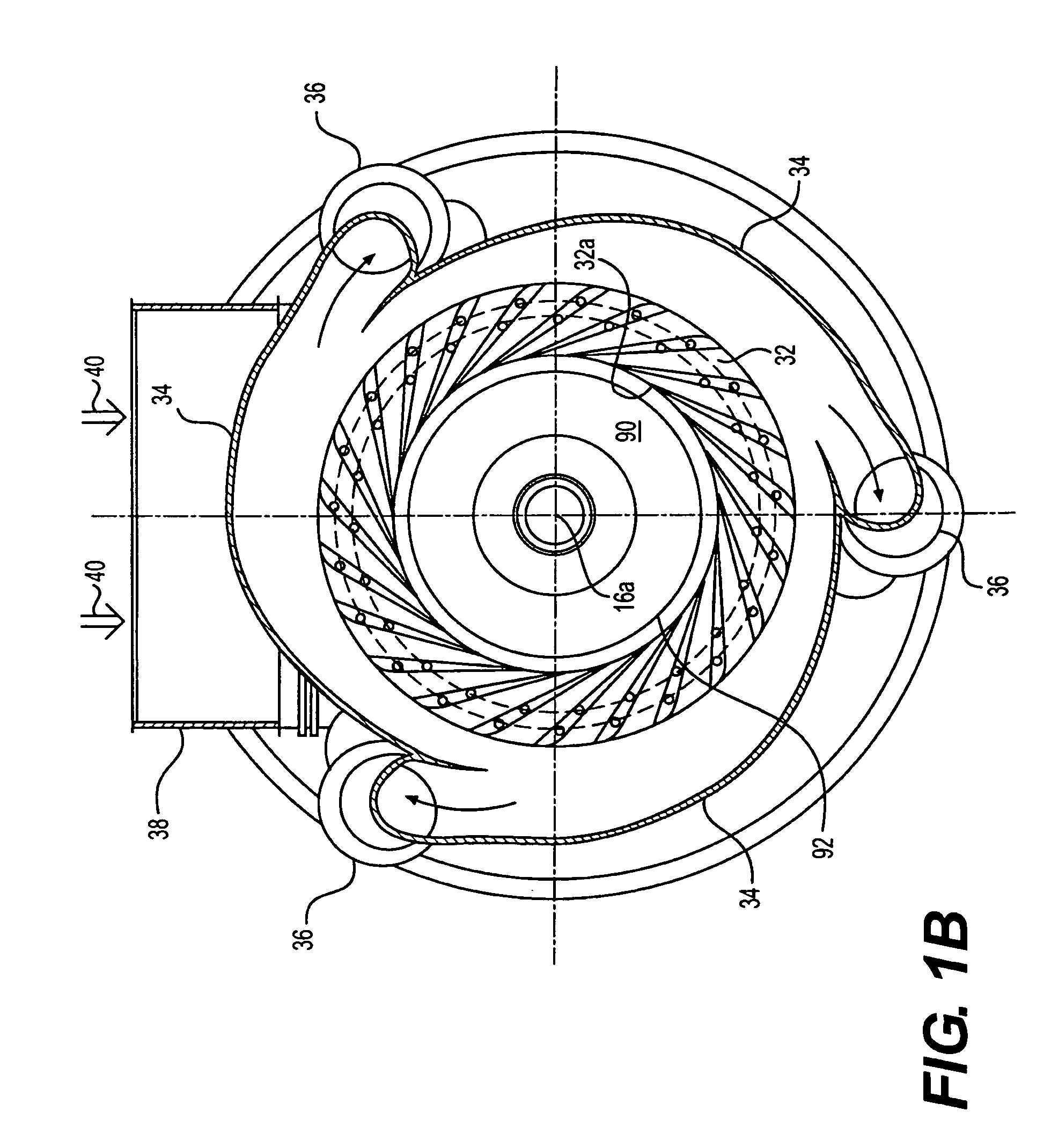

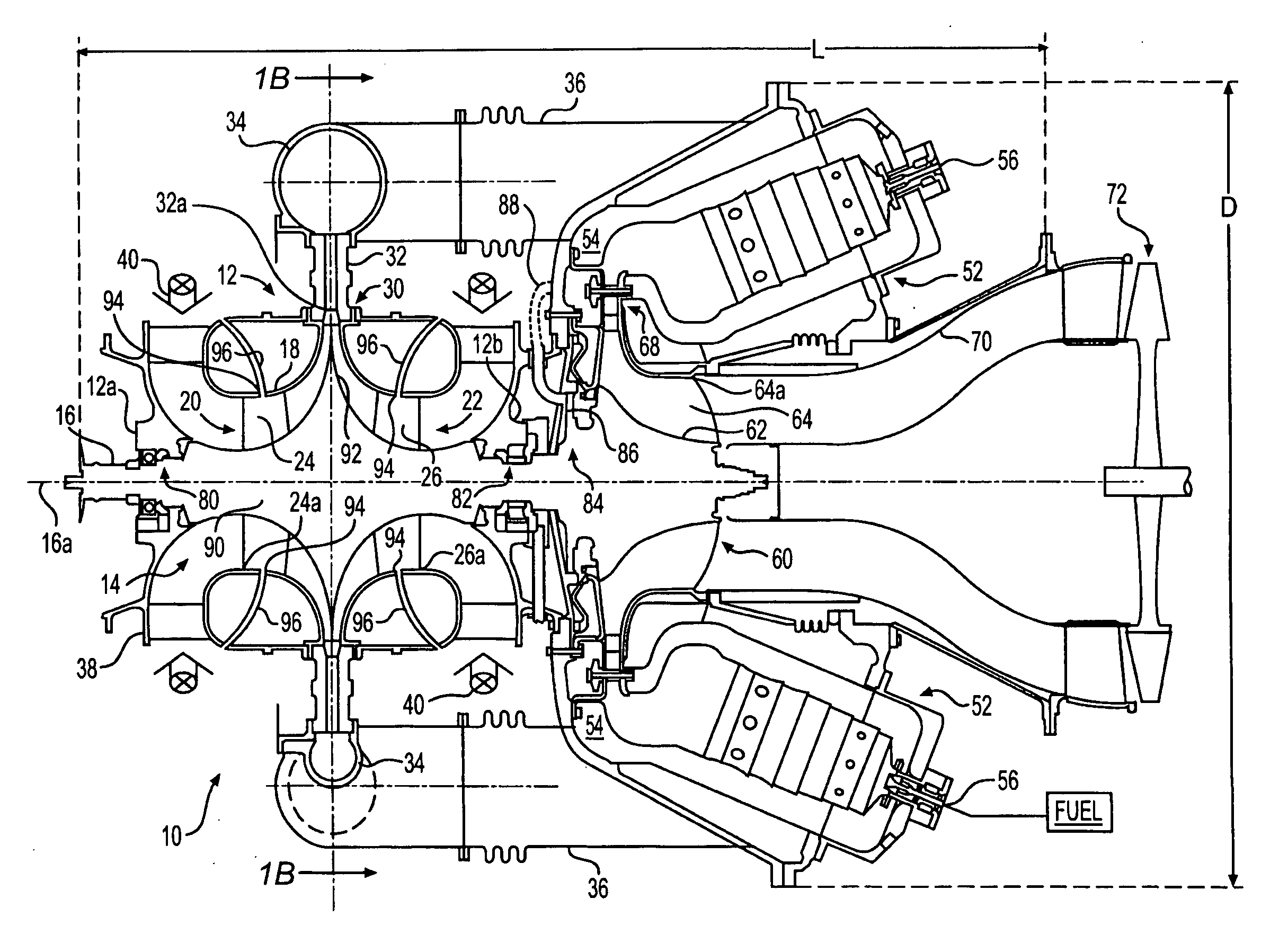

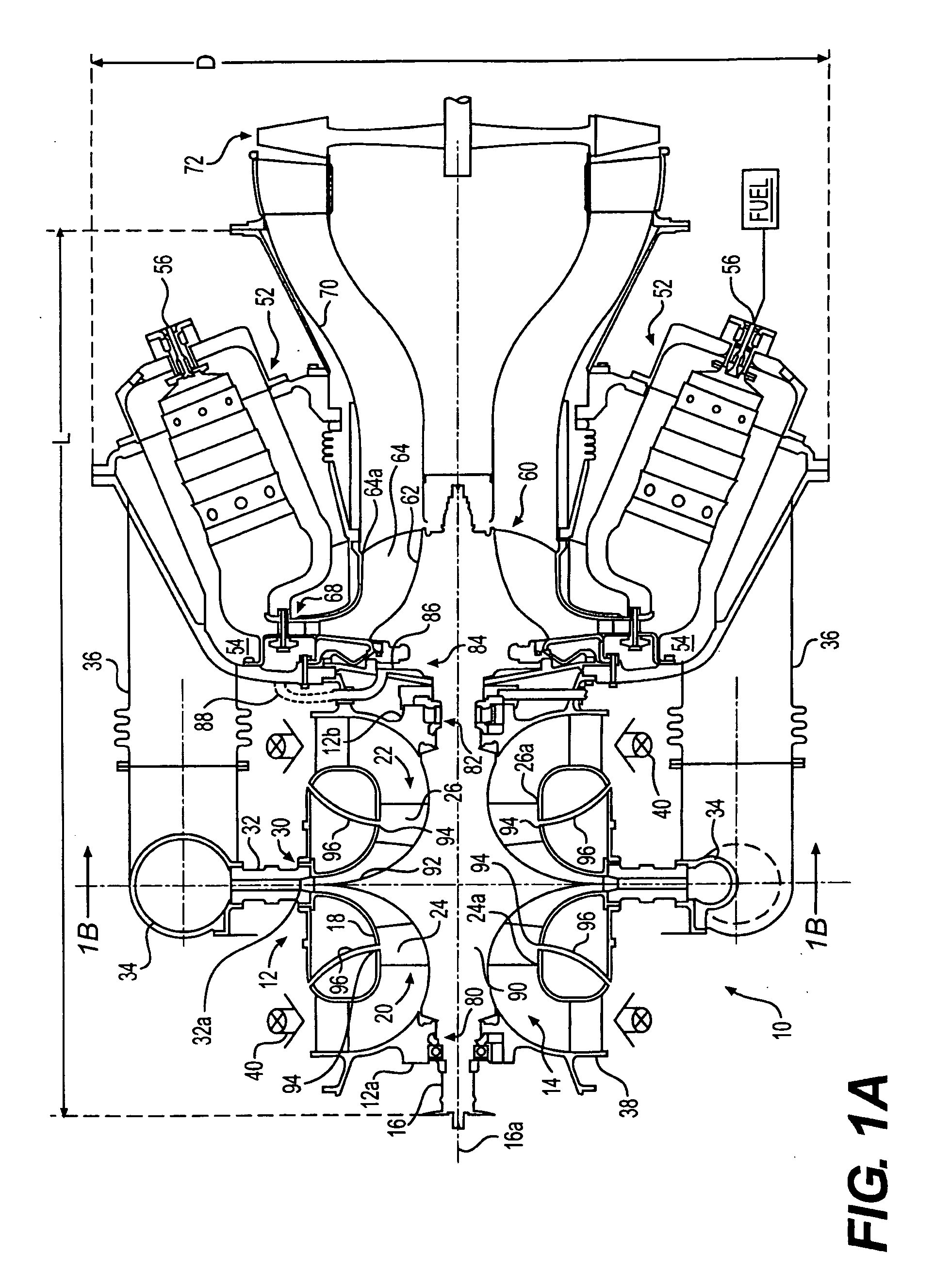

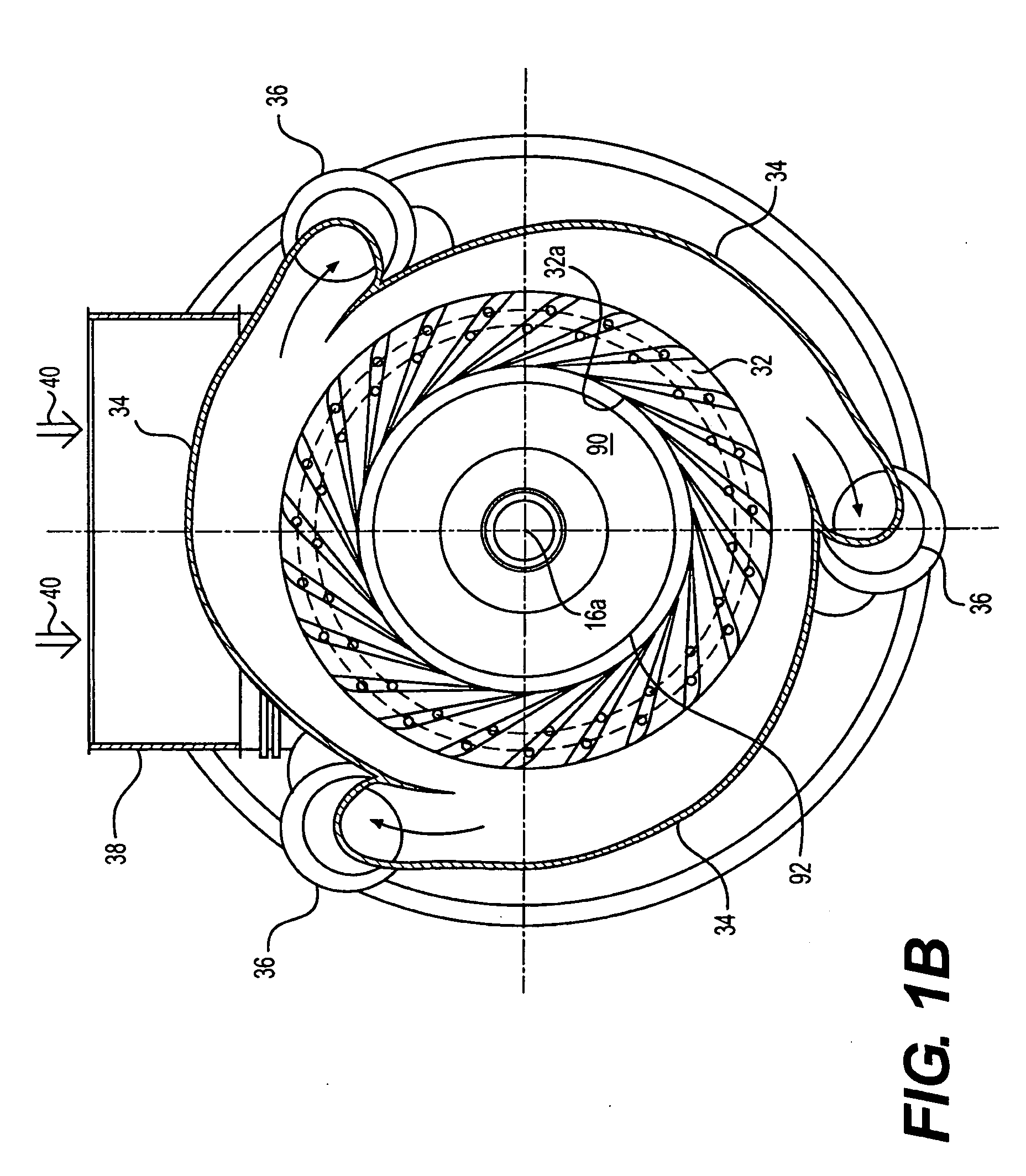

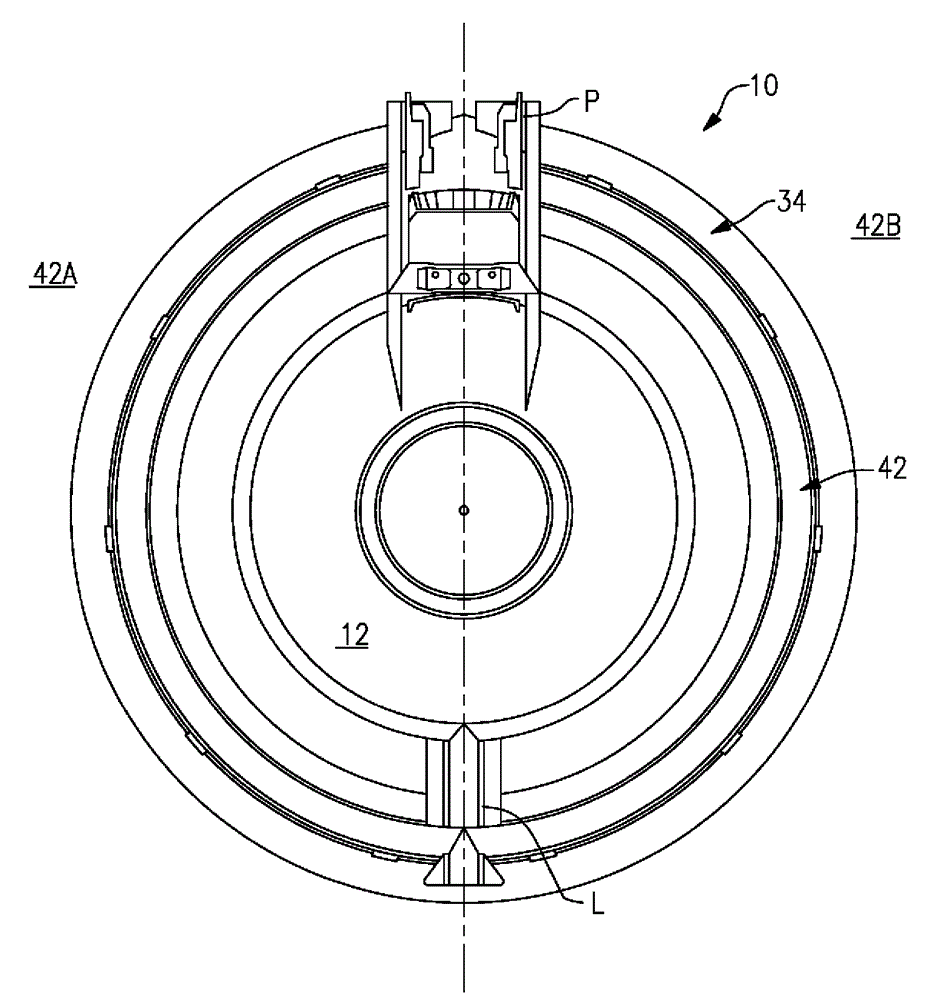

Single stage dual-entry centrifugal compressor, radial turbine gas generator

ActiveUS7628018B2Complete efficientlyHigh lossPump componentsWind motor controlBall bearingHigh pressure

Owner:OPRA TECH

Gas turbine engine with variable overall pressure ratio

Owner:RTX CORP +1

Single stage dual-entry centrifugal compressor, radial turbine gas generator

ActiveUS20090232676A1Complete efficientlyHigh lossPump componentsWind motor controlBall bearingHigh pressure

A compact, single shaft gas turbine gas generator uses a high pressure ratio dual-entry single stage centrifugal compressor, can combustors, and a radial inflow turbine with the compressor configured to achieve an overall pressure ratio of about 12:1 or greater and Mach Numbers less than or equal to about 1.4. The radial inflow turbine is configured to provide an expansion ratio of about 4:1 to about 5:1, to provide partially expanded combustion gases to a free-power turbine or an expansion nozzle, in a work-producing engine configuration. A ball bearing assembly in front of the compressor is used in conjunction with a thrust piston assembly to take up turbine thrust load, while a radial tilt pad bearing assembly is used in front of the turbine. A collector with scroll-shaped sector portions collects compressed air from an annular vaned diffuser, and respective crossover ducts channel the collected diffused compressed air from each sector portion to a plenum feeding can combustors. Bleed systems at each compressor inlet provide increased diffuser stability margins. Gas turbine engines configured with the above gas generator may provide 30% thermal efficiency or more in a rated power range of about 4 Mw or less.

Owner:OPRA TECH

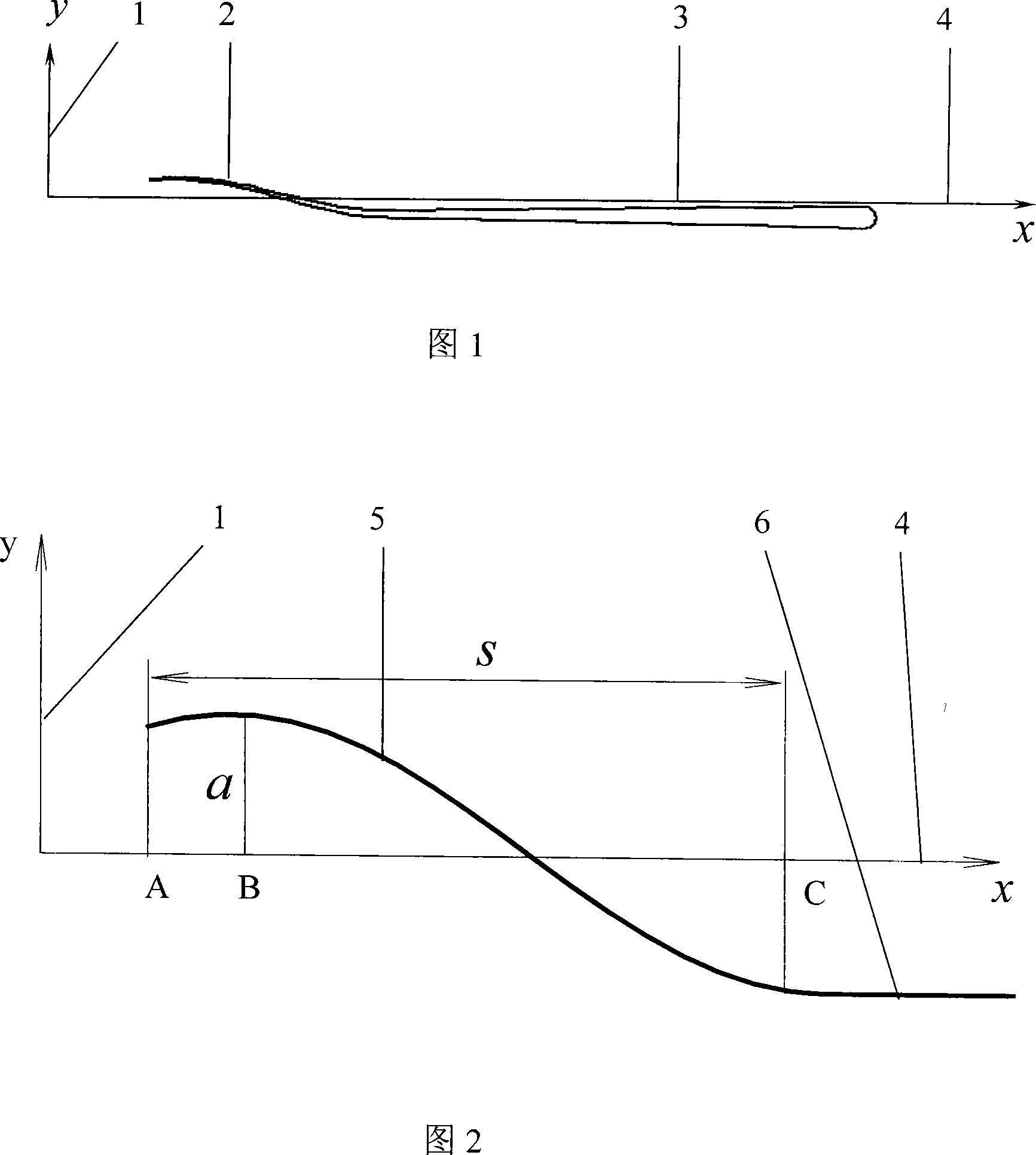

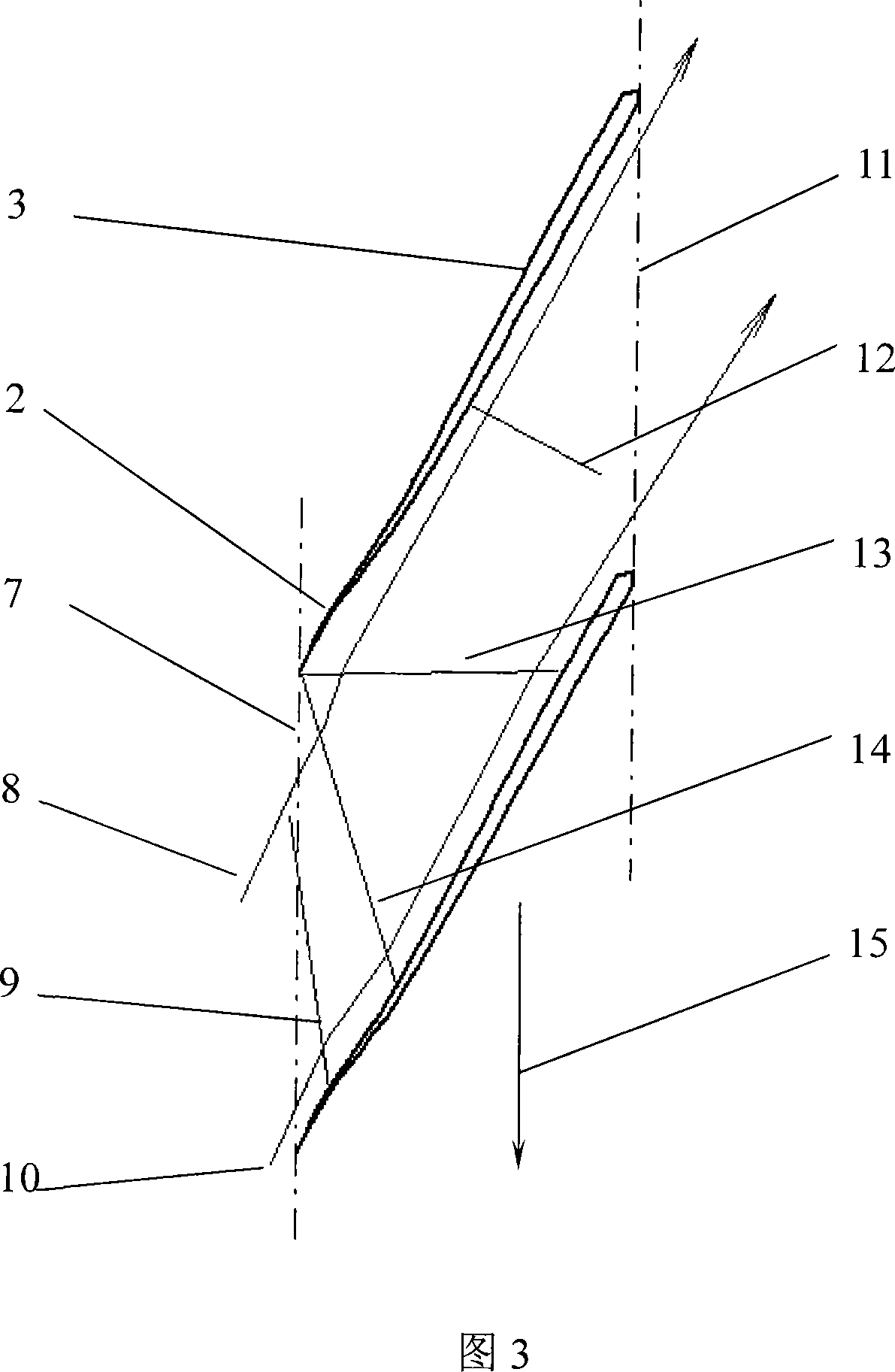

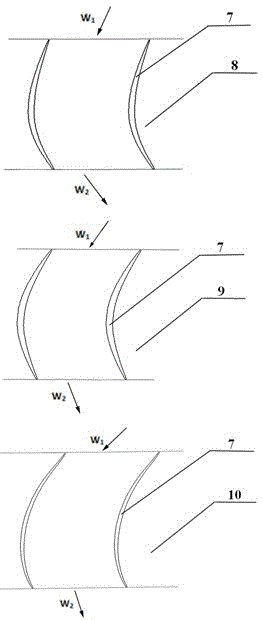

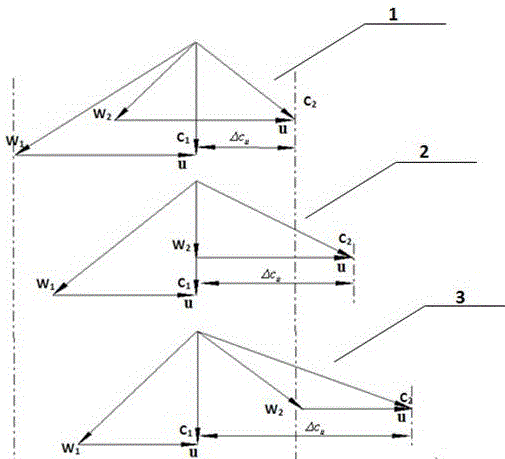

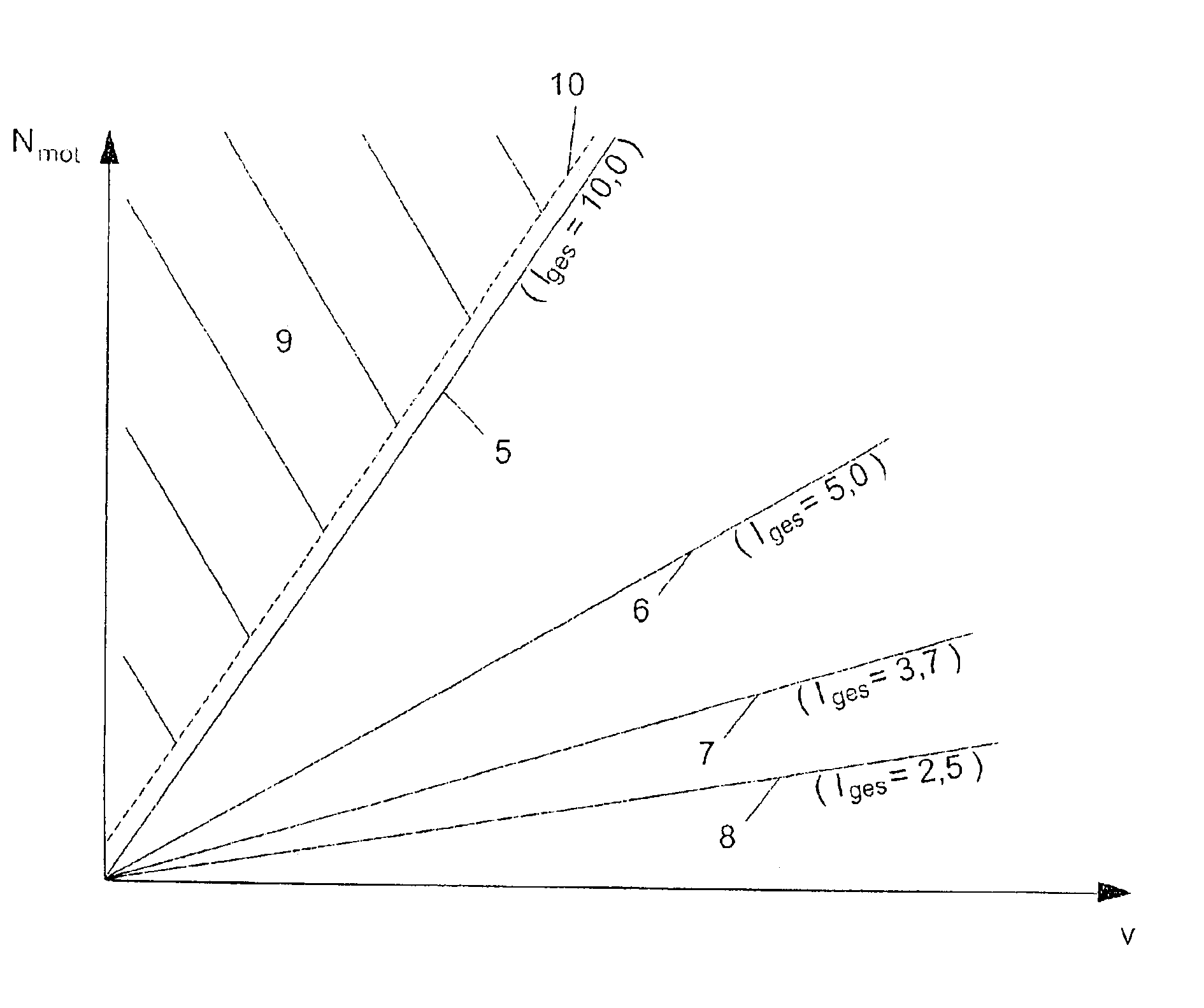

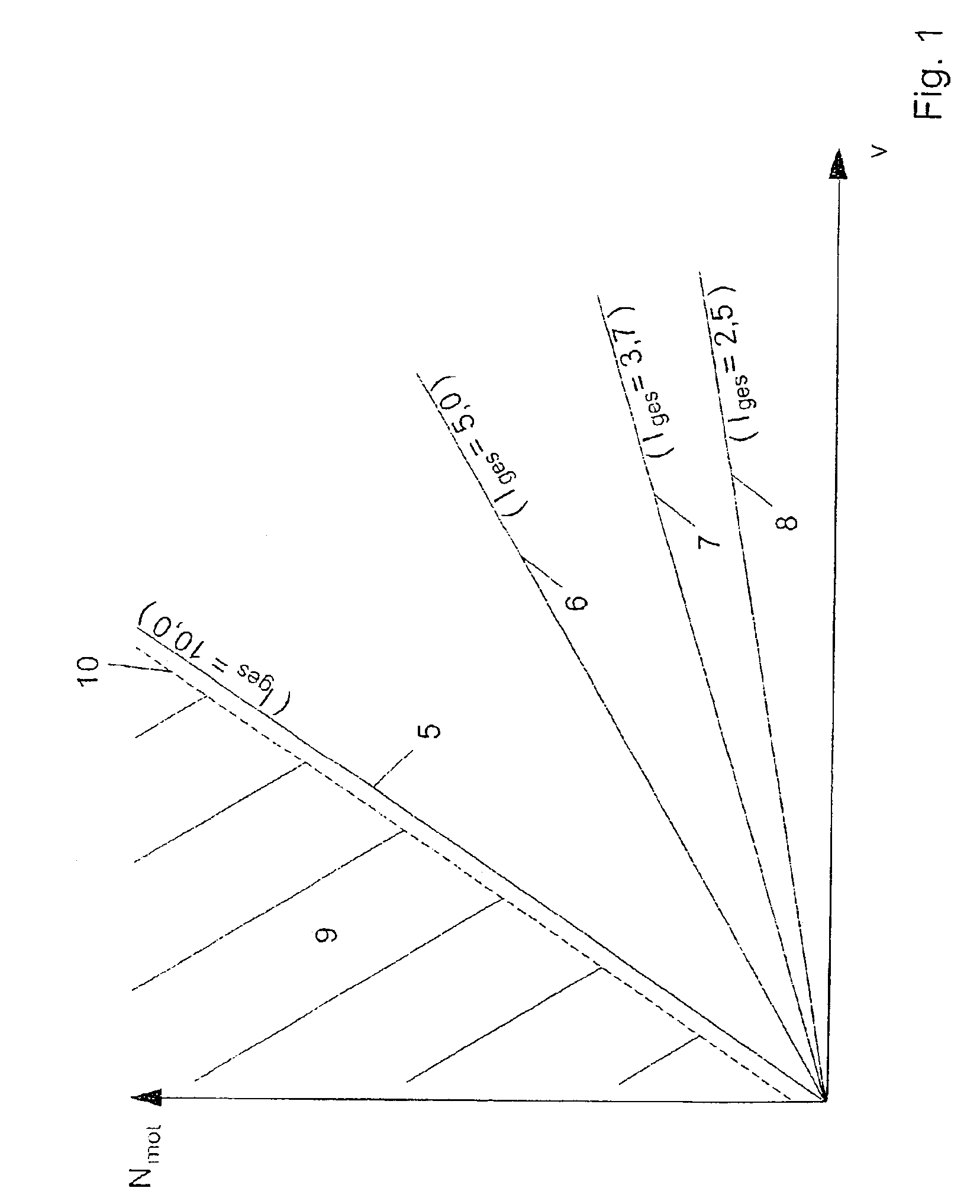

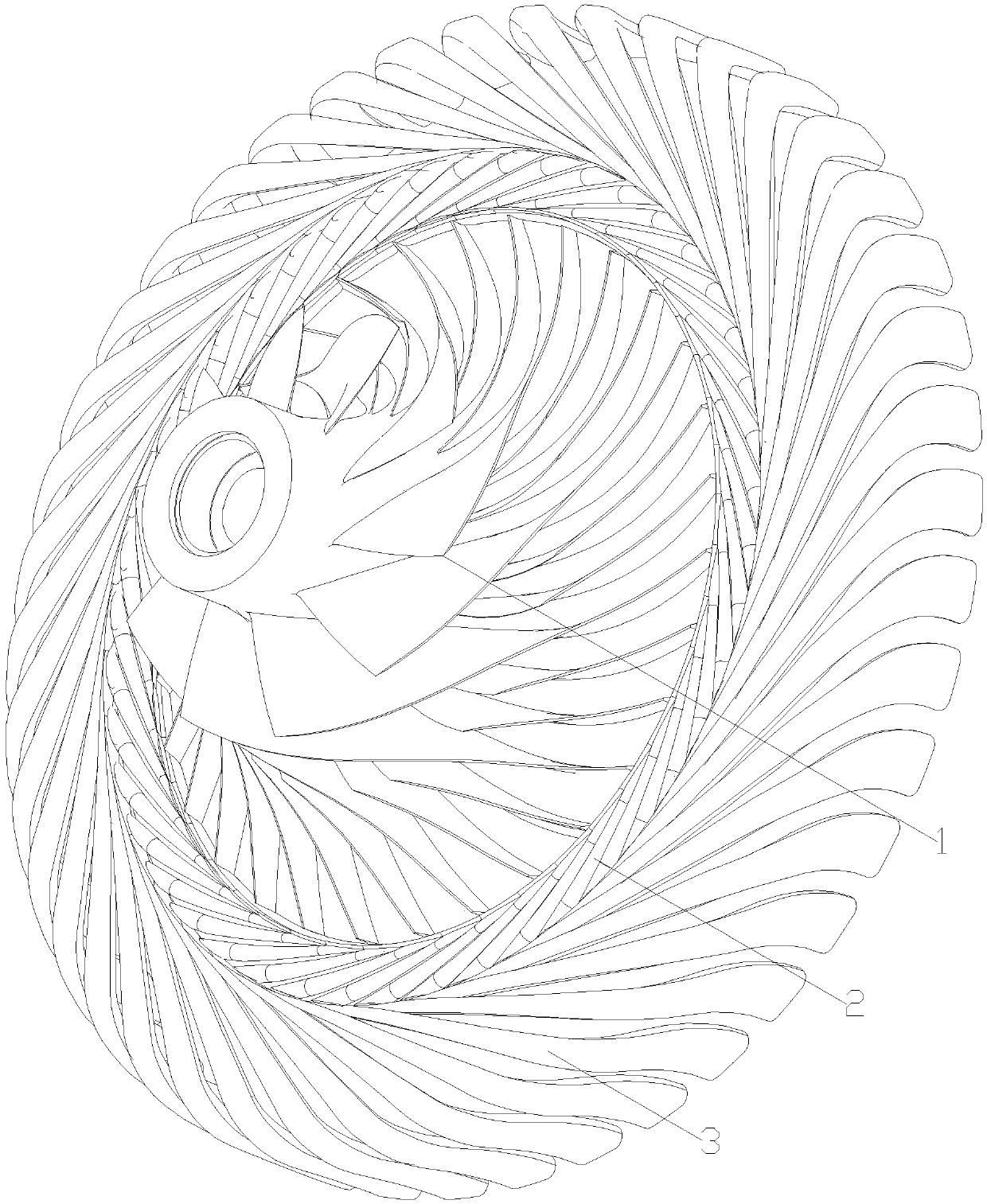

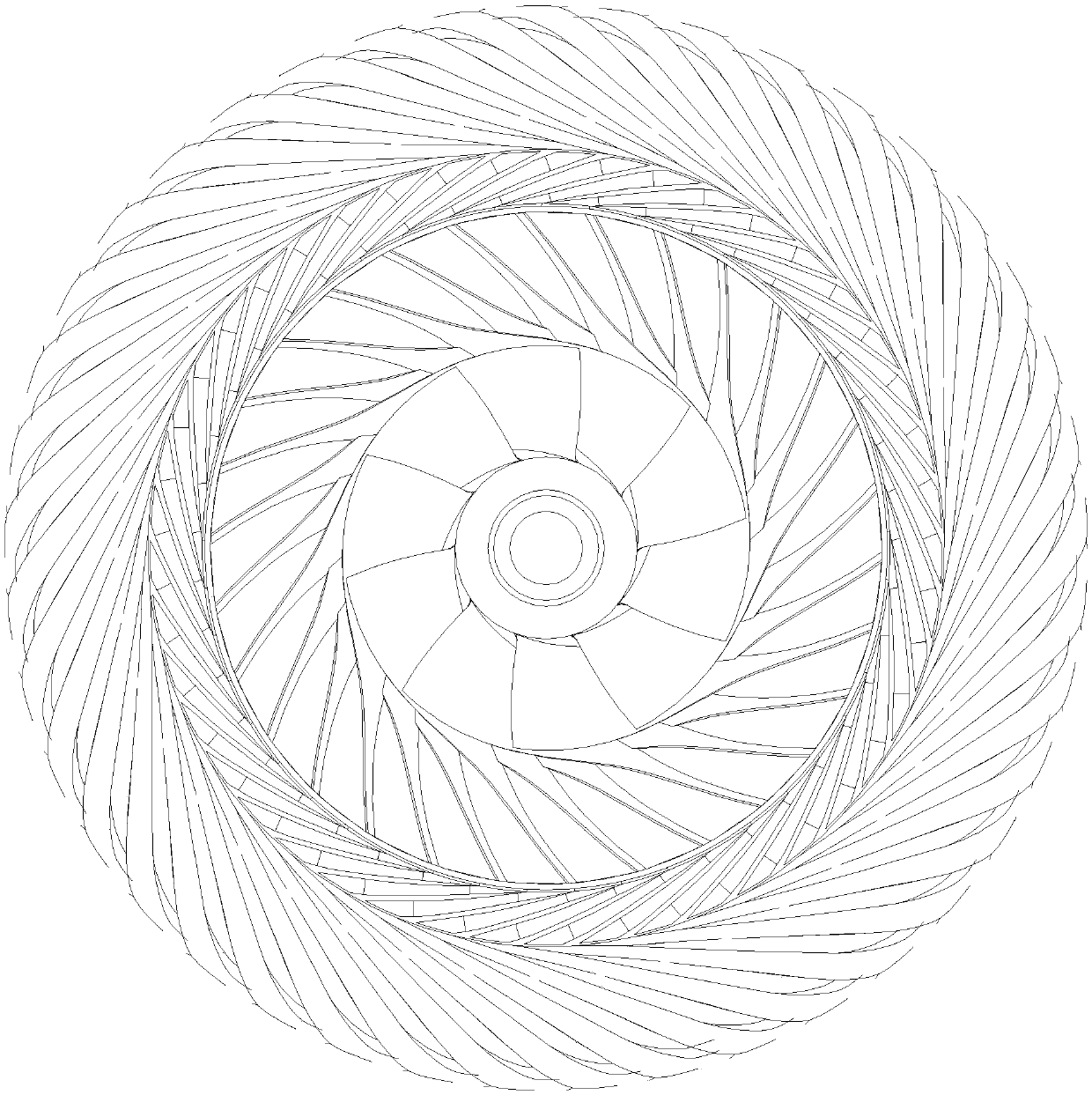

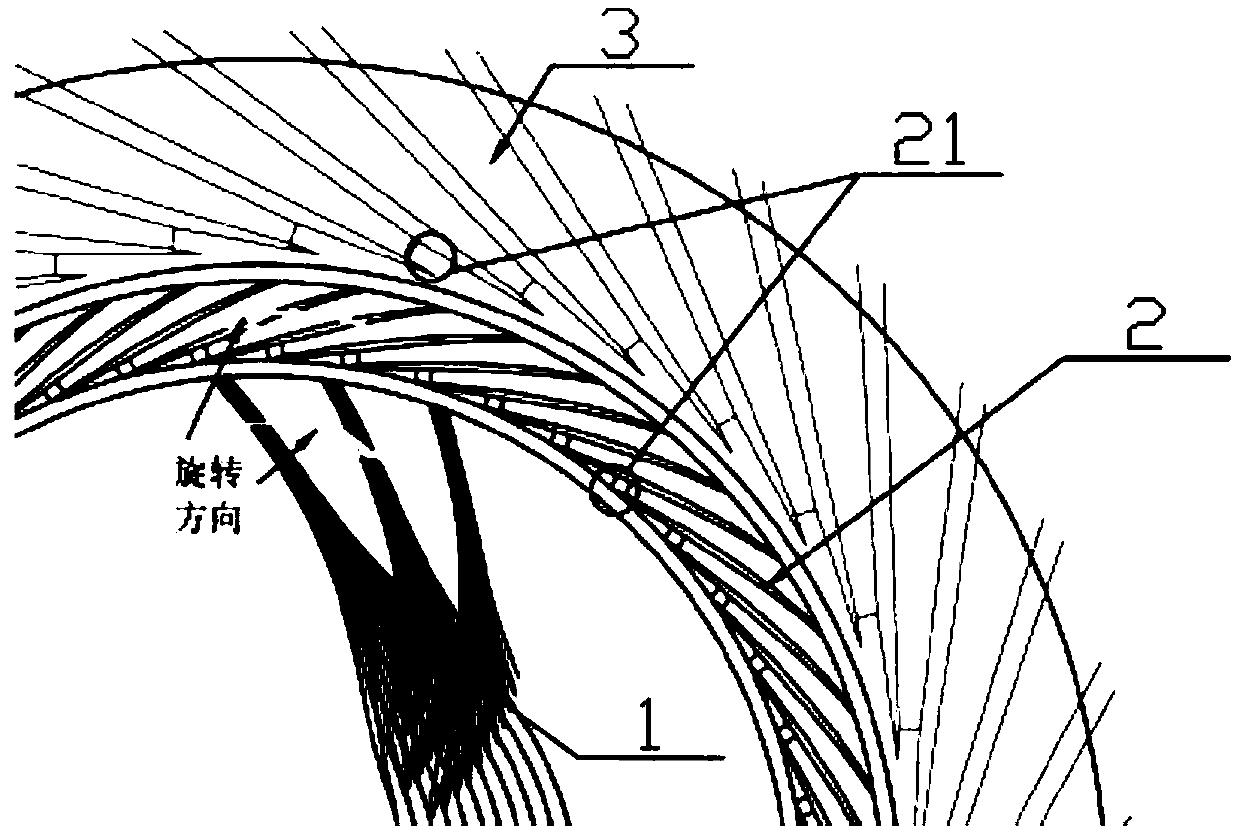

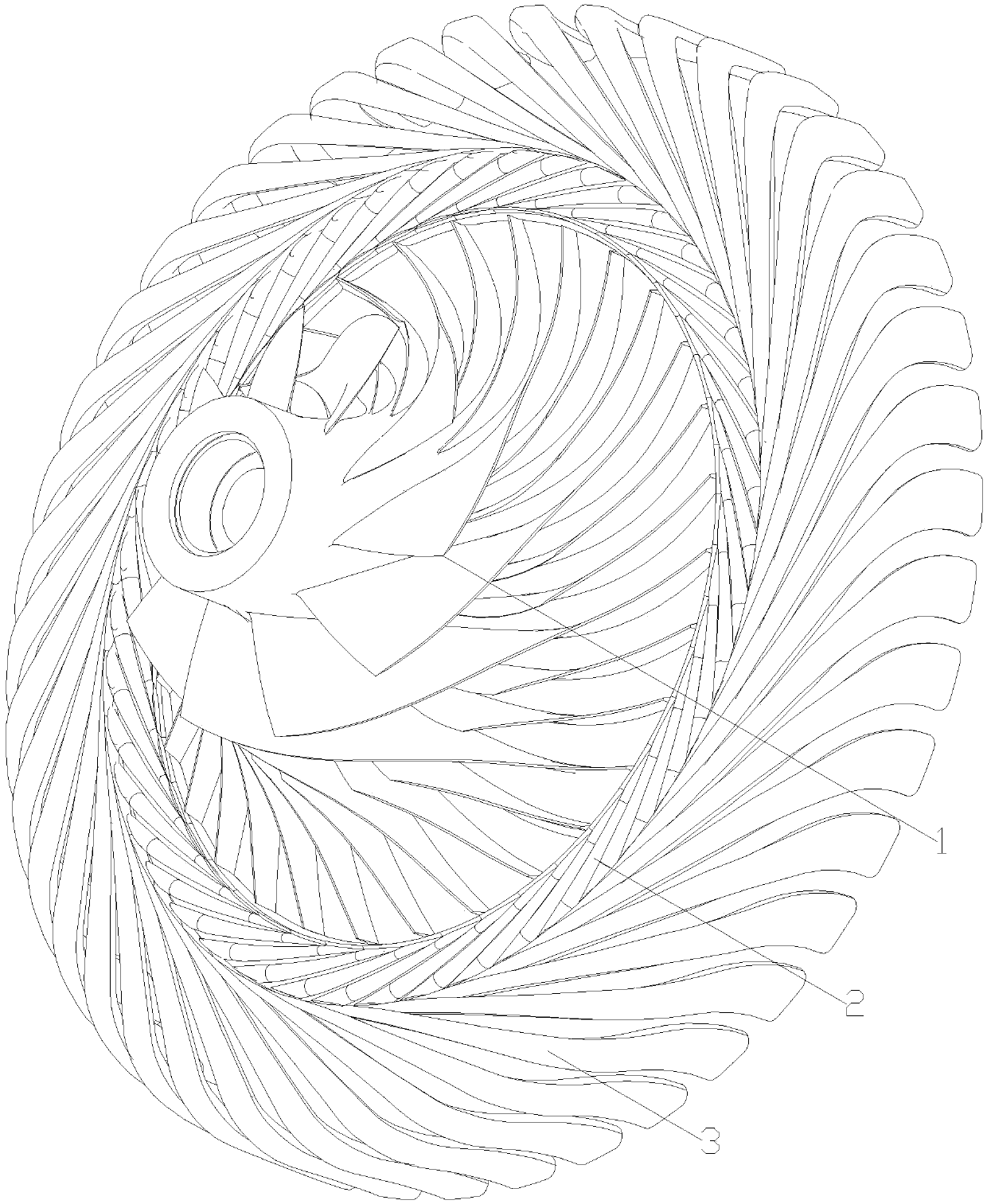

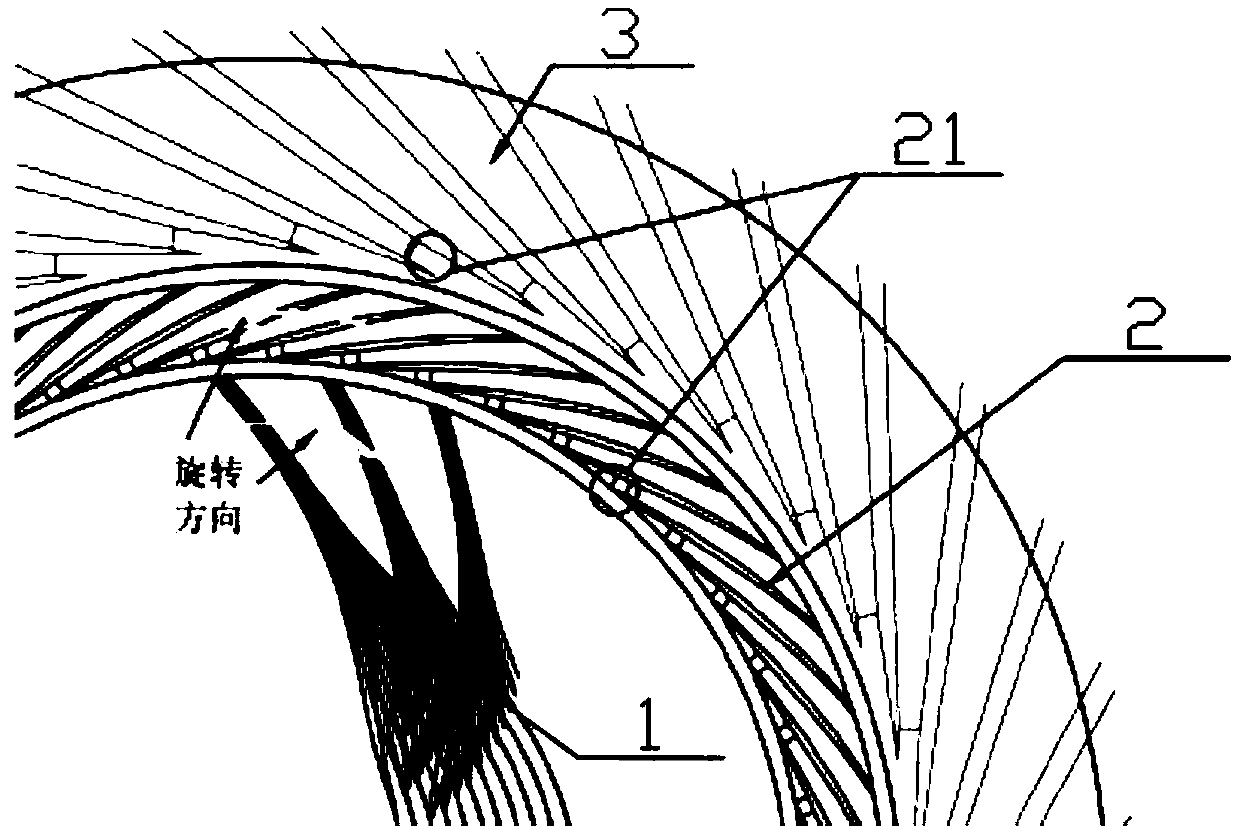

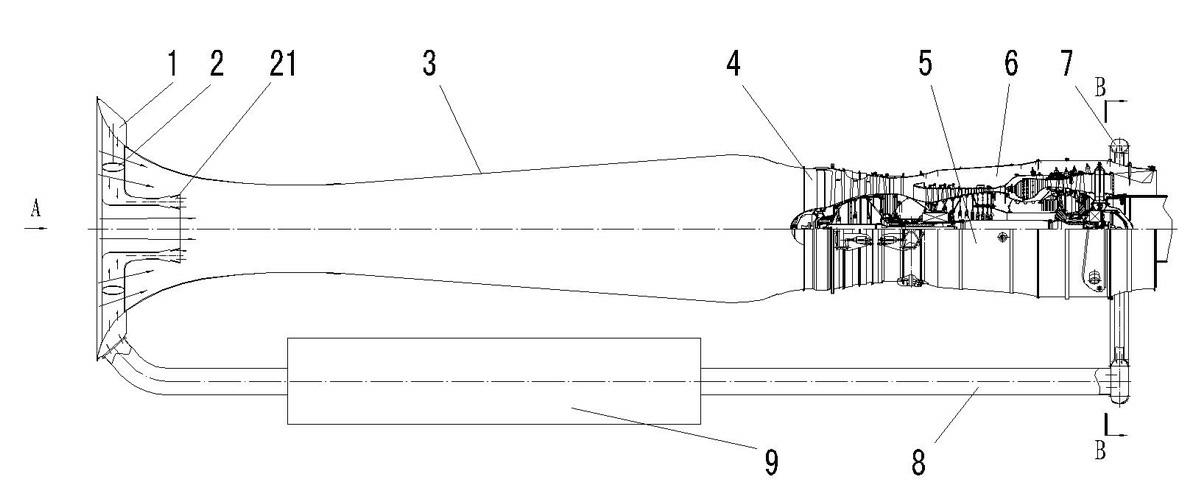

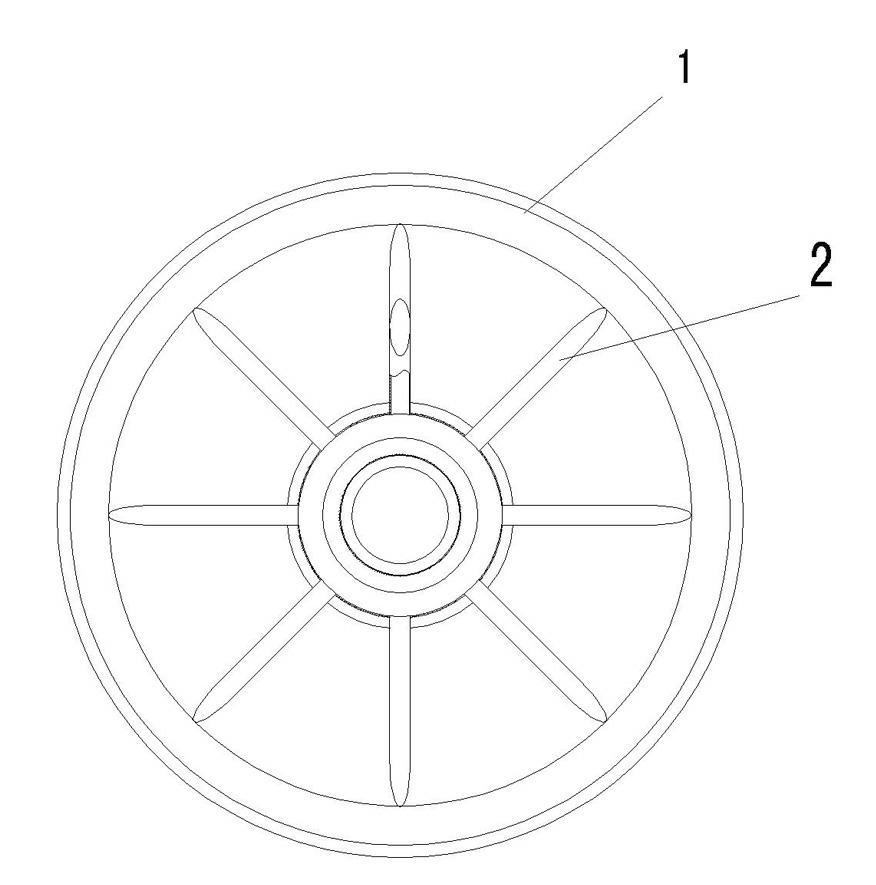

Pneumatic design method for ultrahigh-load, ultralow-rotating-speed and large-bypass-ratio fan rotor

The invention relates to a pneumatic design method for an ultrahigh-load, ultralow-rotating-speed and large-bypass-ratio fan rotor, and belongs to the technical field of impeller machinery. The pneumatic design method includes the steps that firstly, key design parameters are determined through S2 through-flow analysis according to flow and the overall pressure ratio, and the load coefficient is selected between 0.7 and 1.0; secondly, a plurality of S1 stream surface two-dimensional blade forms (7) are designed according to the inlet and outlet parameter distribution, determined according to S2 through-flow analysis, of the rotor; thirdly, the two-dimensional blade forms designed in the second step are stacked in the radial direction to form three-dimensional blades (11), and the fan rotor (12) is formed according to the number of selected blades; and fourthly, the performance curve of a fan is obtained by conducting three-dimensional flow field simulation of the fan rotor (12) through computer simulation or conducting performance tests through experiments, whether design reaches the standard and meets the requirement or not is tested, and improved design is conducted. By means of the pneumatic design method for the ultrahigh-load, ultralow-rotating-speed and large-bypass-ratio fan rotor, on the premise of ensuring the pneumatic performance of the fan, noise and the weight of the fan are effectively reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

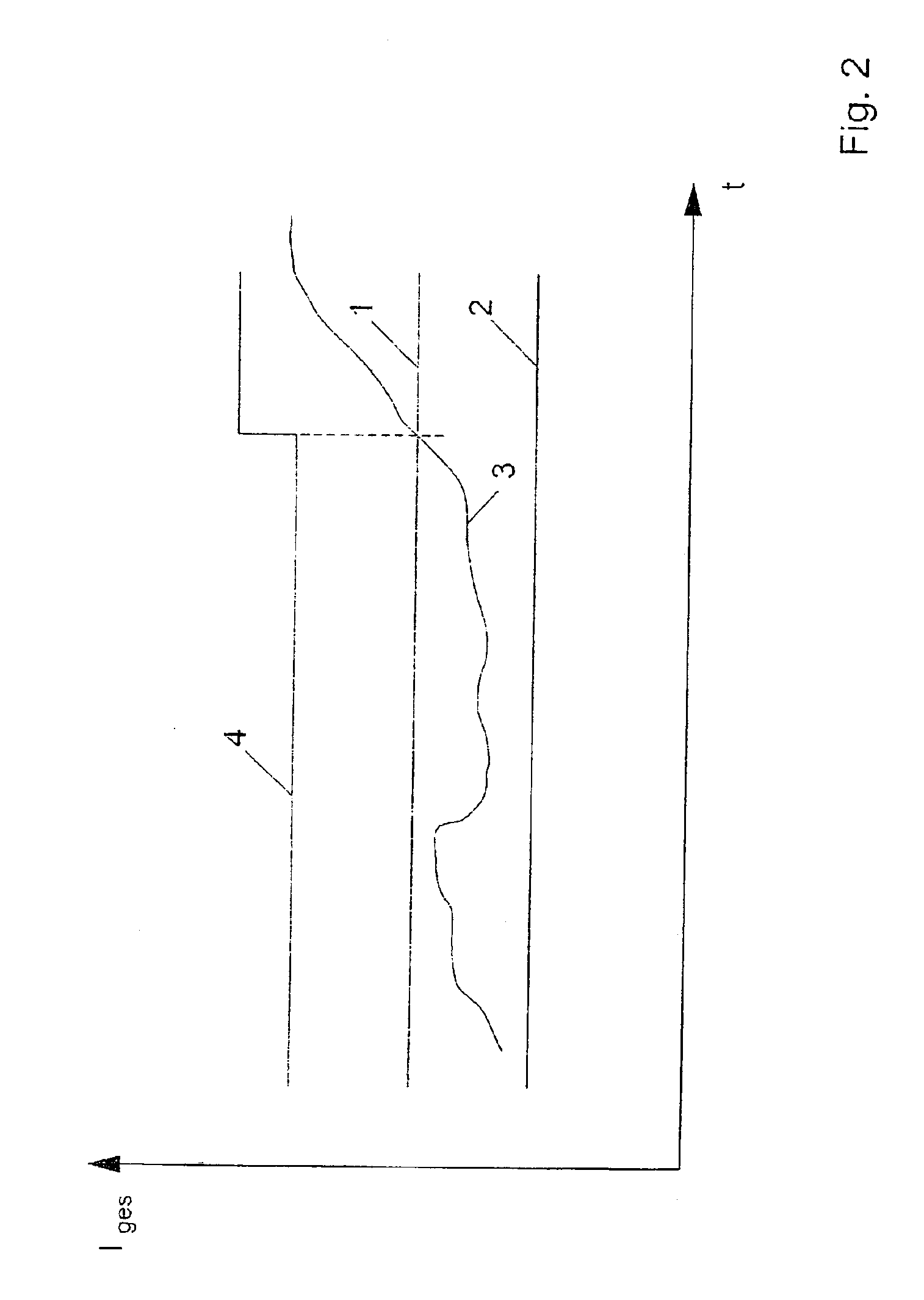

Detecting the clutch state during engine drag torque regulation

InactiveUS6937932B2Prevent extreme engine noiseAvoid noiseElectrical controlDigital data processing detailsTorque regulationDrag torque

A method and a device for detecting the clutch state in a motor vehicle, in particular during engine drag torque regulation, is described. A particularly simple and cost-effective method of detecting the clutch state is made possible by determining the engine speed and a wheel speed and by calculating a gear ratio therefrom. Threshold values for the overall gear ratio are stored in the system for at least each of the lower gears (e.g., the first through the third gear). The clutch state may be identified by comparing the calculated overall gear ratio with the threshold values of the particular gear.

Owner:ROBERT BOSCH GMBH

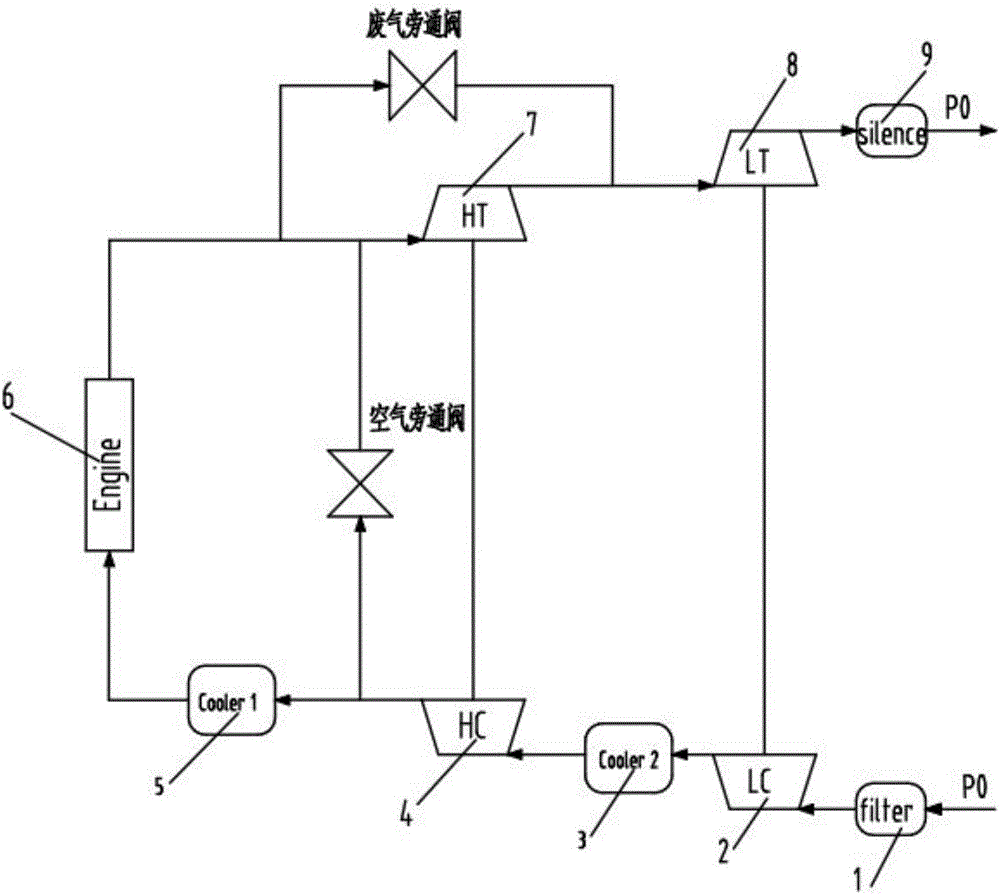

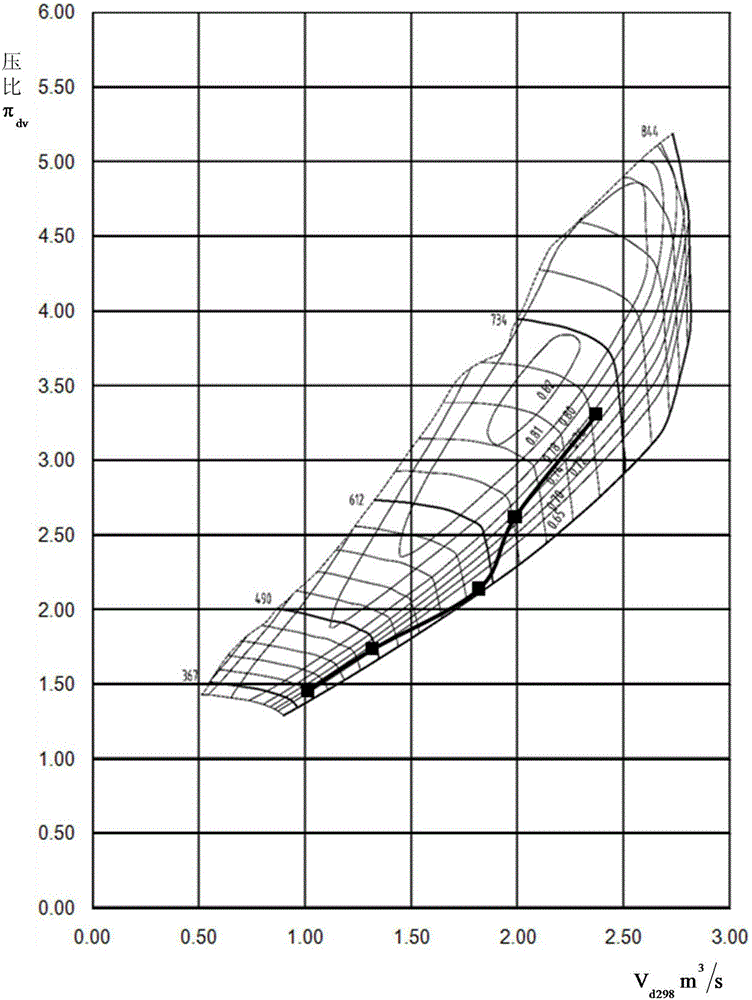

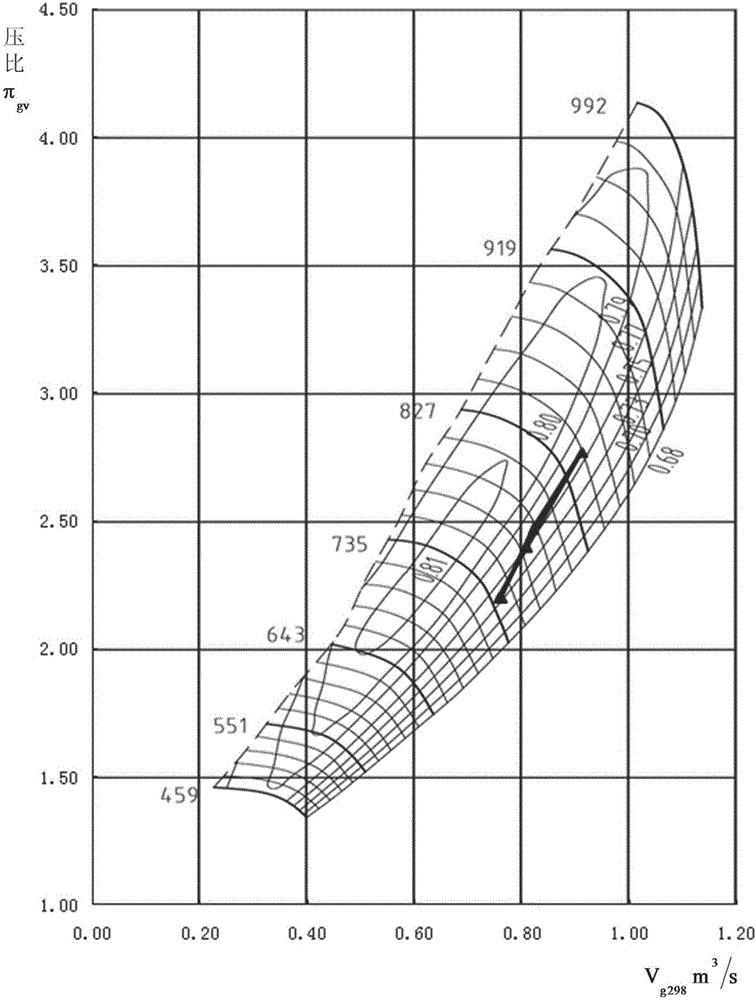

Matching calculation method of two-stage supercharging system and diesel engine

ActiveCN106382155ASolve the tedious and complicated problem of matching calculationQuick matchInternal combustion piston enginesAir volumeModel selection

The invention discloses a matching calculation method of a two-stage highly supercharged system and a diesel engine. The matching calculation method includes the steps that first, according to the given relevant parameters of the diesel engine, the total air mass flow rate and overall pressure ratio required by the diesel engine are calculated; second, the pressure ratio and air volume flow of a low-pressure stage supercharger gas compressor are calculated, and the specification of the low-pressure stage supercharger gas compressor is selected; third, the air volume flow and supercharge ratio of a high-pressure stage supercharger gas compressor are calculated, and the specification of the high-pressure stage supercharger gas compressor is selected; fourth, the expansion ratio and inlet temperature of the turbine end of a high-pressure stage supercharger are calculated, and the turbine specification of the high-pressure stage supercharger is determined; fifth, calculation and model selection are performed on a low-pressure stage turbine; and sixth, a combined operation line of the diesel engine and the superchargers can be estimated according to the specifications of the selected superchargers.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

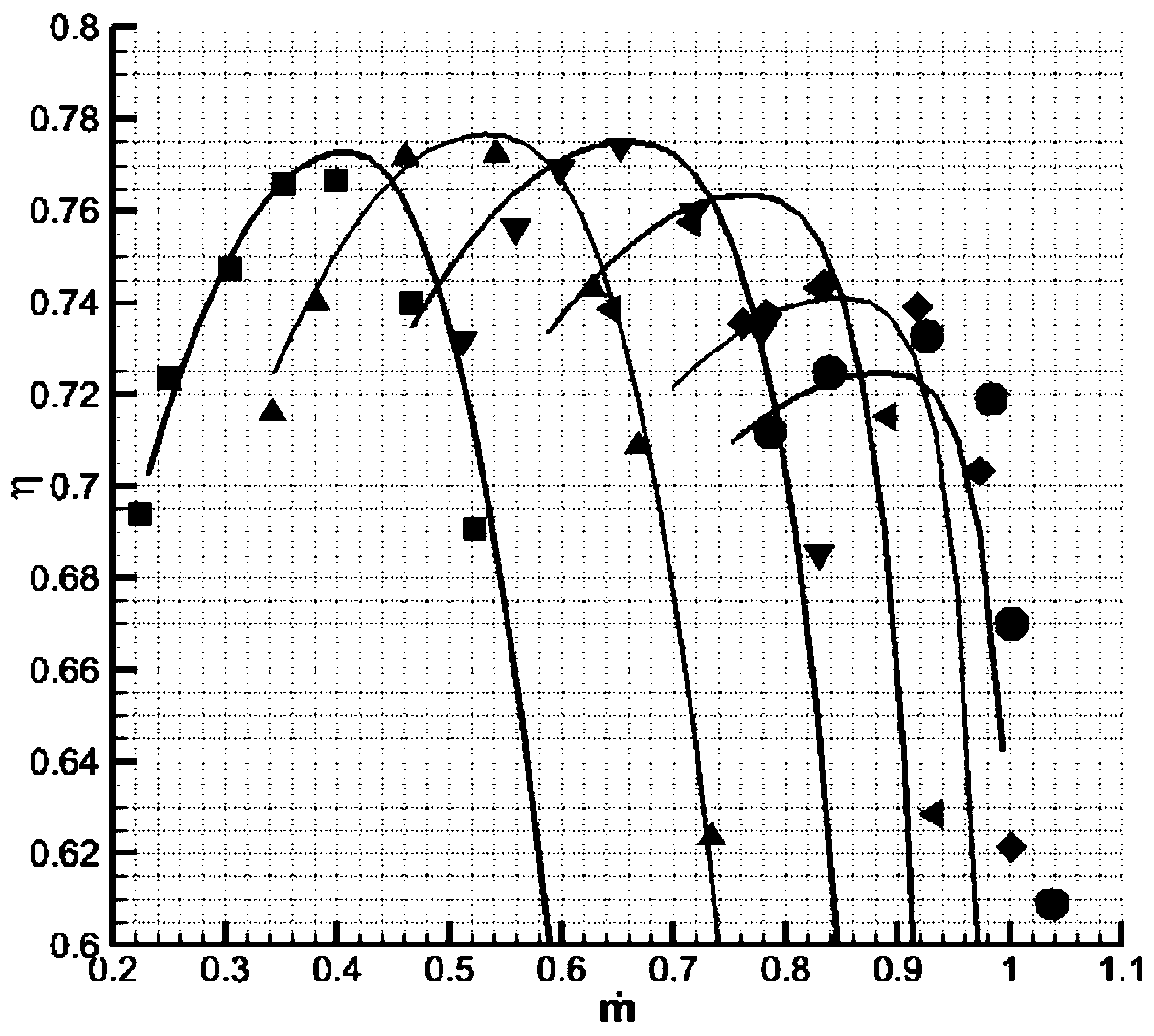

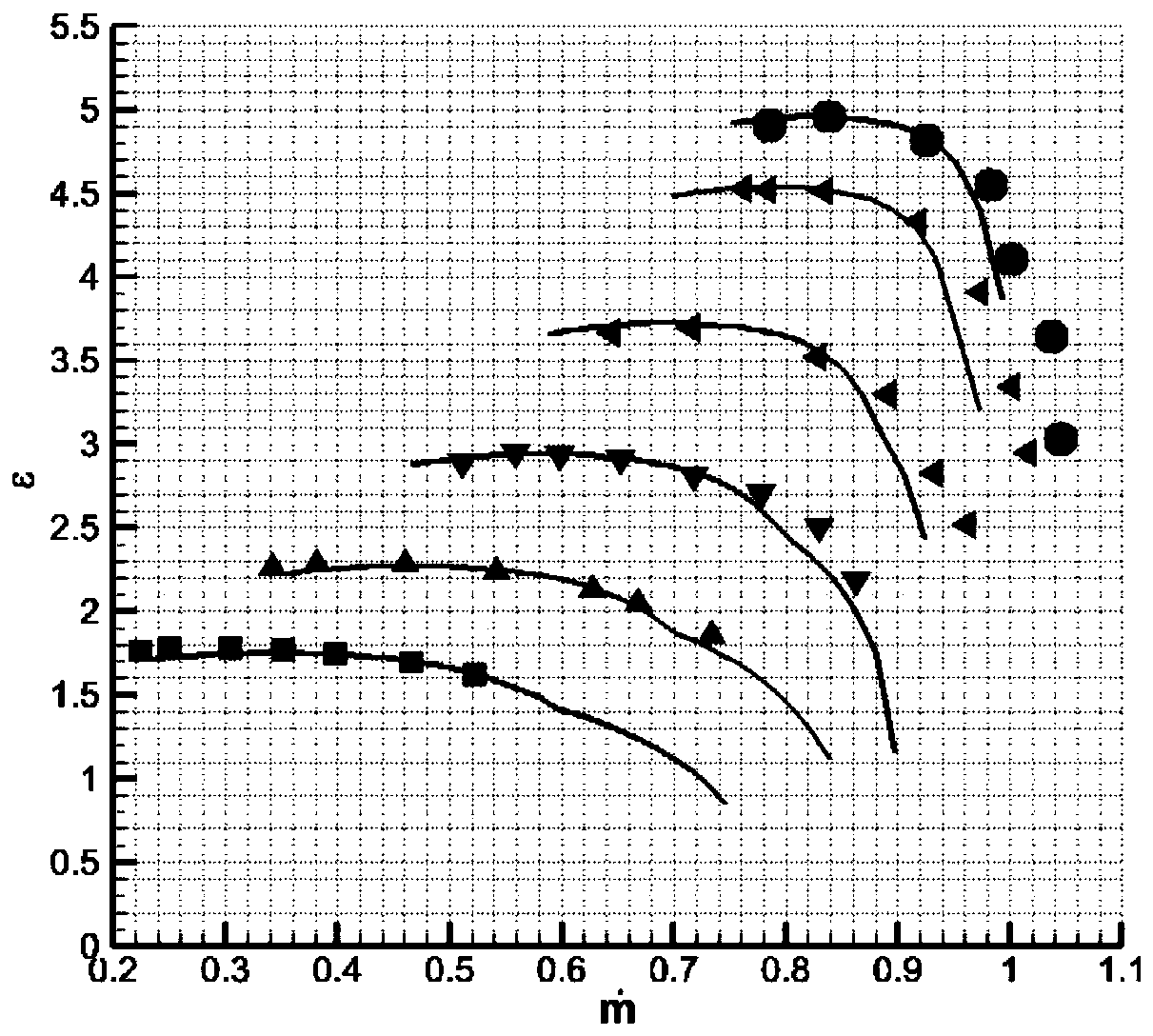

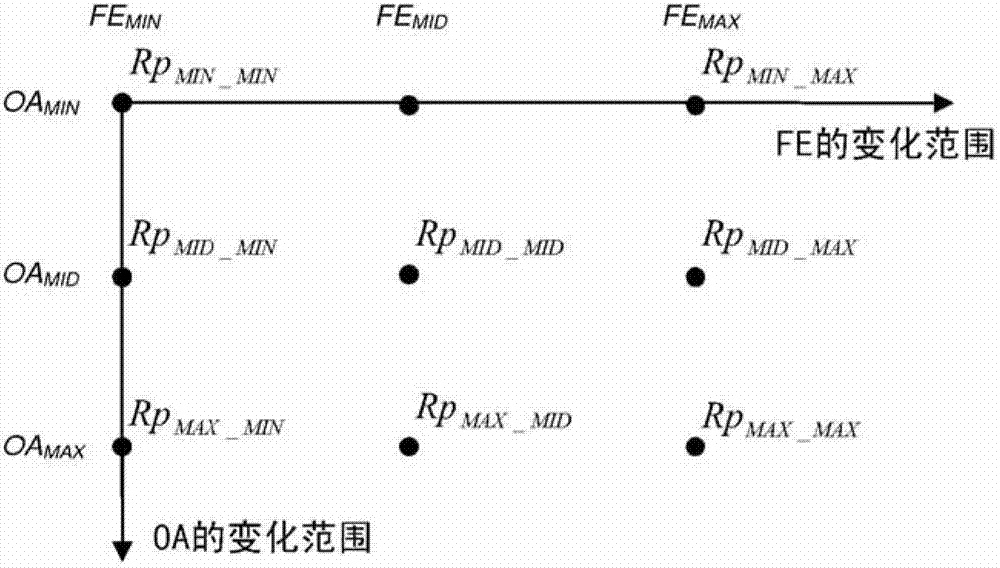

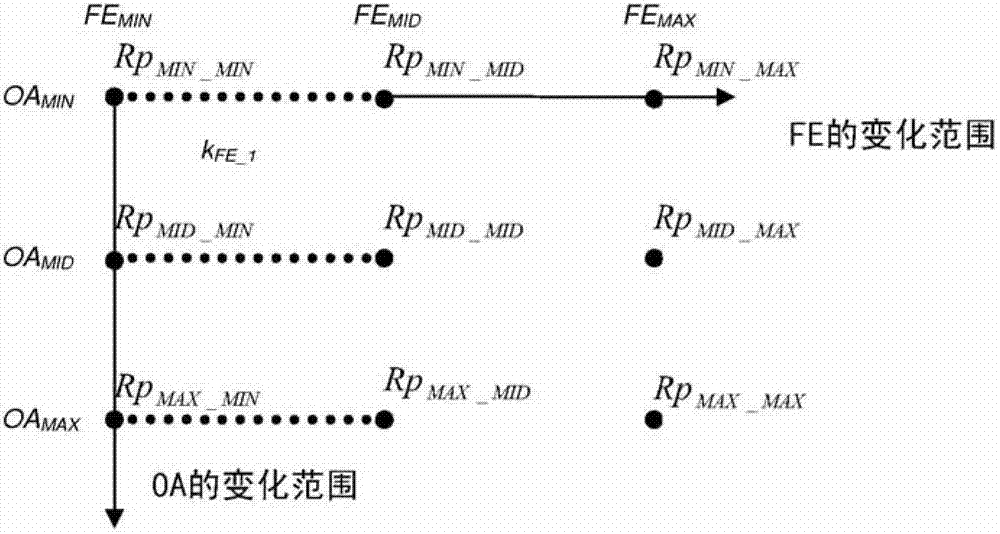

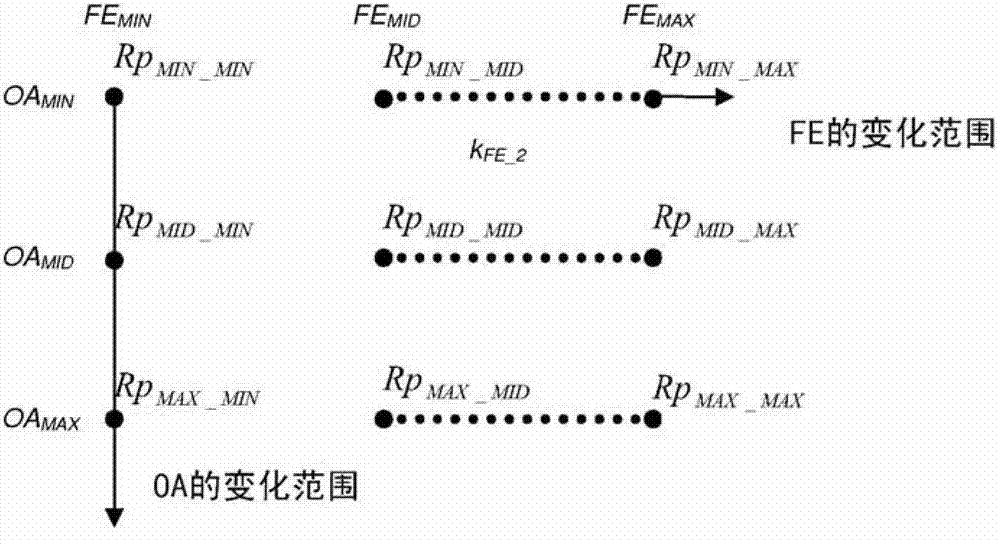

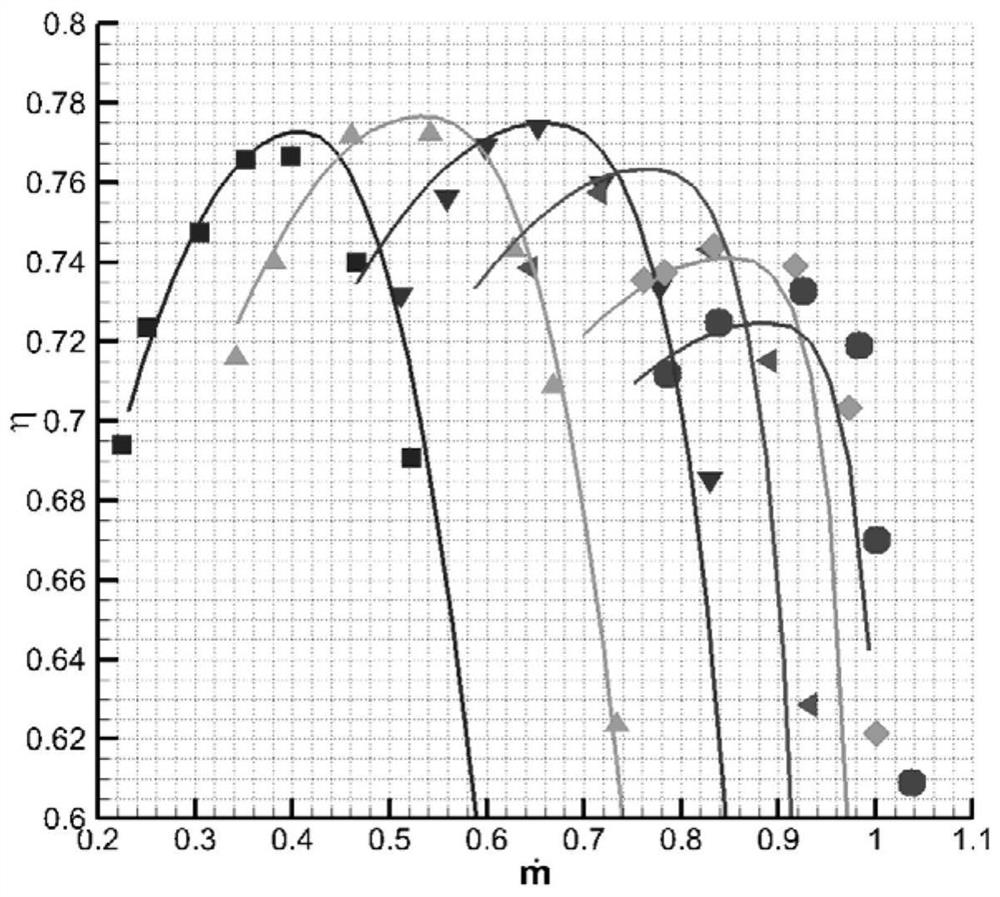

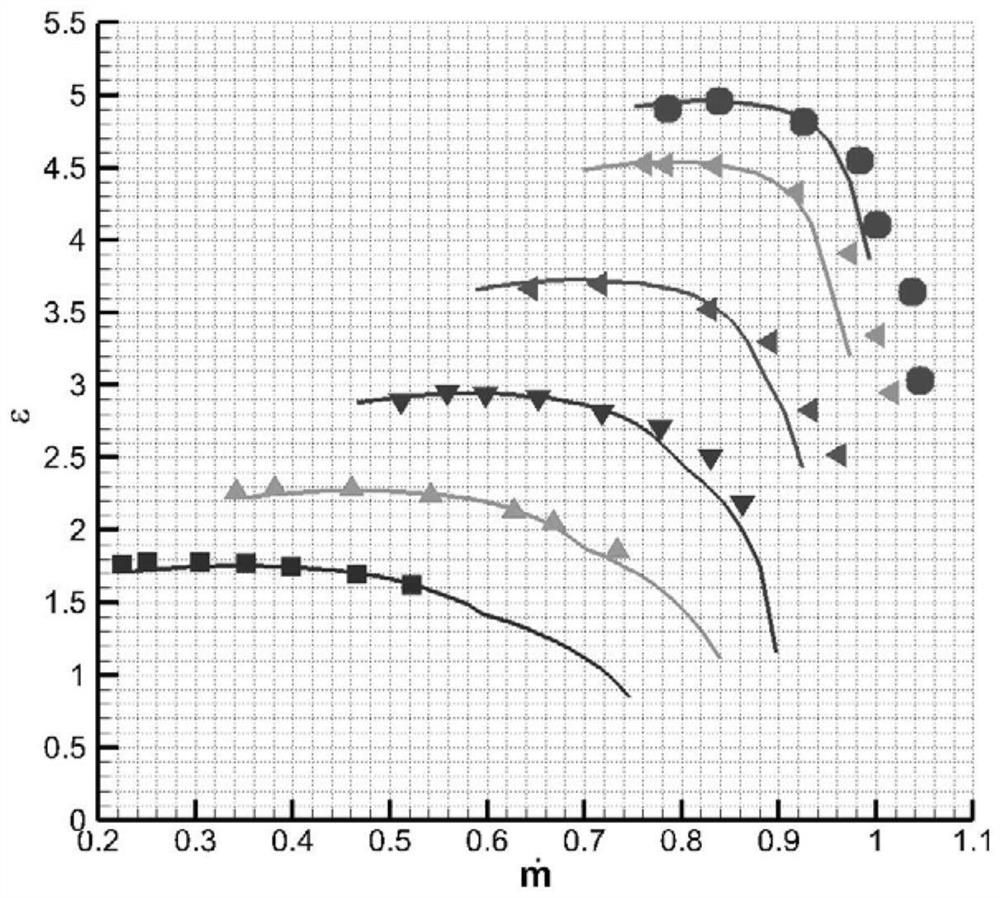

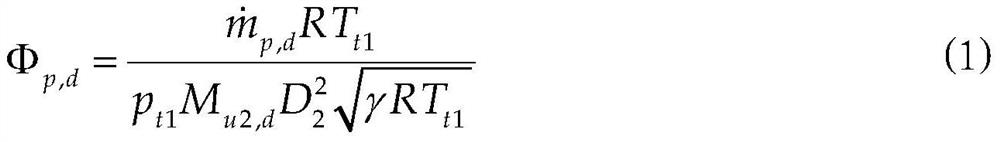

Full-working condition performance prediction method for compressor

ActiveCN110701086ASimple designShorten the design cycleEngine fuctionsPump controlImpellerDesign cycle

The invention discloses a full-working condition performance prediction method for a compressor, and aims at providing a rapid and accurate full-working condition aerodynamic performance prediction method so as to increase the design and optimization efficiency of the compressor. In the method, a formula is established by taking parameters of a design point as the reference to predict the flow, the efficiency and the overall pressure ratio of an off-design working condition; in a flow prediction method, firstly, the flow of the design point is converted according to an empirical formula to flow corresponding to a peak efficiency point at different rotating speeds, and then, blocking flow and surging flow at respective rotating speeds are calculated; in an efficiency prediction method, firstly, the efficiency of the design point is converted according to the empirical formula to peak efficiency at different rotating speeds, and then, the efficiency at different rotating speeds is calculated according to an elliptic piecewise approximation method; and in a prediction method for the overall pressure ratio, work factors at different rotating speeds and different flow are calculated according to the thought of the equivalent width of an impeller exit, and the work factors are combined with current efficiency to obtain the overall pressure ratio. By applying the full-working condition performance prediction method to design and optimization of the compressor, the design cycle can be remarkably shortened, and the design cost is reduced.

Owner:TIANJIN UNIV

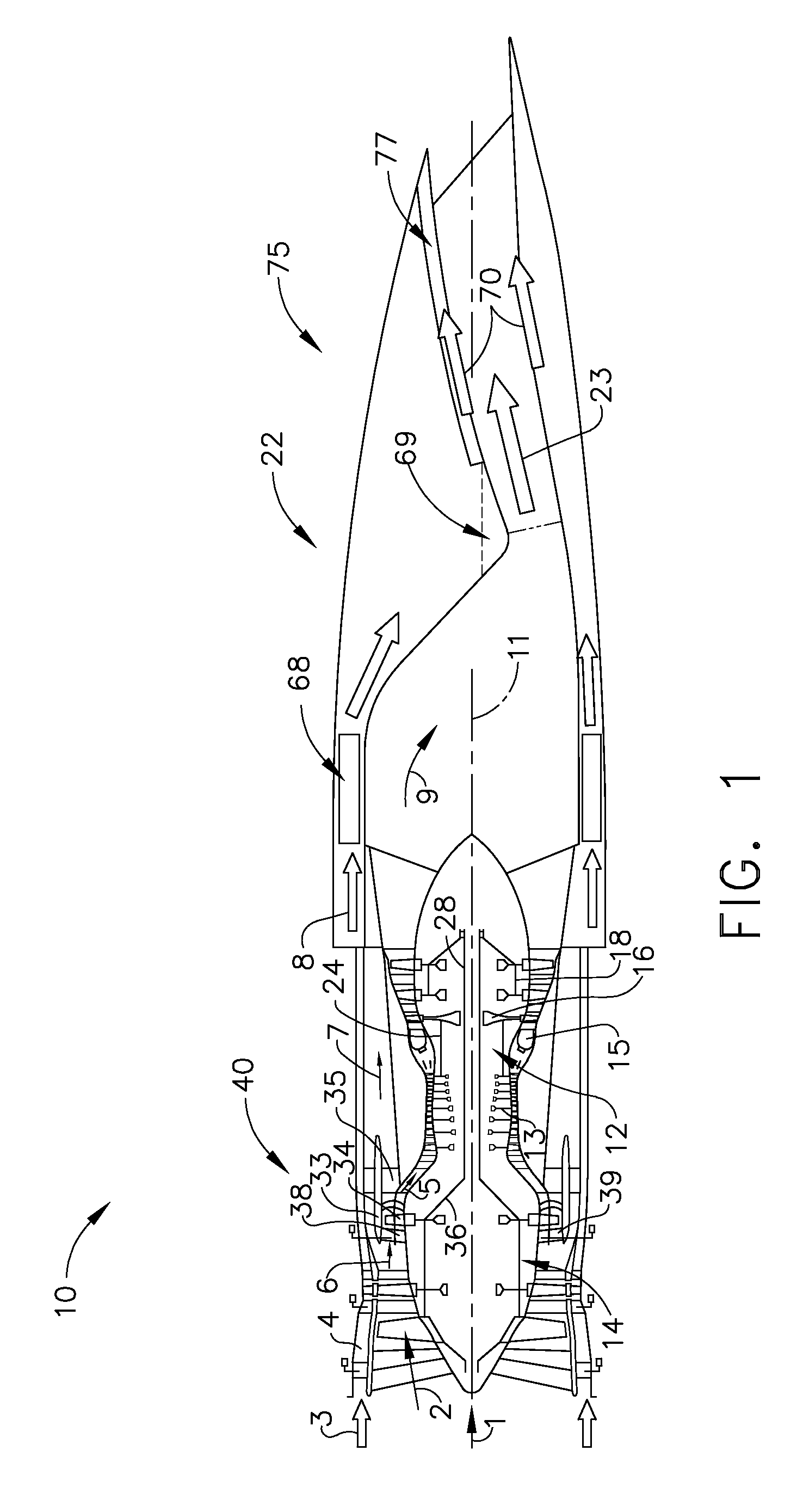

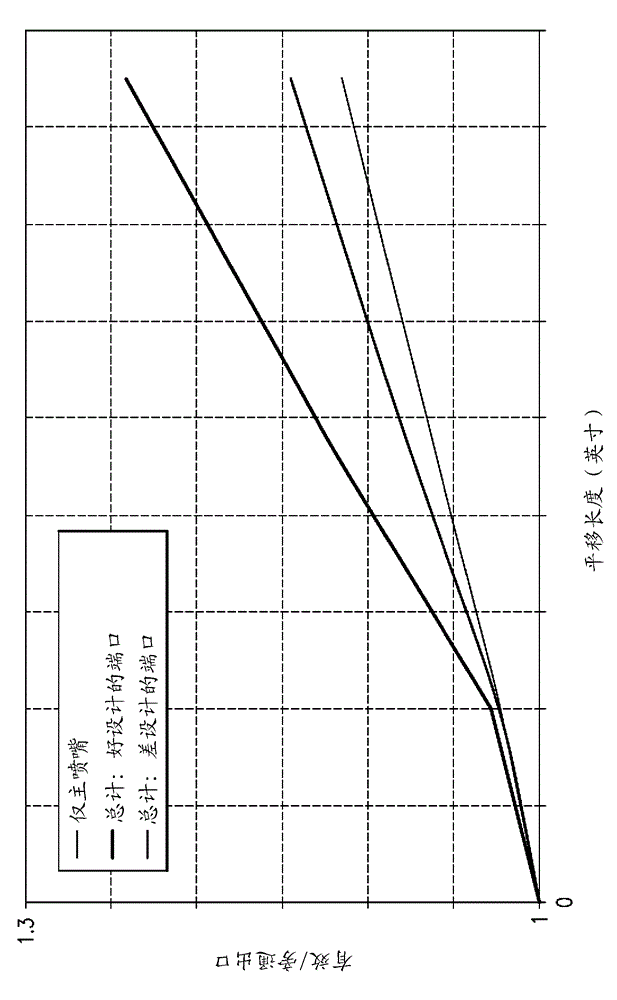

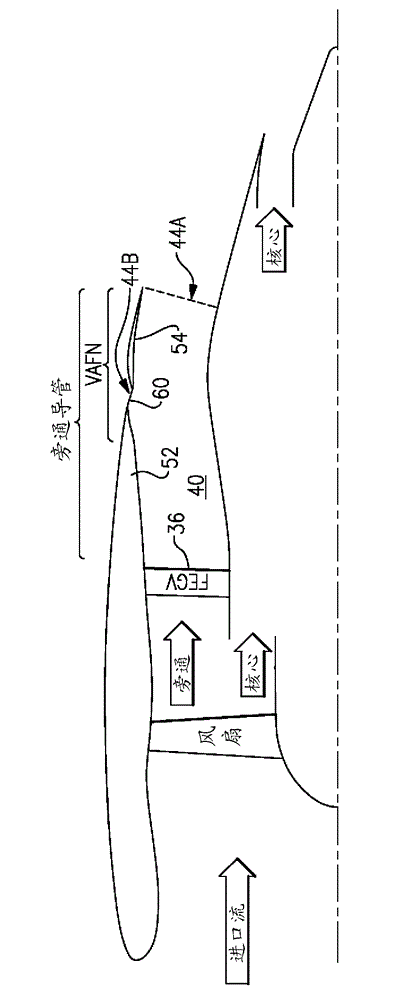

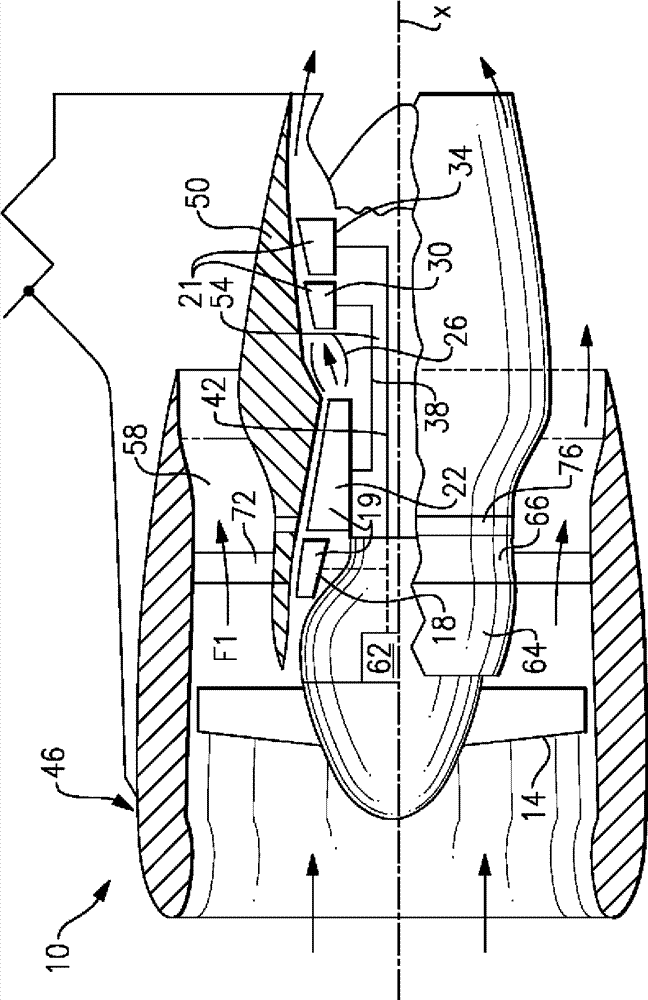

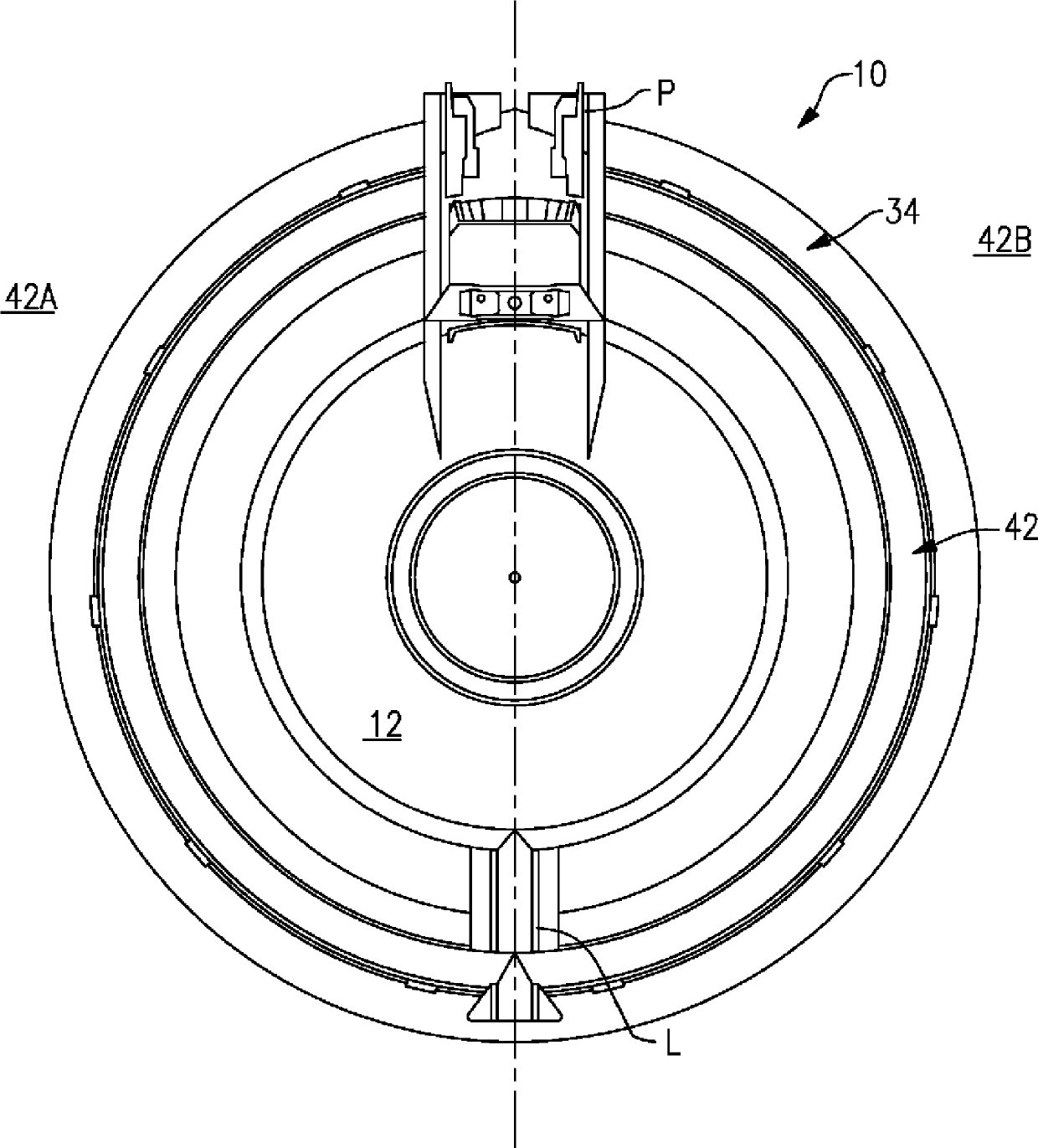

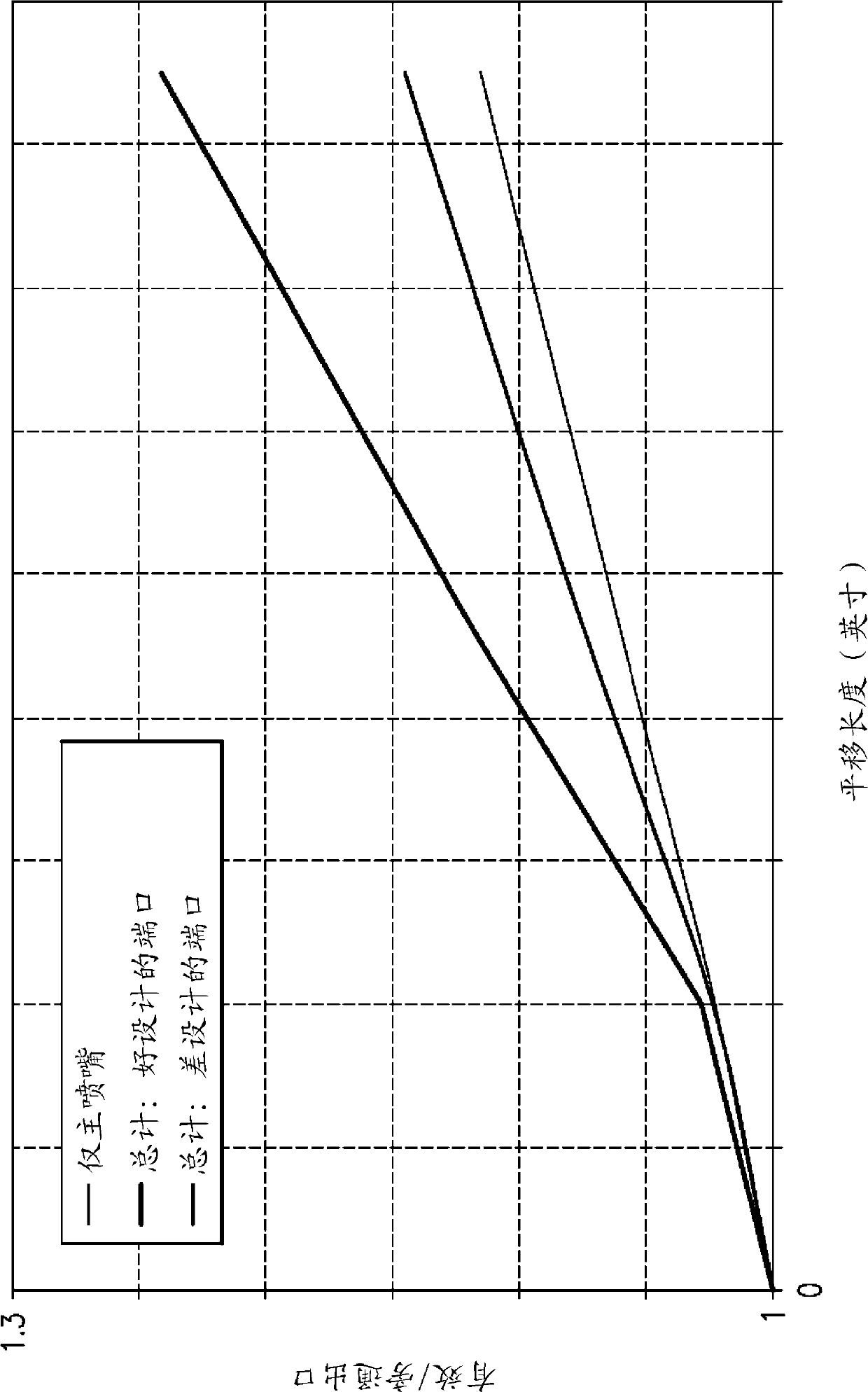

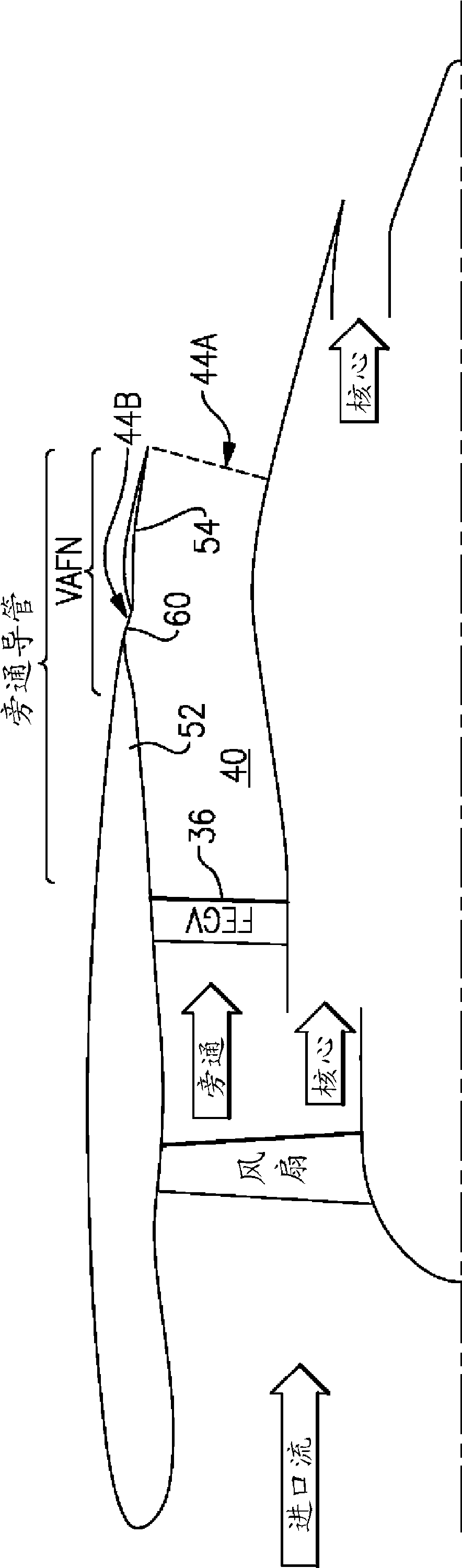

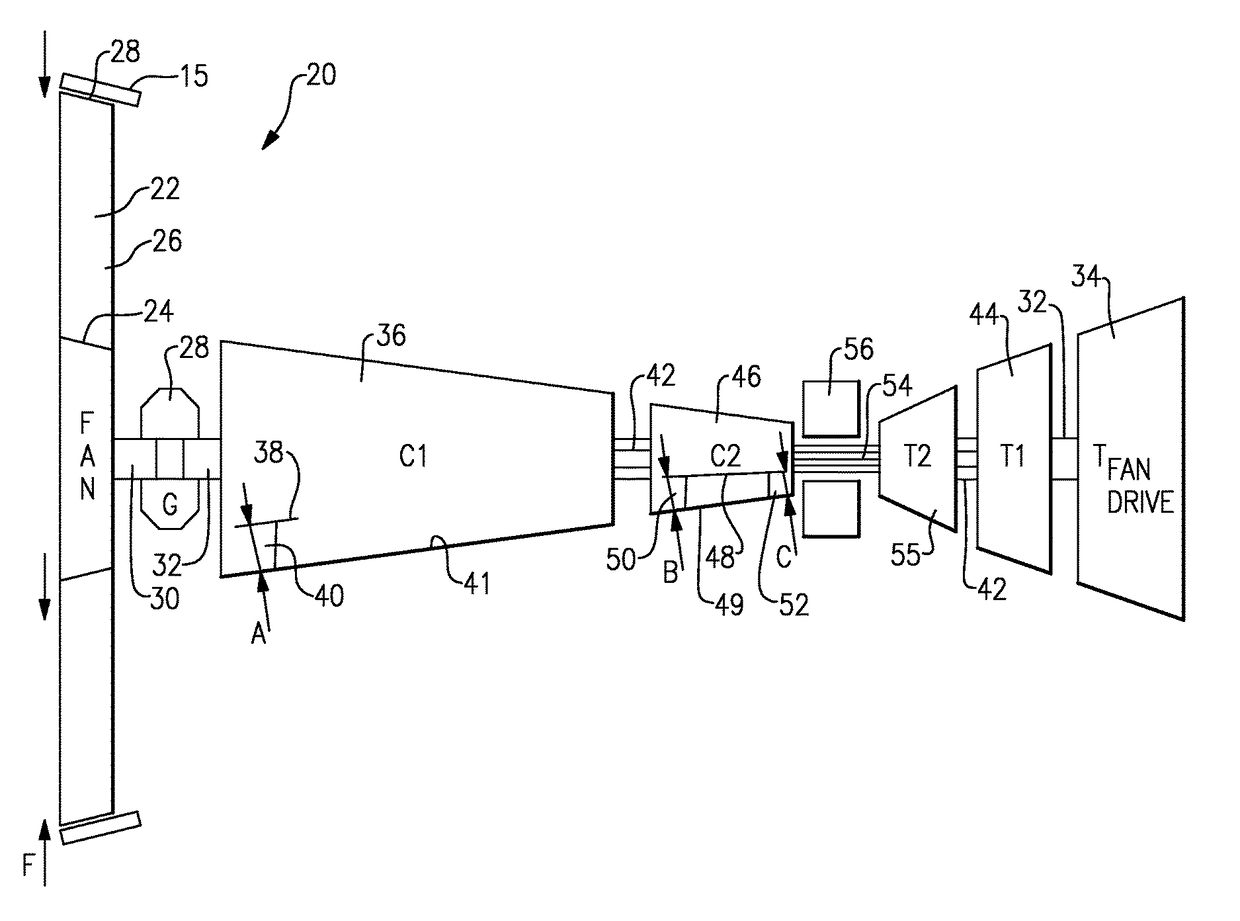

Gas turbine engine with fan variable area nozzle for low fan pressure ratio

A nacelle assembly for a high-bypass gas turbine engine includes a core nacelle defined about an engine centerline axis, a fan nacelle mounted at least partially around the core nacelle to define a fan bypass flow path for a fan bypass airflow, a fan variable area nozzle axially movable relative the fan nacelle to vary a fan nozzle exit area and adjust a fan pressure ratio of the fan bypass airflow during engine operation, the fan pressure ratio less than about 1.45. In a further embodiment of any of the foregoing nacelle assembly for a gas turbine engine embodiment, the assembly further includes a controller operable to control the fan variable area nozzle.

Owner:UNITED TECH CORP

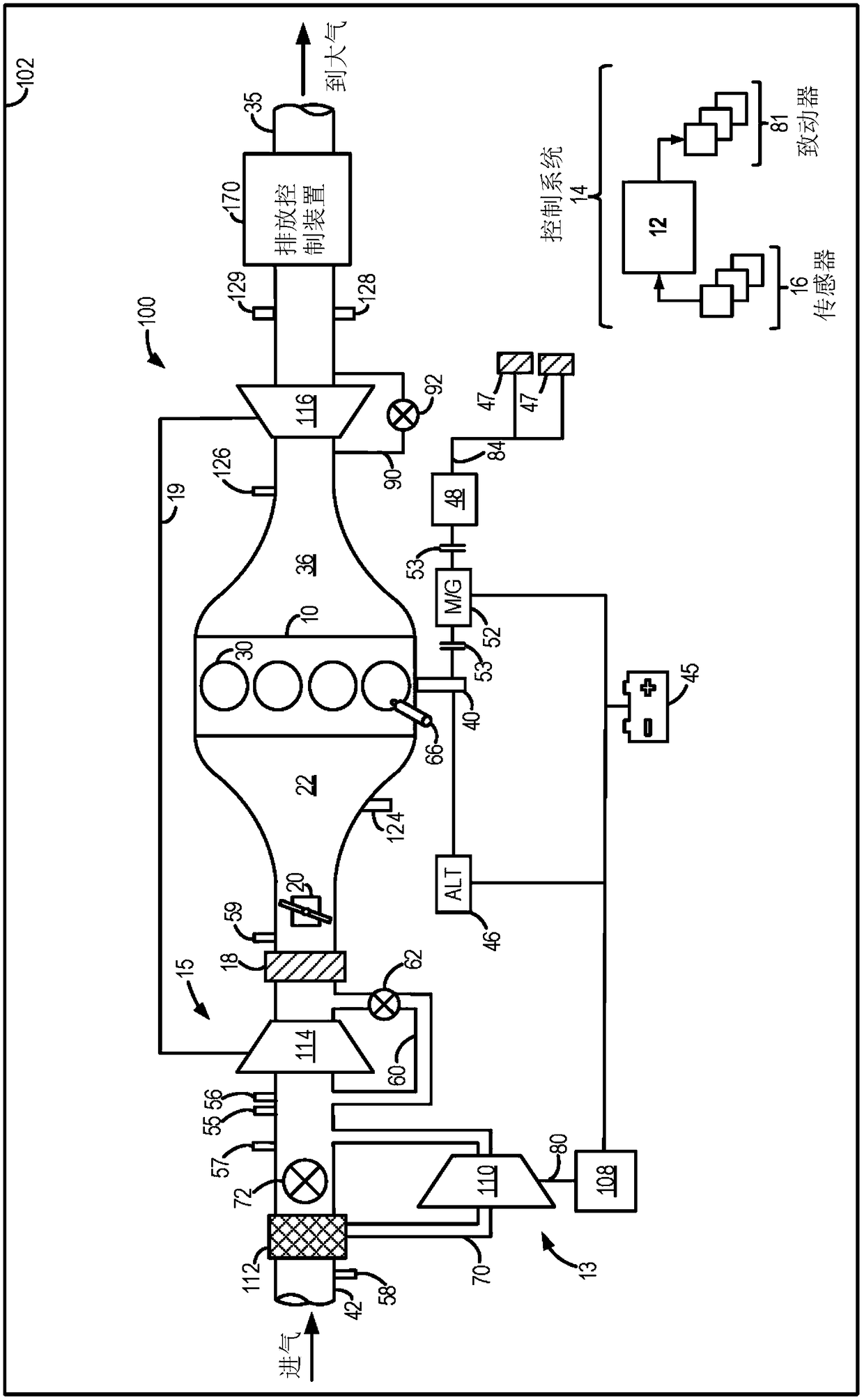

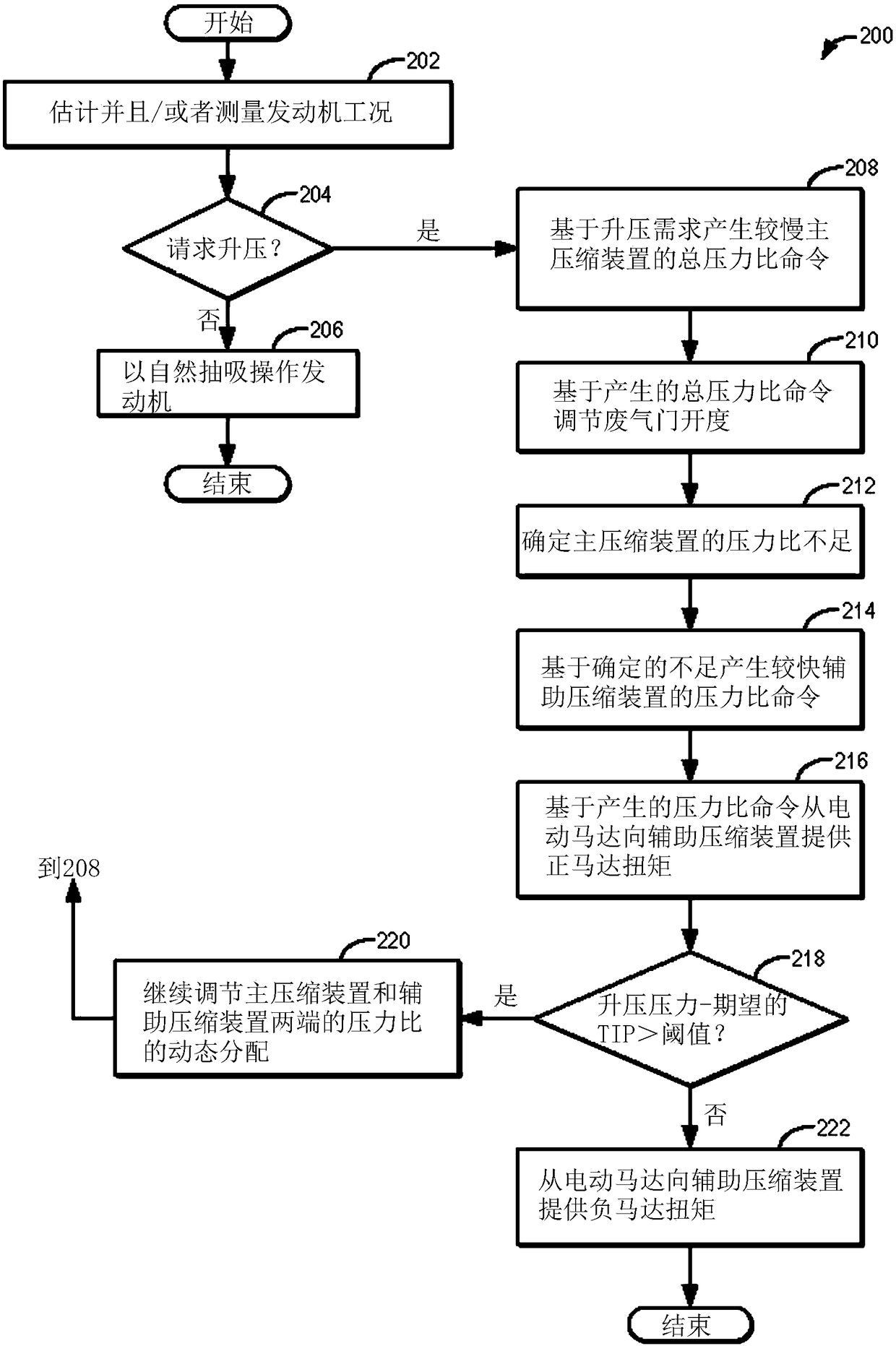

Method and system for a boosted engine

PendingCN109424427AMaximize Energy Recovery CapabilityAchieve target boost pressureElectrical controlInternal combustion piston enginesSteady stateAirflow

The invention relates to a method and a system for a boosted engine. Methods and systems are provided for coordinated control of a compound boosting system, including a first compressor staged upstream of a second compressor in an engine intake. In one example, a method may include operating the second, downstream compressor in steady-state to achieve an overall pressure ratio across the compoundboosting system while operating the first, upstream compressor transiently, based on an airflow shortfall at the downstream compressor. A timing and amount of electric assistance provided to transiently operate the first, upstream compressor may be adjusted dynamically as the pressure ratio across the second compressor changes.

Owner:FORD GLOBAL TECH LLC

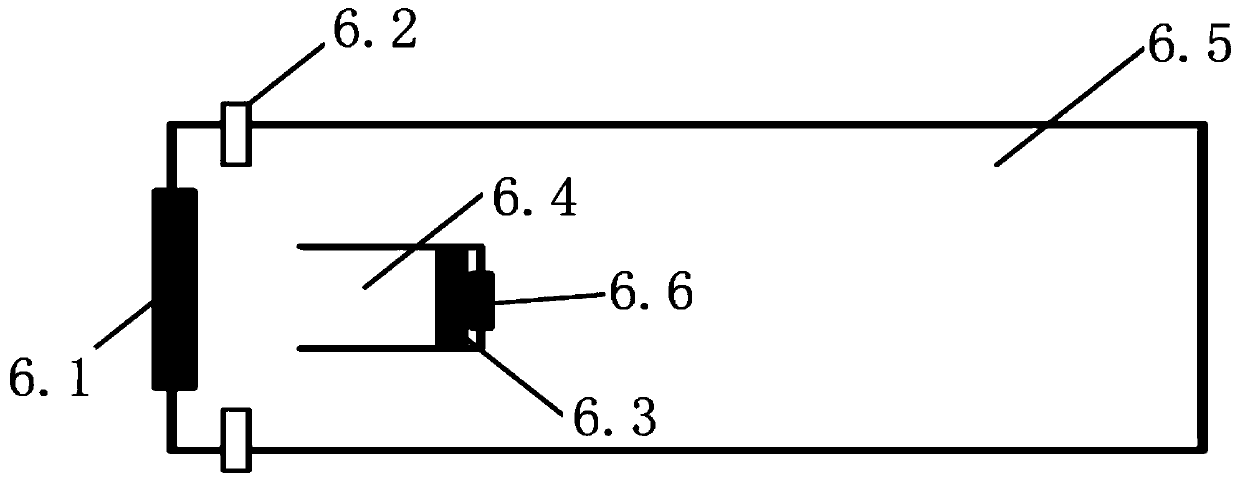

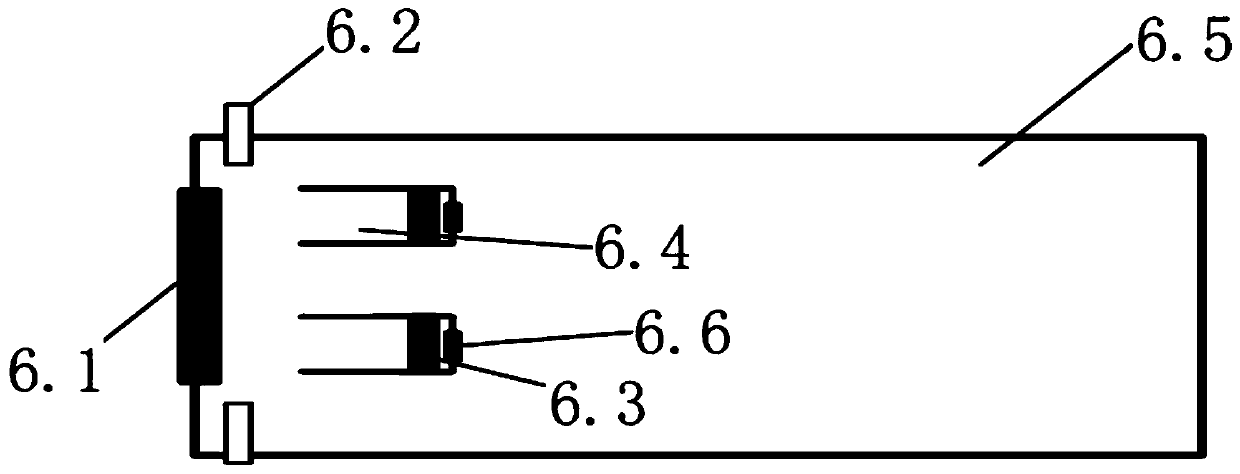

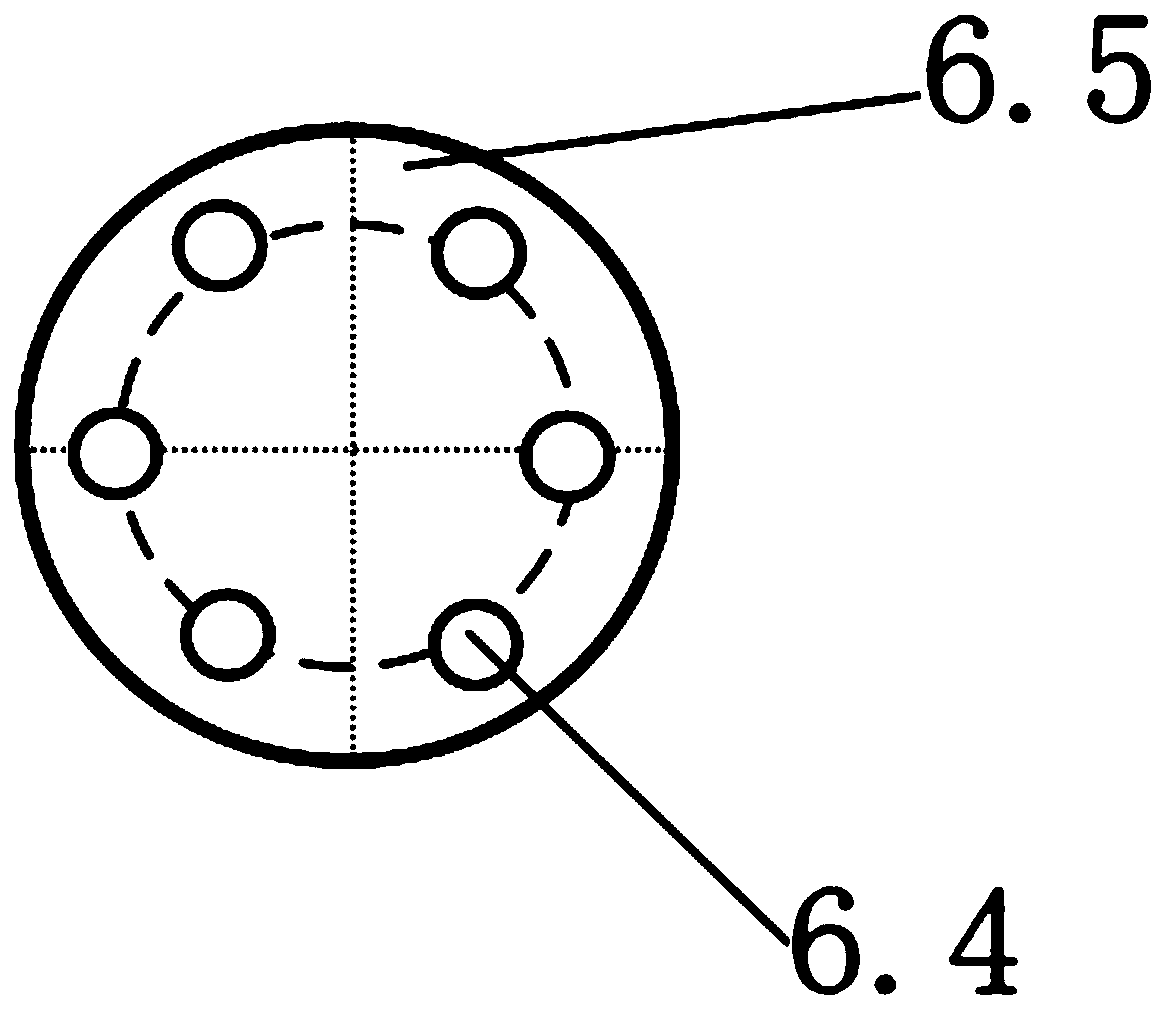

Pulse detonating combustion chamber and air turbine rocket engine based on pulse detonating

PendingCN111305972AReduce weightReduced pressurization capacity requirementsIntermittent jet plantsRocket engine plantsCombustion chamberMetallic aluminum

The invention discloses a pulse detonating combustion chamber and an air turbine rocket engine based on pulse detonating. The pulse detonating combustion chamber adopts an internal jet-flow tube ignition detonating way, and has better efficiency and feasibility in comparison with a transverse heat jet-flow ignition detonating method; internal heat jet-flow ignition is combined with a detonating way of mixing nano particles such as metal aluminum or titanium mixed in fuel oil, so that detonating waves within a relatively short distance and relatively short time can be achieved, and therefore, length of the detonating combustion chamber is shortened, working frequency of an engine is improved, and weight of the engine is reduced. Based on the pulse detonating combustion chamber, the air turbine rocket engine based on pulse detonating disclosed by the invention is improved in parameters such as thrust and specific pulse to certain extent in comparison with those of a conventional ART engine; while an overall pressure ratio of the engine is certain, PDC self-pressurization characteristic can reduce requirements, on pressurization ability of a gas compressor in a PD-ART engine, and grades of rotary parts can be reduced, engine weight is reduced, and therefore, a thrust-weight ratio is increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

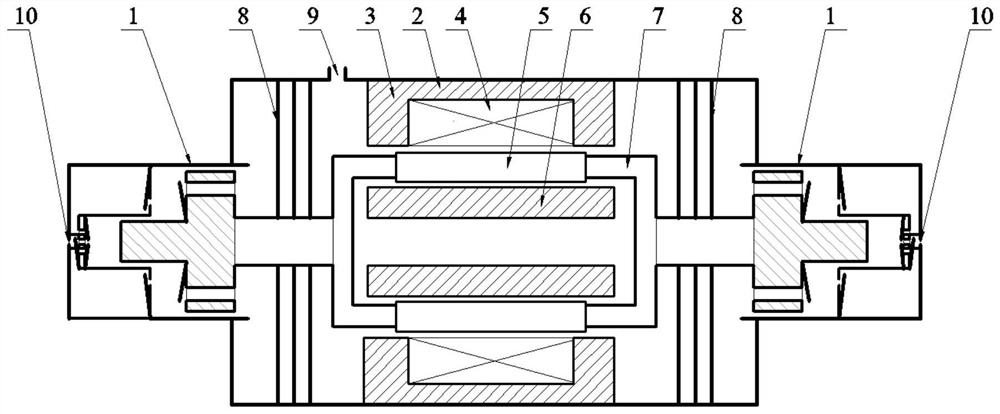

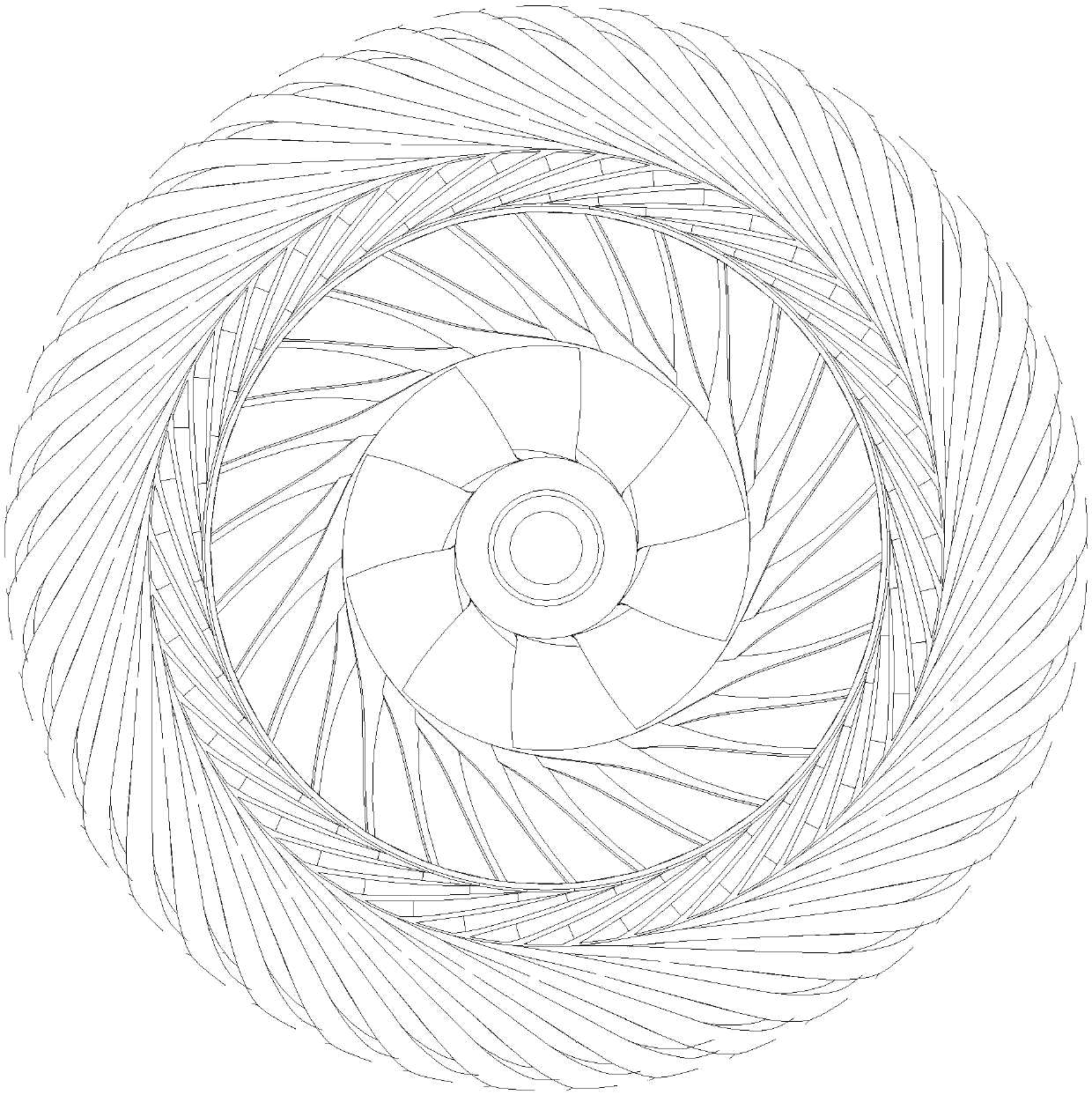

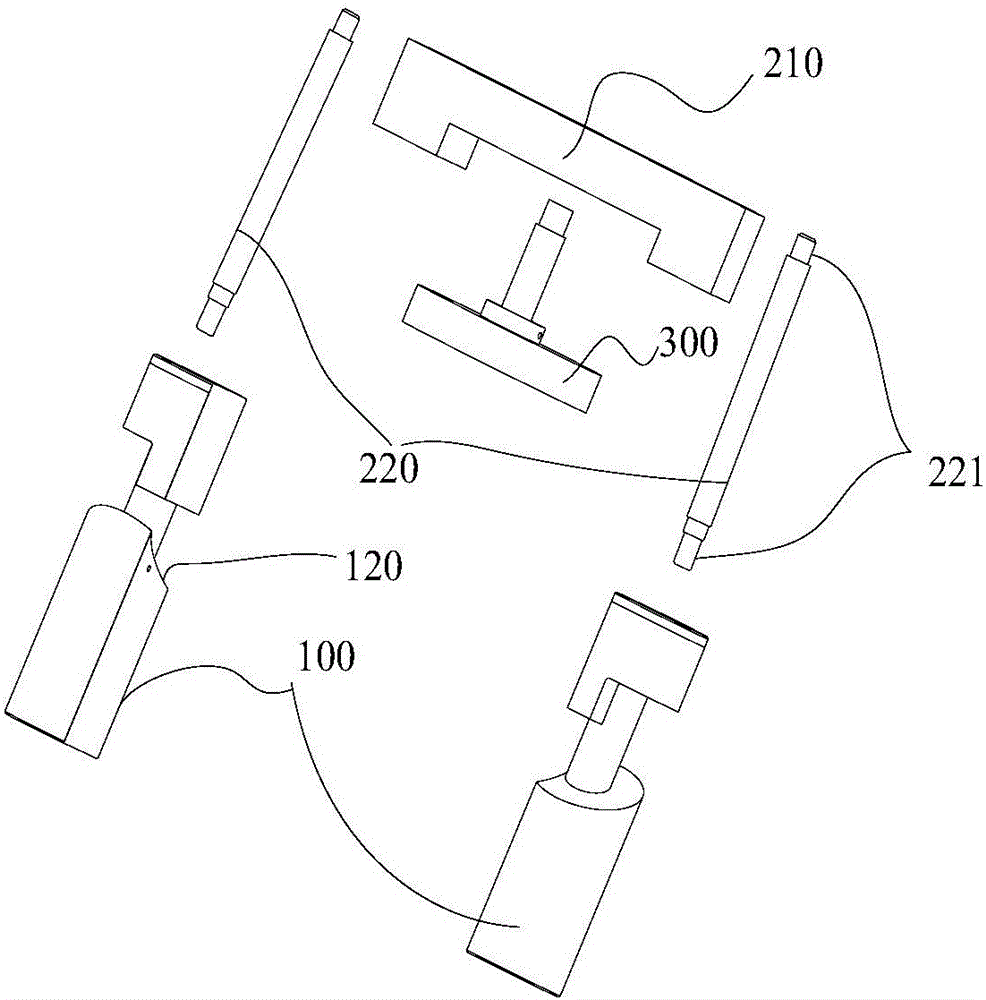

Centrifugal compressor and design method thereof

ActiveCN109611346AIncrease pressure ratioIncrease pressureGeometric CADPump componentsEngineeringCentrifugal force

The invention provides a centrifugal compressor and a design method thereof. The centrifugal compressor comprises a front-row centrifugal impeller, a rear-row centrifugal impeller and an axial diffuser, wherein the front-row centrifugal impeller is used for forming an airflow channel to enable airflow to pass and applying work to the airflow through centrifugal force, the rear-row centrifugal impeller is located at an airflow outlet of the front-row centrifugal impeller and used for forming an airflow channel to enable airflow to pass and applying work to the airflow through centrifugal force,and the axial diffuser is located at an airflow outlet of the rear-row centrifugal impeller and used for speed-reducing diffusion of the airflow and enabling the airflow to be changed to the axial direction from the radial direction. The rotating direction of the rear-row centrifugal impeller is opposite to the rotating direction of the front-row centrifugal impeller, so that the front-row centrifugal impeller provides reversed pre-rotation for the rear-row centrifugal impeller. According to the centrifugal compressor, under the condition that the axial size is basically not changed, the rear-row centrifugal impeller replaces a conventional radial diffuser, the double advantages of centrifugal force and high power capacity of reverse pre-rotation are fully utilized, and the purpose that the overall pressure ratio of the centrifugal compressor is greatly improved under the condition of a compact structure is achieved.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

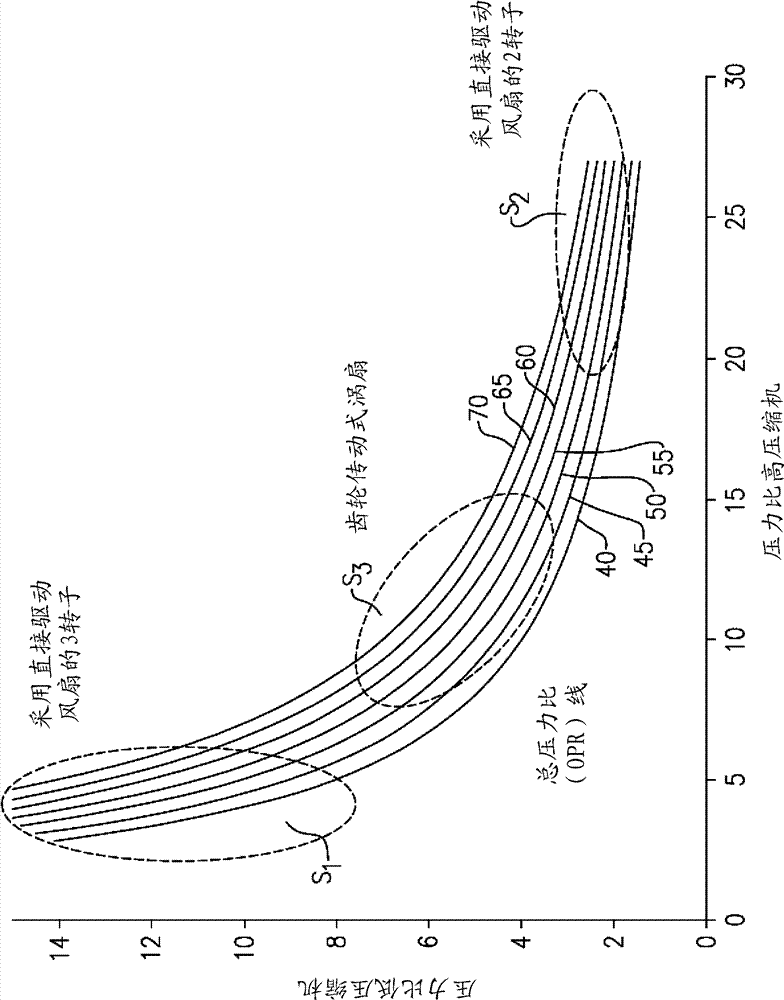

Gas turbine engine compressor arrangement

A gas turbine engine includes a fan section, a gear arrangement configured to drive the fan section, a compressor section and a turbine section. The compressor section includes a low pressure compressor section and a high pressure compressor section. The turbine section is configured to drive compressor section and the gear arrangement. An overall pressure ratio, which is provided by a combination of a pressure ratio across said low pressure compressor section and a pressure ratio across said high pressure compressor section, is greater than about 35. The pressure ratio across the low pressure compressor section is between about 3 and about 8 whereas the pressure ratio across the high pressure compressor section is between about 7 and about 15.

Owner:UNITED TECH CORP

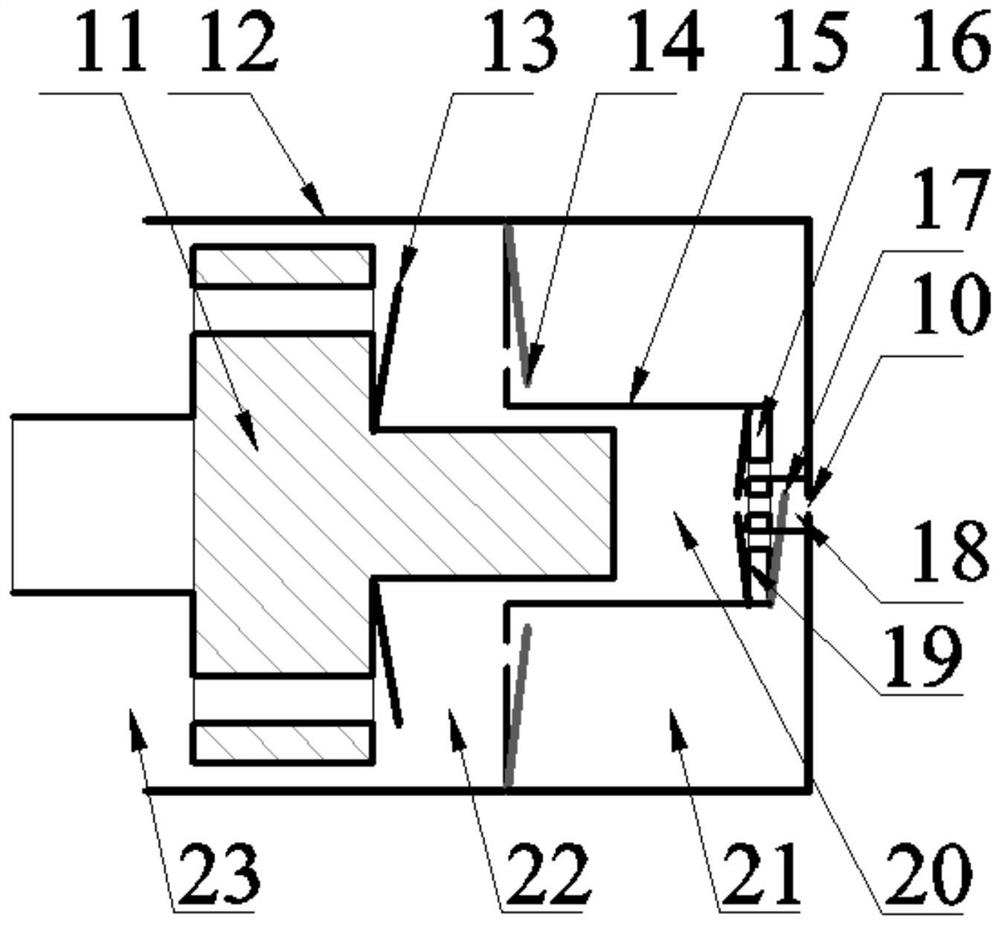

High-pressure-ratio linear compressor with stepped piston

PendingCN114562439ATwo-stage pressure matching is goodThe total pressure ratio is highPositive displacement pump componentsPiston pumpsExhaust valveLinear compressor

The high-pressure-ratio linear compressor comprises a stepped piston compression system, and the stepped piston compression system comprises the stepped piston, a first-stage air cylinder, a second-stage air cylinder and a middle pressure cavity; a first-stage step of the step piston slides in the first-stage air cylinder to form a first-stage compression cavity, a second-stage step of the step piston slides in the second-stage air cylinder to form a second-stage compression cavity, and the middle pressure cavity is adjacent to the first-stage compression cavity and the second-stage compression cavity. A first-stage exhaust valve for connecting and disconnecting the middle pressure cavity and the first-stage compression cavity is arranged in the middle pressure cavity, and a second-stage air suction valve for connecting and disconnecting the second-stage compression cavity and the middle pressure cavity is arranged in the second-stage compression cavity. The stepped piston structure is adopted, the pressure of working medium gas is increased through two-stage compression, the total pressure ratio is high, the matching relation and power distribution of the two-stage pressure ratio can be achieved by changing the diameter ratio of the two-stage piston, the structure is compact, and the two-stage pressure matching performance is good.

Owner:WUHAN GAOXIN TECH

Centrifugal compressor and design method thereof

ActiveCN109519397AIncrease pressure ratioImprove unfavorable intake conditionsGeometric CADPump componentsPower capabilityEngineering

The invention provides a centrifugal compressor and a design method thereof. The centrifugal compressor comprises front-row centrifugal vane wheels, rear-row centrifugal vane wheels, and axial diffusers, wherein the front-row centrifugal vane wheels are used for forming an air flow channel, so that an air flow can pass through the air flow channel and is acted by utilizing a centrifugal force; therear-row centrifugal vane wheels are located at air flow outlets of the front-row centrifugal vane wheels and are used for forming an air flow channel, so that an air flow can pass through the air flow channel and is acted by utilizing a centrifugal force; the axial diffusers are located at air flow outlets of the rear-row centrifugal vane wheels and are used for retarding and diffusing an air flow, so that the air flow is turned into the axial direction from the radial direction; the rotation directions of the rear-row centrifugal vane wheels are opposite to the rotation directions of the front-row centrifugal vane wheels, so that the front-row centrifugal vane wheels provide reverse prerotation for the rear-row centrifugal vane wheels; and air flow inlet parts of blades of the rear-rowcentrifugal vane wheels are of swept forward structures. The centrifugal compressor provided by the invention adopts the rear-row centrifugal vane wheels to replace conventional radial diffusers and fully utilizes the double advantages of high centrifugal force and reverse prerotation power capability so as to achieve the aim of greatly improving the overall pressure ratio of the centrifugal compressor under the condition with a compact structure.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Estimation of the exhaust pressure of a vehicle

The invention relates to a method for estimating the instantaneous exhaust pressure of a vehicle engine, the engine being connected to an exhaust manifold, the vehicle including at least one camshaft controlling intake and exhaust valves. The method is characterized in that it includes the steps of determining an engine speed and a total gas fill in the exhaust; calculating intermediate pressure ratios from mappings having the engine speed and the total fill as inputs; calculating an overall pressure ratio via interpolation of the intermediate pressure ratios; and multiplying the overall pressure ratio by a reference exhaust pressure, the product of the multiplication determining the instantaneous exhaust pressure. The method enables simple and efficient estimation of the instantaneous exhaust pressure of a vehicle engine.

Owner:PEZHO SITROEN AUTOMOBILS SA

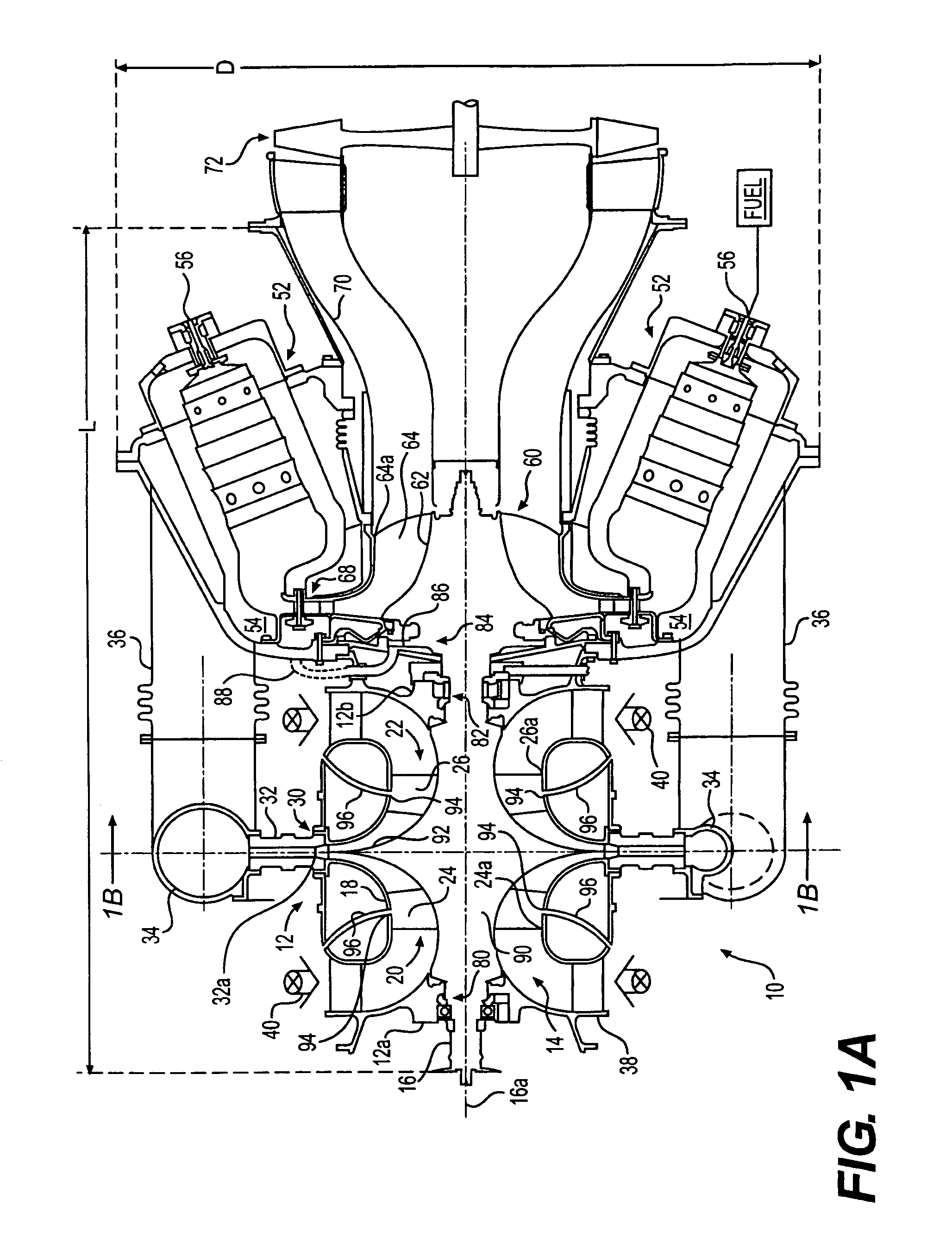

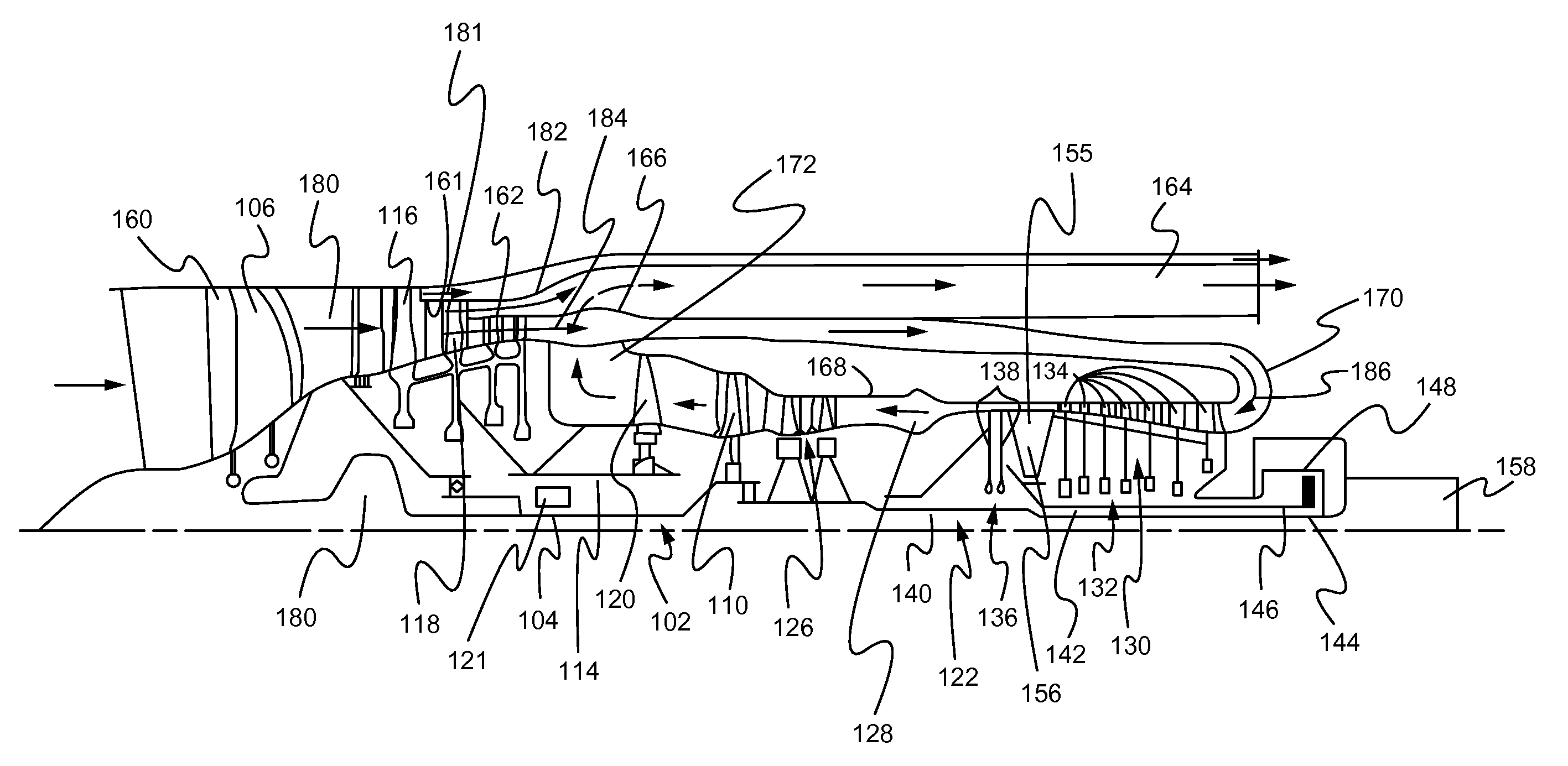

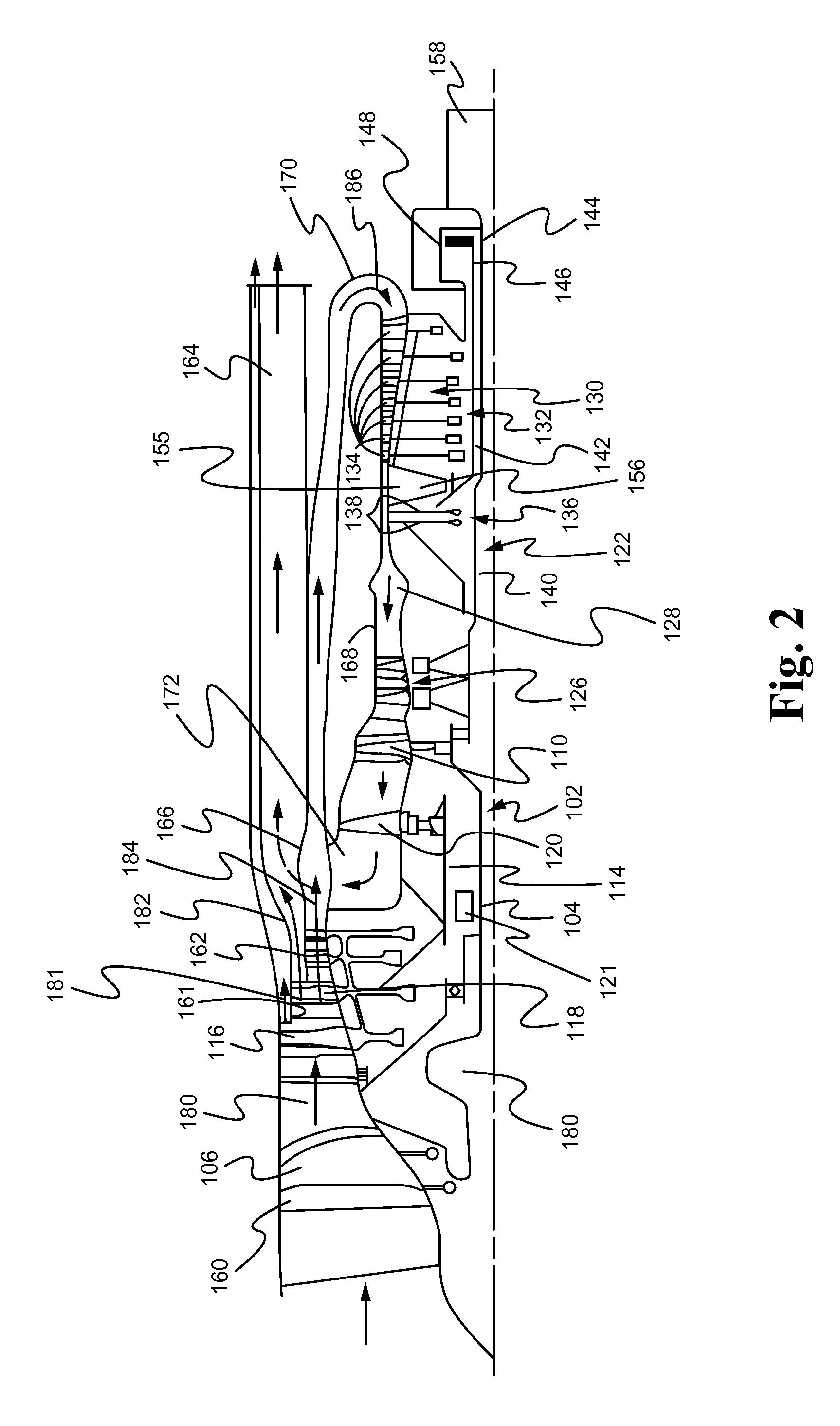

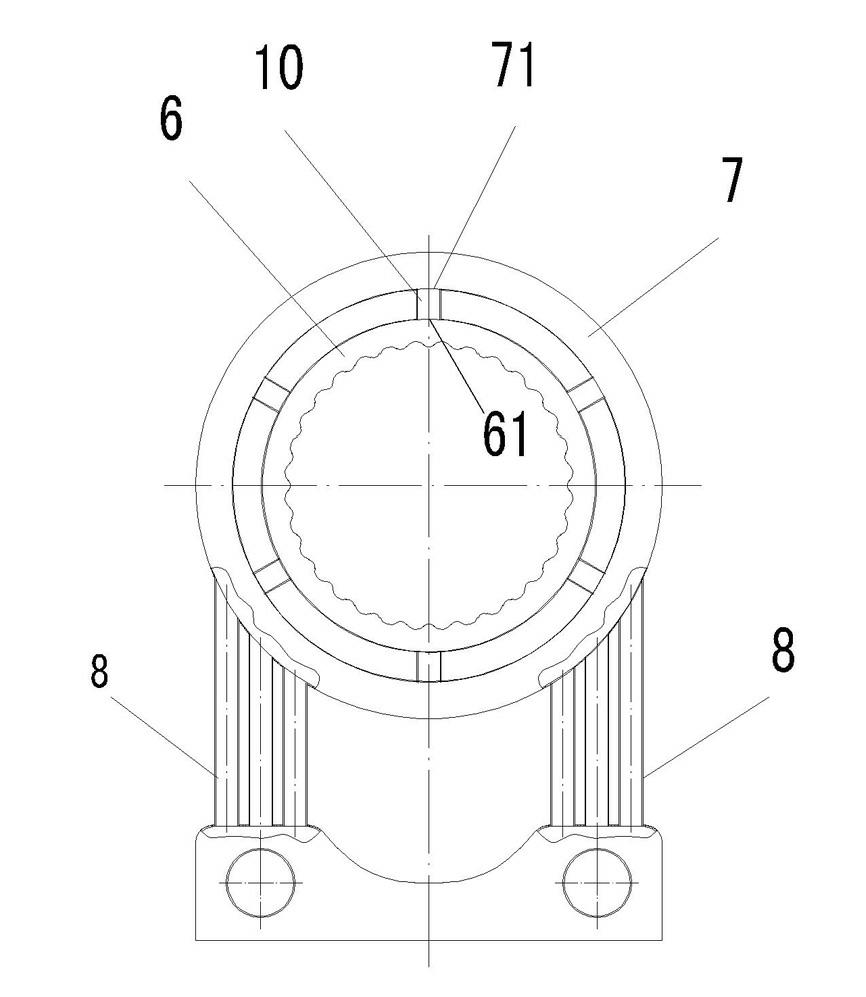

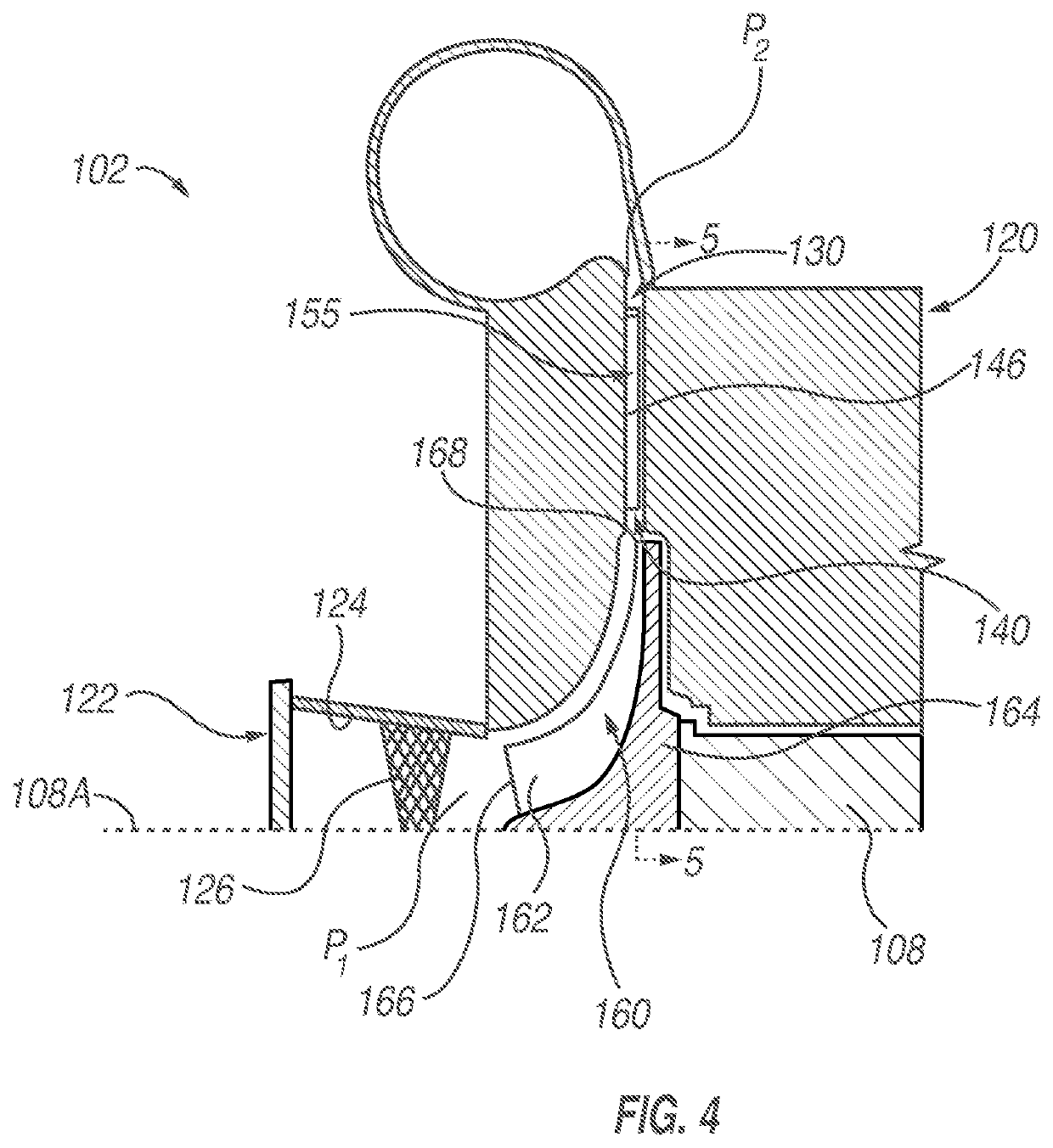

Compressor Areas For High Overall Pressure Ratio Gas Turbine Engine

A gas turbine engine comprises a high pressure turbine rotor, an intermediate pressure turbine rotor and a fan drive turbine rotor. The fan drive turbine rotor drives a fan rotor through a gear reduction. The intermediate pressure rotor drives a low pressure compressor rotor and the high pressure turbine rotor drives a high pressure compressor rotor. A first flow cross-sectional area is between an outer periphery of a hub in the low pressure compressor rotor, and an outer tip of an upstream most blade row of the low pressure compressor rotor. A second flow cross-sectional area is between an outer periphery of a hub in the high pressure compressor rotor, and an outer tip of an upstream most blade row of the high pressure compressor rotor. A ratio of the first and second flow cross-sectional areas is greater than or equal to about 0.12 and less than or equal to about 0.33.

Owner:RTX CORP

Method for refitting retired aircraft into engine, and engine refitted by such method

ActiveCN102606341AIncrease powerIncrease air pressureGas turbine plantsJet propulsion plantsTurbofanCulvert

The invention provides a method for refitting a retired aircraft into an engine, and the engine refitted by the method; the invention aims to solve the problem that the power of the top-removed engine is greatly reduced as the current method for refitting a turbofan engine into a ground engine is to cut off tops of all vanes on a low-pressure compressor. The method is characterized in that: the pressurized air in an external culvert of the turbofan engine is used completely. The technical scheme is as follows: the external culvert air is taken out from the tail part of the external culvert, and then sequentially transferred into a gas injector and a gas inlet of the low-pressure compressor through a gas transfer pipeline. The method for refitting the retired aircraft into the engine and the engine refitted by the method have the following beneficial effects: the overall pressure ratio is enhanced, so that the efficiency of the engine is improved; external air is synchronously inhaled at the gas inlet of the low-pressure compressor, the intake amount is greatly increased, thus the working capacity of the engine is enhanced.

Owner:XIAMEN ZHONGGUANNENG GAS TURBINE TECH CO LTD

Gas turbine engine with variable overall pressure ratio

A gas turbine engine has a variable overall pressure rate (OPR). The engine includes a high pressure compressor having at least a primary stage having a set of primary rotors and a secondary stage having a set of secondary rotors. A clutch is provided to selectively engage the secondary rotors with the primary rotors. Engagement of the clutch may be controlled based on the vehicle travel mode, such as disengaging during a takeoff mode to reduce turbine entry temperature and engaging during a loiter mode to increase OPR.

Owner:UNITED TECH CORP

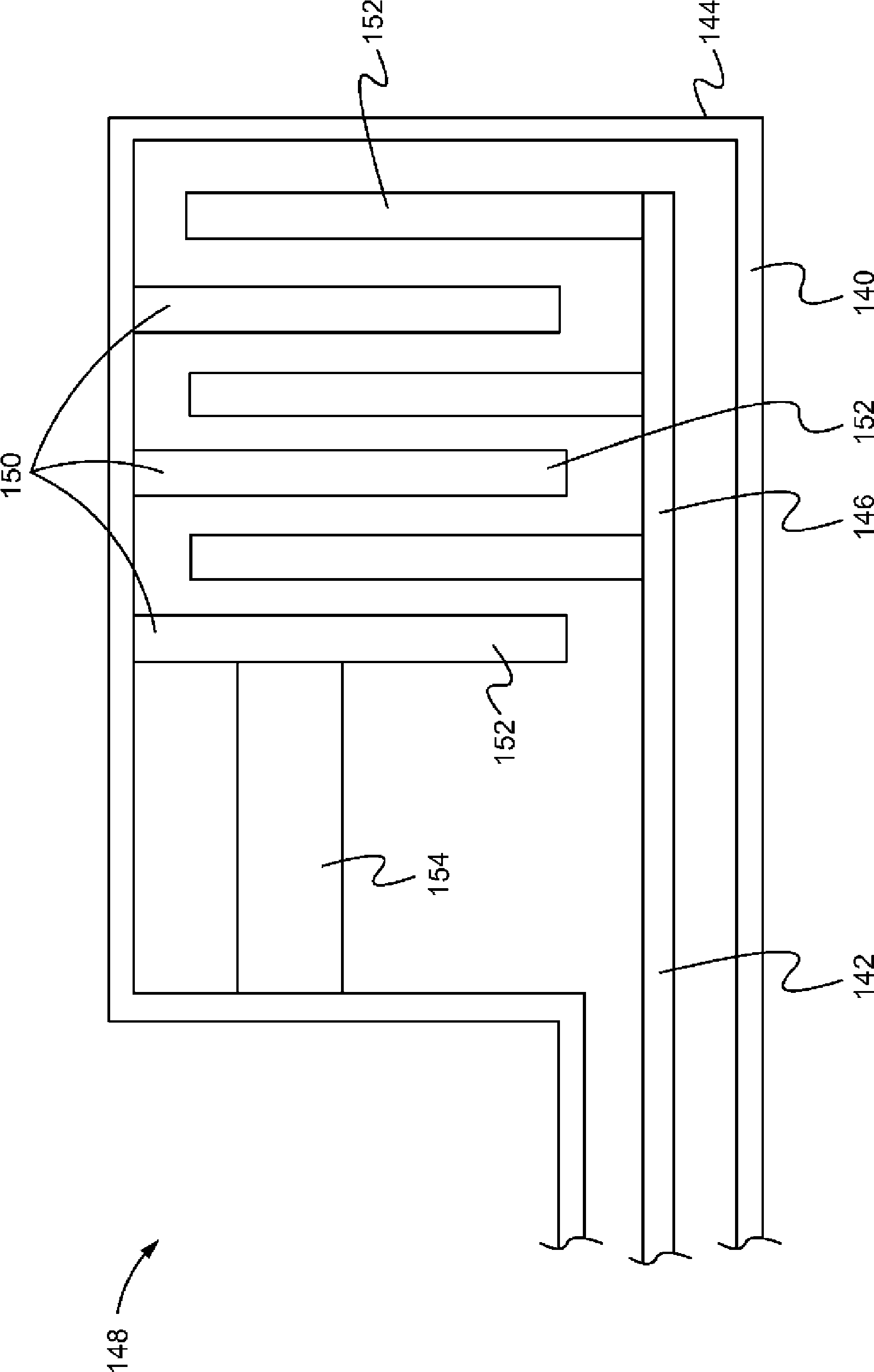

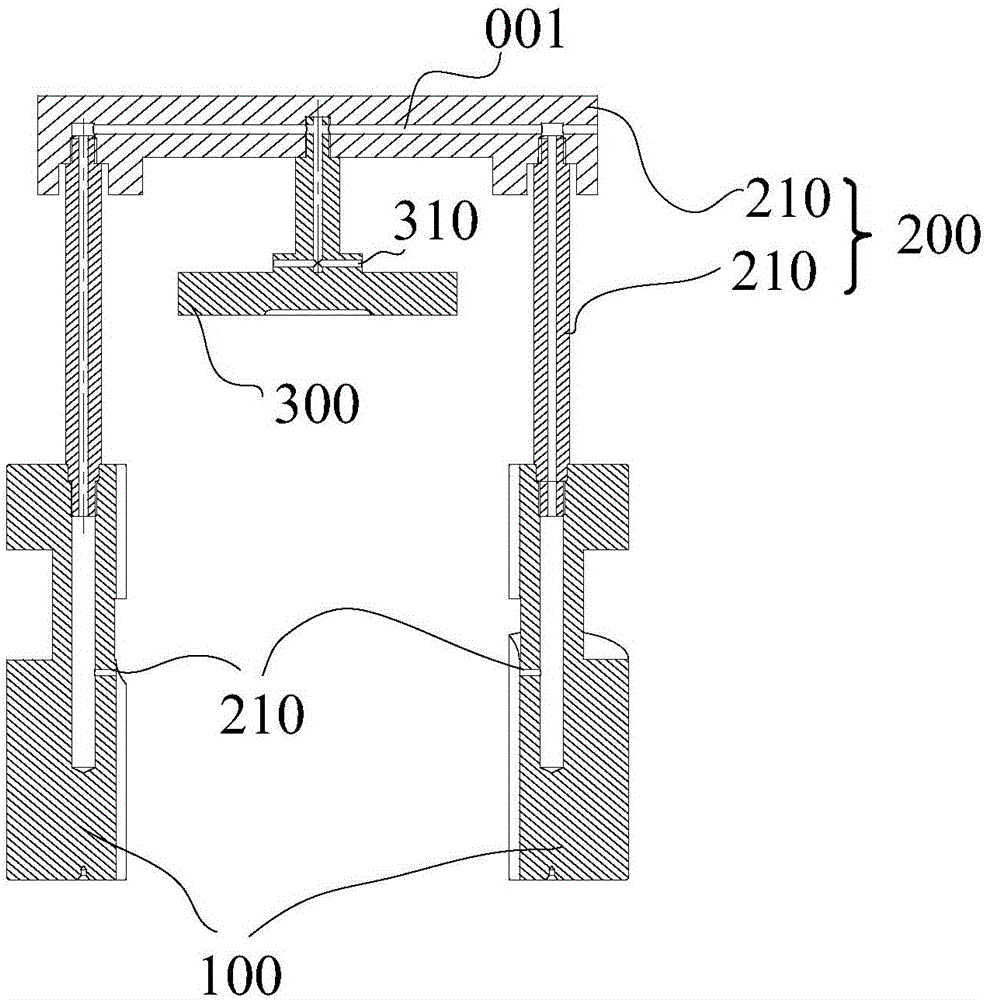

Adjusting mechanism for internal pressure ratio of compressor, and single-screw compressor

ActiveCN106704194AReduce manufacturing costHigh control precisionMachines/enginesInternal pressureEngineering

The invention discloses an adjusting mechanism for the internal pressure ratio of a compressor, and a single-screw compressor. The adjusting mechanism comprises a slide valve, a connection support, a driving piston and a cylinder, wherein the slide valve is connected with the driving piston via the connection support; the cylinder is fixedly connected with the shell of the single-screw compressor; the driving piston is arranged in the cylinder, is in clearance fit with the cylinder and divides the cylinder into a piston pressure chamber and an environmental pressure chamber in a height direction; the piston pressure chamber is connected with the final compression pressure of the single-screw compressor via a first air passage; and the environmental pressure chamber is connected with the exhausting pressure of the single-screw compressor via a second air passage. According to the invention, the final compression pressure of the single-screw compressor is introduced into the piston pressure chamber, the exhausting pressure of the single-screw compressor is introduced into the environmental pressure chamber, and the piston is used for driving the slide valve to move, so the internal pressure ratio of the compressor is adjusted; self-adaptive stepless adjustment of the internal pressure ratio of the compressor is realized, and control precision is improved; and holes are not perforated on the shell of the compressor, so the integral manufacturing cost of the compressor is reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Gas turbine engine with fan variable area nozzle to reduce fan instability

ActiveCN104011362AReduce instabilityEfficient propulsion technologiesJet propulsion plantsNacelleInstability

A nacelle assembly for a high-bypass gas turbine engine according to an exemplary aspect of the present disclosure includes a core nacelle defined about an engine centerline axis, a fan nacelle mounted at least partially around the core nacelle to define a fan bypass flow path for a fan bypass airflow, a fan variable area nozzle axially movable relative the fan nacelle to vary a fan nozzle exit area and adjust a fan pressure ratio of the fan bypass airflow during engine operation, and a controller operable to control the fan variable area nozzle to vary a fan nozzle exit area and adjust the pressure ratio of the fan bypass airflow.

Owner:UNITED TECH CORP

Centrifugal compressor achieving high pressure ratio

Compressors achieve in a single stage a high-pressure ratio (r) of greater than or equal to 2.5:1 on a process fluid having a molecular weight of 12-20, such as natural gas. Two or more of the compressor stages are combined serially to increase overall pressure ratio. Each single-stage includes respective inlet and outlet passages and an unshrouded, centrifugal impeller that includes a plurality of impeller blades. Process fluid is discharged from trailing edges of the impeller blades at a rotational velocity greater than or equal to 1400 feet / second into a diffuser passage of the outlet. Dimension ranges of the annular diffuser passage, the centrifugal impeller, and the diffuser vanes vary as a function of pressure ratio (r) and / or the flow coefficient (φ) of the process fluid flowing between the inlet and the outlet.

Owner:SIEMENS ENERGY INC

Performance Prediction Method of Compressor under All Operating Conditions

ActiveCN110701086BSimple designShorten the design cycleEngine fuctionsPump controlImpellerDesign cycle

The invention discloses a full-working condition performance prediction method for a compressor, and aims at providing a rapid and accurate full-working condition aerodynamic performance prediction method so as to increase the design and optimization efficiency of the compressor. In the method, a formula is established by taking parameters of a design point as the reference to predict the flow, the efficiency and the overall pressure ratio of an off-design working condition; in a flow prediction method, firstly, the flow of the design point is converted according to an empirical formula to flow corresponding to a peak efficiency point at different rotating speeds, and then, blocking flow and surging flow at respective rotating speeds are calculated; in an efficiency prediction method, firstly, the efficiency of the design point is converted according to the empirical formula to peak efficiency at different rotating speeds, and then, the efficiency at different rotating speeds is calculated according to an elliptic piecewise approximation method; and in a prediction method for the overall pressure ratio, work factors at different rotating speeds and different flow are calculated according to the thought of the equivalent width of an impeller exit, and the work factors are combined with current efficiency to obtain the overall pressure ratio. By applying the full-working condition performance prediction method to design and optimization of the compressor, the design cycle can be remarkably shortened, and the design cost is reduced.

Owner:TIANJIN UNIV

Centrifugal compressor inlet guide blade structure with low flow losses under prewhirl condition

ActiveCN107420349AEliminate Separation LossSuppression of high entropy increasing regionsPump componentsPumpsInlet channelEngineering

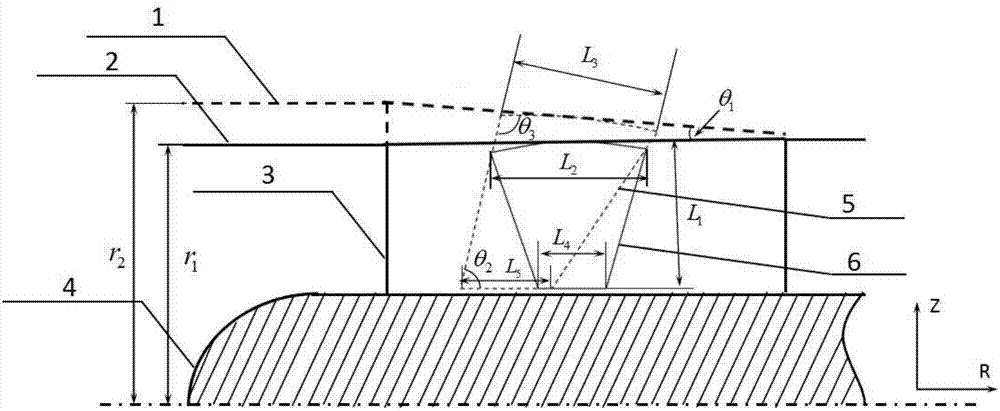

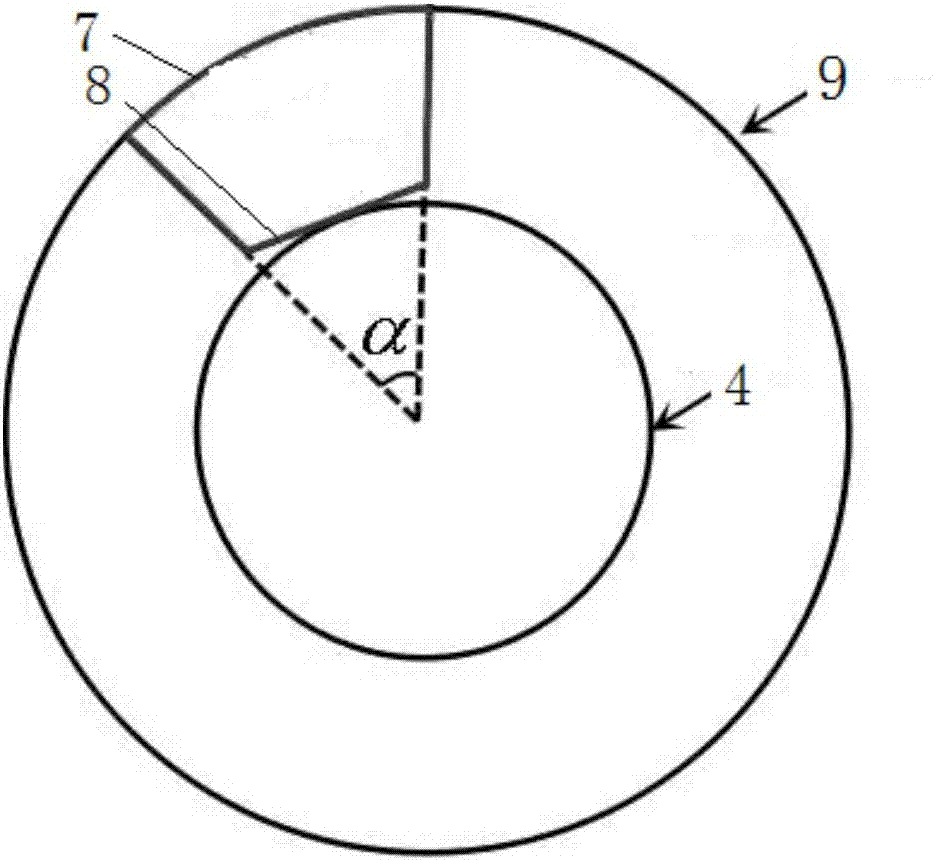

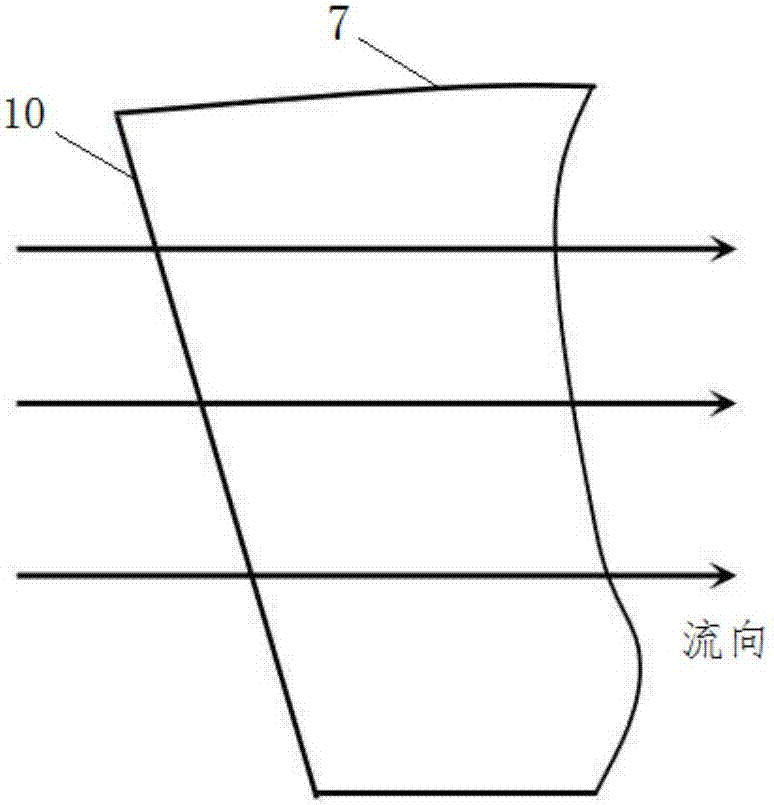

The invention discloses a centrifugal compressor inlet guide blade structure with low flow losses under the prewhirl condition. Original inlet guide blades are determined; the chord lengths of the bottoms of improved guide blades are determined according to the chord length ratio of L5 / L4, the improved guide blades are horizontally moved in the R direction along guide blade wing-section center lines, the front edges of the inlet guide blades form the backward sweep of theta2 relative to the blade bottoms, and thus the front edge positions of the improved guide blades can be determined; the molded line of an original air inlet channel connected with the inlet guide blades is rotated in a clockwise mode at the angle of theta1, and an inlet of the improved air inlet channel is in a horn shape; and the chord lengths of the tops of the improved guide blades are determined according to the chord length ratio of L3 / L2, the improved guide blades are moved upwards to the improved air inlet channel wall surface along the front edge lines of the improved guide blades, and the included angle between the front edges of the inlet guide blades and the tangent line of the arc line midpoints of the blade tops can meet the condition that theta3 is equal to 180 degrees-theta2-theta1. By the adoption of the centrifugal compressor inlet guide blade structure, separation flow losses of the blade surfaces and the close wheel disk sides can be restrained, the centrifugal compressor inlet guide blade structure is suitable for a wide flow range and prewhirl angle range, the complete machine variable efficiency and overall pressure ratio of the centrifugal compressor can be effectively improved and meanwhile the blocking flow amount within the working condition range can be increased obviously.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com