Pneumatic design method for ultrahigh-load, ultralow-rotating-speed and large-bypass-ratio fan rotor

A technology of fan rotor and large bypass ratio, which is applied in the direction of machine/engine, jet propulsion, etc., can solve the problems affecting the stator and rear stage design, achieve high efficiency and low speed design, reduce overall weight, and reduce fan noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

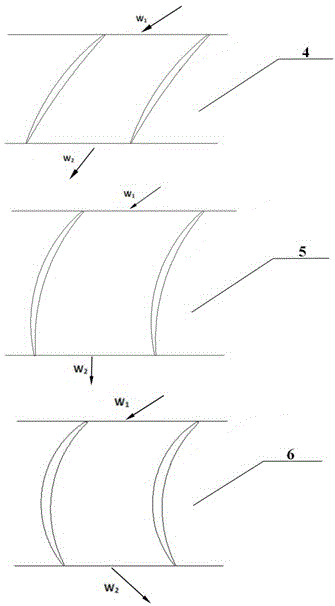

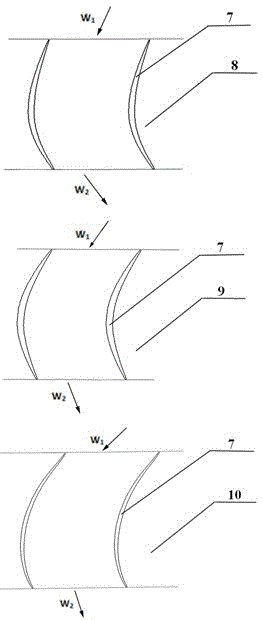

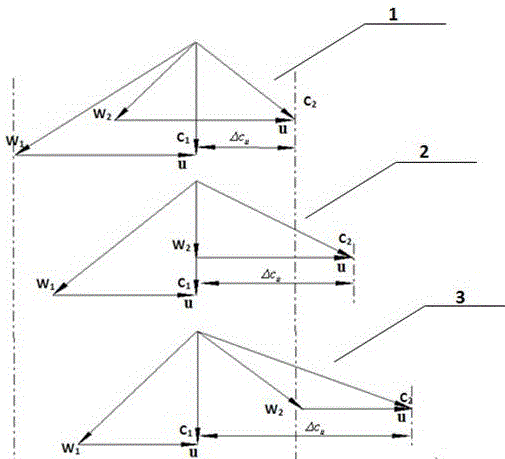

[0026] The following combination Figure 1 to Figure 5 The aerodynamic design method of the fan rotor with ultra-high load, ultra-low speed and large bypass ratio of the present invention is illustrated. ①According to the given flow rate and pressure ratio, the key design parameters are determined by S2 through-flow analysis. The key design parameters include: speed, blade twist, blade inlet and outlet root and tip radii, number of blades, rotor inlet and outlet fluid parameter distribution ; and the load factor , the value of which should be selected to achieve the relative speed of the rotor outlet W 2 greater than the inlet relative velocity W 1 . ②According to the rotor inlet and outlet parameter distribution (including the velocity triangle) determined by the S2 flow design, carry out several S1 flow surface two-dimensional airfoil 7 designs (only typical blade root, blade center, and blade tip blade shapes are given here. ), the airfoil design can be carried out by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com