Centrifugal compressor achieving high pressure ratio

a centrifugal compressor and high pressure technology, applied in the direction of machines/engines, supersonic fluid pumps, liquid fuel engines, etc., can solve the problem of limited pressure ratios within any given stag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

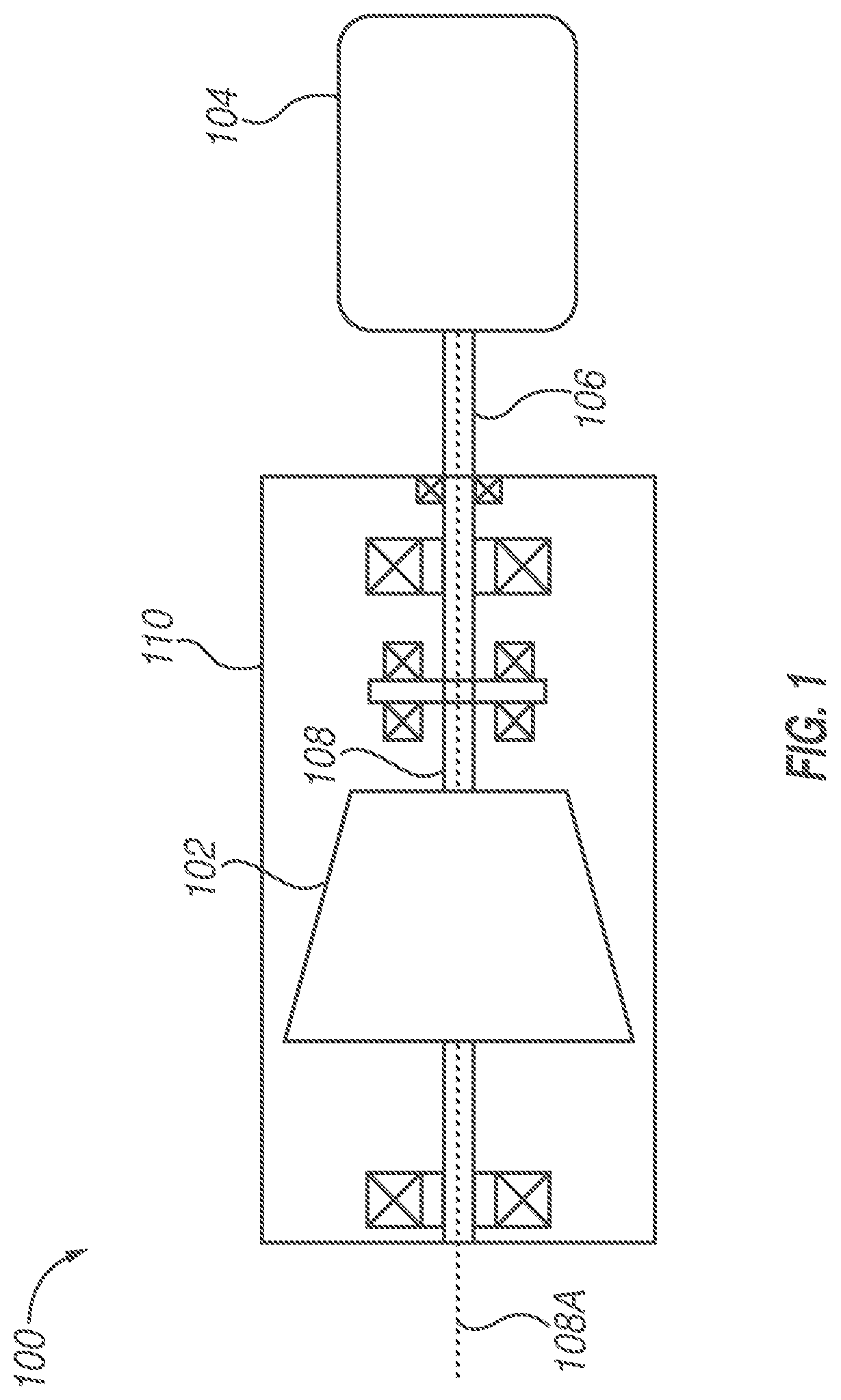

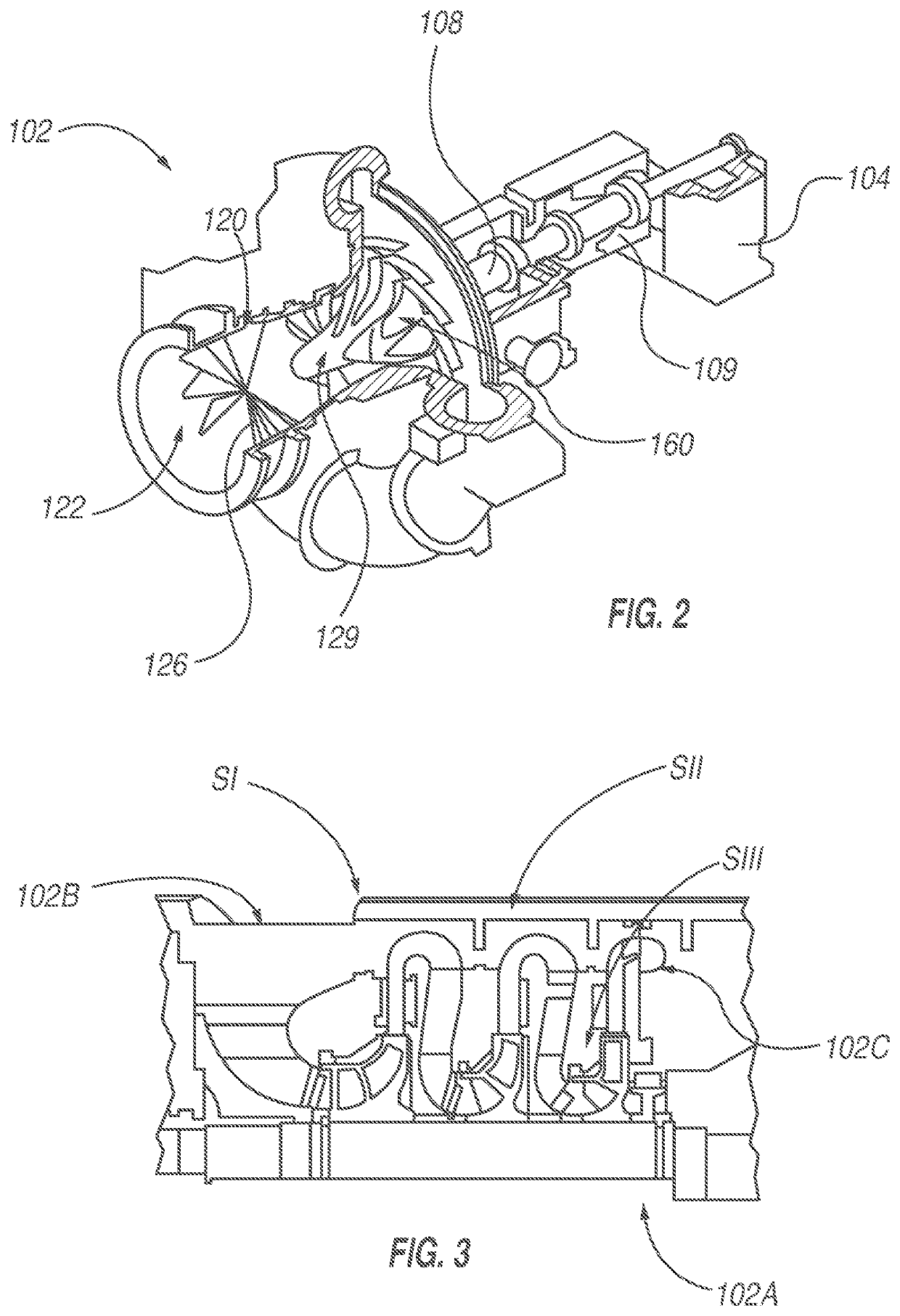

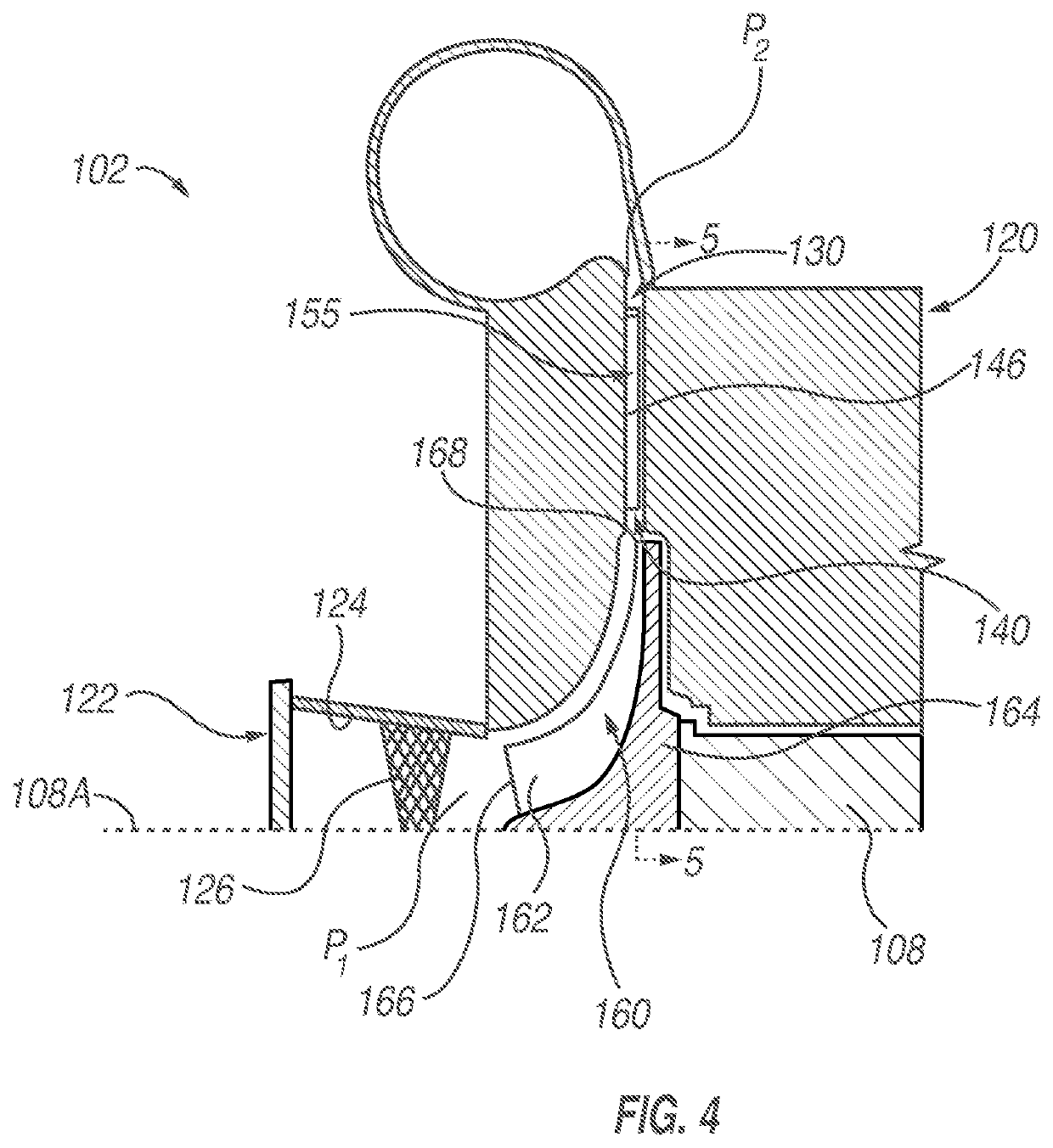

[0035]Exemplary embodiments of the invention are utilized in compressors, and methods of their operation. These exemplary embodiments achieve, in a single compressor stage, between the inlet and outlet of the stage, a high pressure ratio (r) of at least 5:1 on the process fluid having a molecular weight of 24-27.99; or at least 4:1 on a process fluid having a molecular weight of 20-24; or at least 3:1 on a process fluid having a molecular weight of 16-20 or at least 2.5:1 on a process fluid having a molecular weight of 10-16 or at least 2:1 on a process fluid having a molecular weight less than 10. By way of example, an exemplary embodiment achieves a pressure ratio (r) of greater than or equal to 2.5:1 on a process fluid having a molecular weight of 12-20, such as natural gas. Natural gas in that molecular weight range typically comprises methane, other hydrocarbons, and non-hydrocarbon constituents, such as water, and carbon dioxide. In at least one embodiment, the process fluids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com