Gas turbine engine with fan variable area nozzle to reduce fan instability

A gas turbine, low-pressure turbine technology, applied in the direction of machines/engines, climate sustainability, jet propulsion, etc., can solve the problem of increased overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

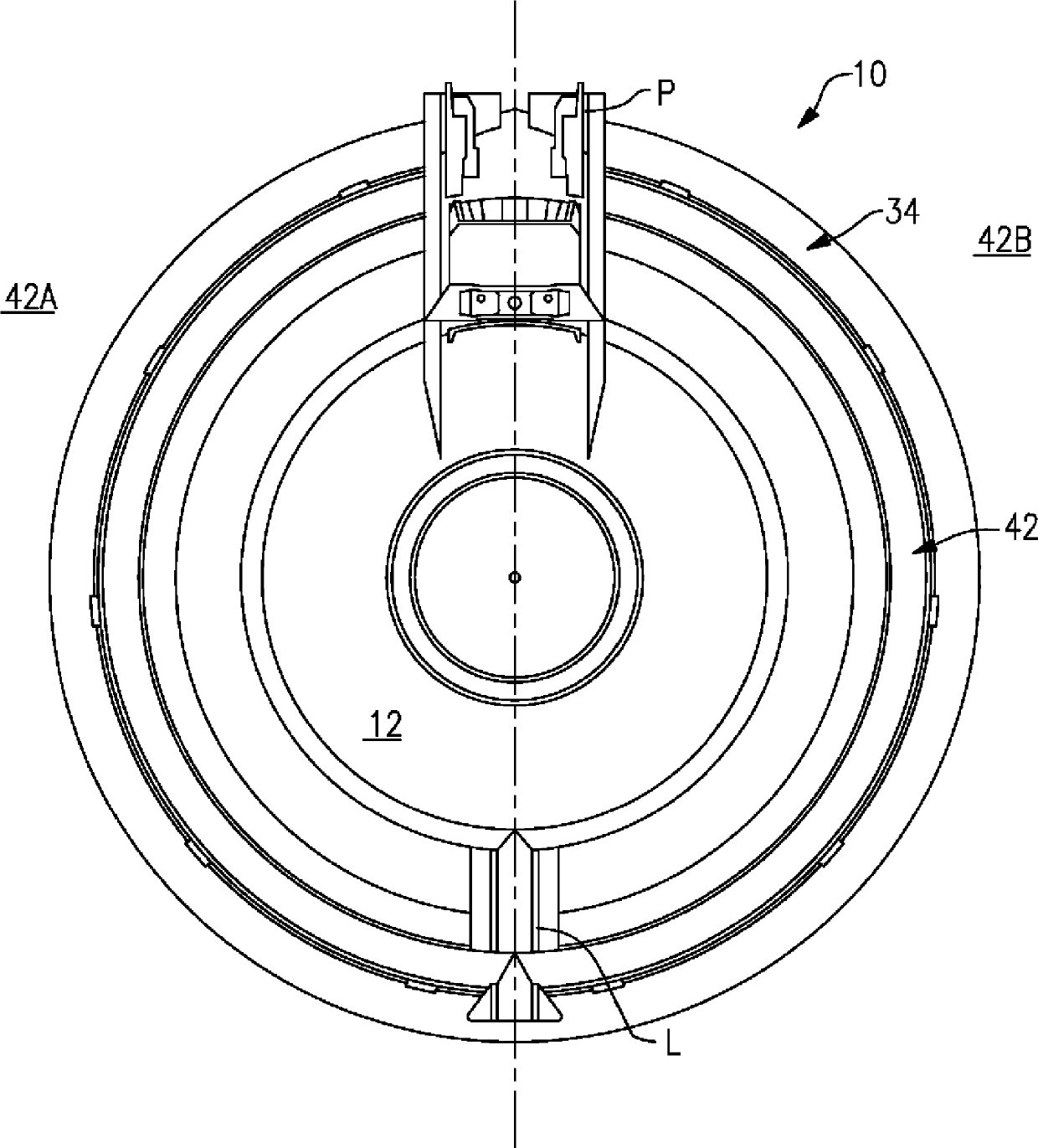

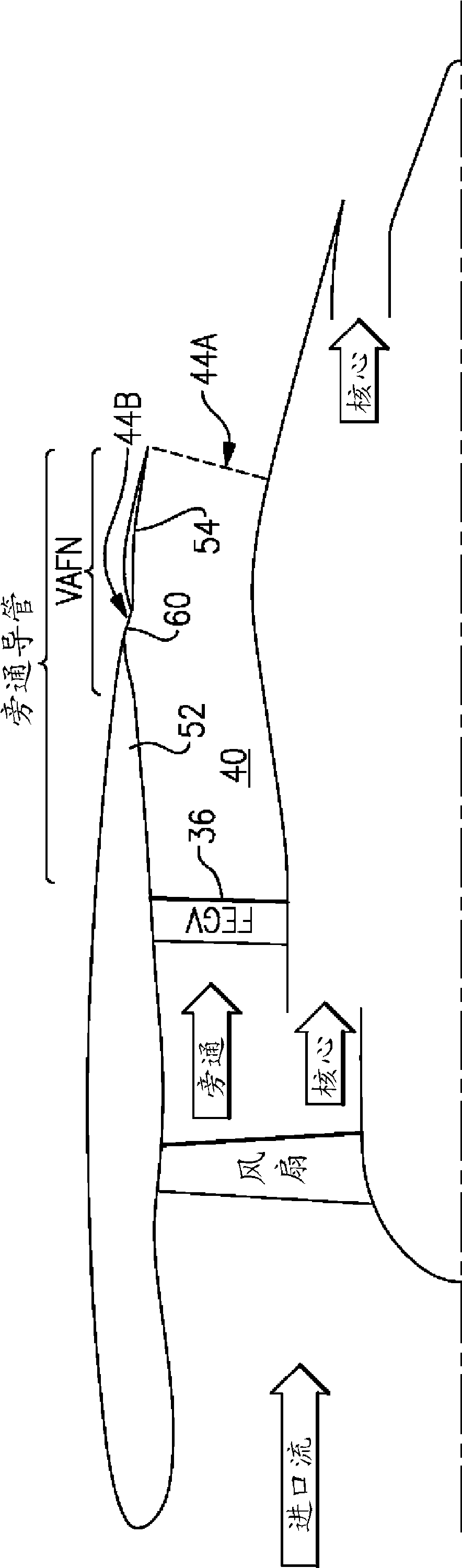

[0036] Figure 1A A general partial fragmentary schematic diagram of a gas turbofan engine 10 is shown suspended from an engine pylon P within an engine nacelle assembly N typical for an aircraft designed for subsonic operation of.

[0037] Turbofan engine 10 includes a core engine within a core nacelle 12 housing a lower rotor 14 and an upper rotor 24 . Lower rotor 14 includes a low pressure compressor 16 and a low pressure turbine 18 . The lower rotor 14 drives the fan section 20 through a gear train 22 . High rotor 24 includes a high pressure compressor 26 and a high pressure turbine 28 . A combustor 30 is arranged between the high pressure compressor 26 and the high pressure turbine 28 . The lower and upper rotors 14, 24 rotate about the axis A of rotation of the engine.

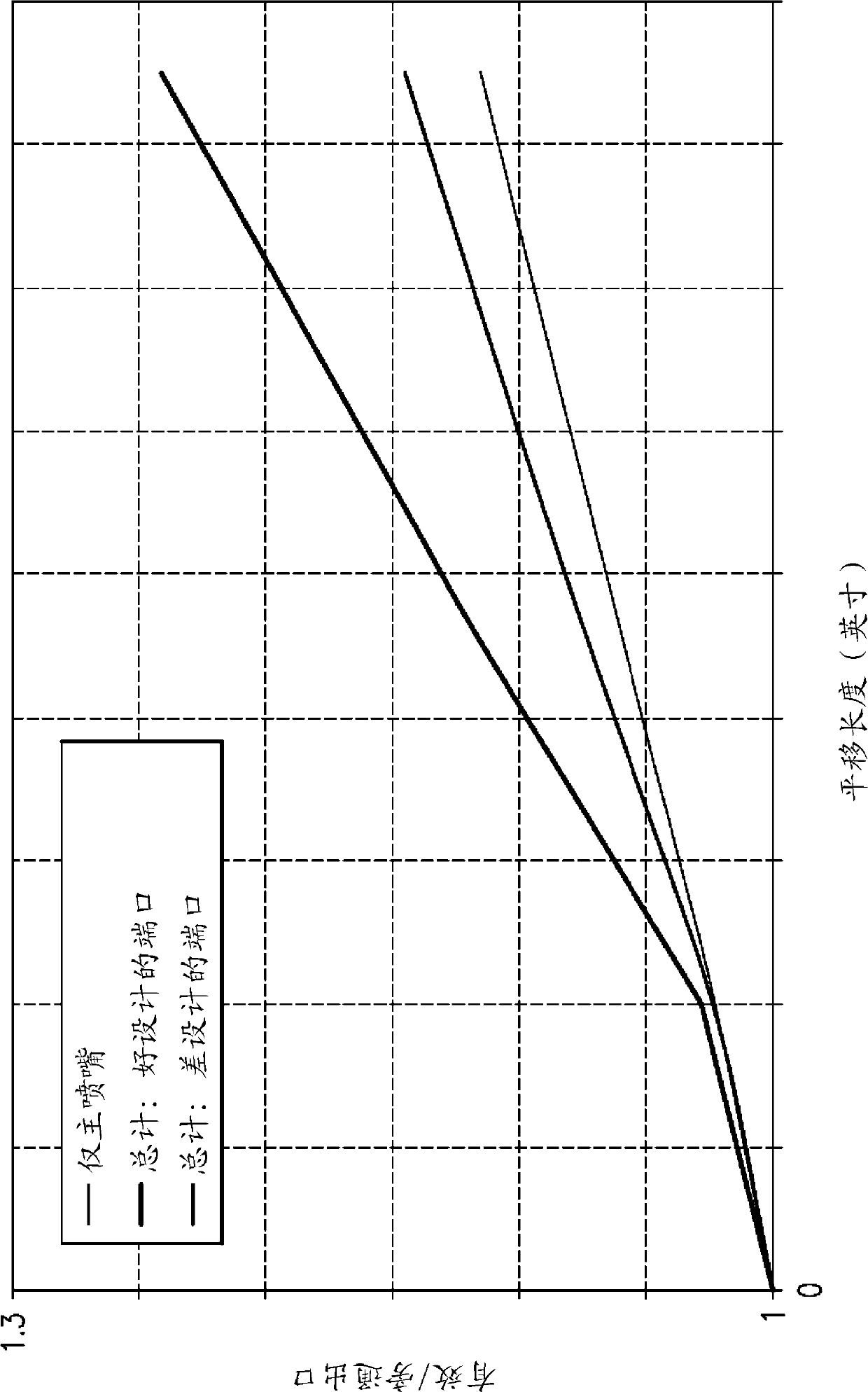

[0038] Engine 10 is preferably a high bypass geared aircraft engine. In one disclosed, non-limiting embodiment, the engine 10 has a bypass ratio greater than about six (6), with an example embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com