Gas turbine engine with variable overall pressure ratio

一种燃气涡轮、发动机的技术,应用在燃气轮机装置、发动机功能、机器/发动机等方向,能够解决增大压缩机成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

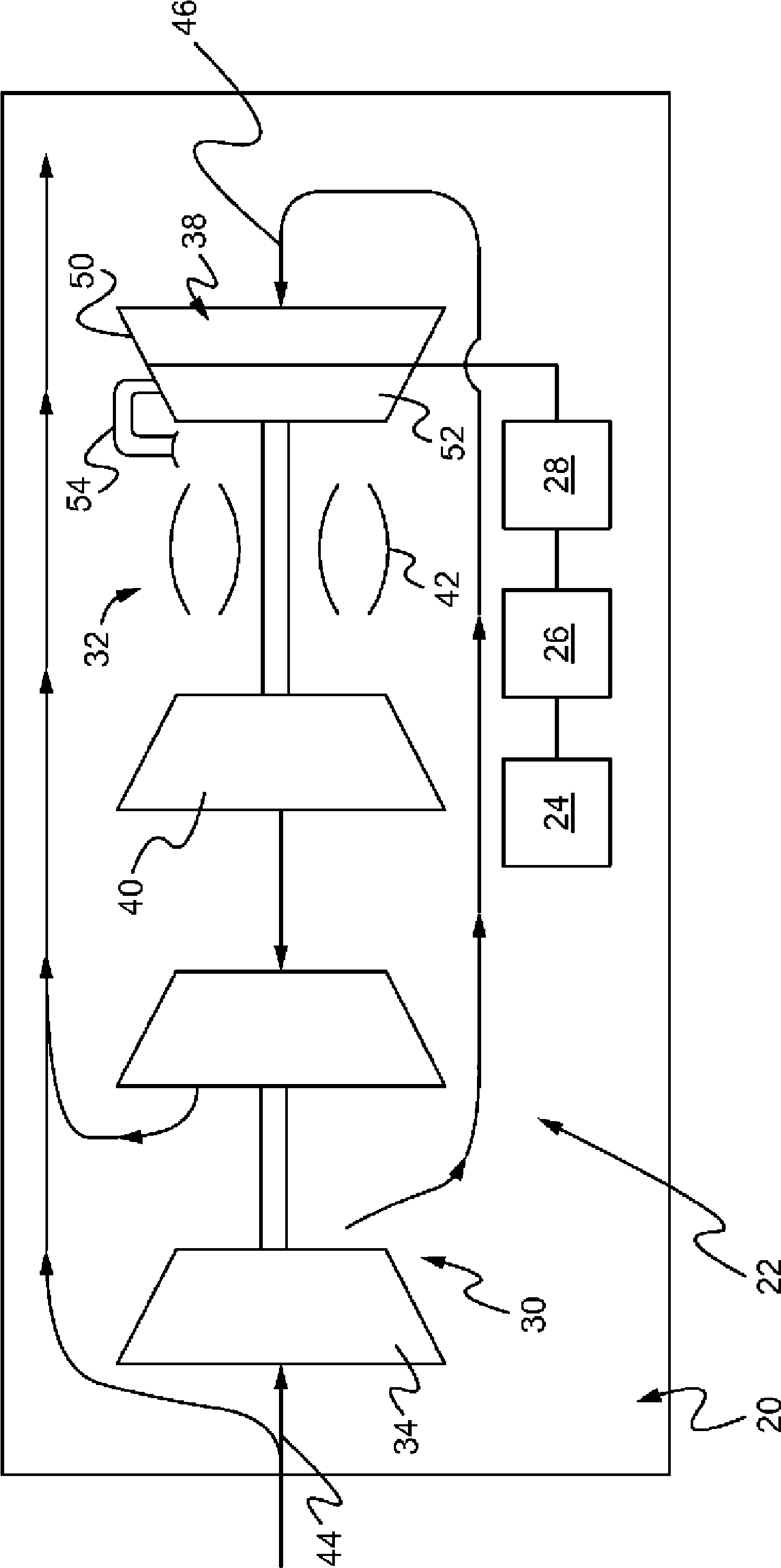

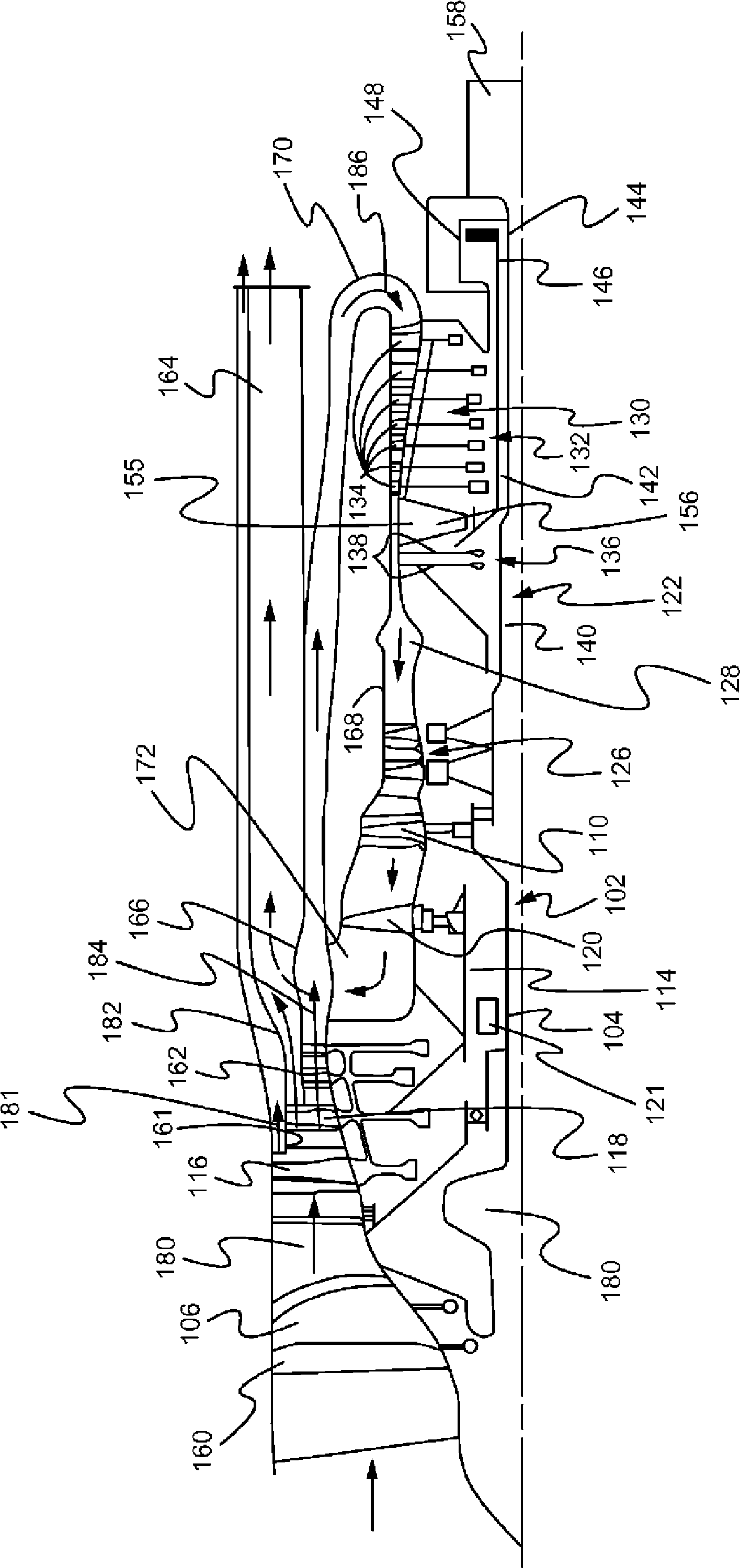

[0022] An exemplary embodiment of a gas turbine engine having a variable overall pressure ratio ("OPR") is disclosed herein. Each engine includes a high pressure compressor having at least a primary stage with a primary set of rotors and a secondary stage with a secondary set of rotors. A clutch is provided to selectively engage the secondary rotor with the primary rotor. During operation of a vehicle having an exemplary gas turbine engine, engagement of the clutch may be controlled based on the vehicle travel mode. For example, on an aircraft, a clutch may be disengaged during a takeoff mode and engaged during a loitering mode. During high propulsion conditions during takeoff, the clutch may be disengaged to stop power to the secondary of the high pressure compressor, thereby reducing turbine inlet temperature ("T3"). By separating the secondary of the high pressure compressor, the OPR is also reduced. Conversely, when the aircraft is at high altitude and cruising in loite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com