Method for refitting retired aircraft into engine, and engine refitted by such method

A technology for decommissioning aircraft and gas turbines, applied in the direction of machines/engines, mechanical equipment, gas turbines, etc., can solve the problems of low-pressure compressor efficiency reduction, gas turbine power reduction, etc., to improve power, increase outlet pressure, and workload. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

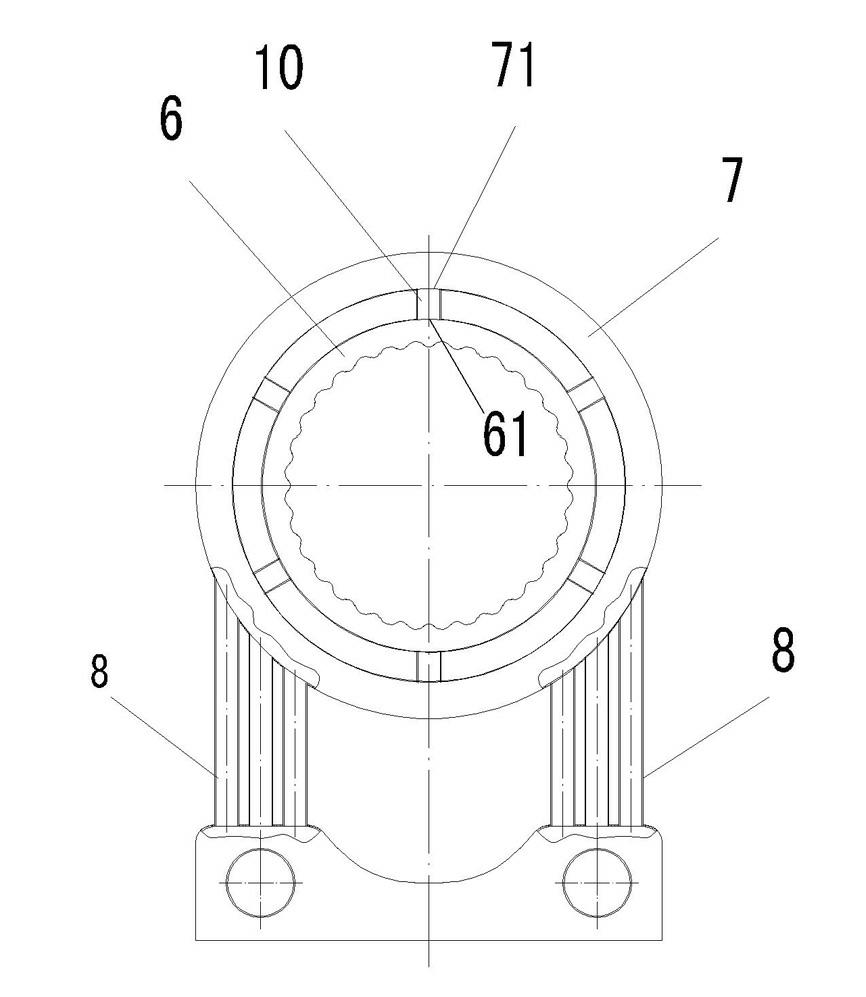

[0014] The method of taking out the outer duct gas from the tail of the outer duct is: (see image 3 ) Firstly, on a circumference of the outer wall of the tail of the outer duct 6, a number of outer duct gas outlets 61 are opened; secondly, a gas turbine outer culvert leading gas collection ring 7 (hereinafter referred to as Tail gas collection ring), the tail gas collection ring is a round tube surrounded by a closed ring, the diameter of the tail gas collection ring (ring) is larger than the diameter of the tail of the outer duct, on the ring wall of the inner diameter of the tail gas collection ring Open a plurality of air inlets 71 of the tail gas collection ring, and the quantity and radial position of the air outlet of the outer duct and the air inlet of the tail gas collection ring correspond one by one. A tail gas outlet pipe 10 is installed between them, and all tail gas outlet pipes are radially distributed, and the outer duct gas is taken into the tail gas collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com