Full-working condition performance prediction method for compressor

A technology of performance prediction and prediction method, applied in the direction of engine function, mechanical equipment, machine/engine, etc., can solve the problems of large workload of coefficient calibration, poor prediction accuracy and poor versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0128] Embodiment: The full working condition aerodynamic performance prediction process of a certain turbocharger compressor from Tianjin North Engine Research Institute is as follows:

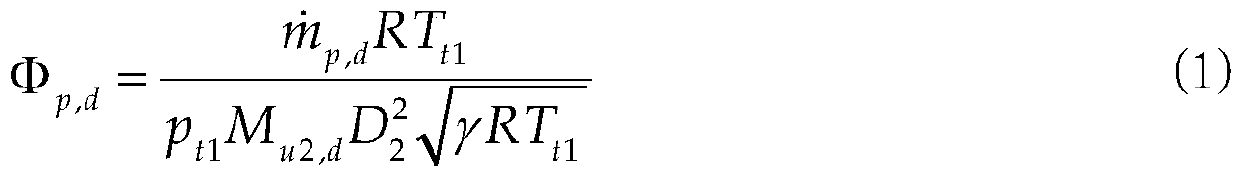

[0129] (1) Given the total inlet temperature of the compressor T t1 =298k, total inlet pressure p t1 =100000pa, specific heat ratio γ=1.4, gas constant R=287J / (kg·k). Given the geometric parameters of the compressor impeller, including: blade outlet installation angle β 2A =15deg, the number of blades Z=18, the meridional inclination of the impeller outlet θ 2 =85deg, blade outlet thickness t 2 =0.0007m, impeller outlet diameter D 2 =0.118m, the rate of change in the installation angle of the impeller outlet blade ξ=11rad / m.

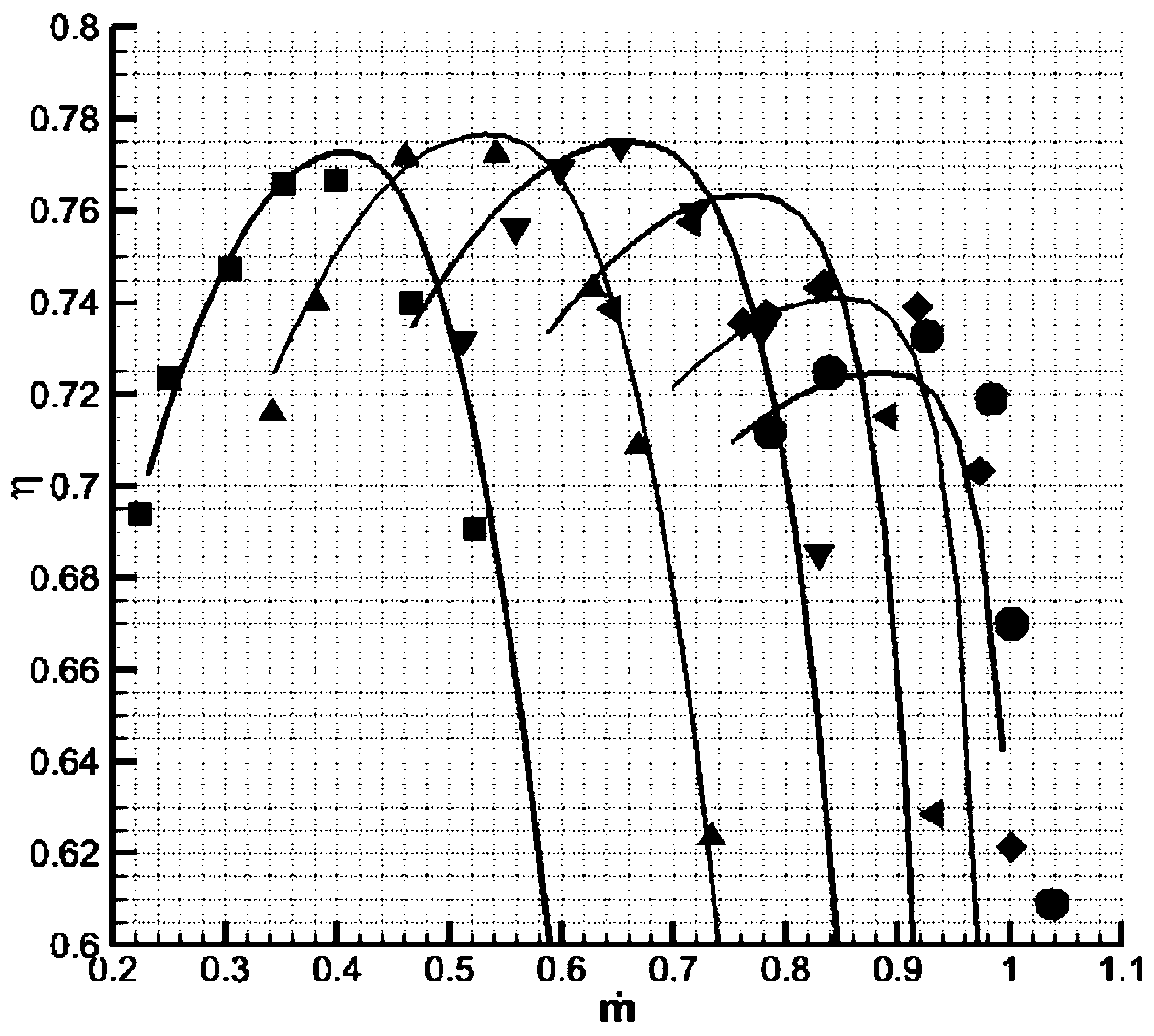

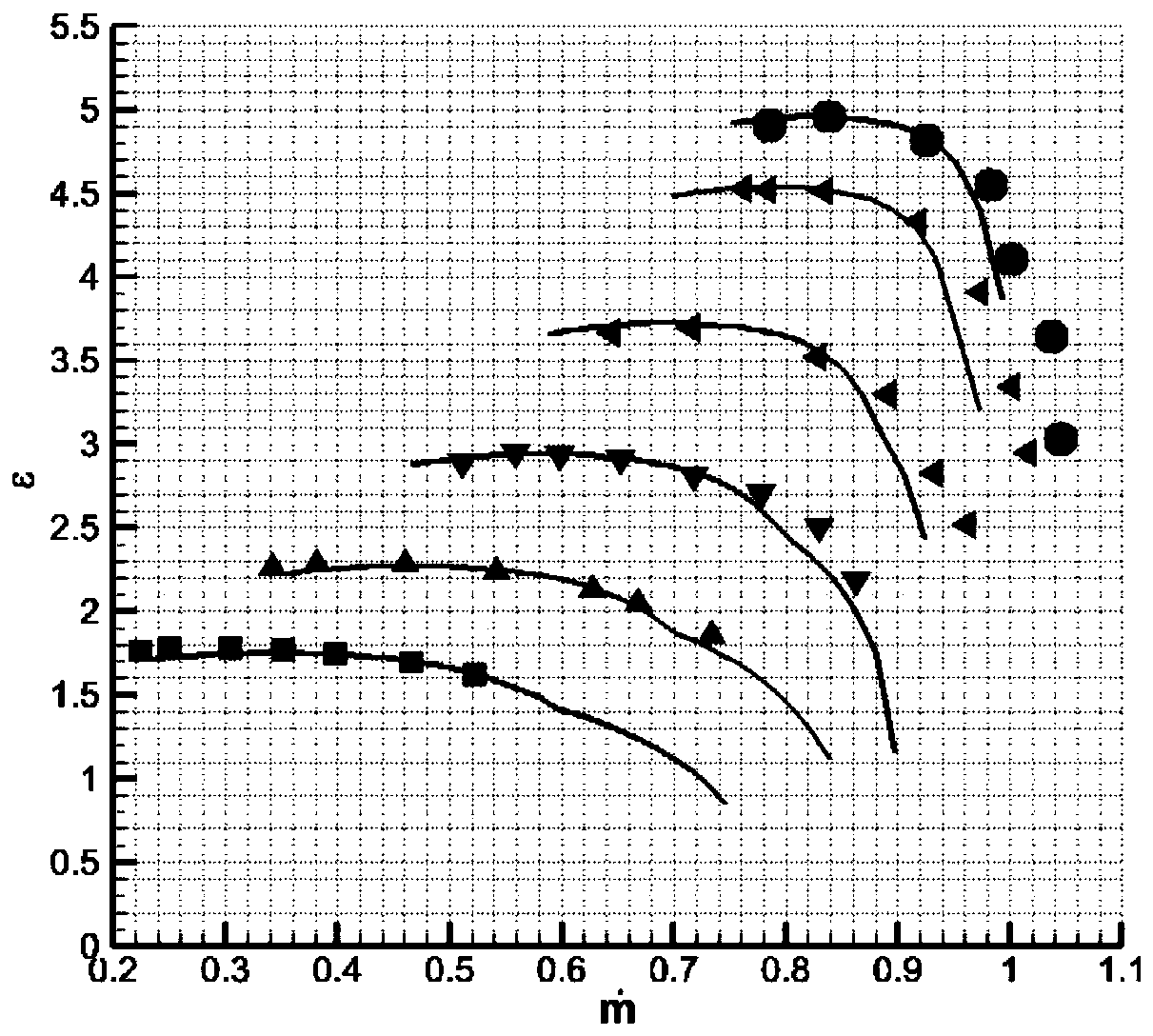

[0130] (2) The parameters of a given design point, including: design machine Mach number M u2,d =1.2321, the highest design speed efficiency η p,d =0.7740, the mass flow rate at the highest efficiency point of design speed The total pressure ratio ε at the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com