High efficiency refrigeration system and cycle

a refrigeration system and high efficiency technology, applied in the field of refrigeration units and operation cycles, can solve the problems of unfavorable cycle efficiency, unfavorable cycle efficiency, and uncertainty about toxicity and flammability, and achieve the effects of reducing the total compression of the refrigeration cycle, reducing the electric power consumption of the vapor compressor, and improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

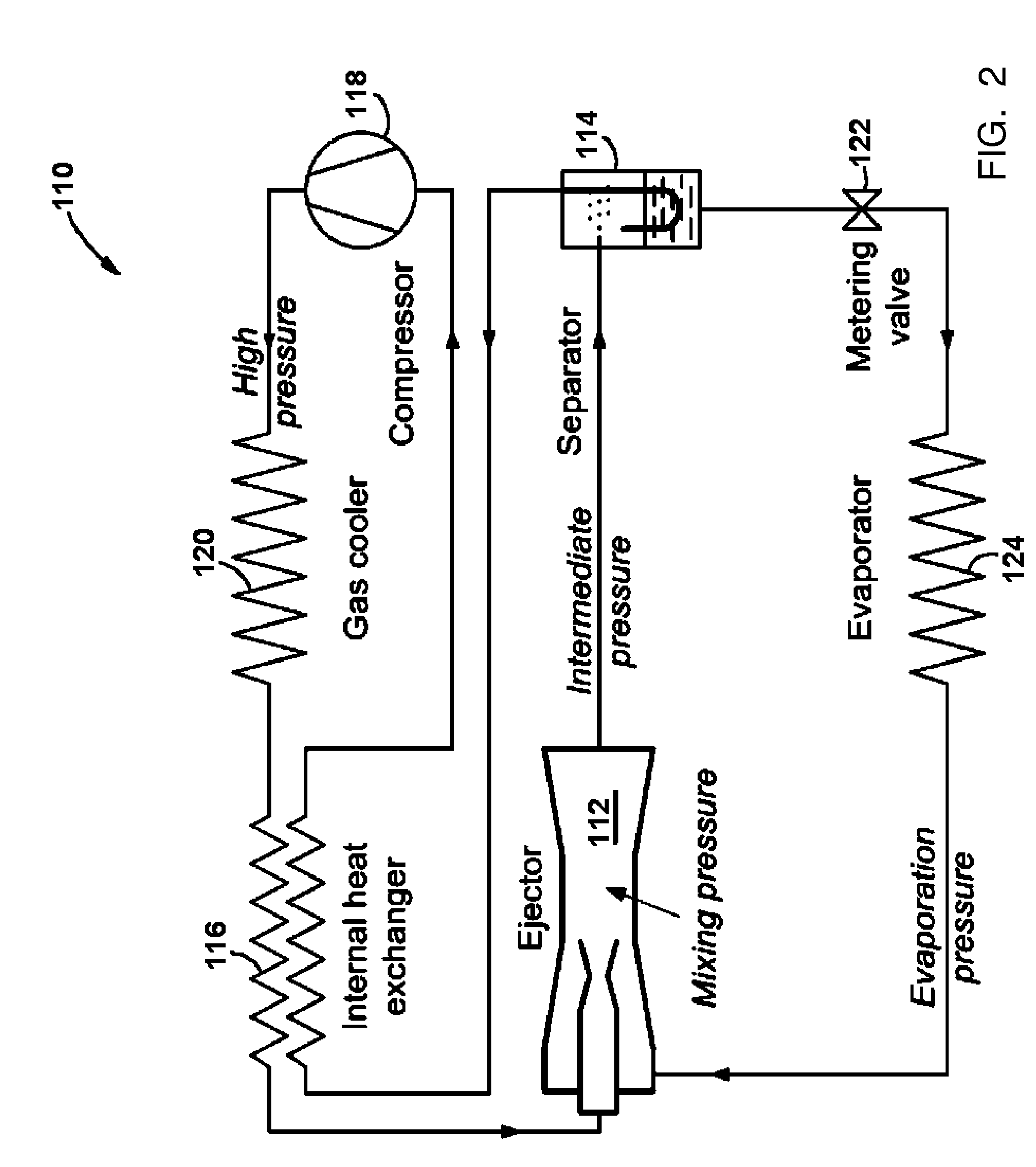

[0028]FIGS. 3 and 4 represent an embodiment of a vapor compression refrigeration system and cycle in accordance with the present invention. More specifically, FIG. 3 illustrates the present invention in the form of a water-cooled chiller, generally designated by reference numeral 210, which is one of several applications for the innovative refrigeration cycle of the present invention. FIG. 4 provides an exemplary pressure-enthalpy thermodynamic diagram for the water-cooled chiller of FIG. 3. Both FIGS. 3 and 4 identify and correspond to various steps in the refrigeration cycle by reference to reference designators.

[0029]The illustrated water-cooled chiller generally has a 150-ton capacity and comprises a mechanical vapor compressor 212 driven by a high-speed electric motor 214. The vapor compressor 212 may be either a single stage or multi-staged compressor and of either a positive displacement-type or a centrifugal turbo-type. As illustrated in FIG. 3, the compressor 212 is a centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com