Valve for essentially gastight closing a flow path

A flow path and airtight technology, applied in the direction of sliding valves, lift valves, valve details, etc., can solve the problems that aluminum is not suitable for corrugated parts, etc., and achieve the effects of reduced danger, small flow loss, and small reaction surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

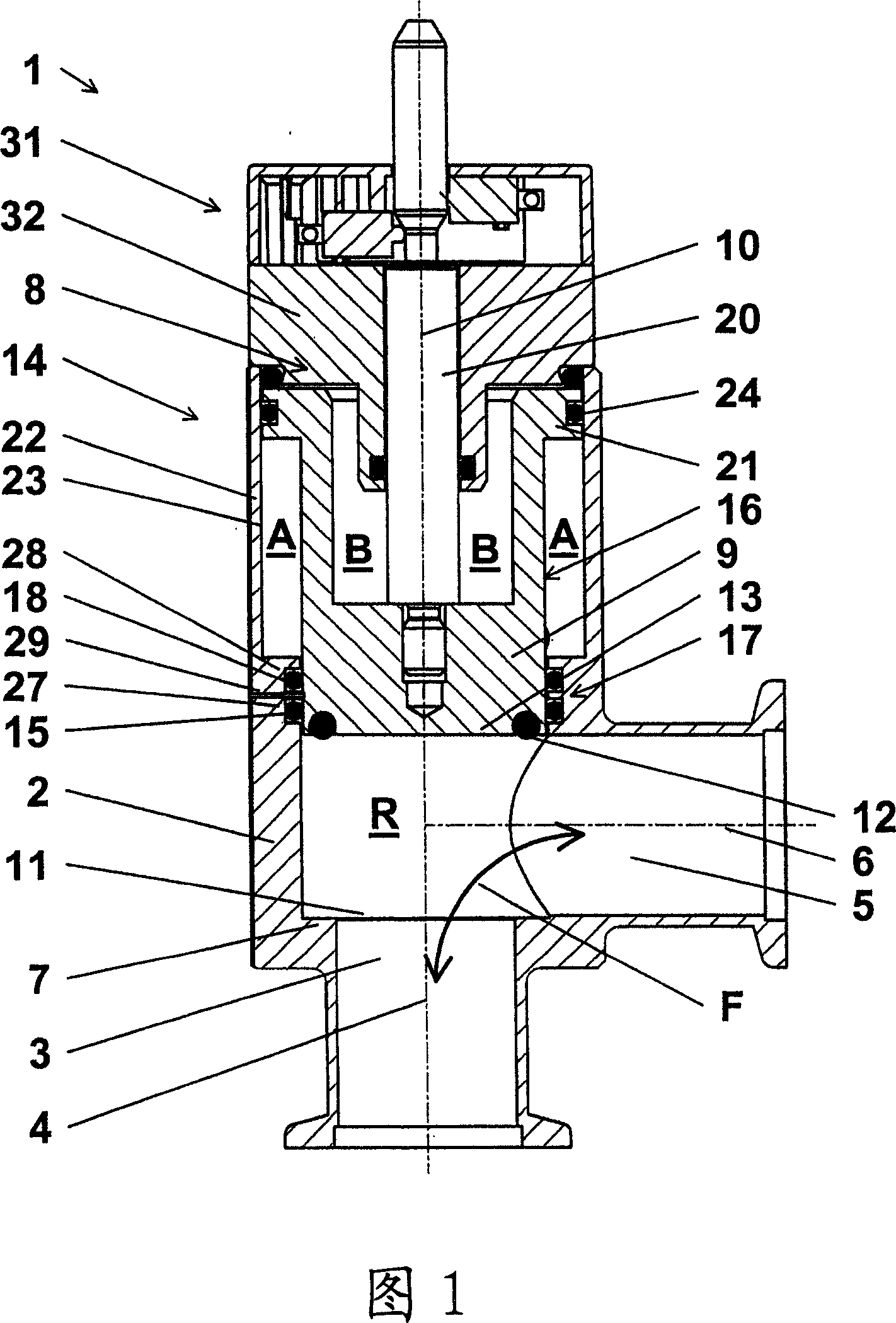

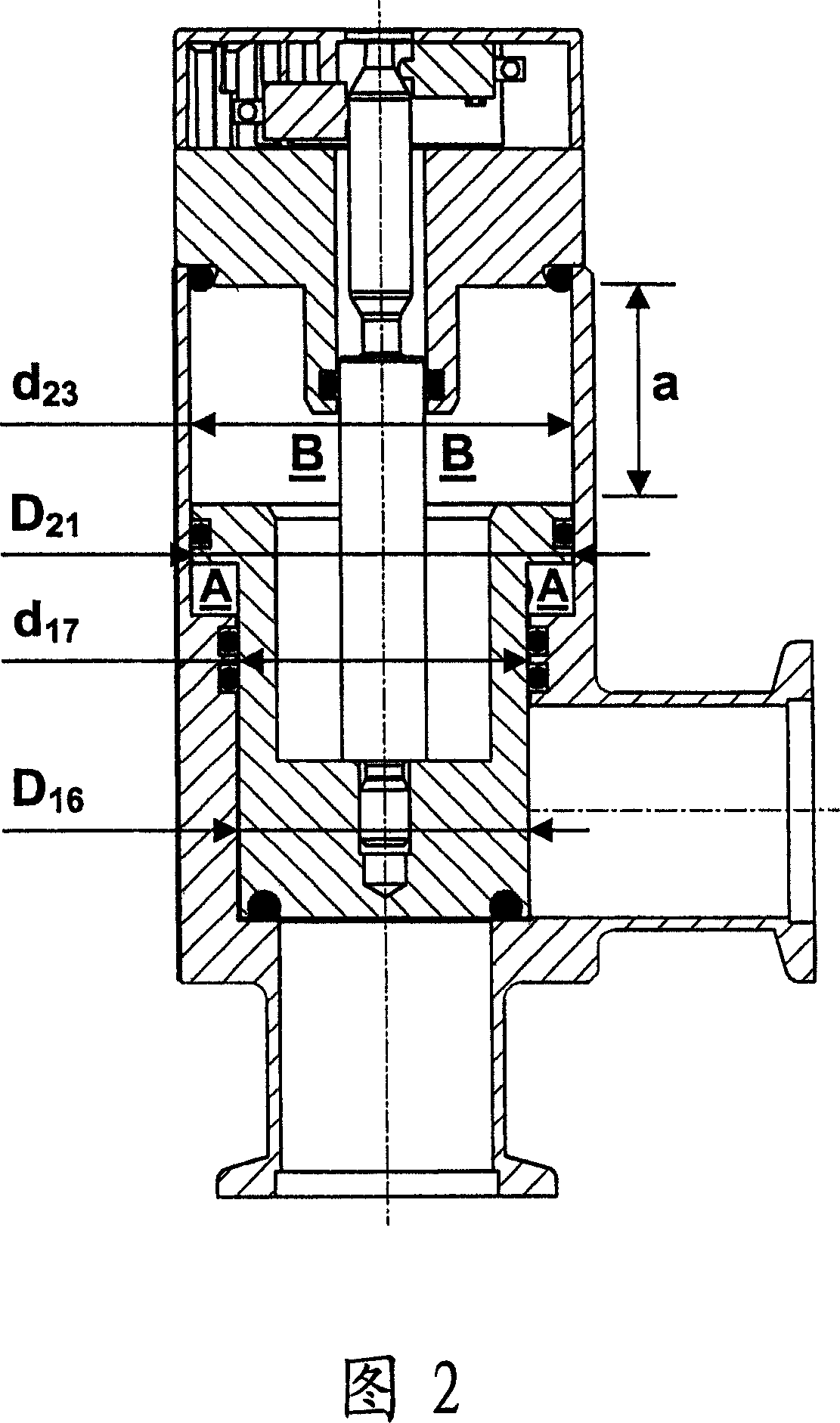

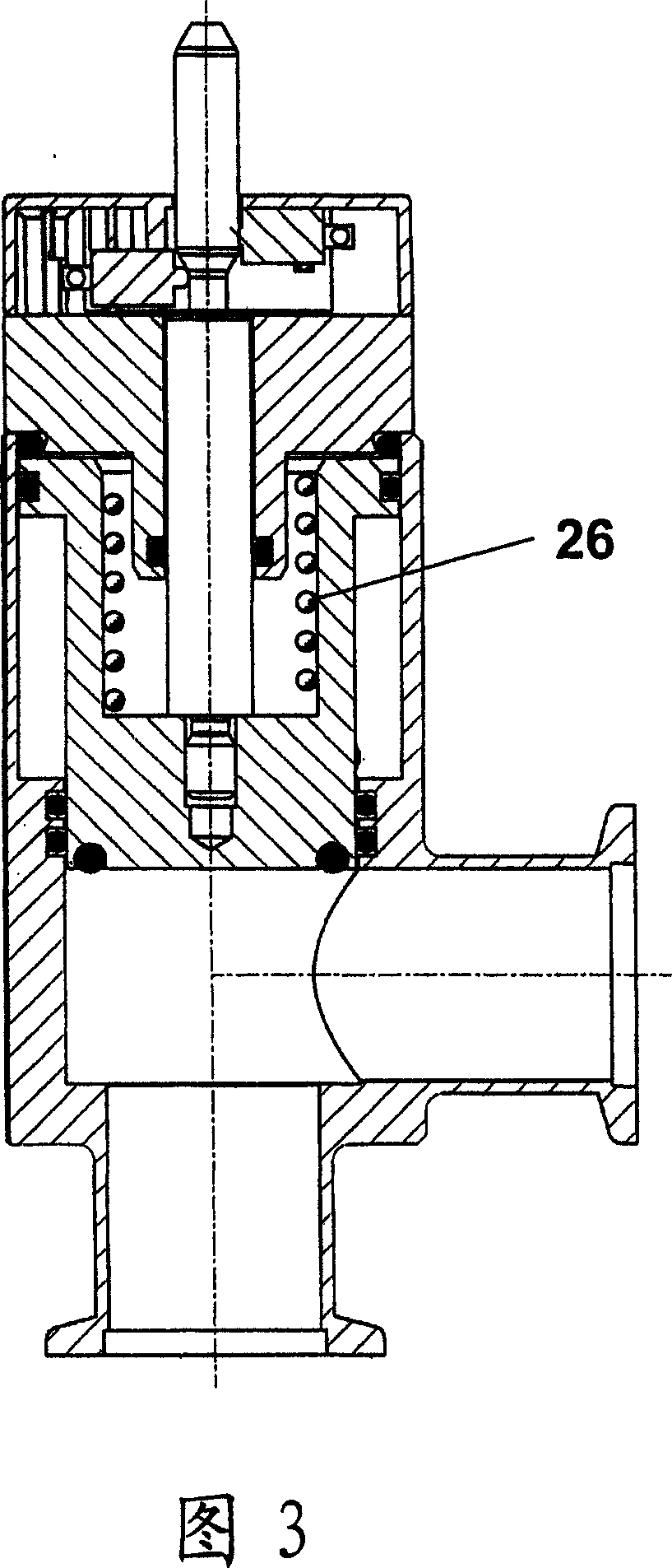

[0026]FIG. 1 shows an embodiment of a valve 1 according to the invention in a longitudinal section in a fully open state. The same valve 1 is shown in Figure 2, but in a fully closed state. Therefore, Figs. 1 and 2 will be described together below. In FIG. 2 , reference numbers already shown in FIG. 1 are omitted.

[0027] The valve 1 has a valve housing 2 comprising a first port 3 and a second port 5 . Both port 3 and port 5 have a circular section and are in the form of a connection to the flow space R of valve 1 . The ports 3 and 5 are arranged perpendicular to each other (in an angled form) such that the first axis 4 of the first port 3 is perpendicular to the second axis 6 of the second port 5 . The first axis 4 and the second axis 6 are defined by the longitudinal axes of the ports 3 and 5 . The flow passage F in the flow space R interconnects the first port 3 and the second port 5 in the open state of the valve 1 . Formed in the valve housing 2 is a valve seat 7 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com