Large-diameter composite butt and strap joint rainwater pipe system and construction method

A rainwater pipe and composite technology, which is applied in the sewer system, waterway system, water supply device, etc., can solve the problems of poor connection of rainwater pipes, twisted sealing ring, stuffy nose, etc., to improve the waterproof effect, facilitate installation and positioning, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

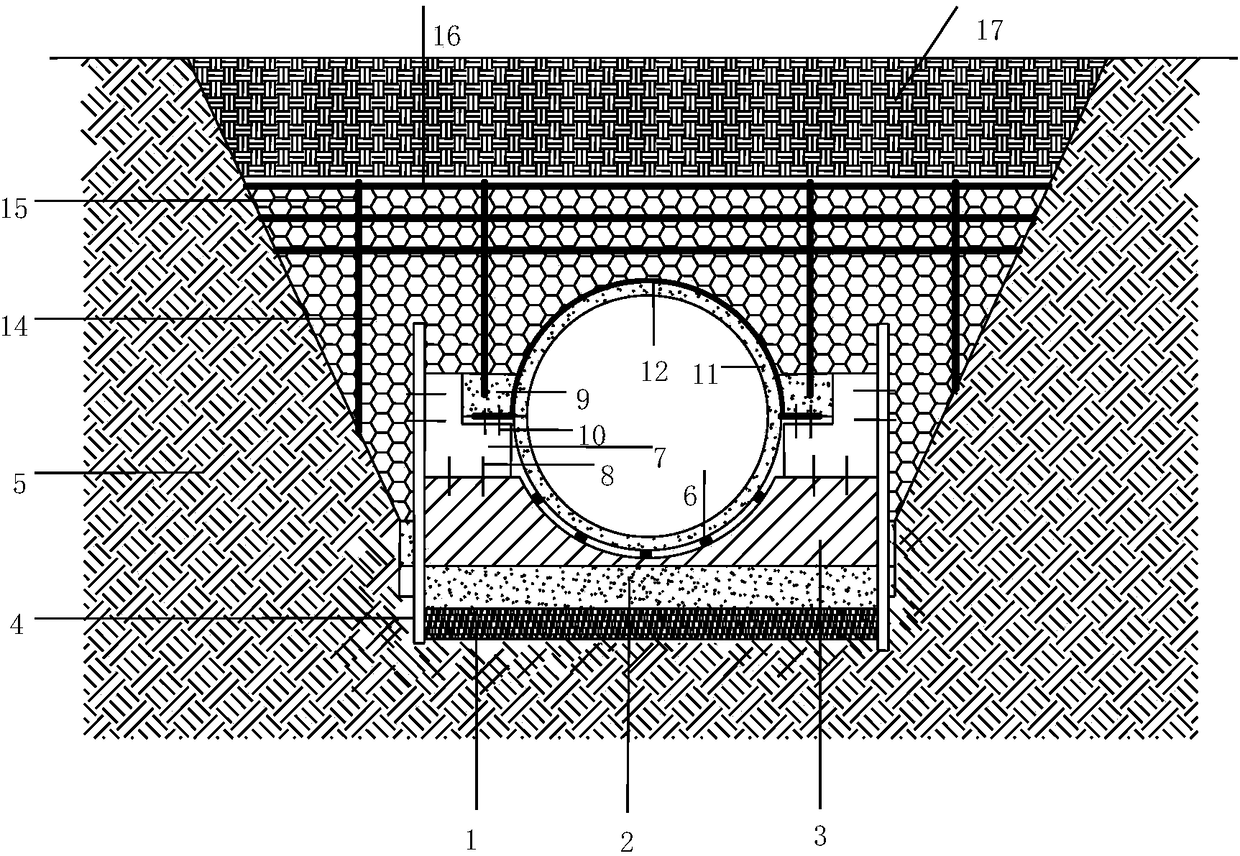

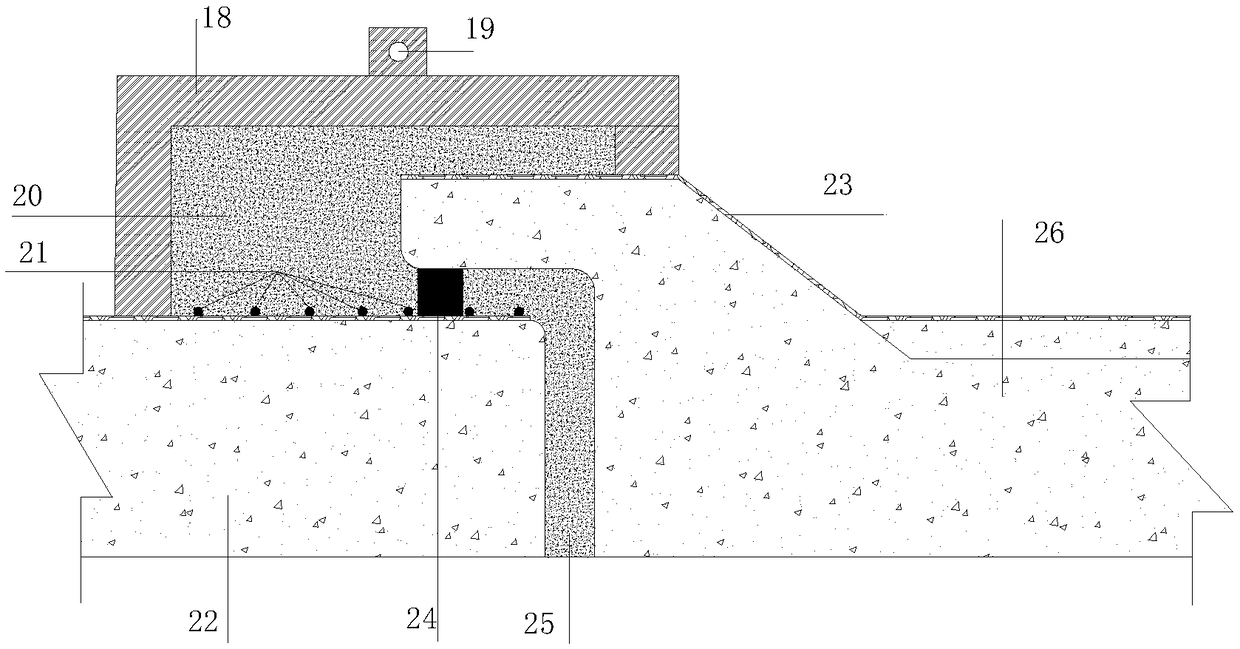

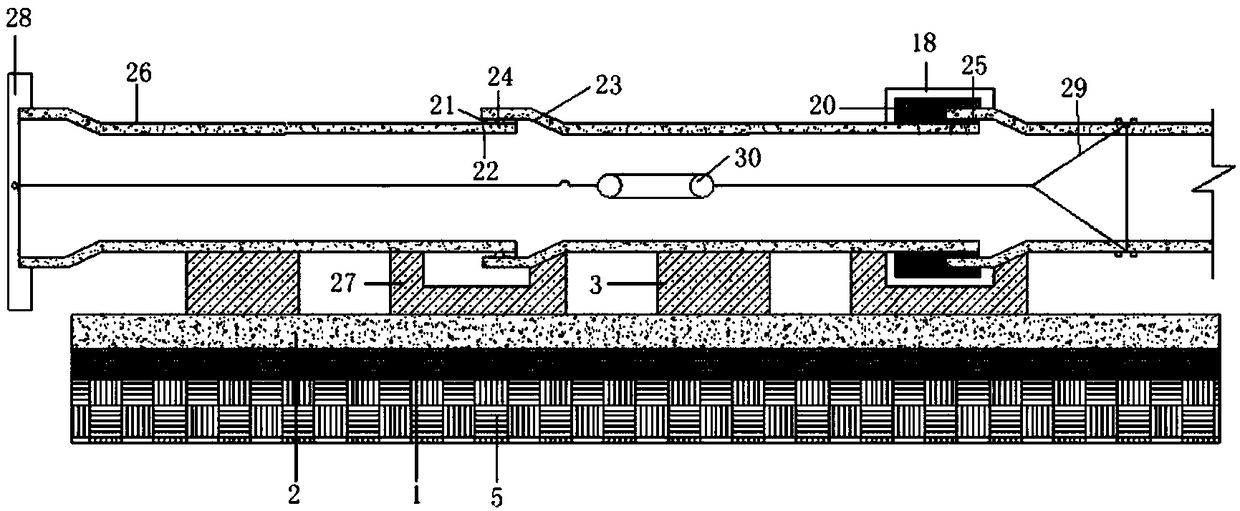

[0032] Hereinafter, the present invention will be further described with reference to the accompanying drawings of the specification, and this embodiment focuses on the structure-related embodiments of the present invention.

[0033] figure 1 It is a cross-sectional schematic diagram of a large-diameter rainwater pipe composite wiper interface. Reference figure 1 As shown, the large-diameter composite wiping tape interface rainwater pipe system construction system of the present invention mainly includes: flexible cushion 1, plain concrete cushion 2, pipe segment prefabricated arc-shaped lock pipe base 3, embedded slat fixing bolt 4, partition Empty block 6, fixed wing plate with stepped hole 7, fixed soil nail 8, mortar sealing hole 9, locking nail rod 10, rainwater pipe 11, arc lock 12, bubble concrete 14, vertical support rib 15, horizontal reinforcement net Sheet 16, plain soil backfill layer 17, cement mortar wiping belt 20, prefabricated arc-shaped locking tube base 27 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com