Self heat insulation laminated shear wall structure and construction process

A technology of superimposed shear walls and construction technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of high strength of self-insulating formwork and permanent formwork, and achieve the goal of eliminating support measures, saving construction period and improving strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

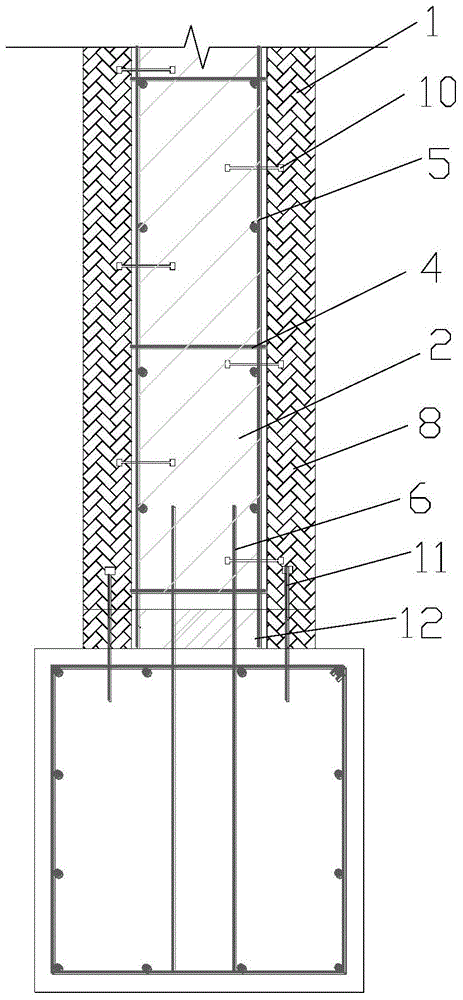

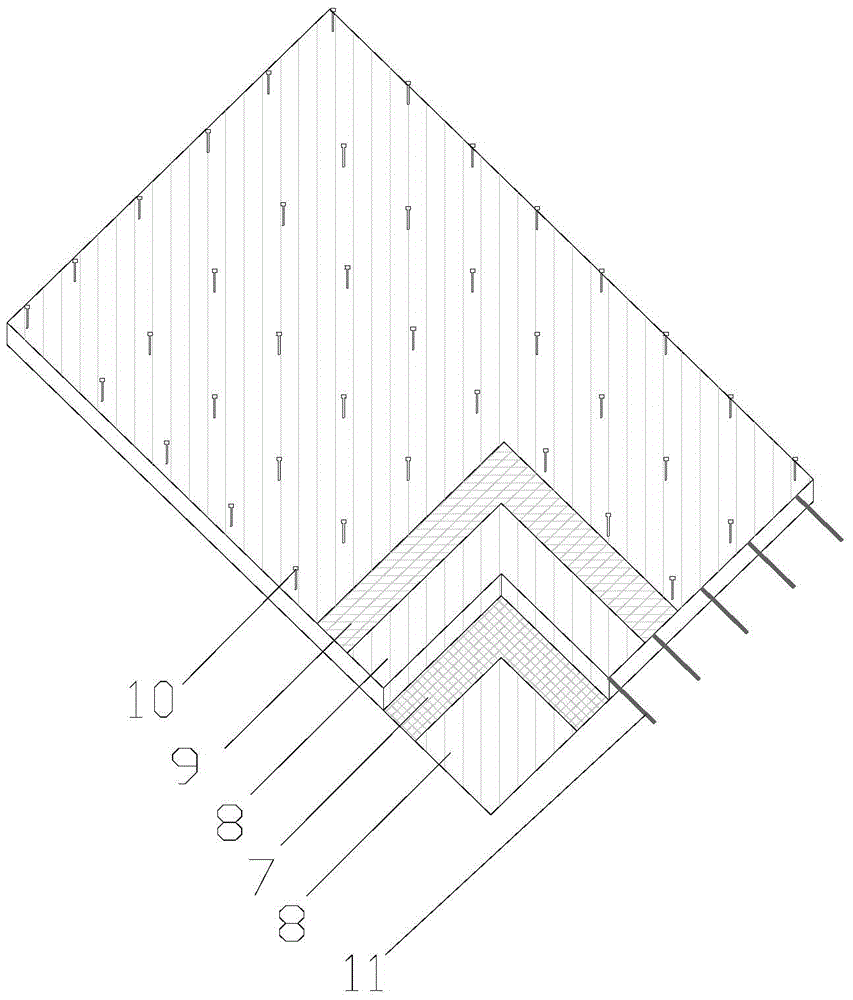

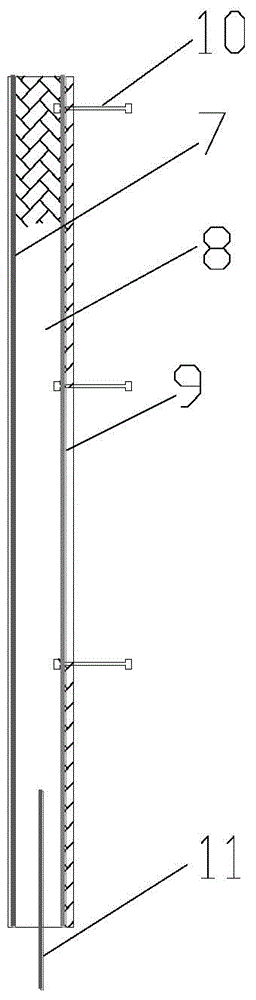

[0038] Such as Figure 1-3 As shown, a self-insulation composite shear wall structure includes a lightweight self-insulation concrete formwork 1, a cast-in-place reinforced concrete structure layer 2 and a foundation 3, and the lightweight self-insulation concrete formwork 1 is made of an outer lightweight self-insulation concrete Formwork and inner lightweight self-insulation concrete formwork, the cast-in-place reinforced concrete structure layer 2 is arranged between the outer lightweight self-insulation concrete formwork and the inner lightweight self-insulation concrete formwork, and the foundation 3 is located under the shear wall;

[0039] The cast-in-place reinforced concrete structure layer 2 is provided with transversely distributed steel bars 4 and distributed steel bars 5, and the lower part of the cast-in-place reinforced concrete st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com