Double-eccentric fixture and machining method for double-eccentric shaft

A double eccentric and fixture technology is applied in metal processing equipment, metal processing machinery parts, clamping, etc., which can solve the problems of high processing cost of double eccentric shafts, large equipment investment, and large loss of guide rails and screw screws of machine tools. Reduce processing costs, save costs, and facilitate adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

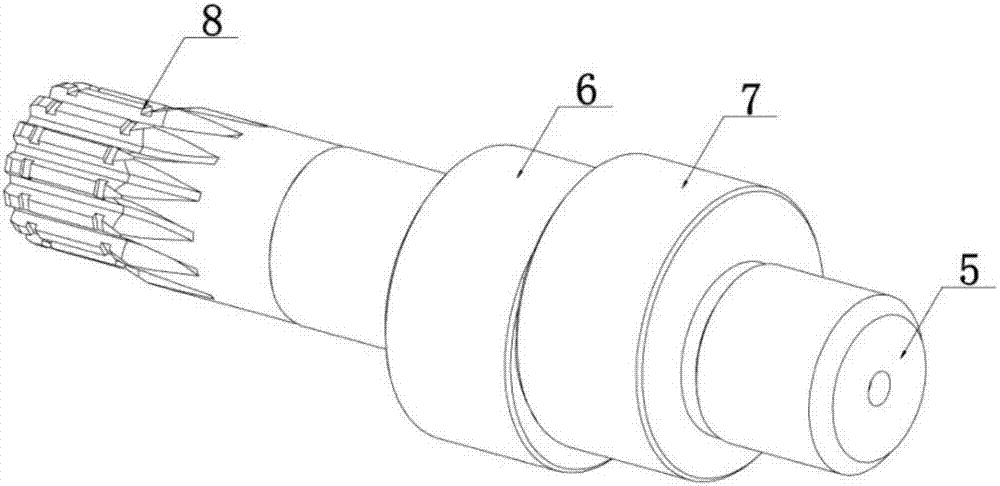

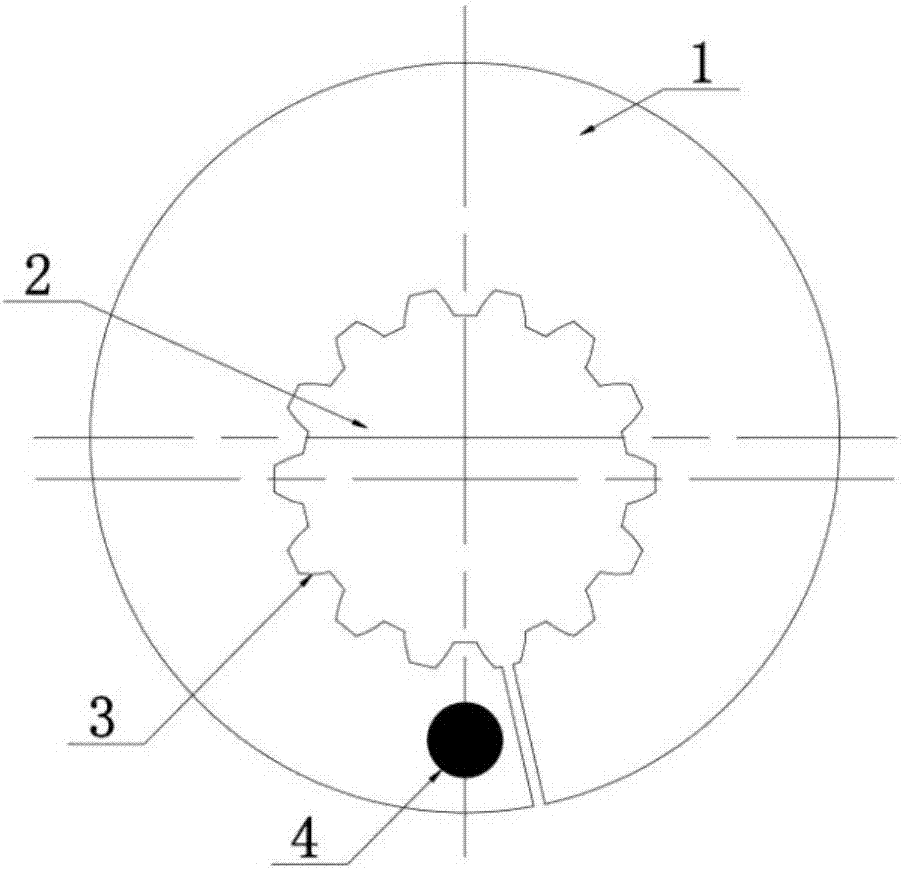

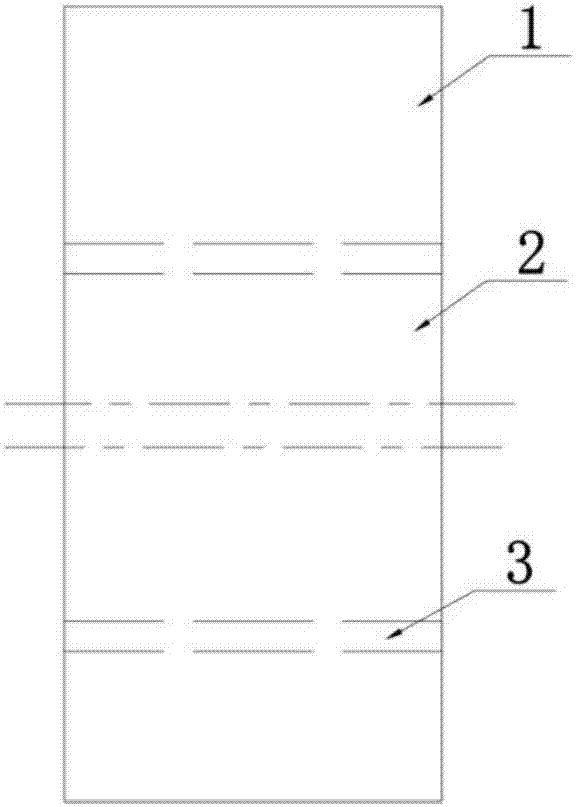

[0039] Example 1, such as Figure 4-Figure 10 Shown, a kind of processing method of double eccentric shaft comprises lathe and above-mentioned double eccentric fixture, and described lathe comprises three-jaw chuck and turning mechanism, and the number of teeth of the inner spline on the described eccentric inner spline through hole is an even number, the maximum eccentric radius of the eccentric circle is the maximum value from the axis center of the workpiece axis to be processed to the outer contour of the eccentric circle, and the maximum eccentric radius of the first eccentric circle on the workpiece axis to be processed is R1, and the second eccentric circle The maximum eccentric radius of the double eccentric fixture is R2; the maximum value from the center of the eccentric inner spline through hole of the double eccentric fixture to the outer contour is the maximum eccentric radius R0, and the double eccentric fixture is also provided with a reference black dot mark, an...

Embodiment 2

[0045] Example 2, such as Figure 11-Figure 14 Shown, a kind of processing method of double eccentric shaft comprises lathe and above-mentioned double eccentric fixture, and described lathe comprises three-jaw chuck and turning mechanism, and the number of teeth of the inner spline on the described eccentric inner spline through hole is an even number, taking the number of external spline teeth of the double eccentric shaft to be processed as 12 as an example, set the maximum eccentric radius of the eccentric circle to be the maximum value from the axis center of the workpiece shaft to be processed to the outer contour of the eccentric circle, and set The maximum eccentric radius of the first eccentric circle is R1, and the maximum eccentric radius of the second eccentric circle is R2; if the maximum value from the center of the eccentric inner spline through hole of the double eccentric clamp to the outer contour is the maximum eccentric radius R0, the double eccentric clamp ...

Embodiment 3

[0051] Embodiment 3, a processing method of a double eccentric shaft, including a lathe and the above-mentioned double eccentric fixture, the lathe includes a three-jaw chuck and a turning mechanism, the inner spline on the eccentric inner spline through hole The number of teeth is an even number, and the maximum eccentric radius of the eccentric circle is set to be the maximum value from the axis center of the workpiece axis to be processed to the outer contour of the eccentric circle, and the maximum eccentric radius of the first eccentric circle on the workpiece axis to be processed is R1, and the second eccentric radius The maximum eccentric radius of the circle is R2; the maximum value from the center of the eccentric inner spline through hole of the double eccentric fixture to the outer contour is the maximum eccentric radius R0, and the double eccentric fixture is also provided with a reference black dot mark, and the reference The black dot mark is set on the double ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com