Serial-parallel type multi-evaporator loop heat pipe

A technology of loop heat pipes and evaporators, which is applied to circuits, electric solid-state devices, semiconductor devices, etc., can solve the problems of large heat dissipation devices, high cost, and high noise, and achieves easy positioning and installation, improved heat conduction efficiency, and reduced total cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

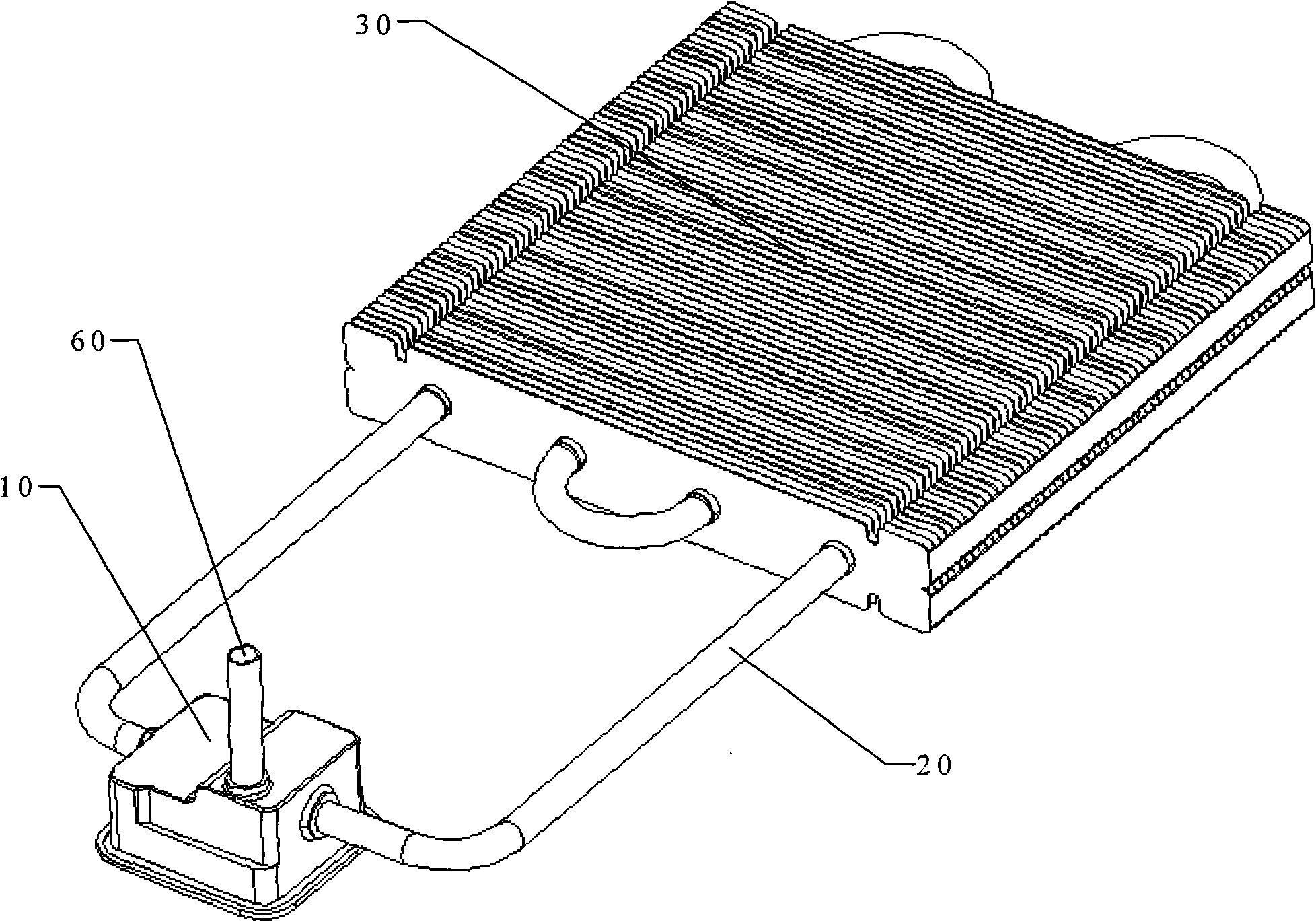

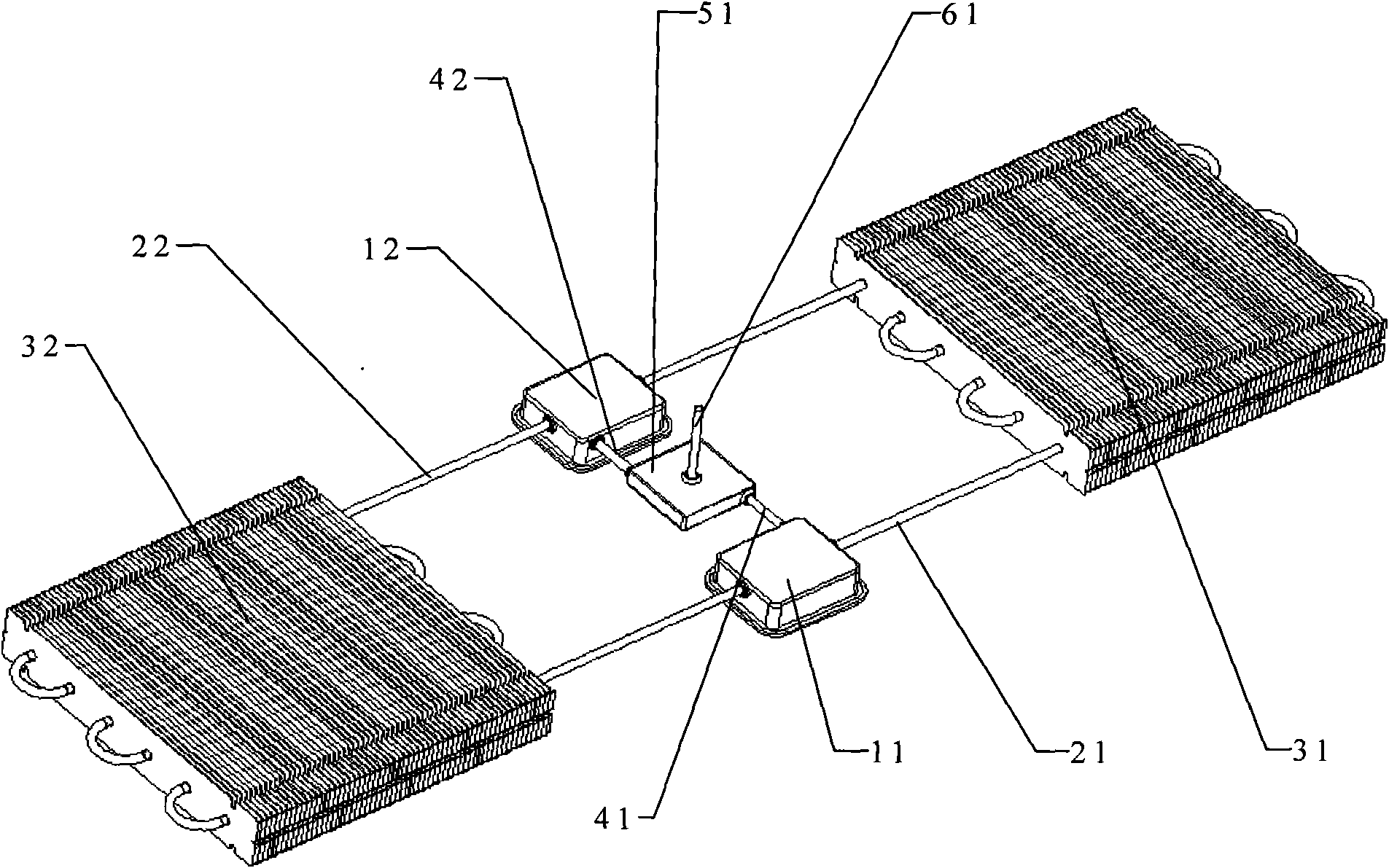

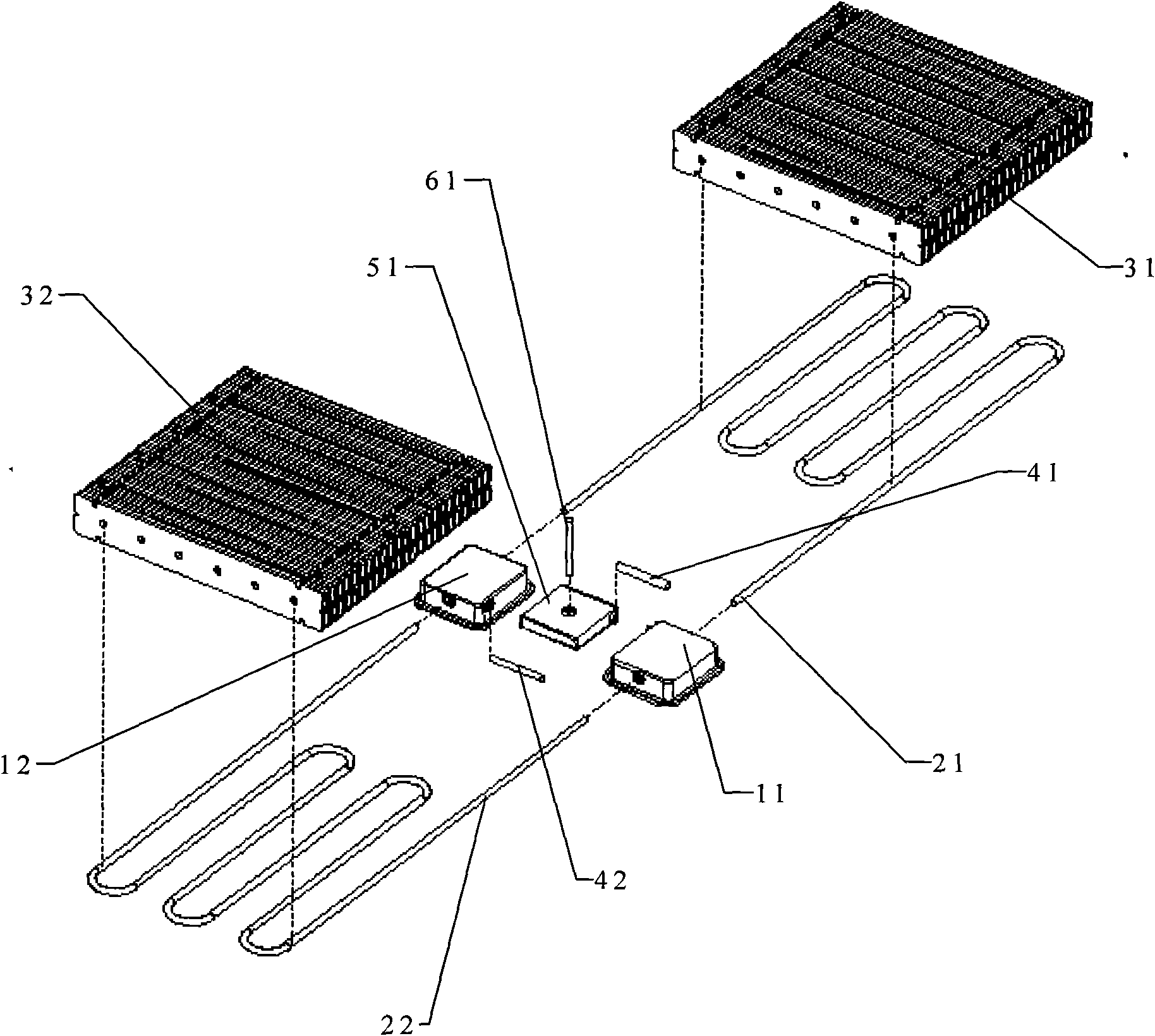

[0033] The invention is a series-parallel multi-evaporator loop heat pipe, please refer to the specific structure figure 2 , image 3 An embodiment shown, the embodiment of the series-parallel multi-evaporator loop heat pipe mainly includes two sets of loop heat pipe evaporators 11, 12, two loop heat pipe gas-liquid pipelines 21, 22, two sets of loop heat pipes Heat pipe condensers 31, 32, a group of loop heat pipe working liquid compensation chambers 51, loop heat pipe working liquid compensation pipelines 41, 42, and loop heat pipe liquid filling and vacuumizing pipelines 61.

[0034] The liquid inlets and steam outlets of the two groups of evaporators 11, 12 are connected in series by two gas-liquid pipelines 21, 22, that is, the steam outlet of the evaporator 11 and the liquid inlet of the evaporator 12 are connected through a gas-liquid pipeline 22 ; At the same time, the liquid inlet of the evaporator 11 and the steam outlet of the evaporator 12 are connected through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com