Assembling mold for all-composite corrugated sandwich cylindrical shells

A technology of composite materials and combined molds, which is applied in the field of combined molds for all-composite corrugated interlayer cylindrical shells, can solve the problems of complex preparation process, lack of molds, and difficulty in mass production, so as to achieve simple process realization, avoid fiber winding, Guaranteed stable and non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

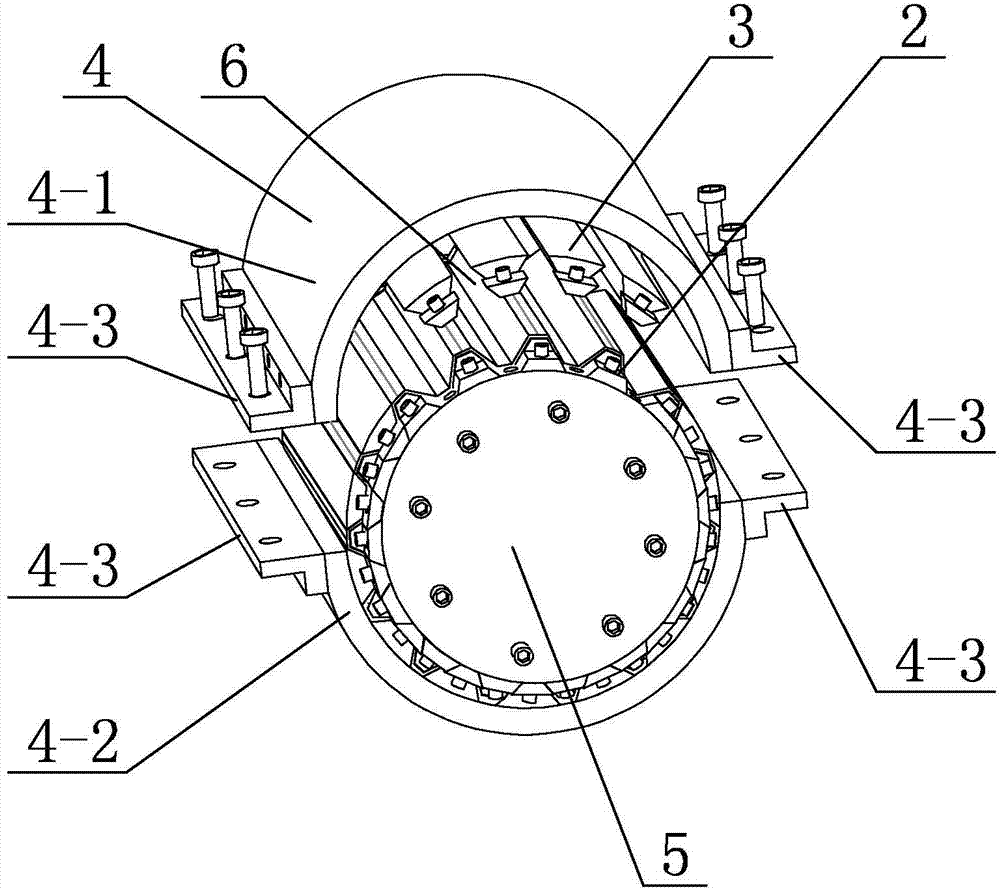

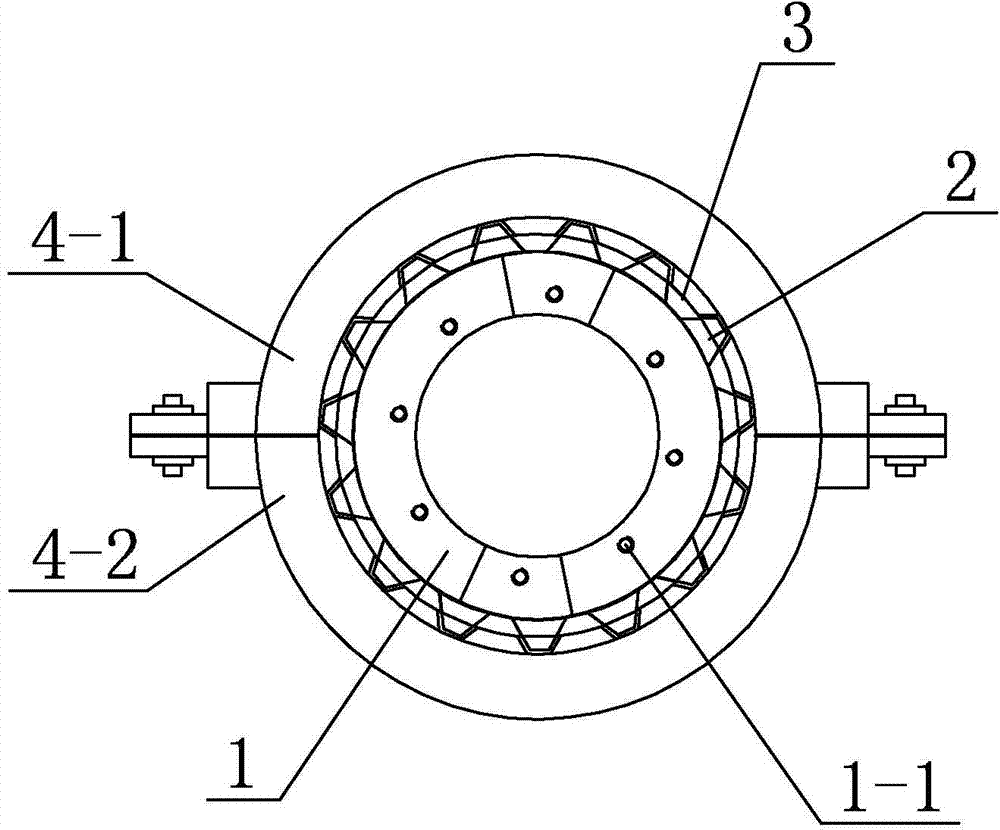

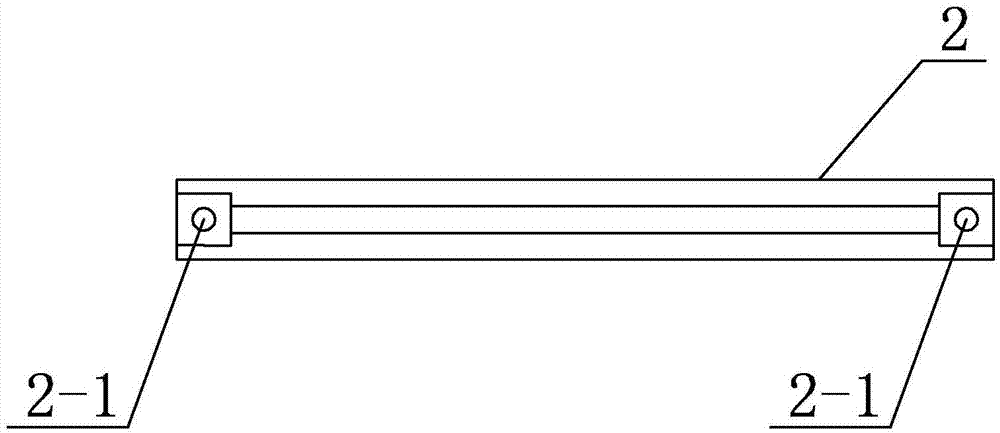

[0031] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 14 Describe this embodiment, in this embodiment it comprises stem 1, mold clamping fixture 4, two end caps 5, a plurality of inner core strip bodies 2 and a plurality of outer core strip bodies 3, and described stem post 1 is split The two end caps 5 are detachably connected to the top surface and the bottom surface of the stem 1 respectively, and a plurality of inner core strips 2 and a plurality of outer core strips 3 alternate along the axial direction of the stem 1 Arranged on the outer circumference of the core column 1, there is a gap between each inner core bar body 2 and its adjacent outer core bar body 3, the mold clamping fixture 4 is cylindrical, and the mold clamping fixture 4 is set On the stem 1 with a plurality of inner core strips 2 and a plurality of outer core strips 3, the inner wall of t...

specific Embodiment approach 2

[0032] Specific implementation mode two: combination figure 2 , Figure 7 , Figure 8 and Figure 14 To illustrate this embodiment, in this embodiment, the top surface and the bottom surface of the stem 1 are respectively processed with end cap connection holes 1-1; the outer surface of the stem 1 is uniformly processed in multiple rows along its radial direction The first core bar connection hole 1-2. In this embodiment, the connection hole 1-1 of the end cap is to realize the connection of the stem 1 and the end cap 5; Connection of a plurality of outer core strip bodies 3 . In this embodiment, the end cap 5 is also processed with connection holes corresponding to the end cap connection holes 1-1, and the end cap 5 and the stem 1 are detachably connected by screws, thereby realizing the end cap 5 and the stem. 1 is effectively connected to ensure the basic framework of the stem 1. Other unmentioned components and connections are the same as those in the first embodime...

specific Embodiment approach 3

[0033] Specific implementation mode three: combination figure 1 , image 3 and Figure 4 Describe this embodiment. In this embodiment, when the inner core strip body 2 is placed vertically, the cross section of the inner core strip body 2 in the horizontal direction is trapezoidal, and the inner core strip body 2 is processed with a The first core strip connection hole 1-2 corresponds to the second core strip connection hole 2-1. When the inner core strip body 2 is detachably connected to the core column 1 through the second core strip connection hole 2-1, the inner core strip The width of one end surface of the strip body 2 close to the stem 1 is gradually reduced to the width of the other end surface far away from the stem 1 . In this embodiment, the width of the end surface of the inner core strip body 2 on the side close to the stem 1 on the inner core strip body 2 gradually decreases to the width of the end surface of the inner core strip body 2 on the side away from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com