Method for easily replacing igniter of sintering machine

A replacement method and igniter technology, applied in the furnace type, furnace, lighting and heating equipment, etc., can solve the problems of limited operating area, easy cracks, falling off, etc., to achieve the effect of ensuring installation quality and maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail with the accompanying drawings and specific embodiments.

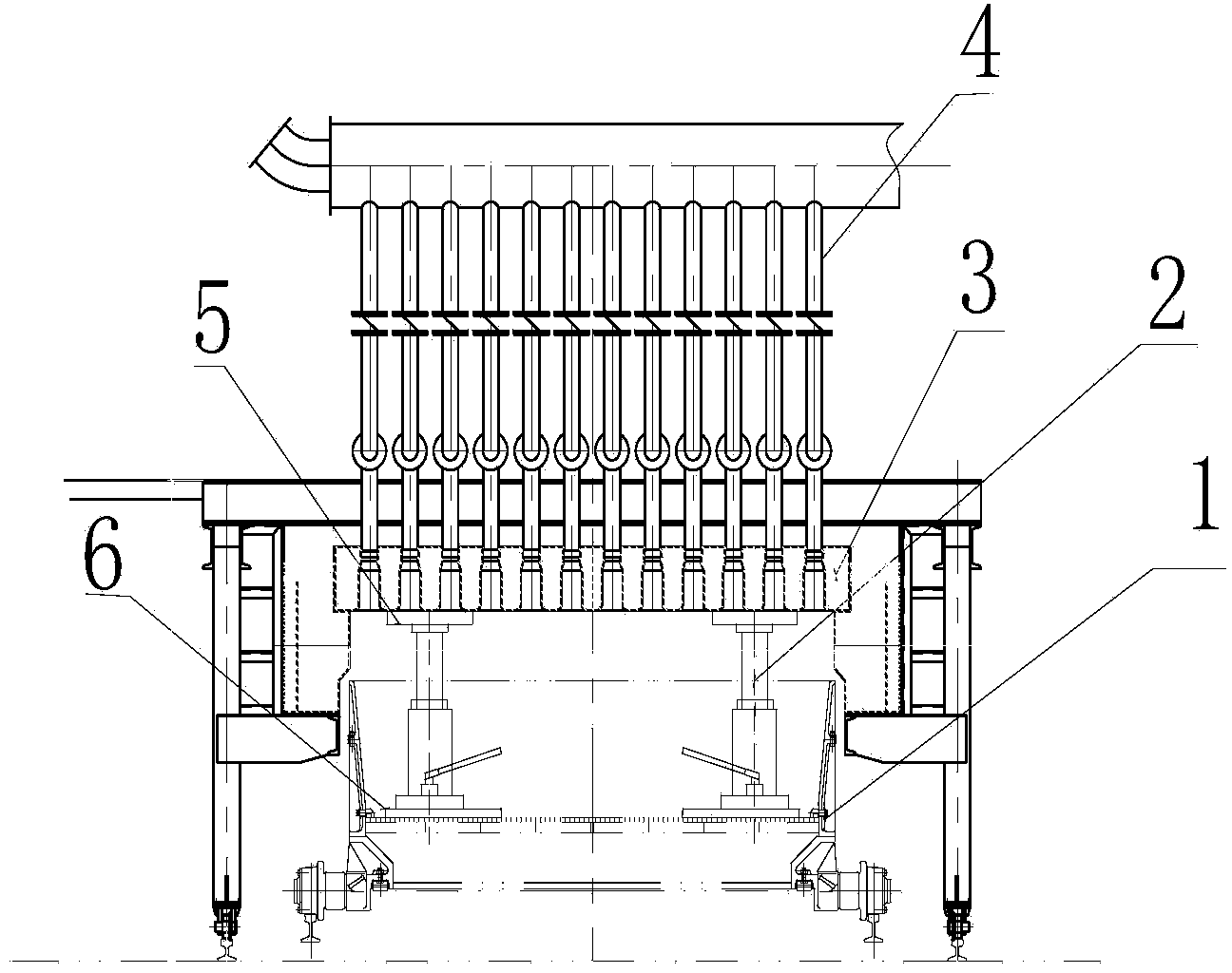

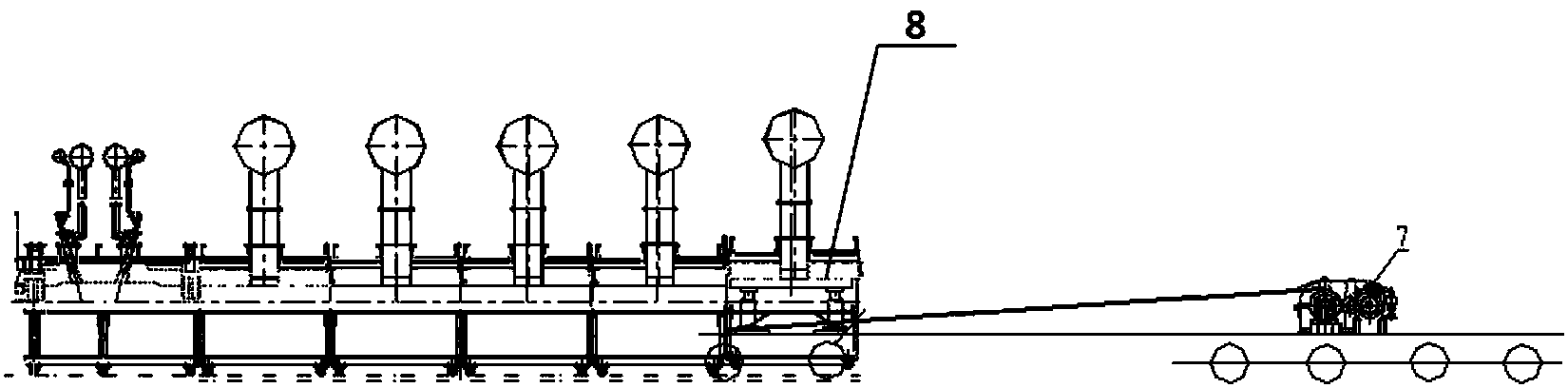

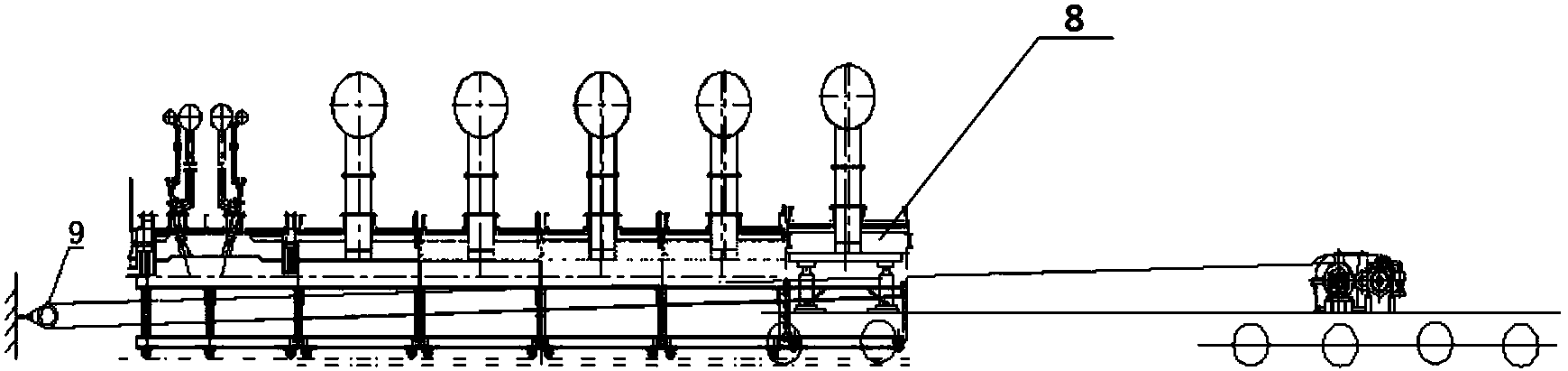

[0029] Such as figure 1 , figure 2 and image 3 Shown, a sintering machine igniter simple replacement method, the method includes the following steps:

[0030] Preparation

[0031] 1) Reinforcement of igniter 8: In order to ensure the overall stability of the new igniter without deformation during hoisting, the igniter 8 should be reinforced, specifically, 25# channel steel should be welded vertically and horizontally at appropriate positions around the new igniter, and the old igniter should also be reinforced. Corresponding reinforcement;

[0032] 2) Preparation of hoisting tools: The following main hoisting tools should be prepared: one 50T winch, four 32T short-body screw jacks, two 300*3000mm H-shaped steel pieces, four 500*500*50mm steel plates, and 100 meters of 25MM diameter steel wire rope;

[0033] 3) Preparation of the trolley: Remove the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com