Hole reserving construction method for tightly-fixed steel sleeve

A construction method and a technology for reserving holes, which are applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of poor construction safety and economy, hole deformation, etc., and achieve saving raw materials and Production cost, green construction, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] The construction method of reserved holes for tight-set steel casing, the construction steps are as follows:

[0036] (1), construction preparation:

[0037] (1.1) Familiar with the construction drawings, draw the reserved drawings of the pipeline holes and the production drawings of the perforated steel casings, and prepare for the technical disclosure to the operators;

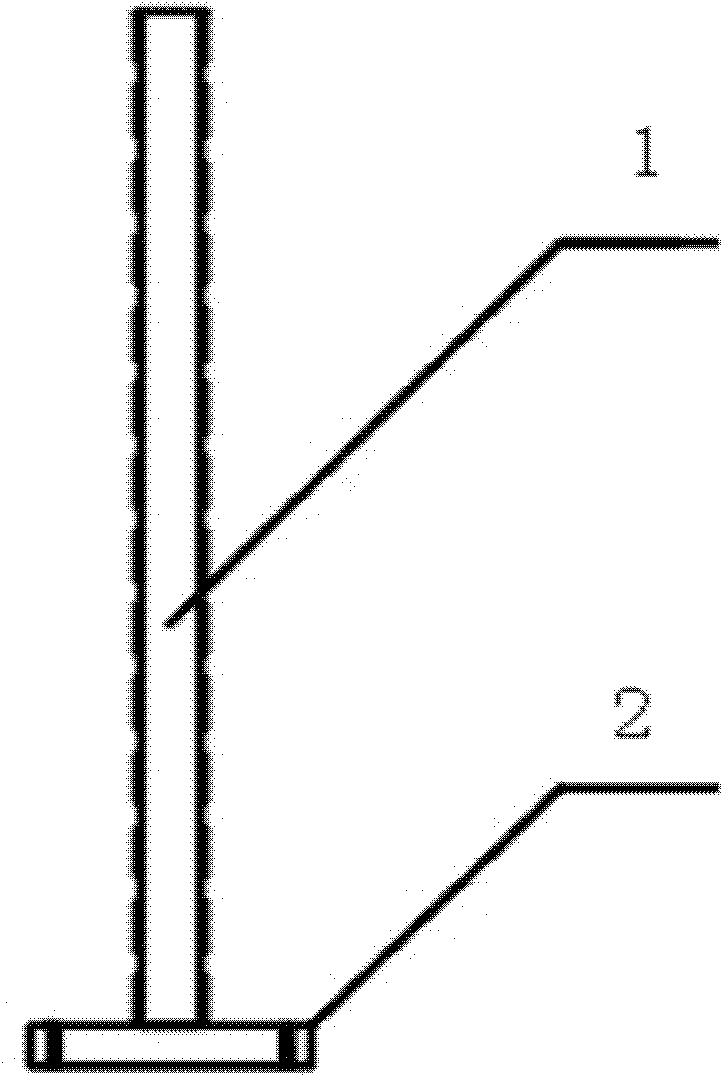

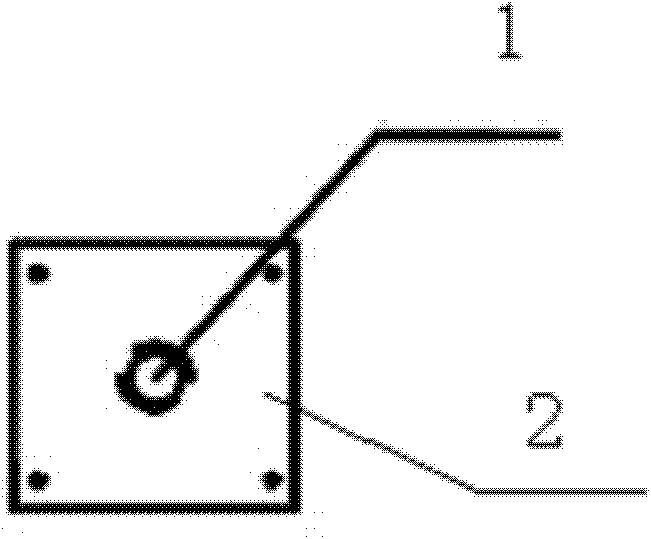

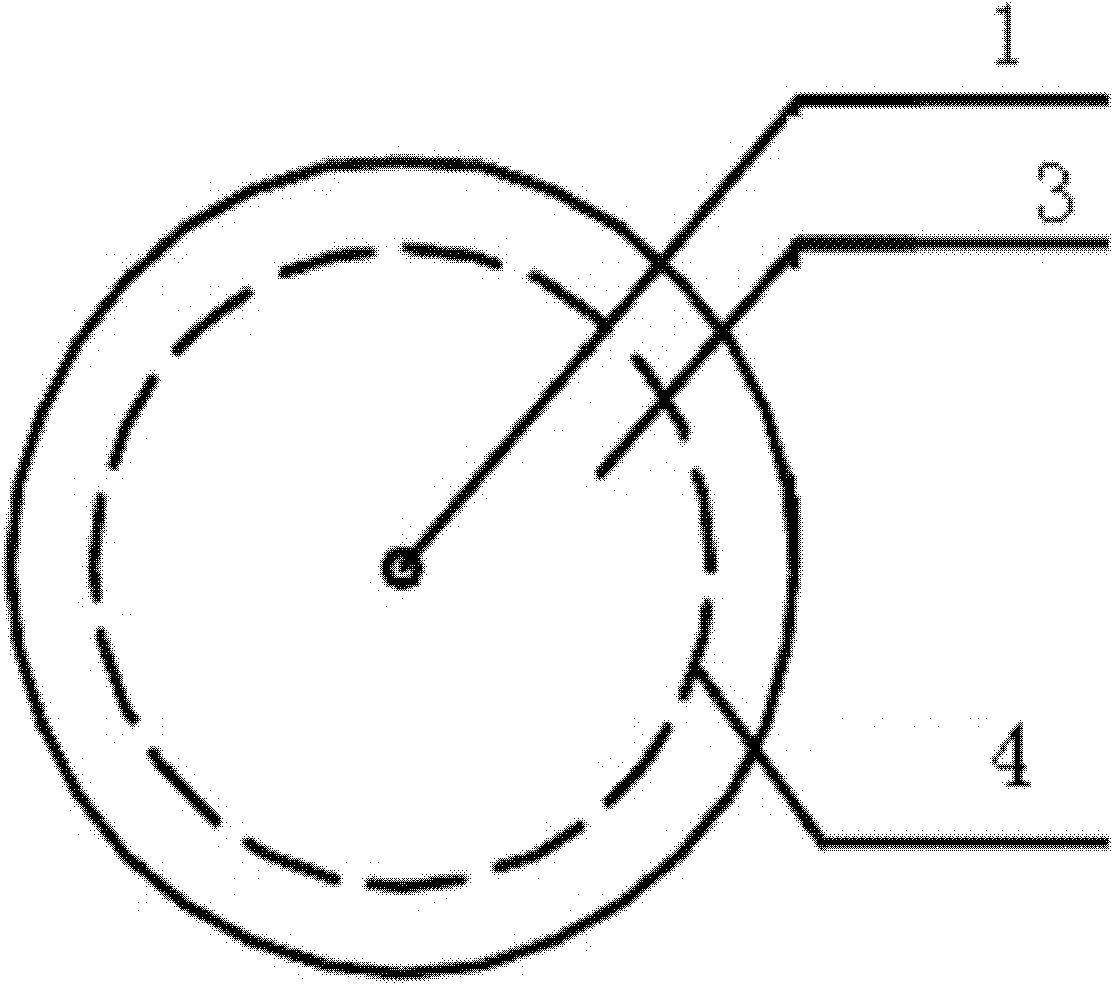

[0038] (1.2) Configure the perforated steel casing that needs to be positioned, and process and manufacture the perforated steel casing according to the specification requirements and the drawings of the perforated steel casing. The perforated steel casing is composed of positioning screw 1, positioning screw base 2, and retaining Hole steel casing body 4, casing top cover 3 and nut 5 are composed, figure 1 , figure 2 and image 3 ;

[0039] (1.3) Configure the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com