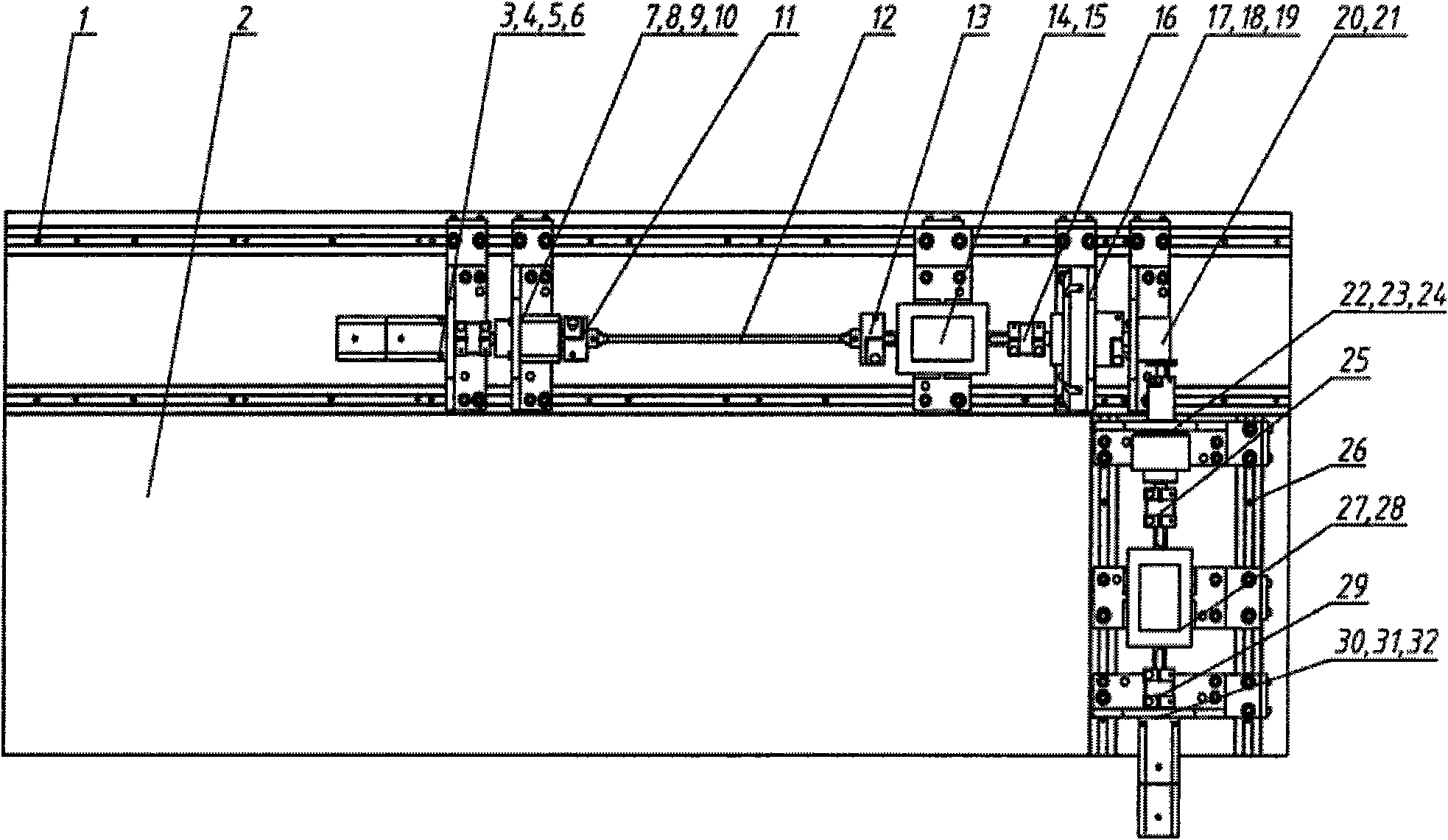

Experiment table for detecting dynamic characteristics of harmonic reducers

A technology of harmonic reducer and dynamic characteristics, applied in the field of harmonic reducer performance test bench, can solve problems such as difficulty in ensuring installation accuracy, low degree of automation, multiple tooling, etc., and achieve a wide range of test models and a high degree of automation High effect of high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

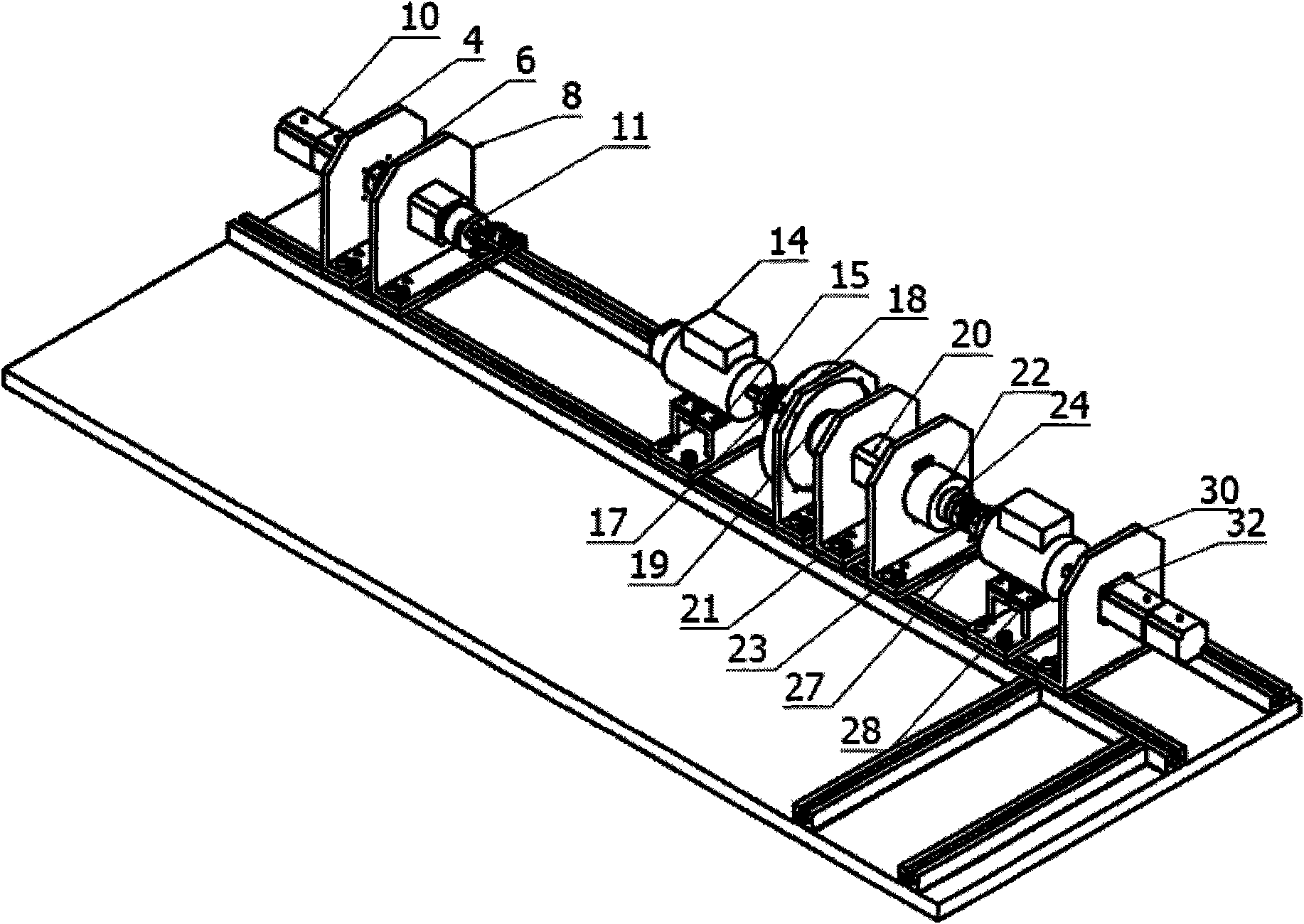

[0013] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

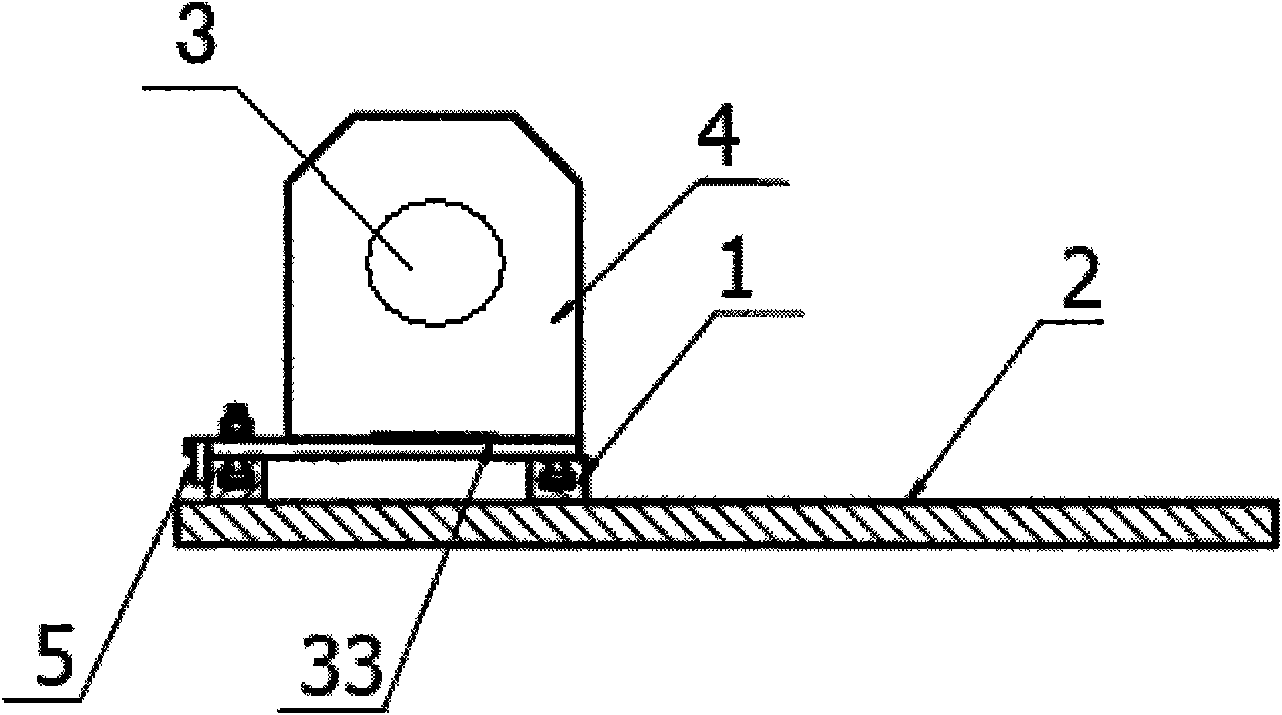

[0014] see figure 1 , a universal harmonic reducer performance test bench, including long and short guide rails 1, 26 installed on the bottom plate 2 perpendicular to each other, the X-direction servo motor 3 is installed on the motor bracket 4 through the seam, and the motor bracket 4 is positioned by The block 5 and the bolts are positioned and fixed on the long guide rail 1, and the servo motor 3 is connected with the servo harmonic reducer 7 through the elastic coupling 6. The follow-up harmonic reducer 7 is installed on the long guide rail 1 through the installation frame 8, the positioning block 9 and the bolt 10. Rigid couplings 11 , 13 connect the torsion bar 12 with the drive harmonic reducer 7 and the torque sensor 14 . The torque sensor 14 is installed on the long guide rail 1 through a support 15 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com