Patents

Literature

37results about How to "Easy to install and detect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

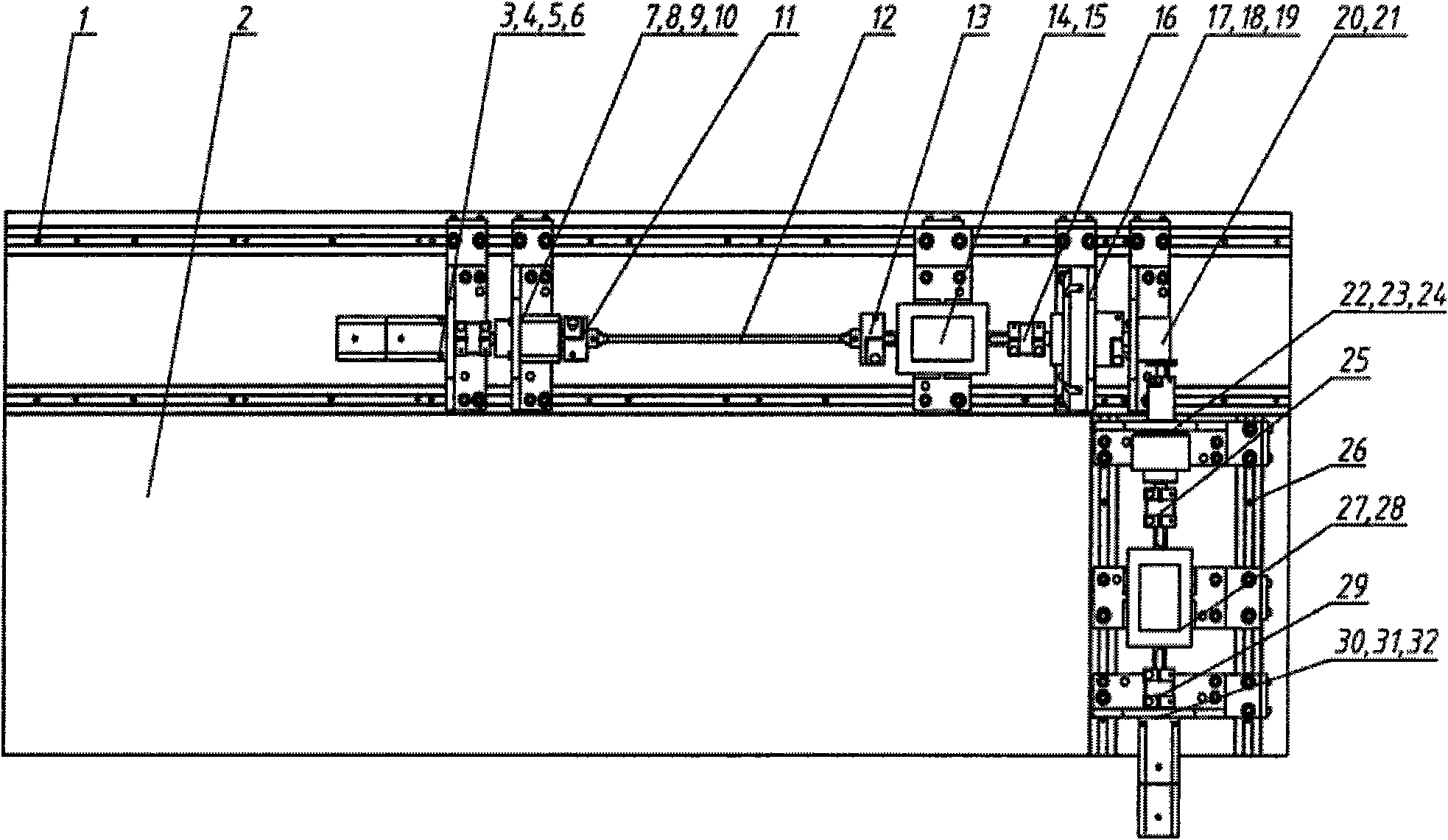

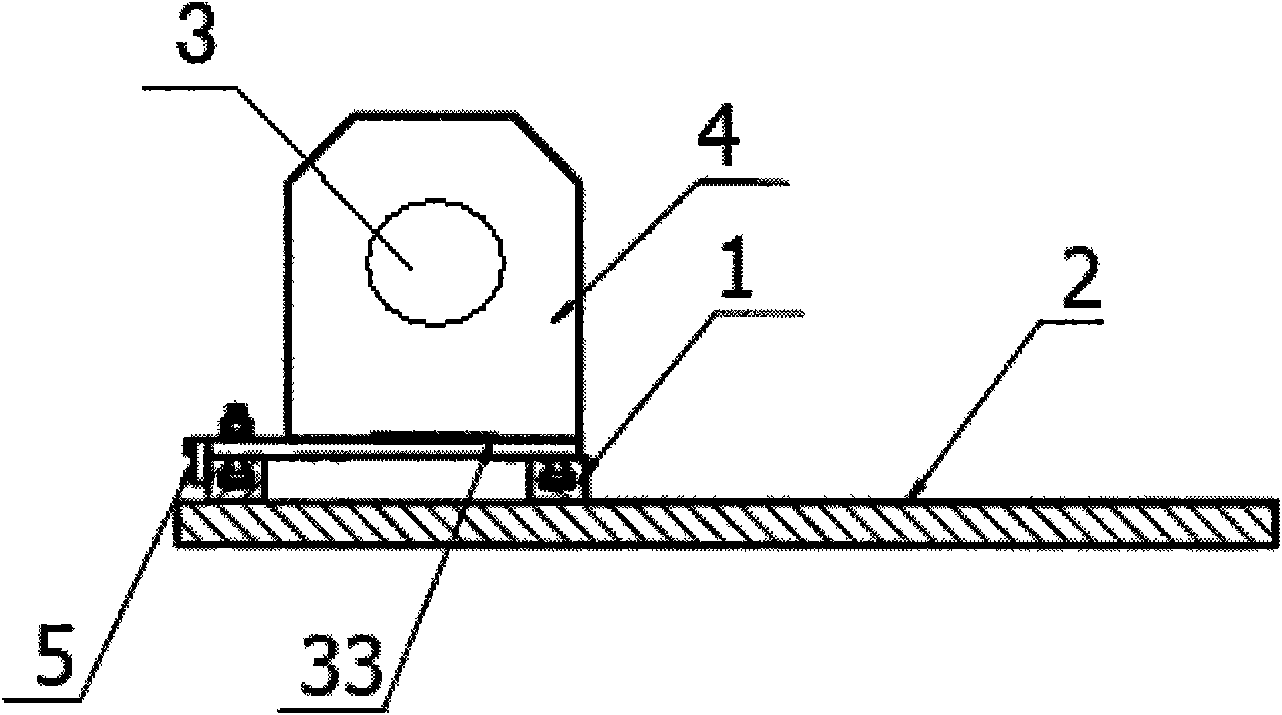

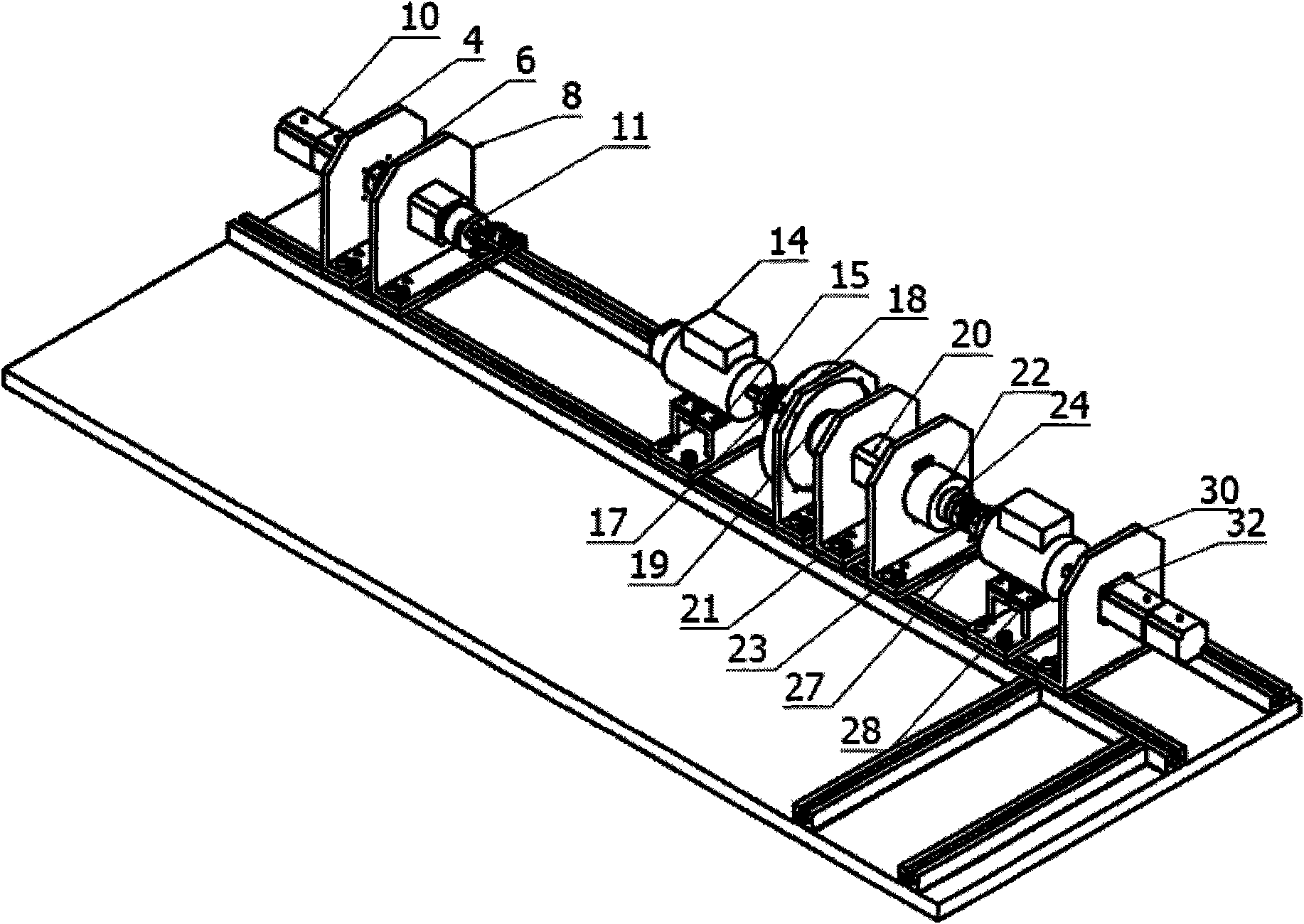

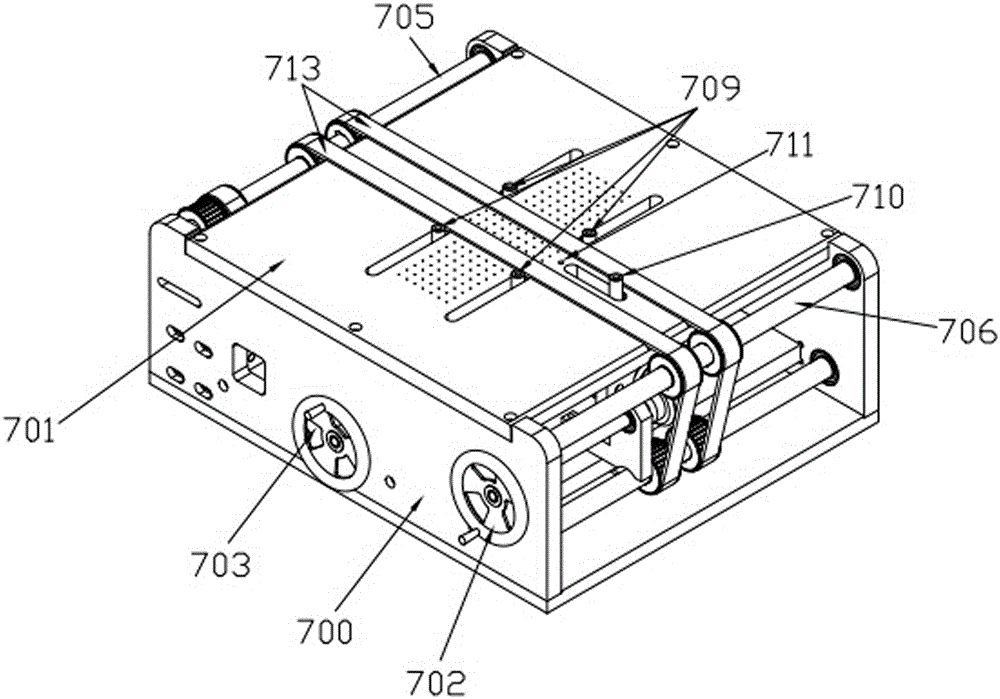

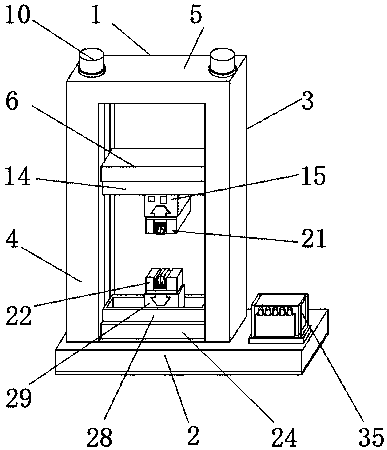

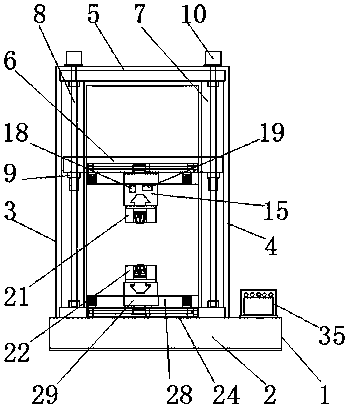

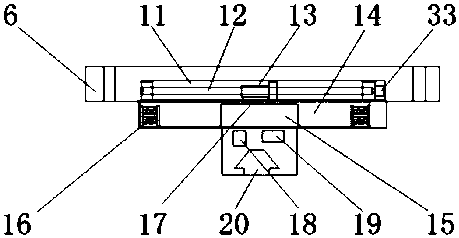

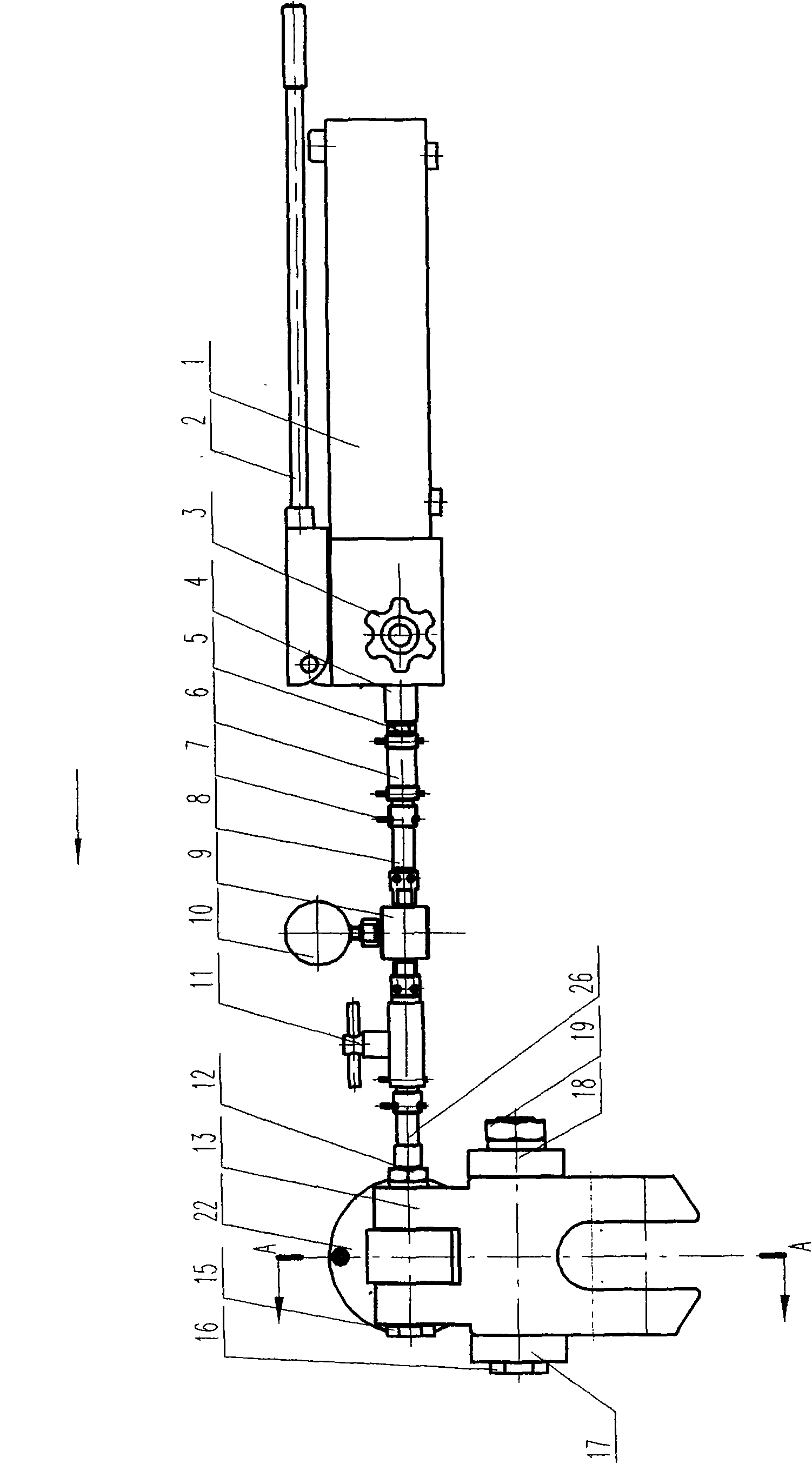

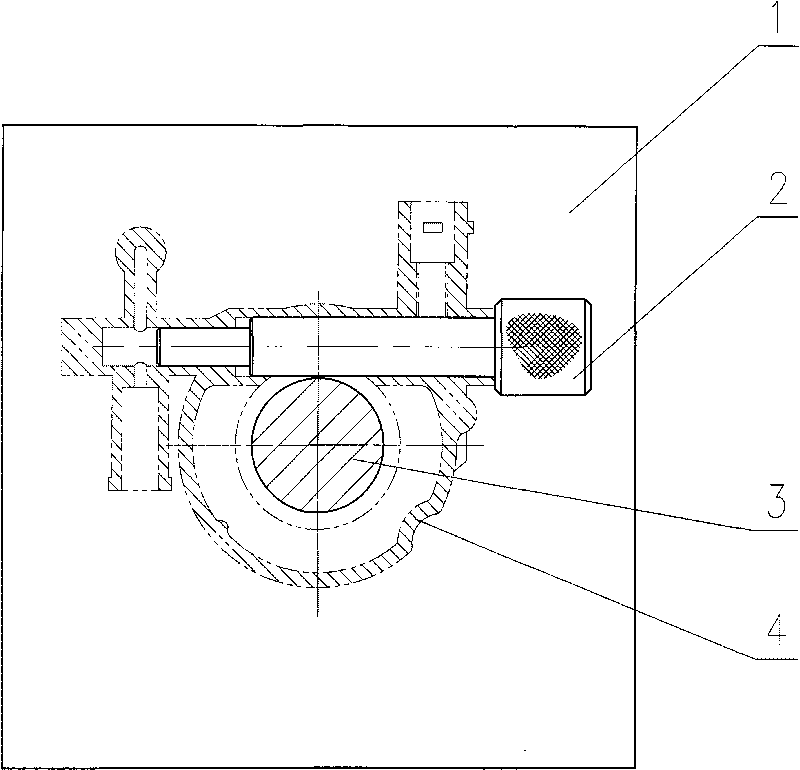

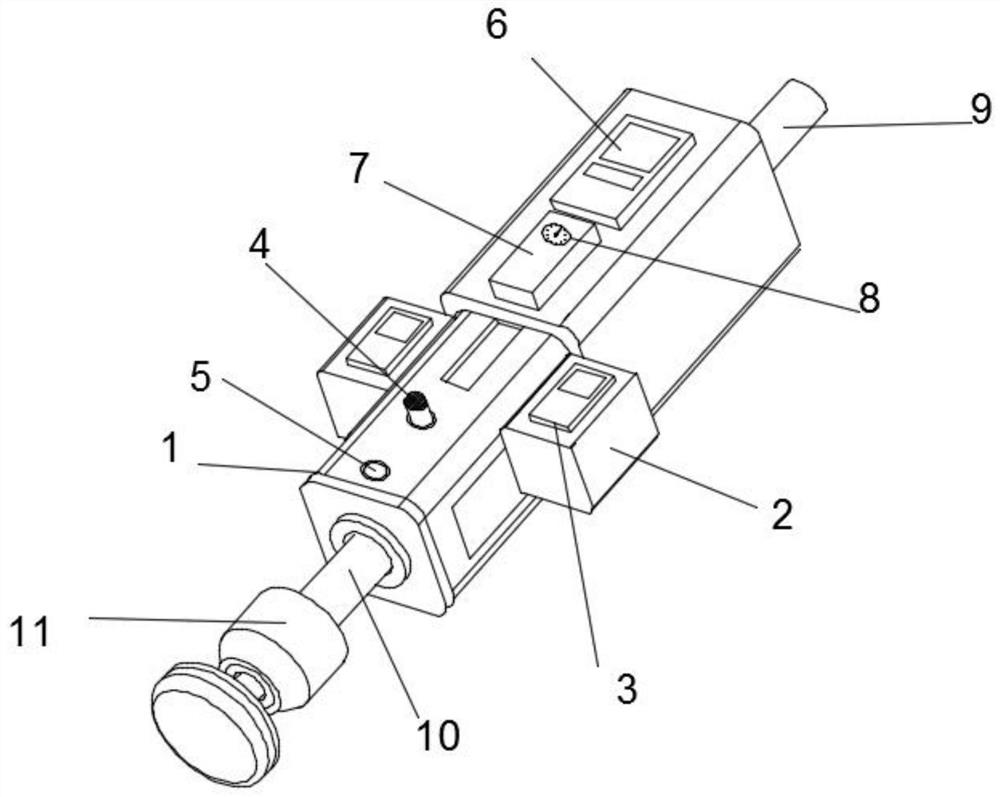

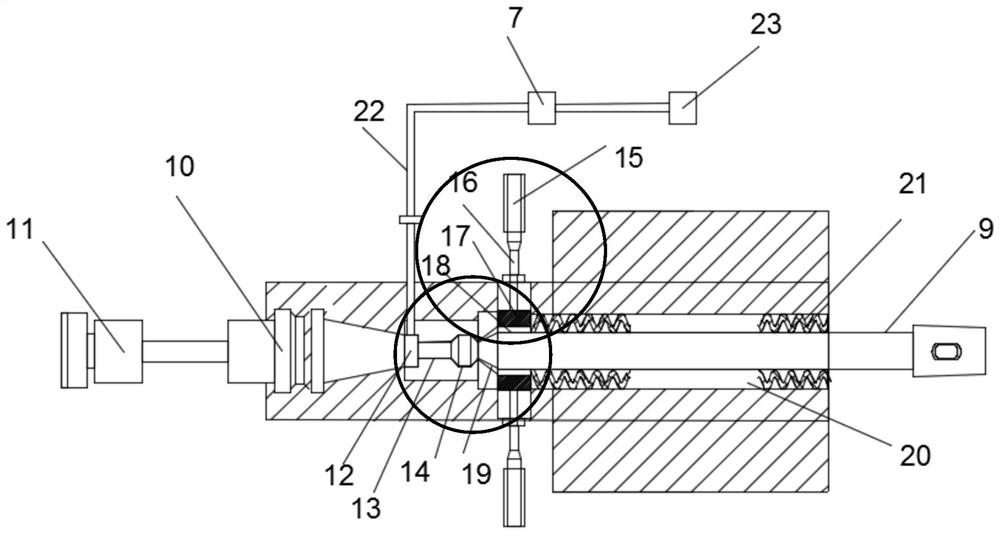

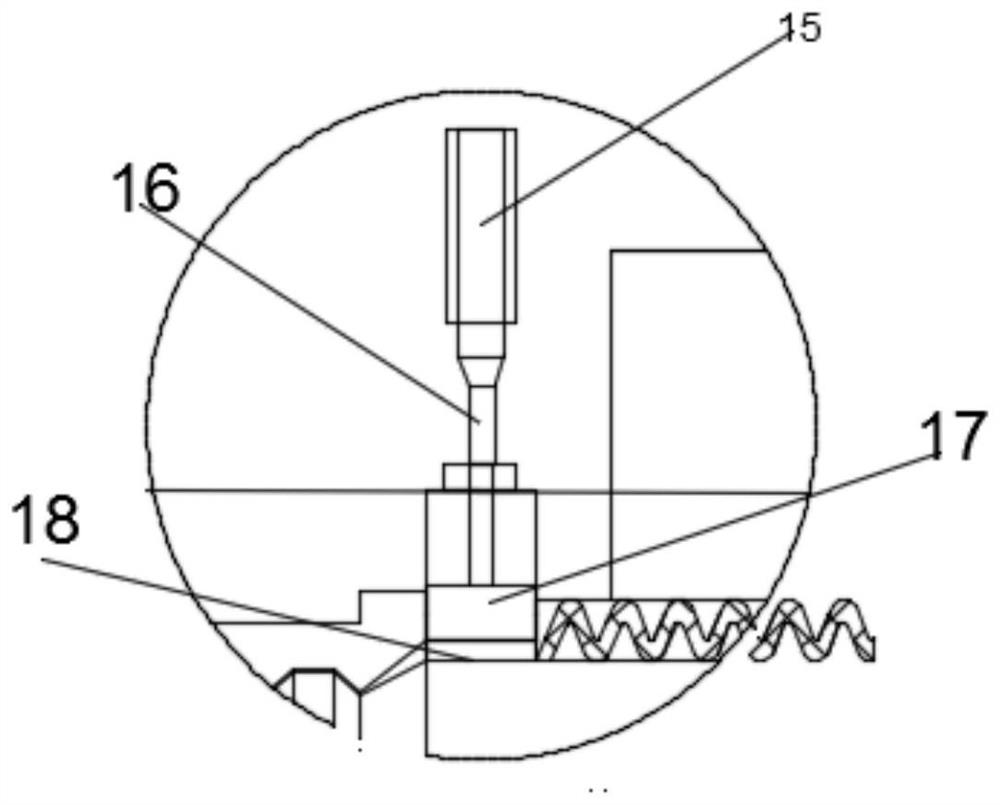

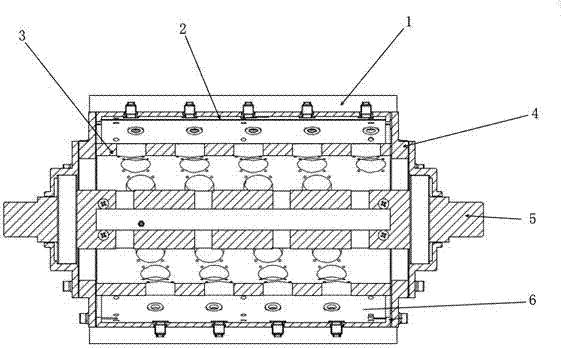

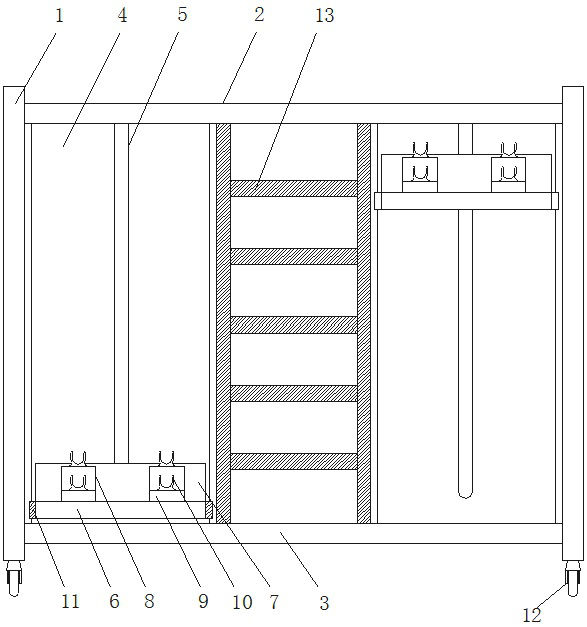

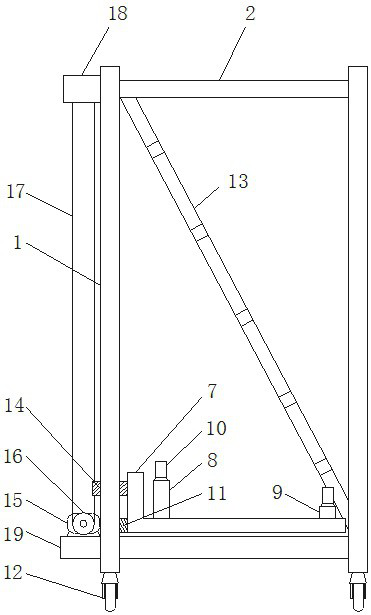

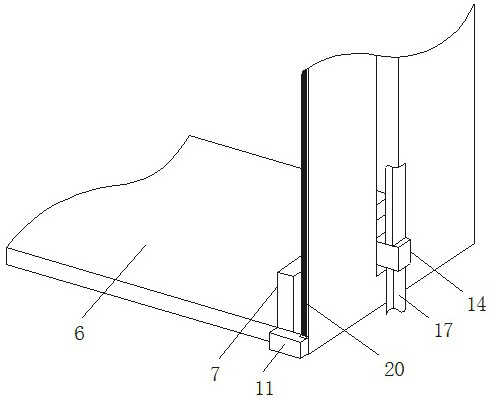

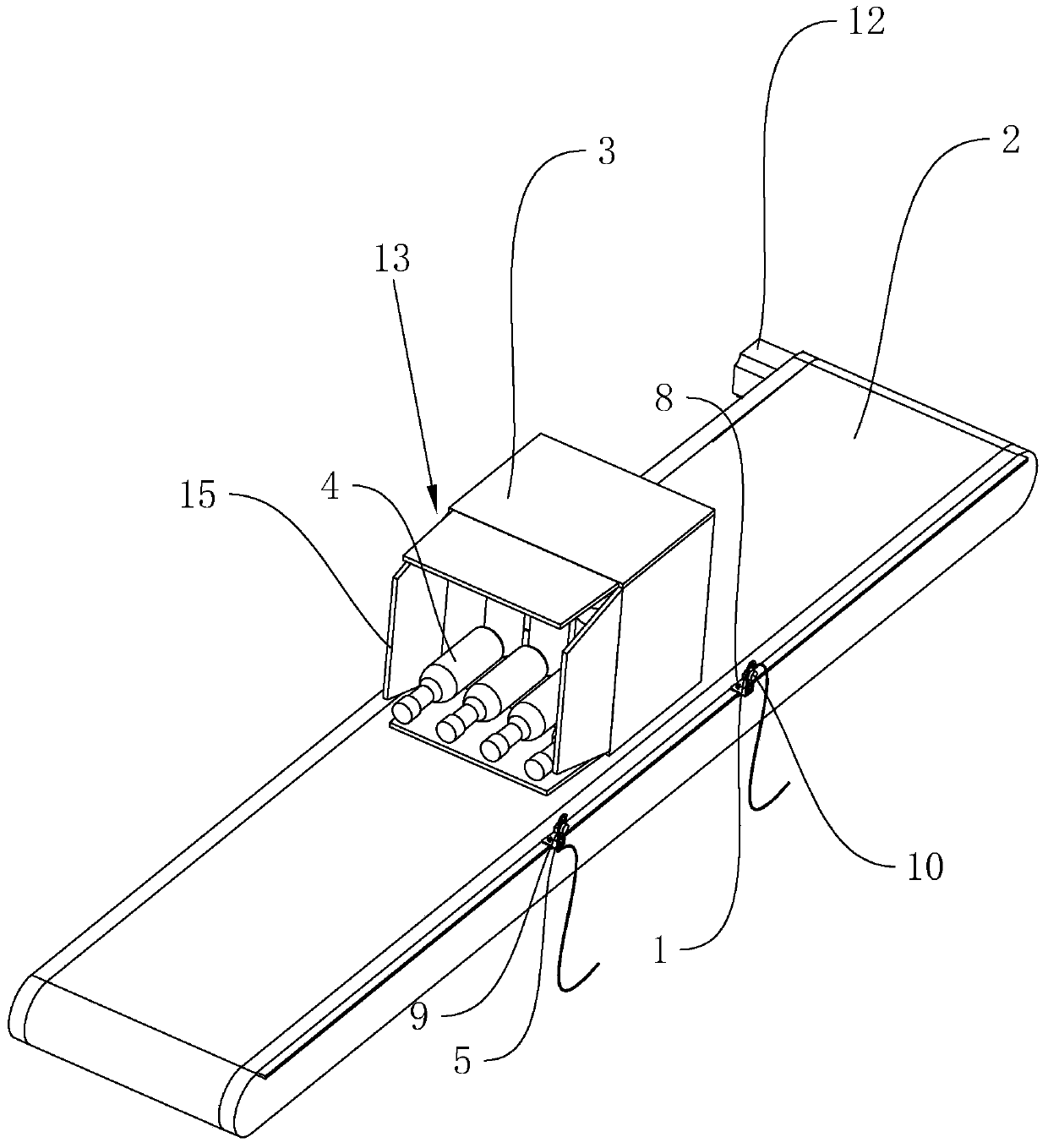

Experiment table for detecting dynamic characteristics of harmonic reducers

InactiveCN101587015AImprove versatilityWide range of test modelsMachine gearing/transmission testingHarmonicReduction drive

The invention discloses an experiment table for detecting dynamic characteristics of harmonic reducers, which comprises an X guide rail arranged on a bottom plate, as well as a first servo motor, wherein the first servo motor is fixed on the X guide rail and is axially connected with a follow-up harmonic reducer; the follow-up harmonic reducer is fixed on the X guide rail and is axially connected with a first torque sensor through a first torsion bar; the first torsion bar sensor is axially connected with a first angle measuring device; the first angle measuring device is connected with a first connecting shaft; and a detected harmonic reducer is arranged on the X guide rail through a mounting bracket and a positioning piece. The experiment table is characterized in that a Y guide rail perpendicular to the X guide rail is arranged on the bottom plate; when the detected harmonic reducer is a right-angled reducer, a second angle measuring device is arranged on the Y guide rail and is axially connected with a second torque sensor; and the second torque sensor is axially connected with a second servo motor. The experiment table has the advantages of good universality and capability of completing the task of testing the dynamic characteristics of a plurality of detected harmonic reducers on one experimental device.

Owner:XI AN JIAOTONG UNIV

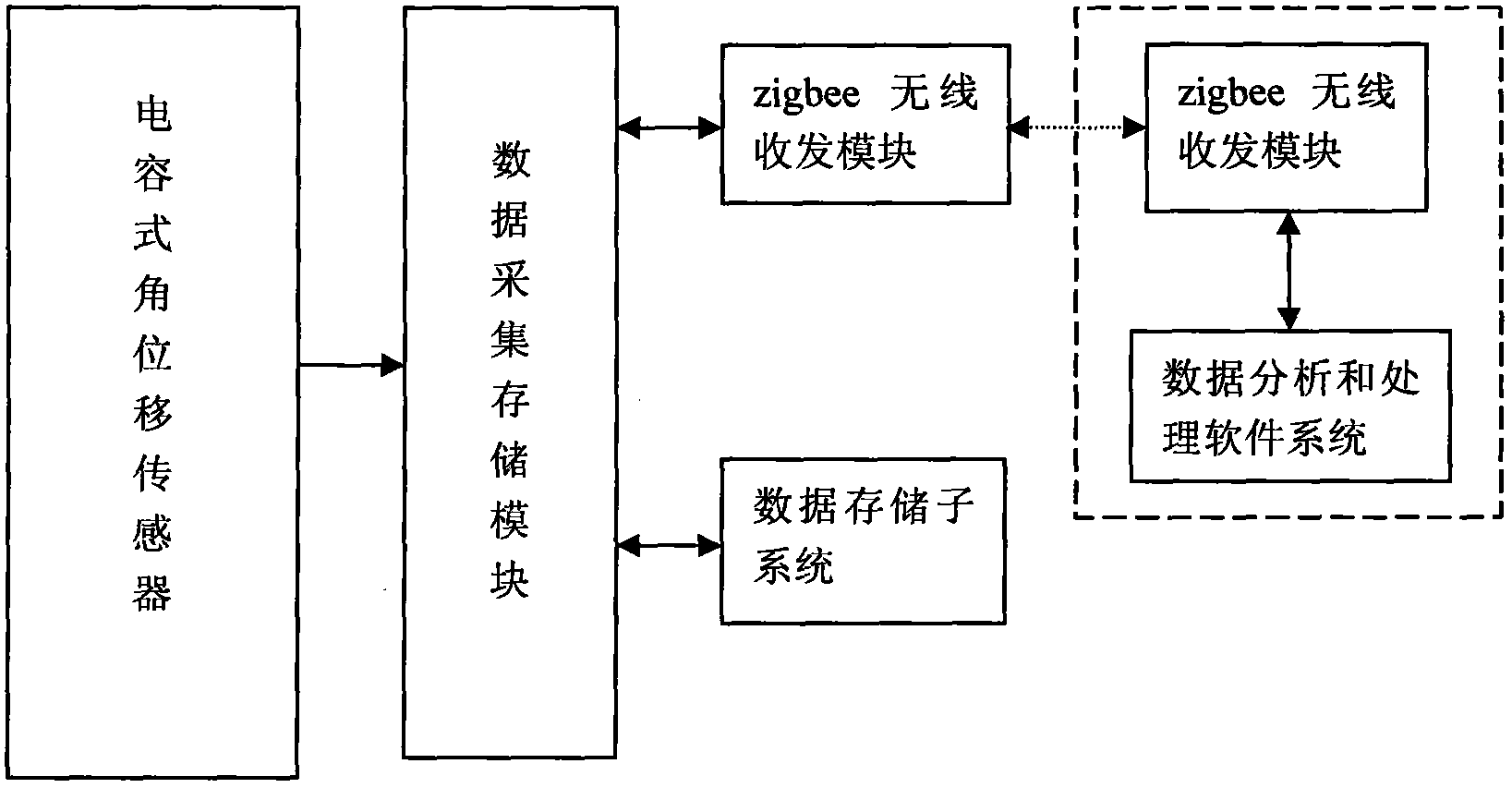

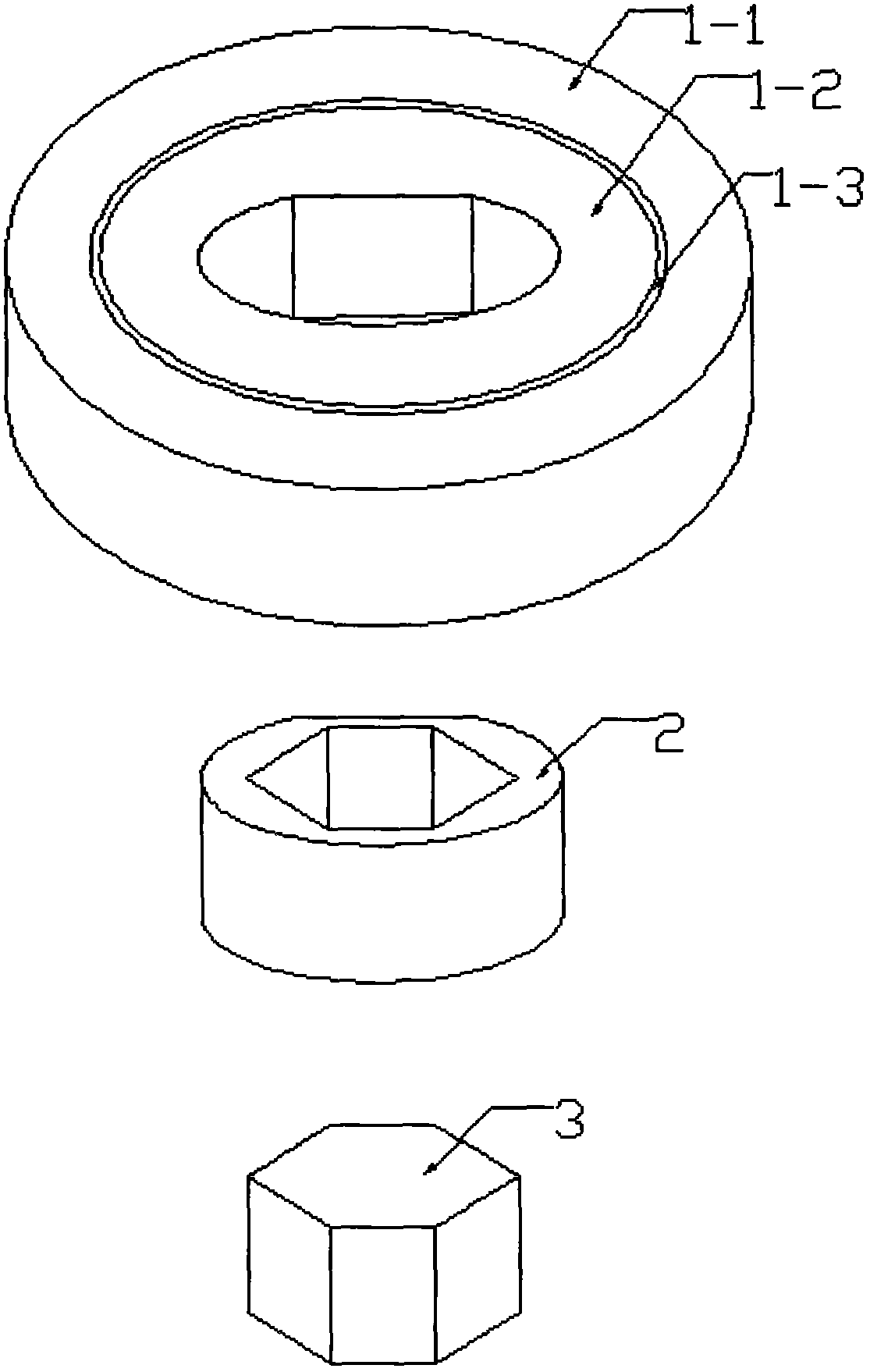

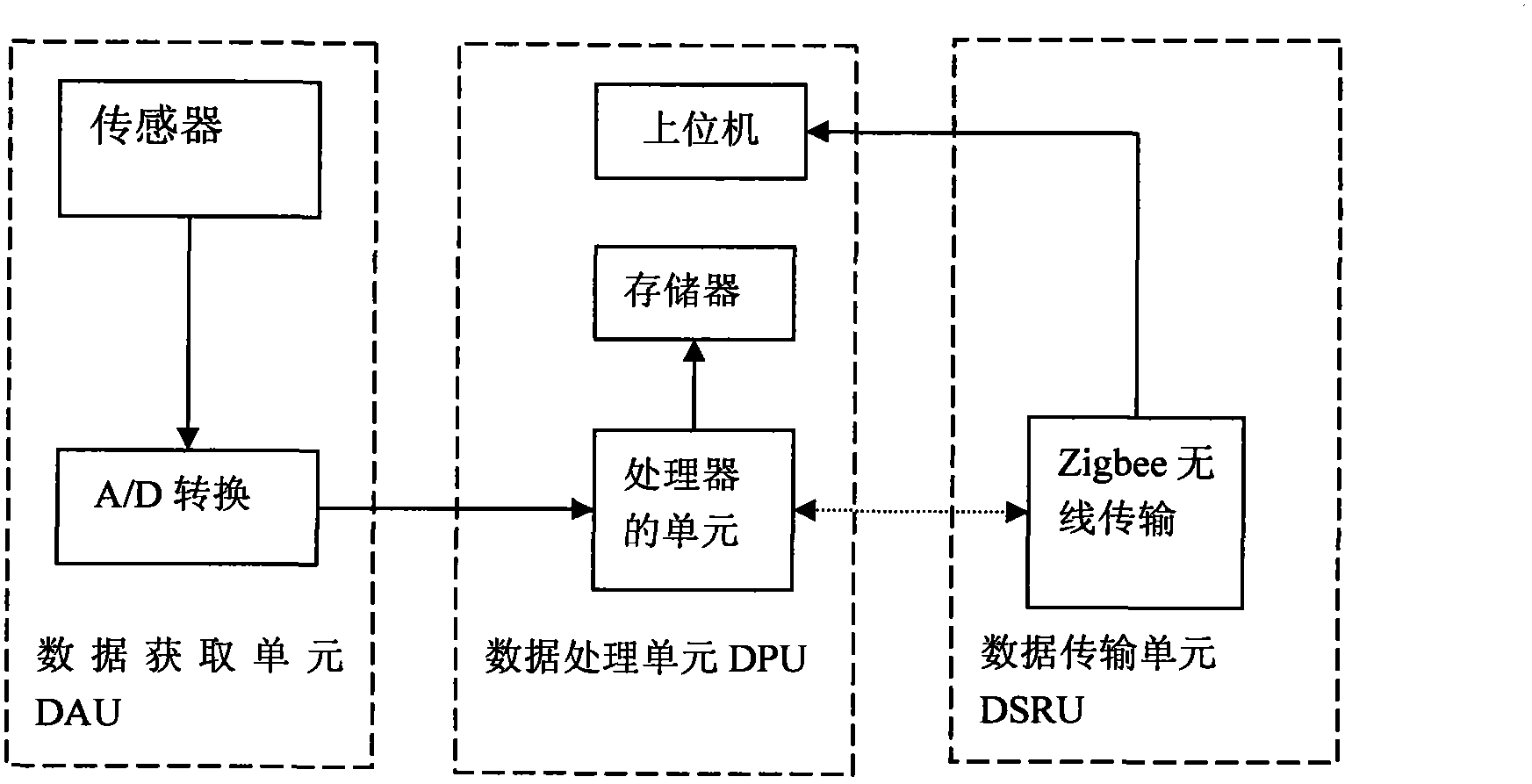

Bolt looseness detecting device of pantograph type current collector of high-speed train

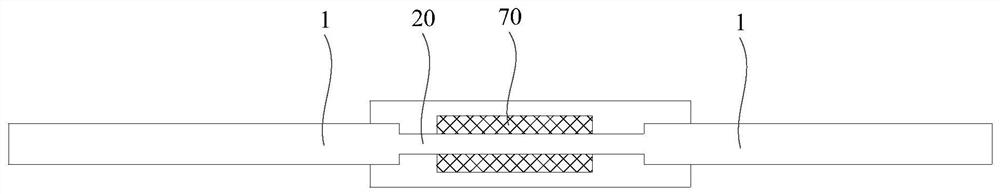

InactiveCN102706504AAvoid other external forcesEasy to install and detectTransmission systemsMeasurement of torque/twisting force while tighteningCapacitanceDynamic monitoring

The invention relates to a bolt looseness detecting device of a pantograph type current collector under travel of a high-speed train. The device provided by the invention comprises a sensor module, a data gathering and storing module, a wireless network transmission module, a data processing module, and the like. The sensor module is a capacitance angular displacement sensor and is separately designed for dynamic monitoring of a lower bolt of the pantograph type current collector; the data gathering and storing module utilizes an A / D (analog-to-digital) converter chip to gather multiple access signals, stores data in real time and then sends the data to the wireless network transmission module at the rear end; the wireless network transmission module is constructed by the Zigbee network and is used for sending angular displacement detection data from the outer part of the train to the inner part of the train; and the data processing module is used for analyzing and processing bolt looseness angular displacement index test data, compares and analyzes received data and built-in standard data and displays the bolt looseness state.

Owner:SOUTHWEST JIAOTONG UNIV

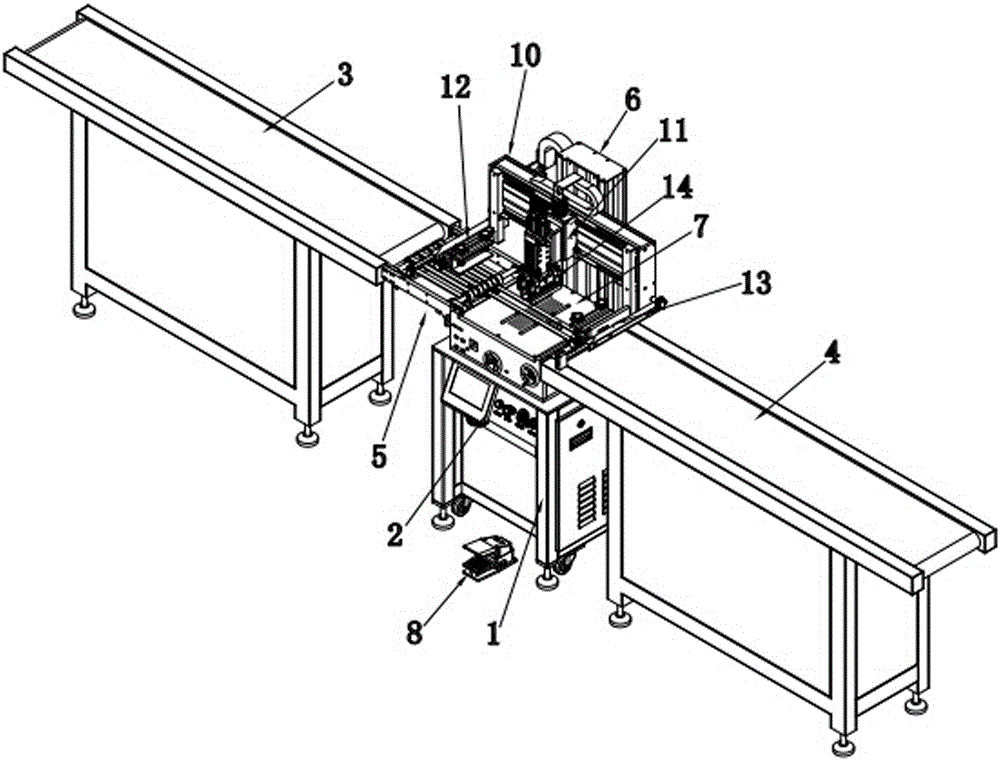

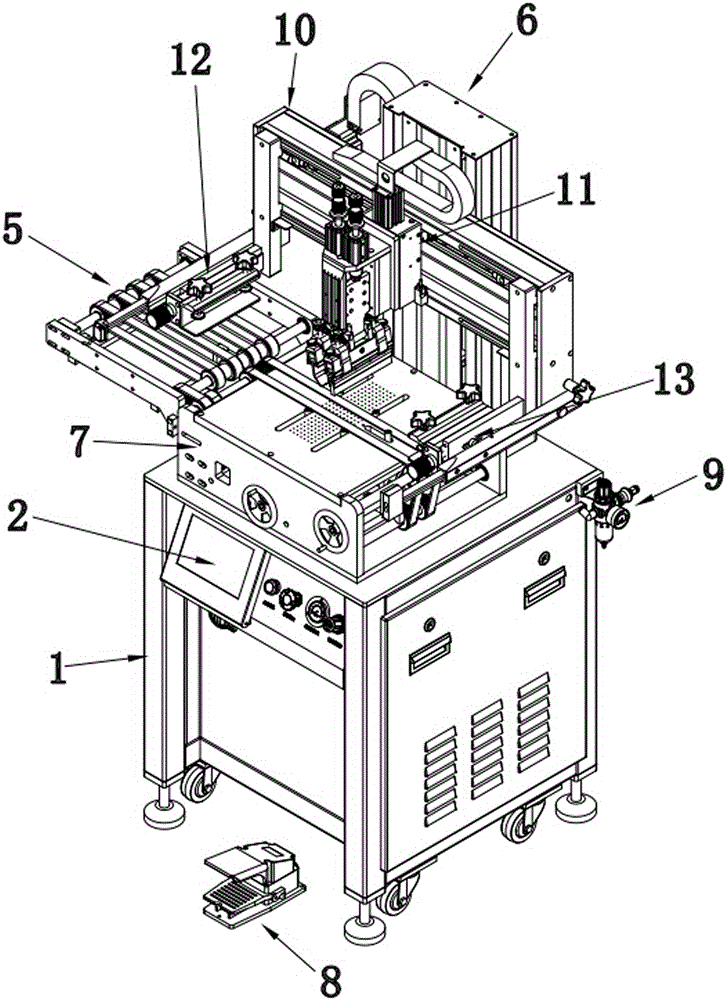

Silkscreen machine with automatic positioning function

ActiveCN105034554APrecise positioningSize is easy to controlScreen printersHuman–machine interfaceAssembly line

The invention discloses a silkscreen machine with an automatic positioning function and belongs to the technical field of printing equipment. The silkscreen machine comprises a rack of the silkscreen printer and an interface operation system arranged on the rack. At least one feeding conveying belt and at least one discharging conveying belt are arranged on the left side and the right side of the rack. The silkscreen machine further comprises a conveying frame, a lifting column, a positioning workbench, a footbrake switch and an oil mist filter. A printing base transverse beam capable of vertically moving along the lifting column is arranged on the lifting column. A printing base capable of moving leftwards and rightwards along the printing base transverse beam is arranged on the printing base transverse beam. The printing base transverse beam is composed of two symmetrical transverse arm side cover plates, an upper transverse plate and a lower transverse plate, wherein the upper transverse plate and the lower transverse plate are arranged between the two transverse arm side cover plates. A left screen arm and a right screen arm which extend outwards are symmetrically arranged along the bottoms of the two transverse arm side cover plates. Charging is carried out in an assembly-line automatic feeding mode, so that printing precision is improved, the speed is high, and noise is low. A human-computer interface is controlled digitally, and various functions and operation parameters can be set.

Owner:广东恒锦智能装备有限公司

Method for assembling rotary kiln

ActiveCN102706139AEasy, quick and accurate installationEasy to install and detectRotary drum furnacesEngineeringRotary kiln

The invention relates to a method for assembling a rotary kiln. The method for assembling the rotary kiln includes steps: respectively marking out end face center points on two end faces of each section of a barrel of the rotary kiln pertinently; erecting a laser emitting device which emits laser beams according to the technique inclination of the rotary kiln; adjusting relative positions of the laser emitting device and a preset section so as to enable the laser beams to shoot the center points of the two end faces of the preset section provided with a transmission gear to establish a laser datum line; sequentially adjusting positions of the other sections except the preset section according to the distances from the other sections to the laser emitting device from near to far so that distances from the shooting position of the laser datum line on each end face to the center point of the end face in an X-direction and a Y-direction are within a preset error range; and fixedly connecting the sections. By the aid of the technical scheme of the method for assembling the rotary kiln, the rotary kiln can be conveniently and rapidly assembled, measuring accuracy can be improved, deviation is avoided to the greatest extent, and design requirements of the rotary kiln are met.

Owner:中色十二冶金建设有限公司

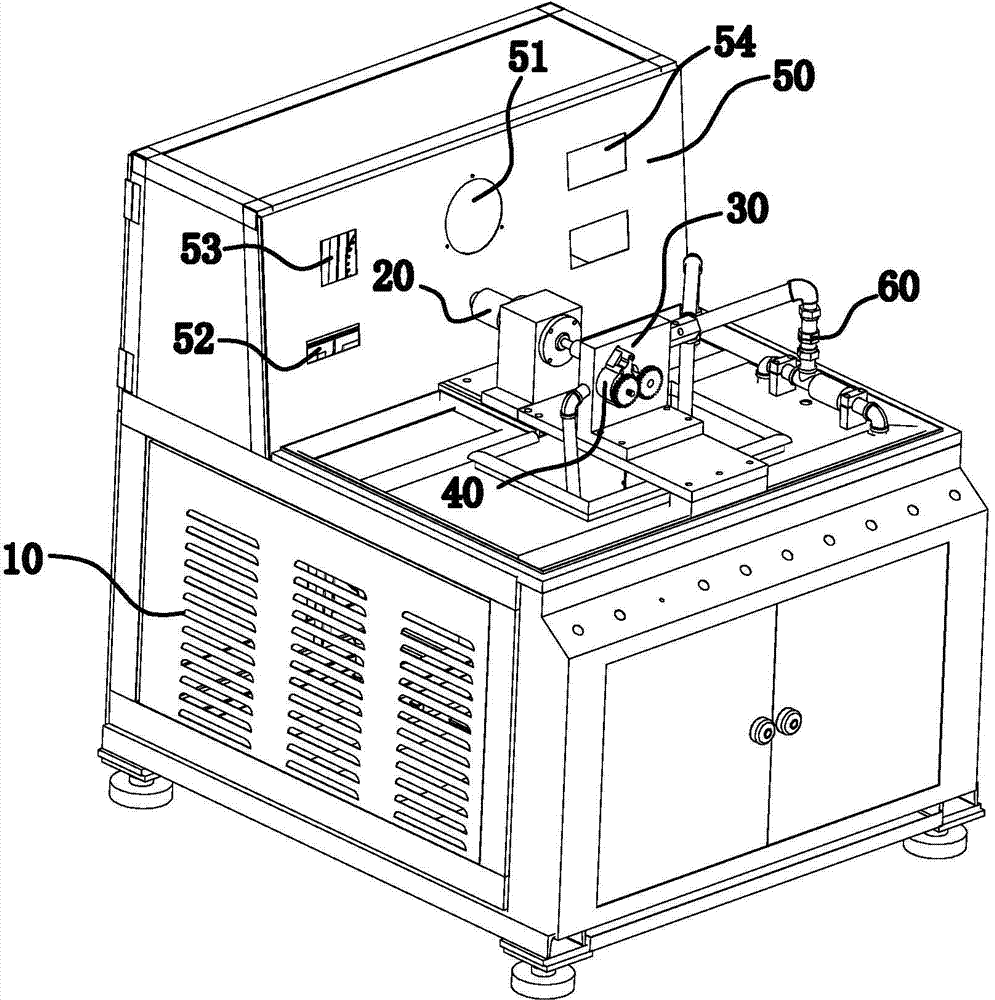

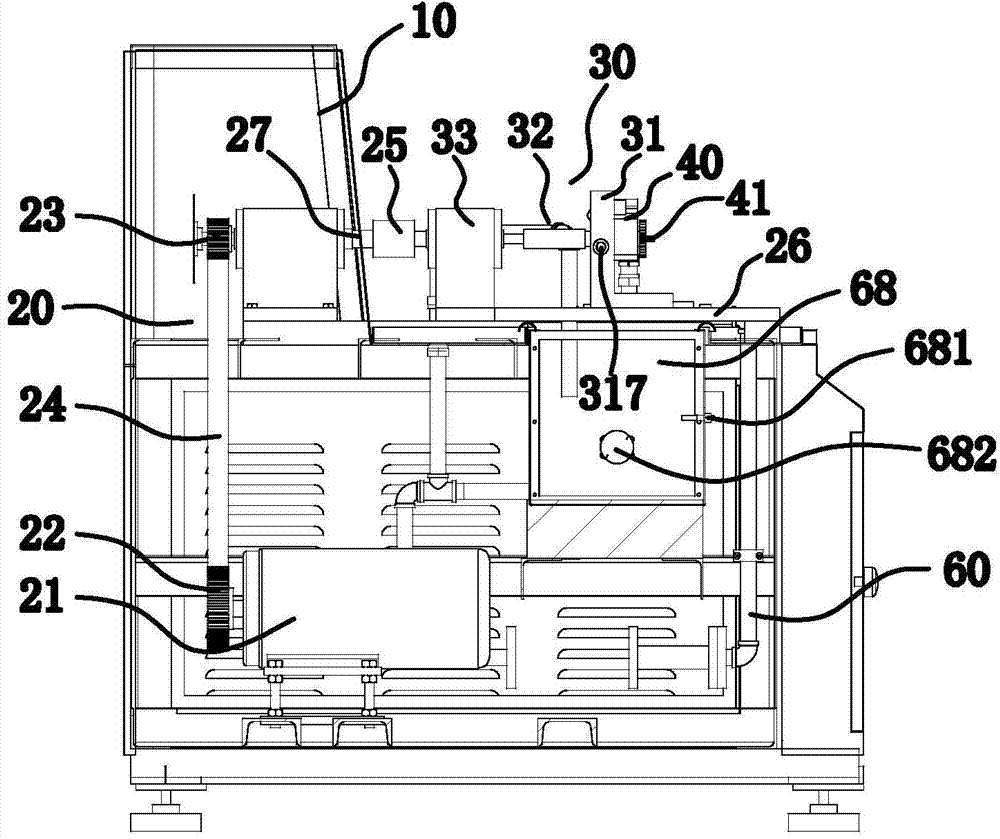

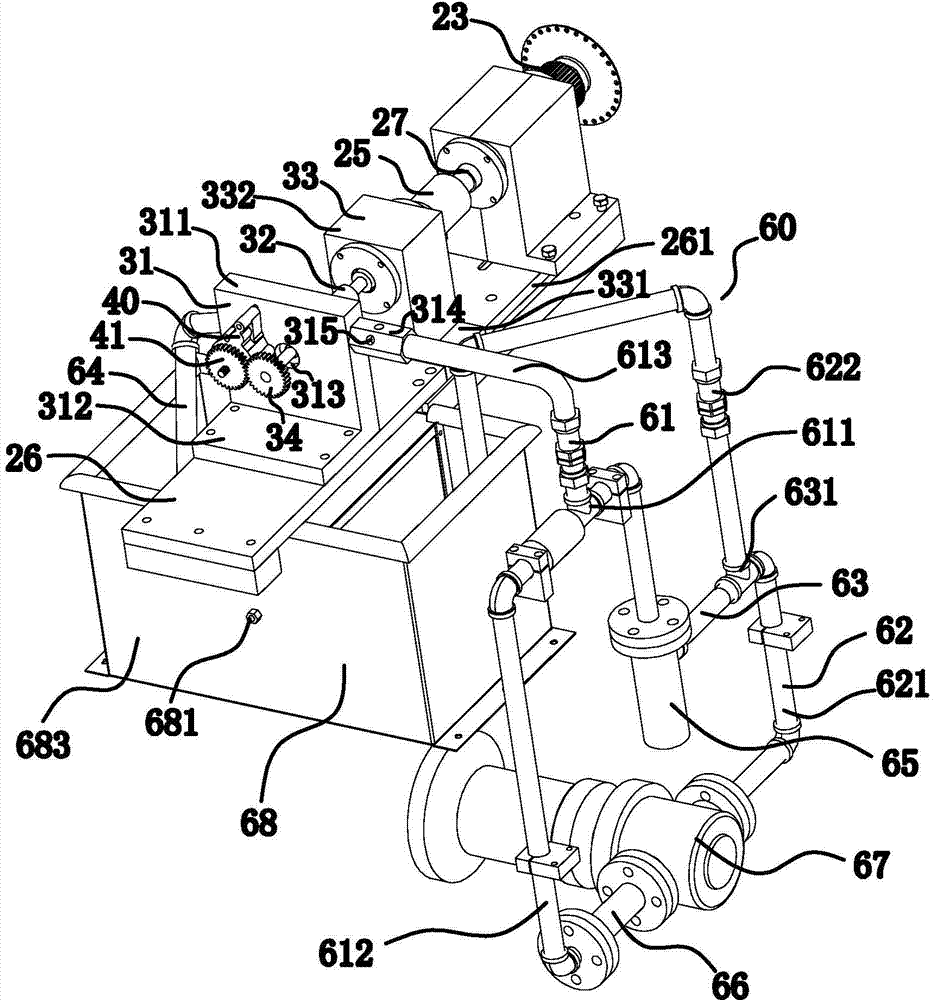

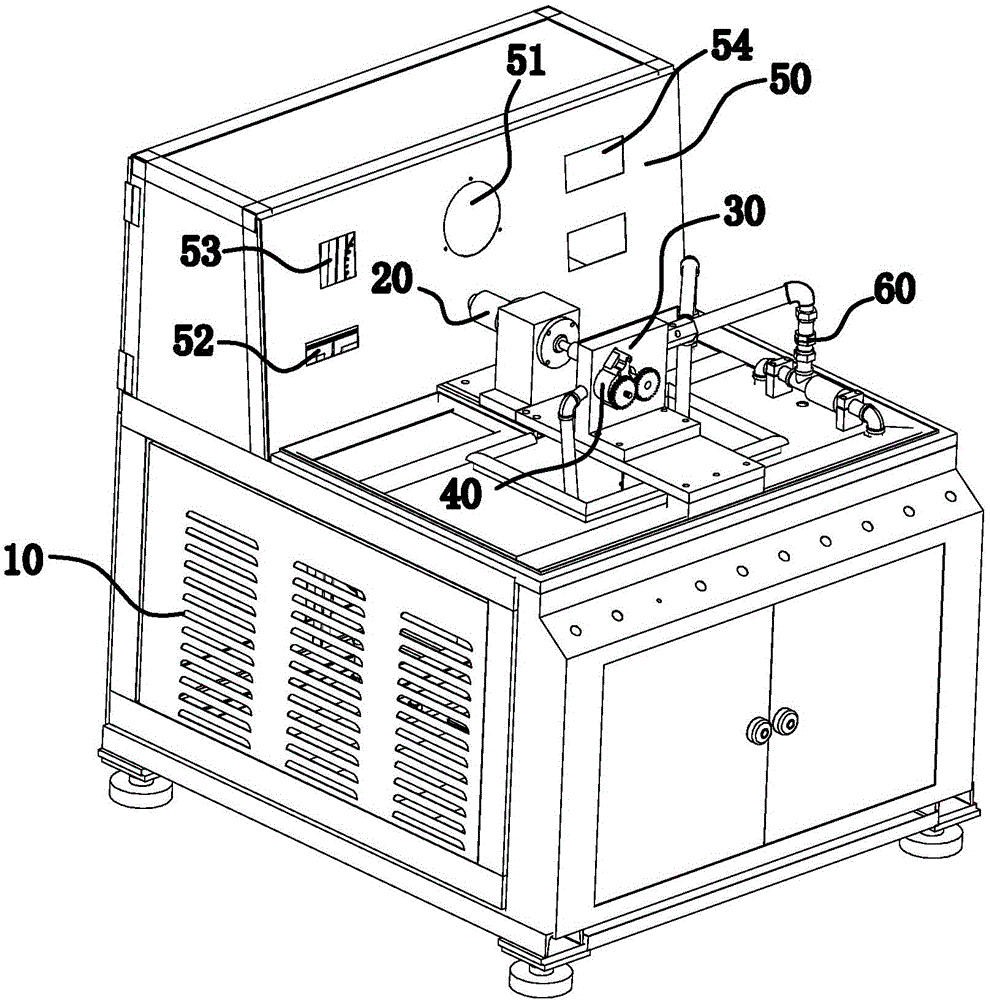

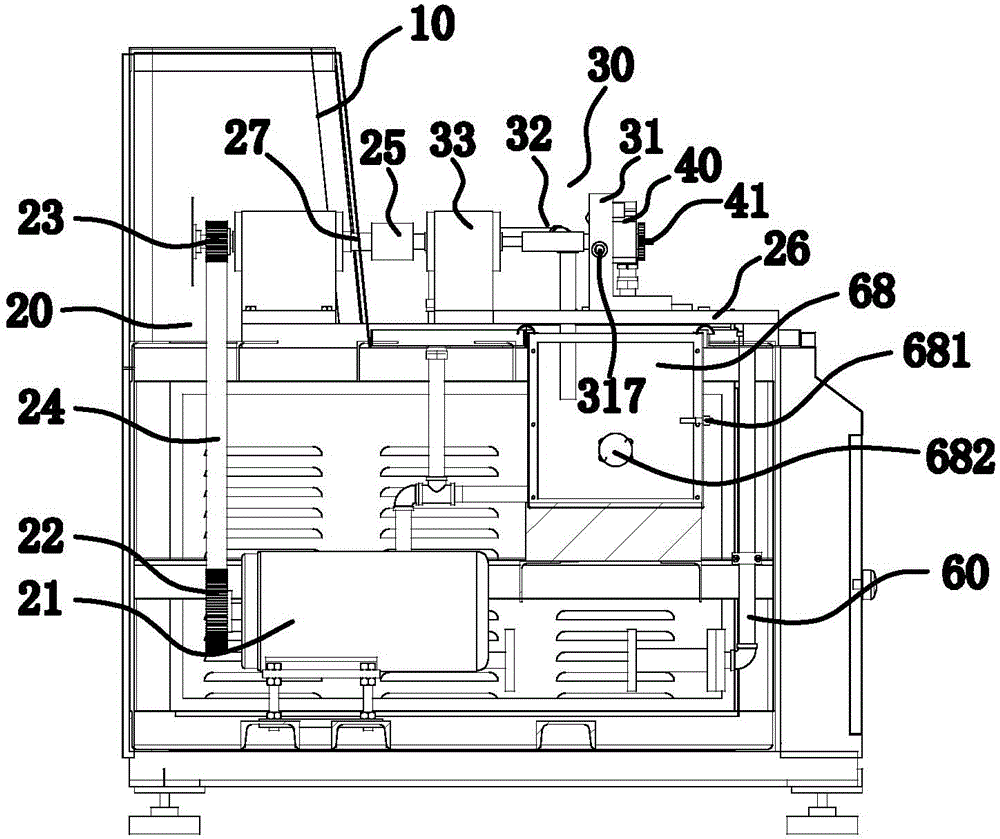

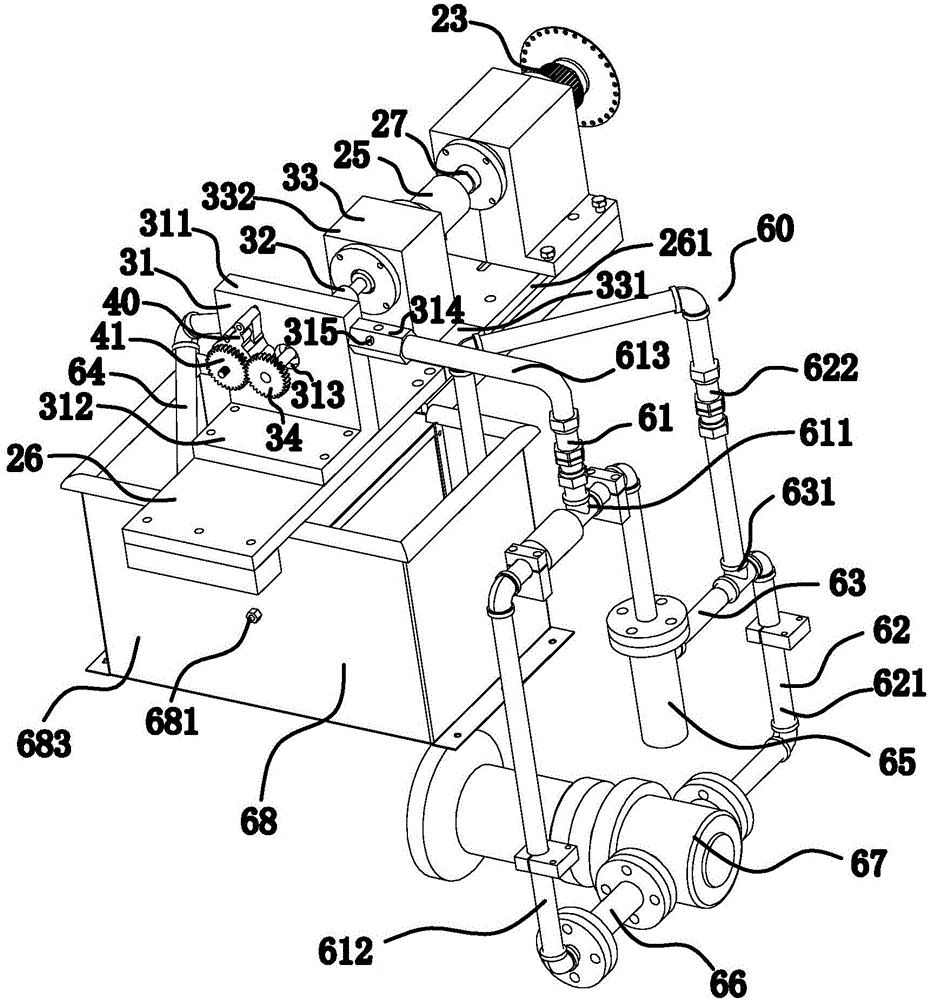

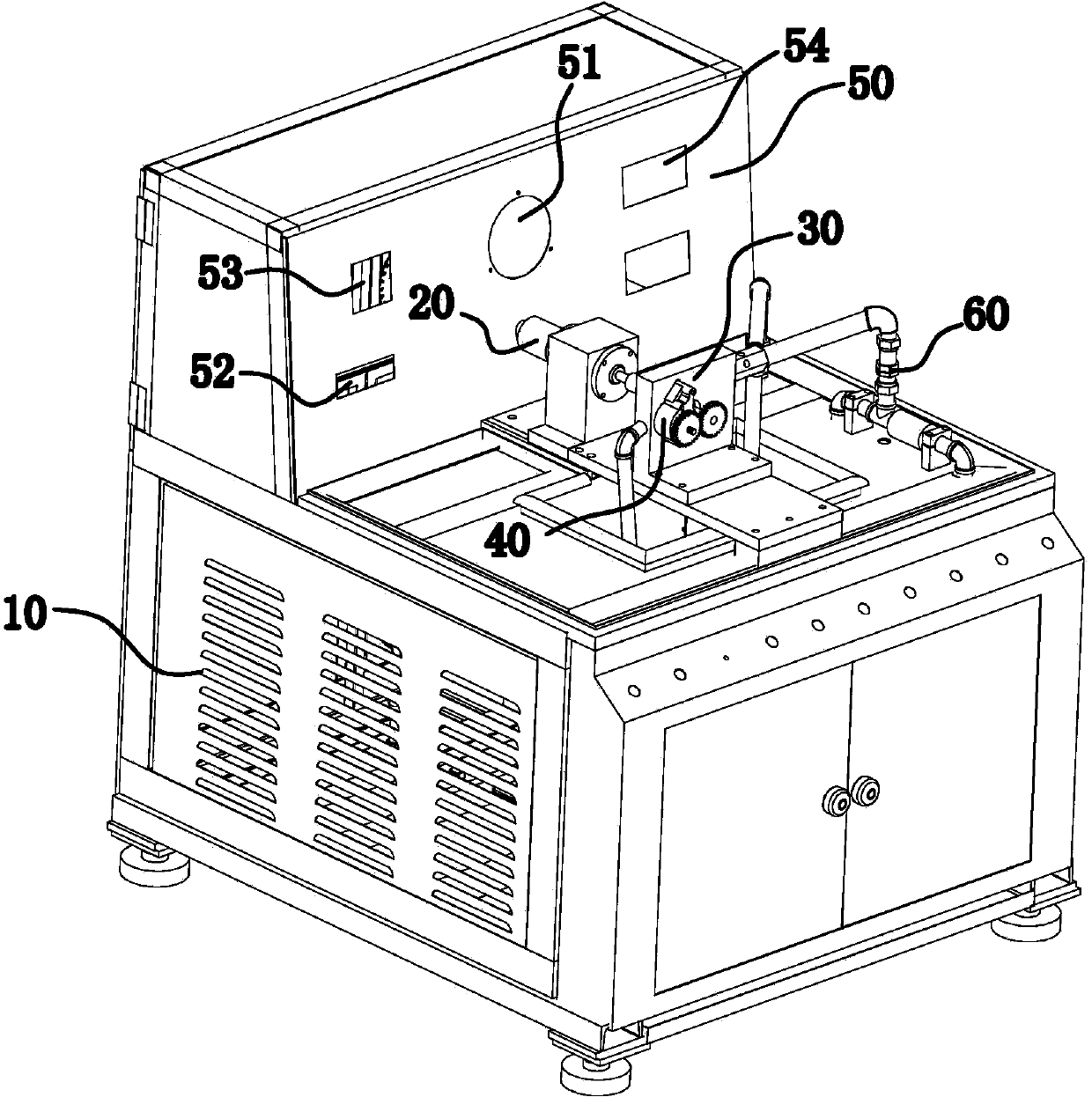

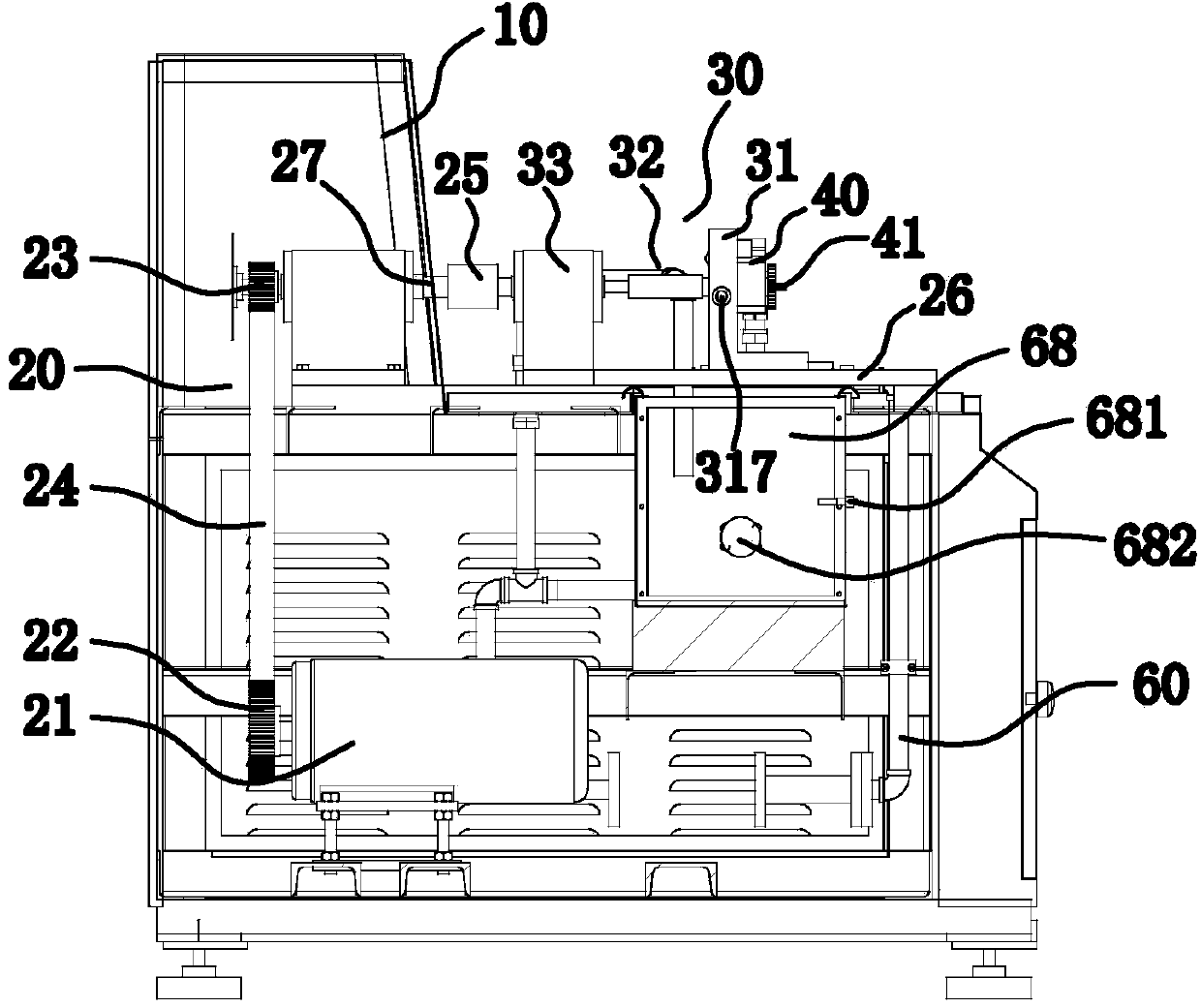

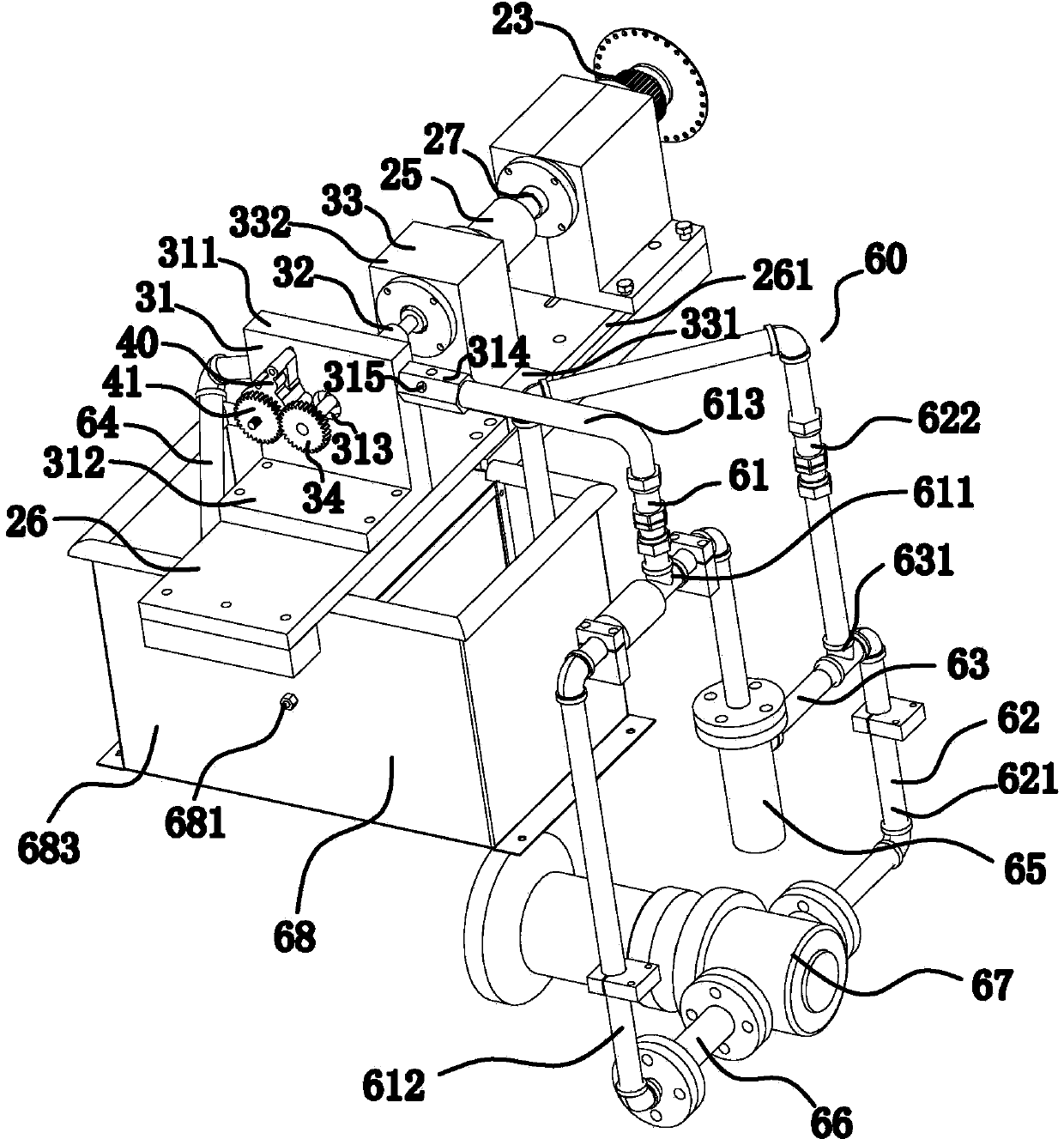

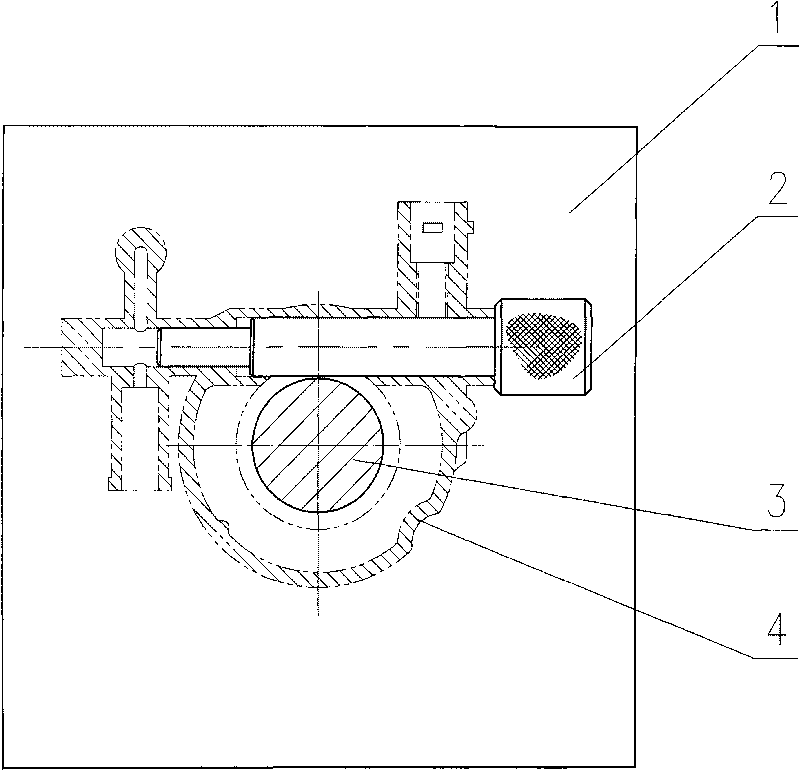

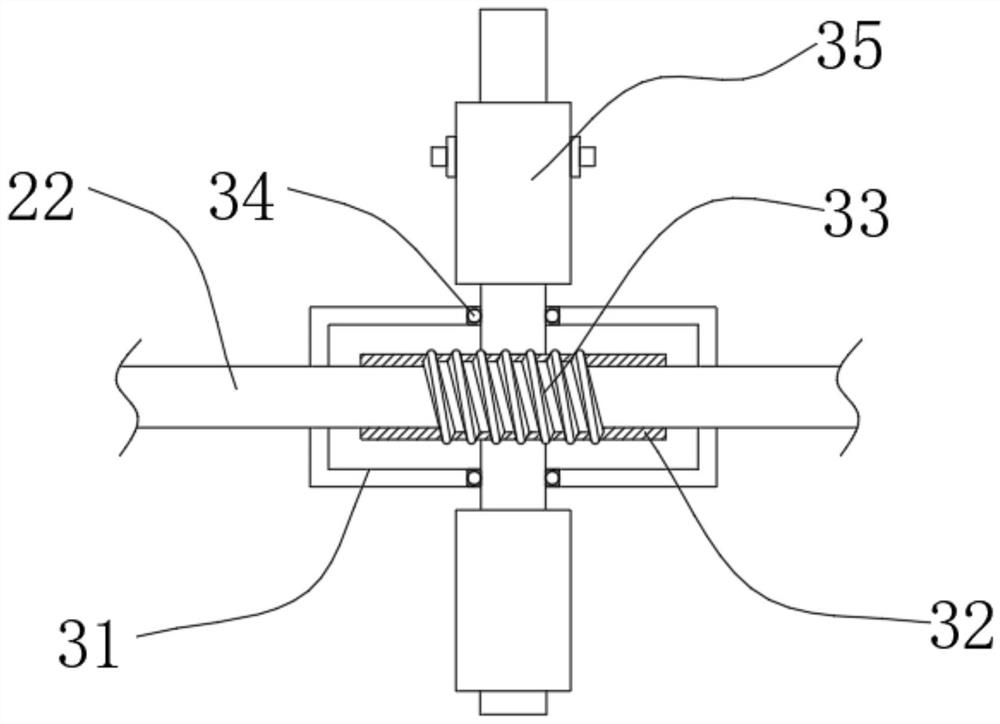

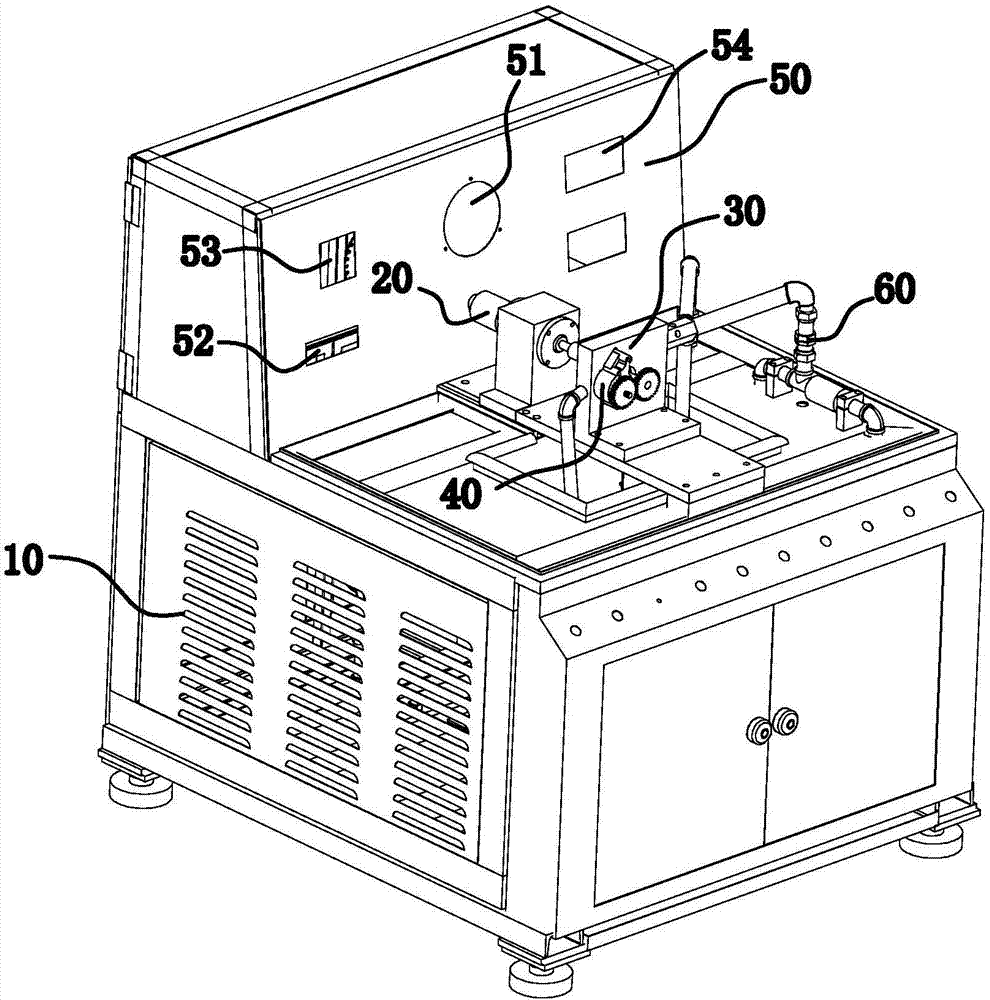

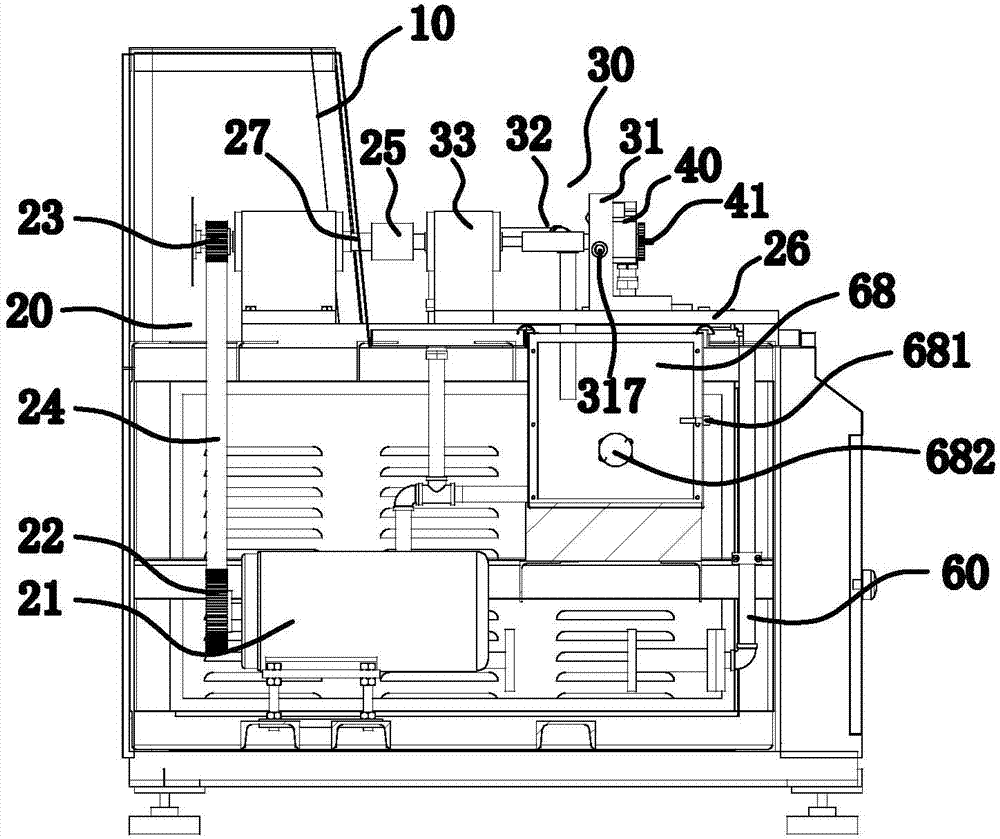

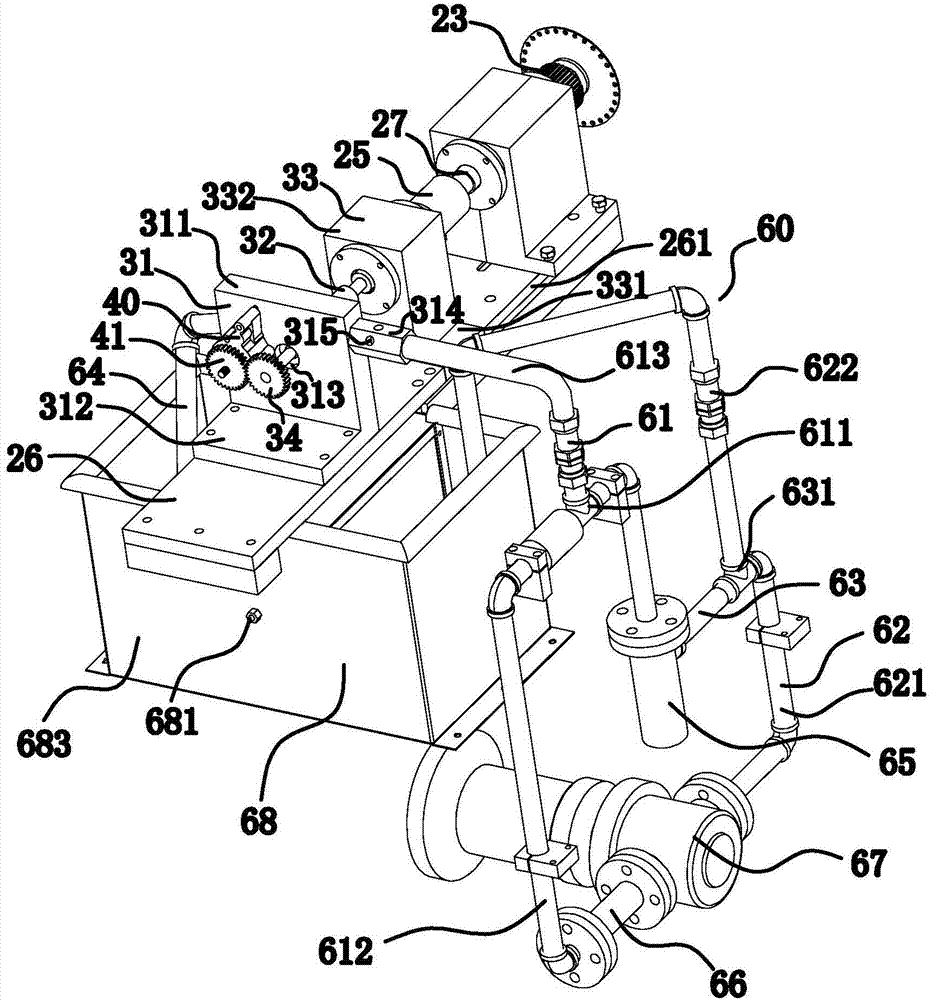

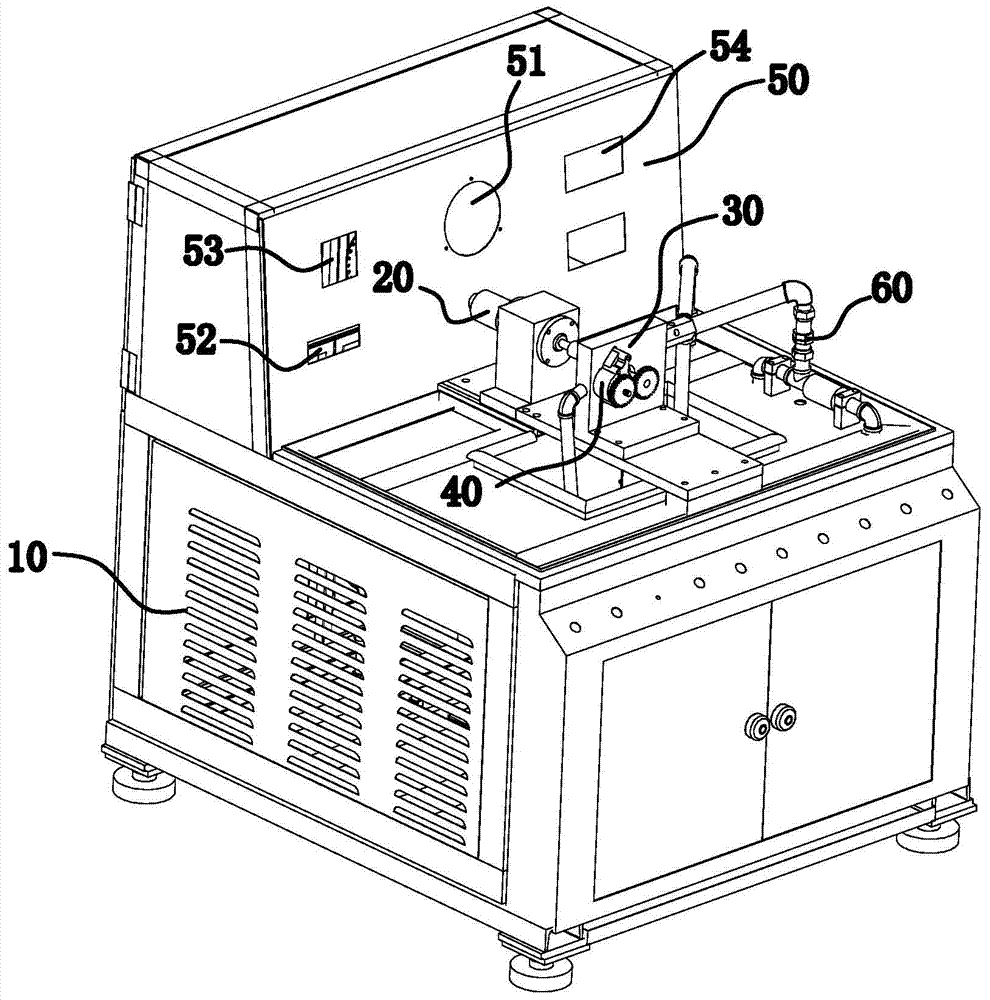

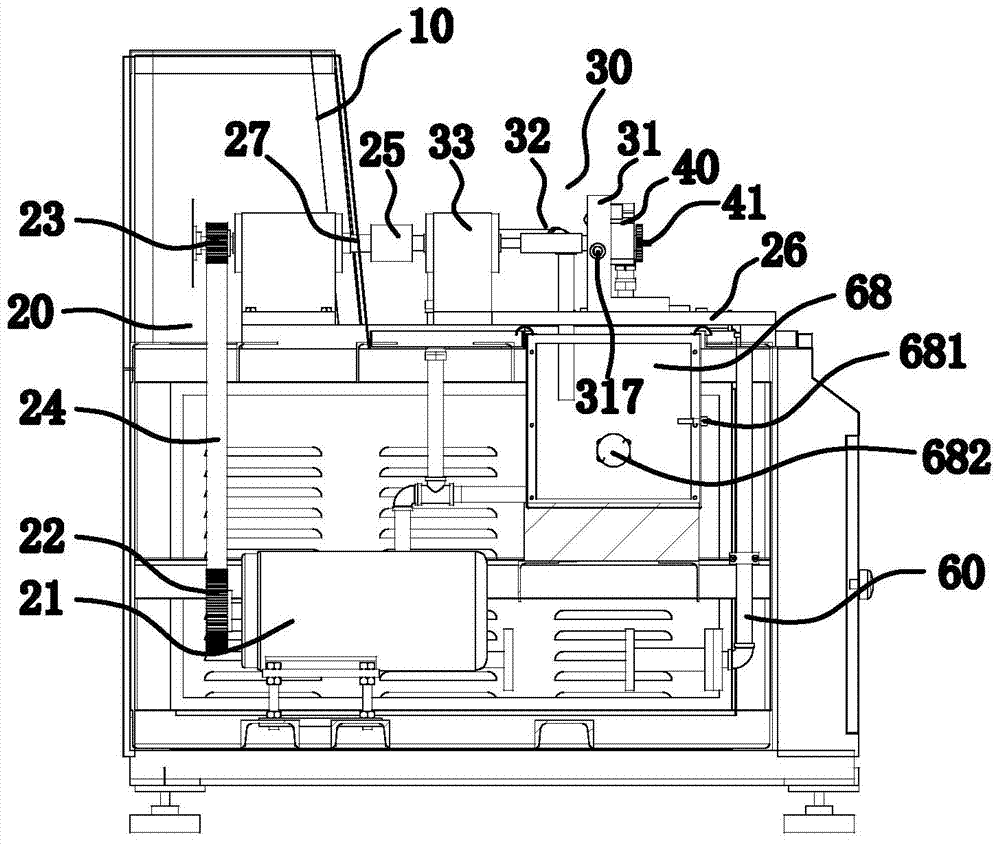

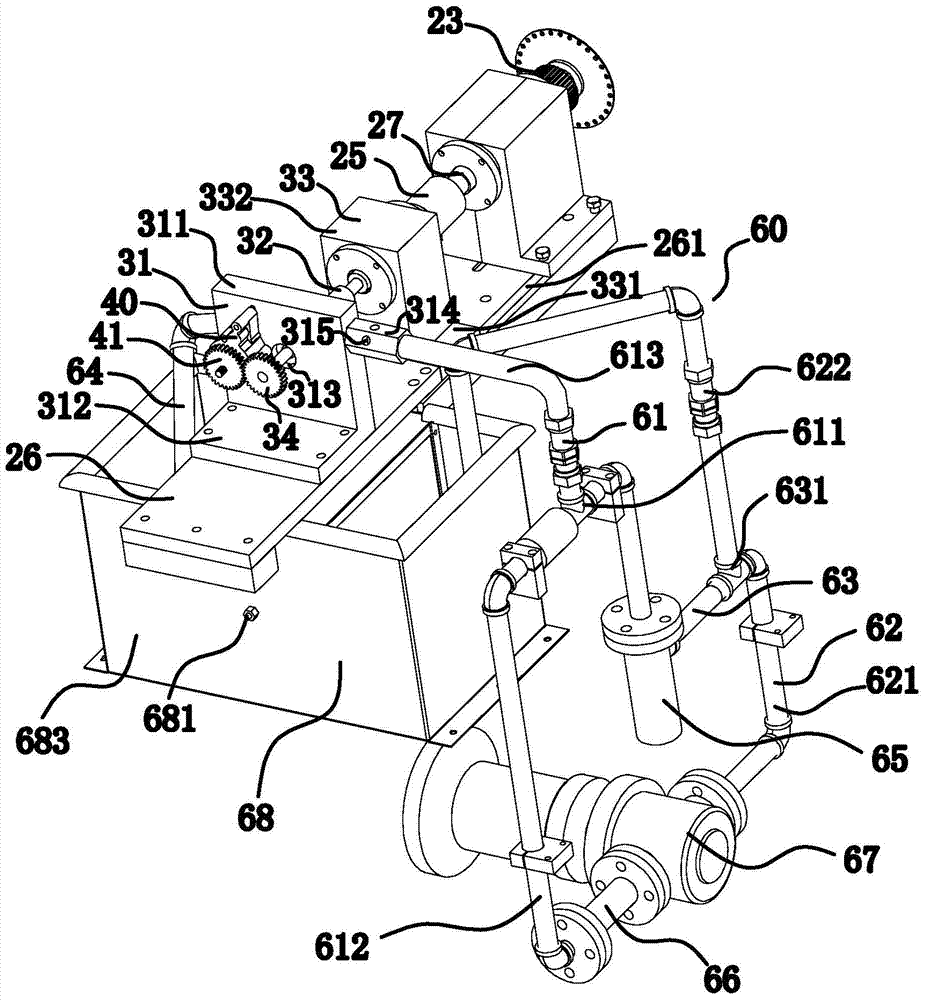

Horizontal type test equipment for oil pump

ActiveCN104121180AEasy to testSimple structurePump testingPositive-displacement liquid enginesTest performanceDrive shaft

The invention provides a horizontal type test equipment for an oil pump, and belongs to the technical field of test equipment. The horizontal type test equipment for the oil pump solves the problem that test performance of existing test equipment is not accurate enough. The horizontal type test equipment for the oil pump comprises a rack, a clamp system, a power system, a pipeline system and a detection system, the power system is connected to the clamp system and transmits torque to the clamp system, the oil pump is mounted on the clamp system, the pipeline system is connected to the oil pump, the detection system is mounted on the pipeline system and carries out detection, the clamp system comprises an adjusting support, a transmission shaft and a test plate, the transmission shaft penetrates through the adjusting support, one end of the transmission shaft is connected to the power system, the other end of the transmission shaft is provided with a main gear, an auxiliary gear is mounted on the oil pump, the main gear is meshed with the auxiliary gear, the oil pump is attached to the test plate in a sealing mode, an oil inlet and an oil outlet are formed in the test plate, and the pipeline system is connected to the oil inlet and the oil outlet respectively. The horizontal type test equipment for the oil pump has the advantages of being accurate in testing and good in stability.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

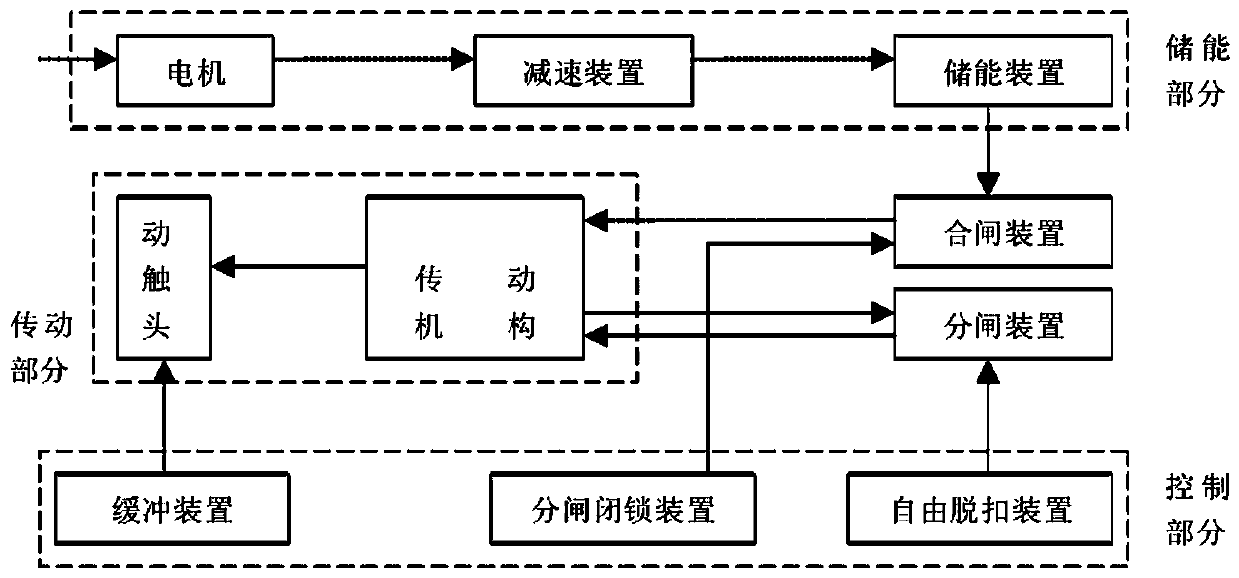

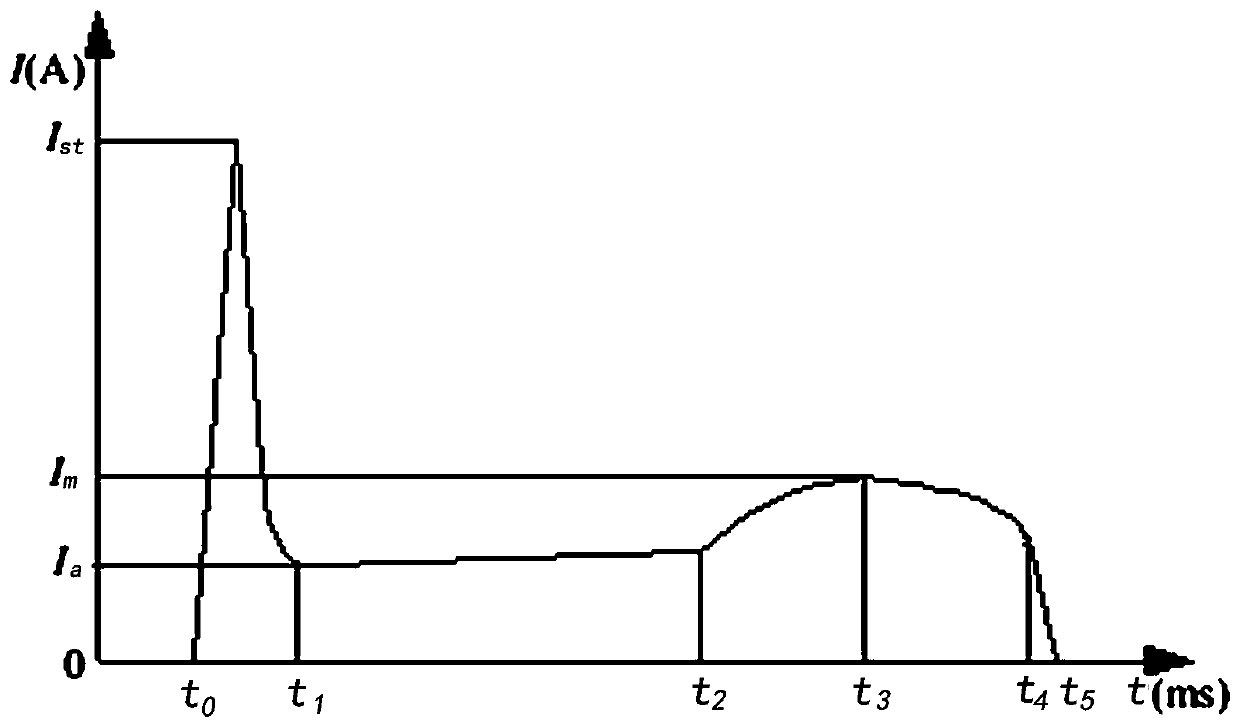

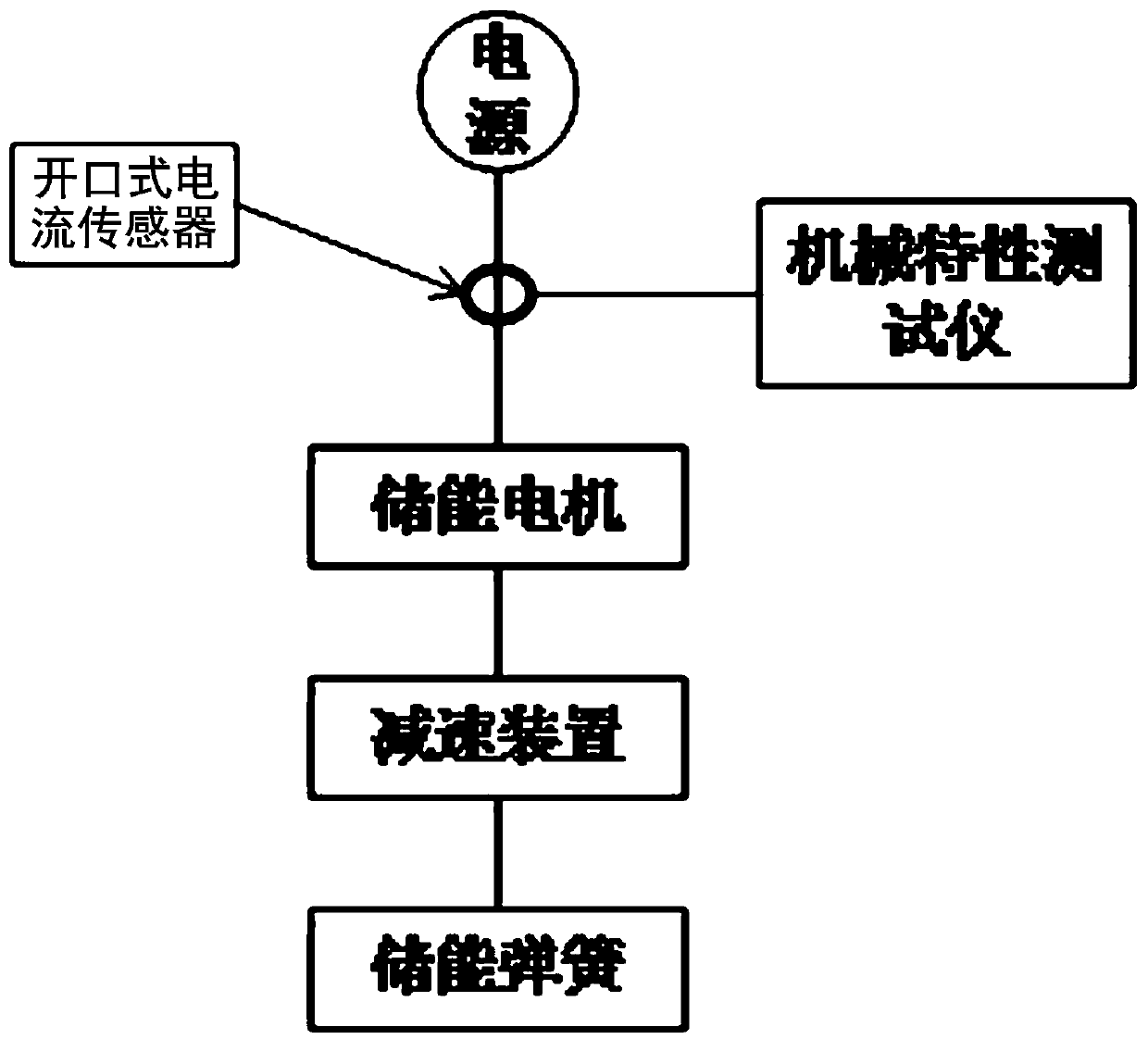

High-voltage circuit breaker energy storage device health state evaluation method based on energy storage current analysis

InactiveCN110780192AWill not affect normal operationEasy to install and detectCircuit interrupters testingCurrent transducerCurrent analysis

The invention discloses a high-voltage circuit breaker energy storage device health state evaluation method based on energy storage current analysis. The high-voltage circuit breaker energy storage device health state evaluation method comprises the steps that: an open type current sensor is clamped on a power line of an energy storage motor for acquiring a current in the whole operation process of the motor; a current value acquired by means of the open type current sensor is transmitted to a mechanical characteristic tester; and the mechanical characteristic tester records a current waveformof the motor. According to the high-voltage circuit breaker energy storage device health state evaluation method, an online monitoring mode is adopted, a measuring device is directly arranged on a circuit breaker energy storage device and can be implemented without dismounting a spring; the measuring device is arranged in the operation process of a circuit breaker, and normal operation of the circuit breaker is not influenced; and the current of the energy storage motor of the circuit breaker is monitored in real time, and the integrity and continuity of detection data are ensured, so that the defect trend of the energy storage device is analyzed and judged, the economical efficiency of equipment replacement is achieved, and the defect expansion is avoided.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

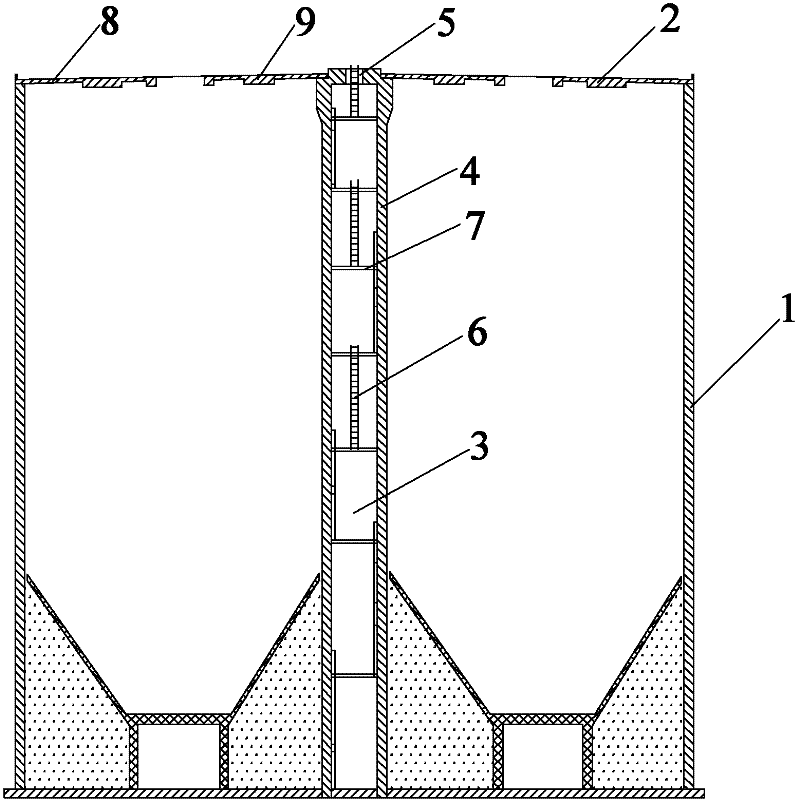

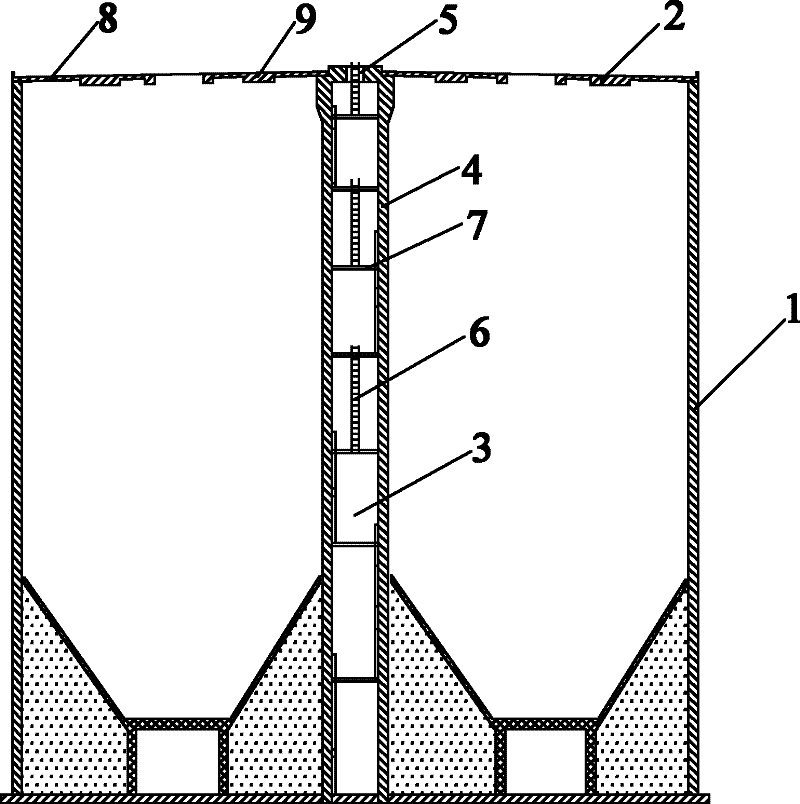

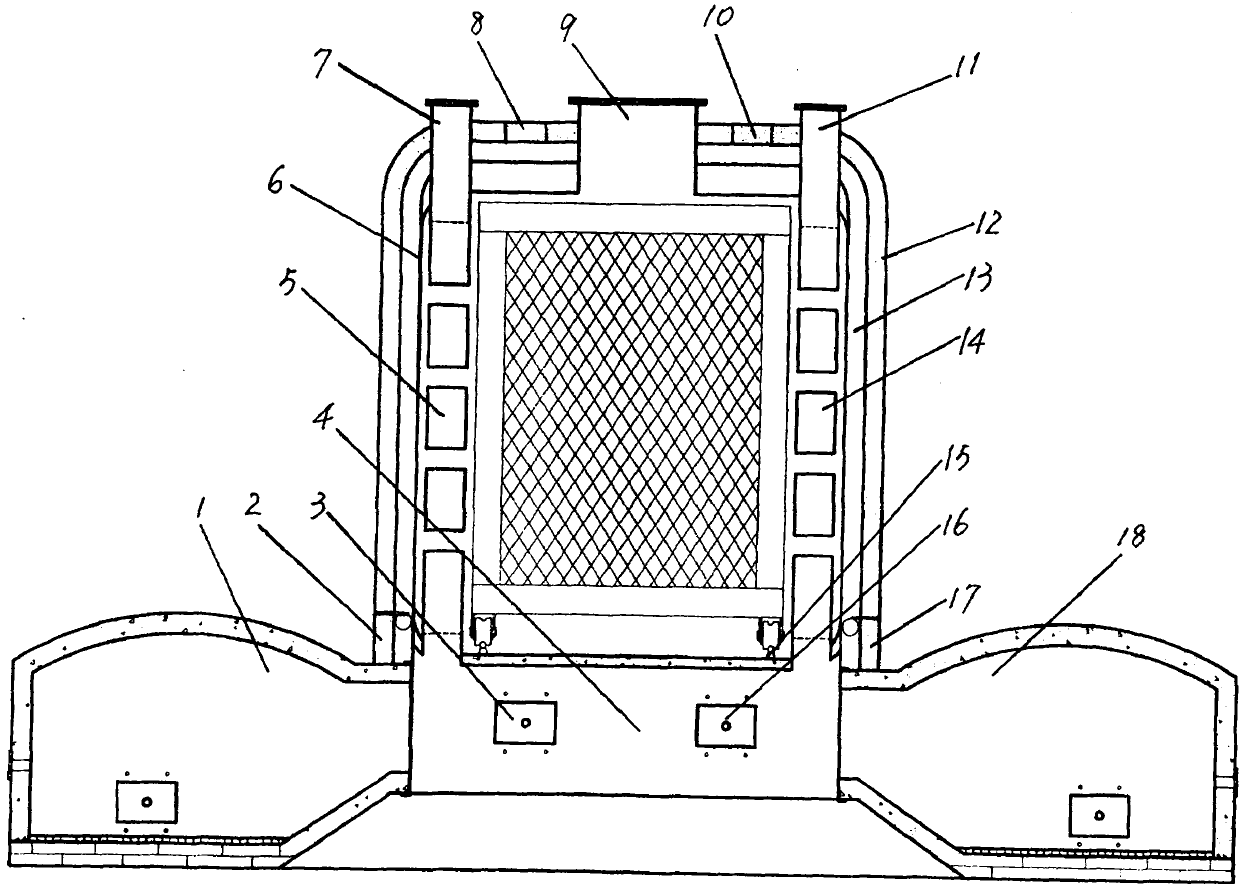

Silo

ActiveCN102359299AIncreased load-bearing capacityImprove integrityBulk storage containerCarrying capacityEngineering

The invention discloses a silo. The silo comprises a silo wall (1), a silo top (2) and a central post (3) for supporting the silo top (2), wherein the central post (3) is in a shape of a hollow pipe; an outer wall (4) of the central post (3) is provided with a detection device; and the upper end of the central post (3) is provided with a first opening (5). The silo has a stable structure and high carrying capacity; meanwhile, the detection device is easily arranged in the silo, so that conditions such as temperature, humidity and the like in the silo are convenient to detect; and people can enter the central post through the first opening at the upper end of the central post to maintain the detection device and the like.

Owner:CHINA SHENHUA ENERGY CO LTD +3

Horizontal testing equipment for oil pump

ActiveCN104153983AExtended service lifeCompatibility is reasonablePump testingPortable liftingTesting equipmentDrive shaft

The invention relates to horizontal testing equipment for an oil pump. The horizontal testing equipment comprises a rack, a clamp system, a power system, a pipeline system and a detection system, the power system is connected with and transmits torque to the clamp system, the oil pump is mounted on the clamp system, the pipeline system is connected on the oil pump, the detection system is mounted on the pipeline system for detection, the clamp system comprises an adjusting support, a transmission shaft and a testing plate, the transmission shaft penetrates the adjusting support, one end of the transmission shaft is connected to the power system while the other end of the same penetrates the testing plate, and a main gear is mounted at the other end of the transmission shaft; the oil pump is mounted on the testing plate, an auxiliary gear is mounted on the oil pump, the main gear is meshed with the auxiliary gear to form a gear member which is made by carbon-tempered steel, the oil pump is close to and sealed on the testing plate, an oil incoming hole and an oil outgoing hole which are communicated to the oil pump are formed in the testing plate, and the pipeline system is connected on inlets of the oil incoming hole and the oil outgoing hole respectively. The horizontal testing equipment is simple in structure, convenient in testing, accurate in testing performance and long in service life.

Owner:JIANGSU CHANGHUI COMPLETE EQUIP

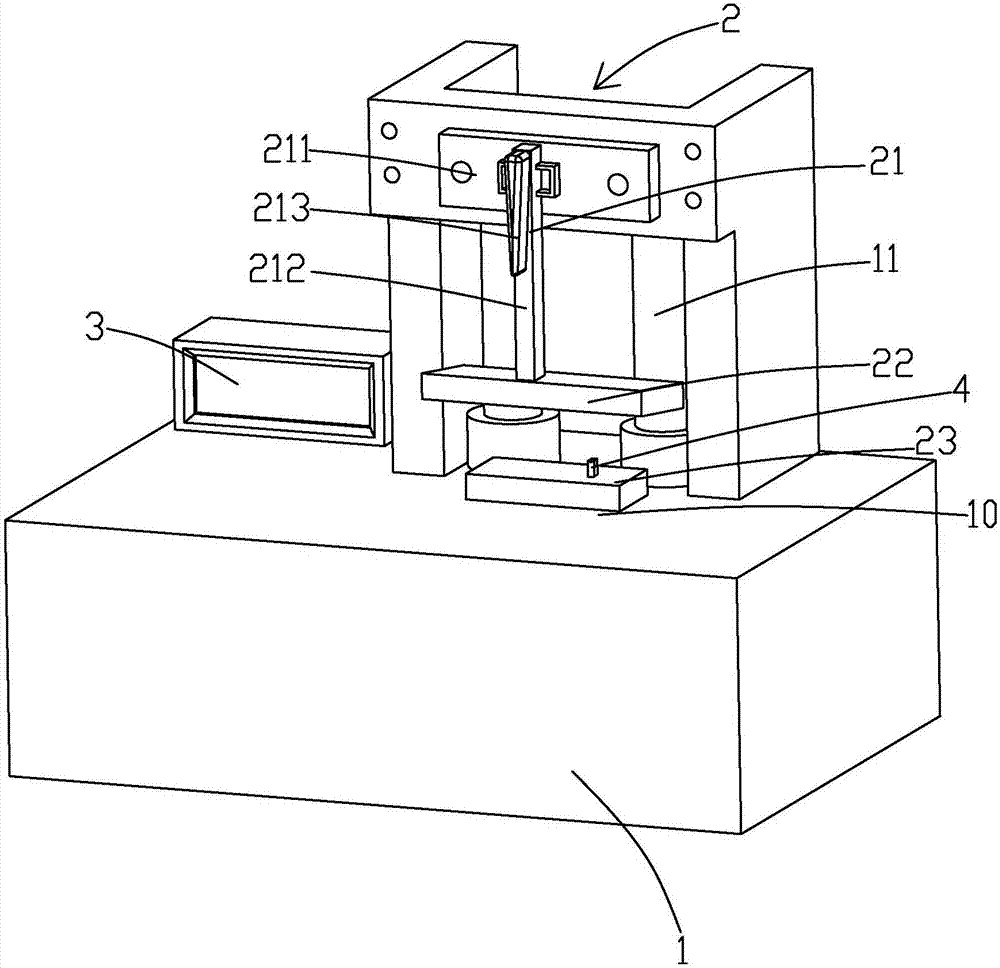

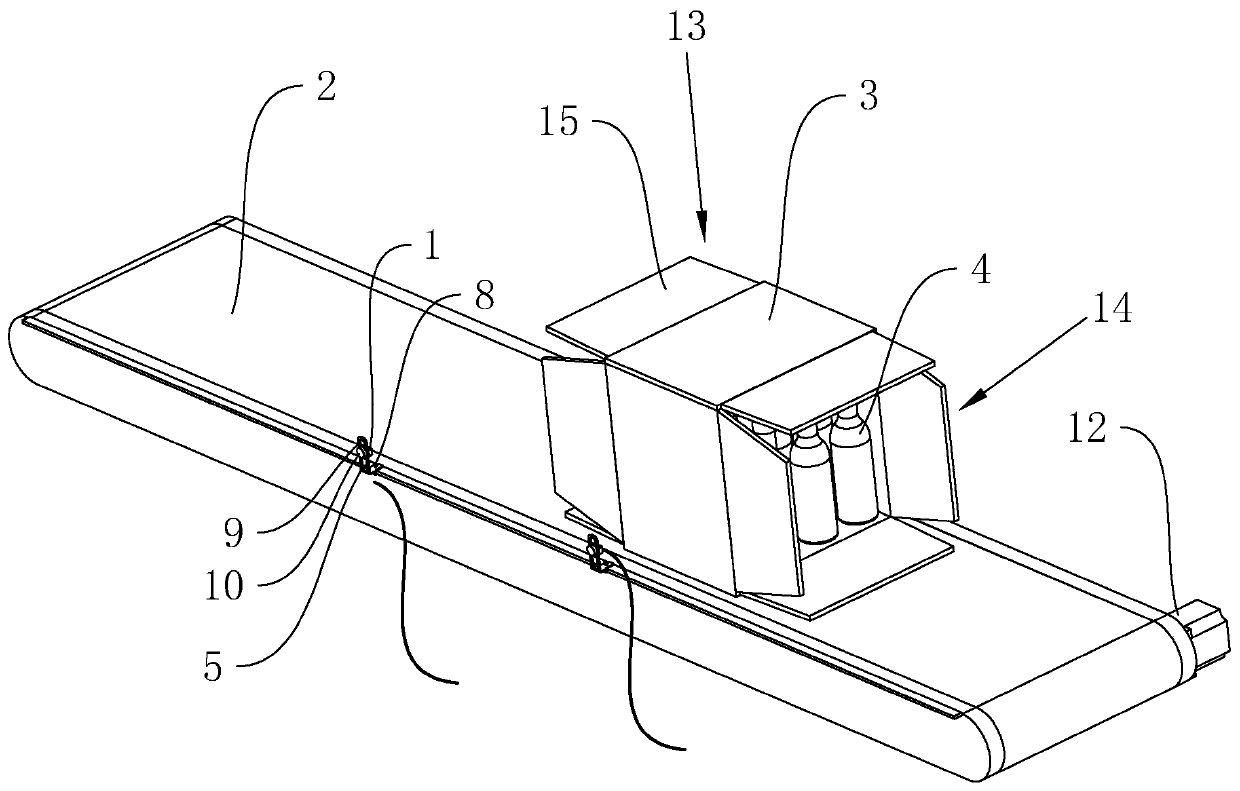

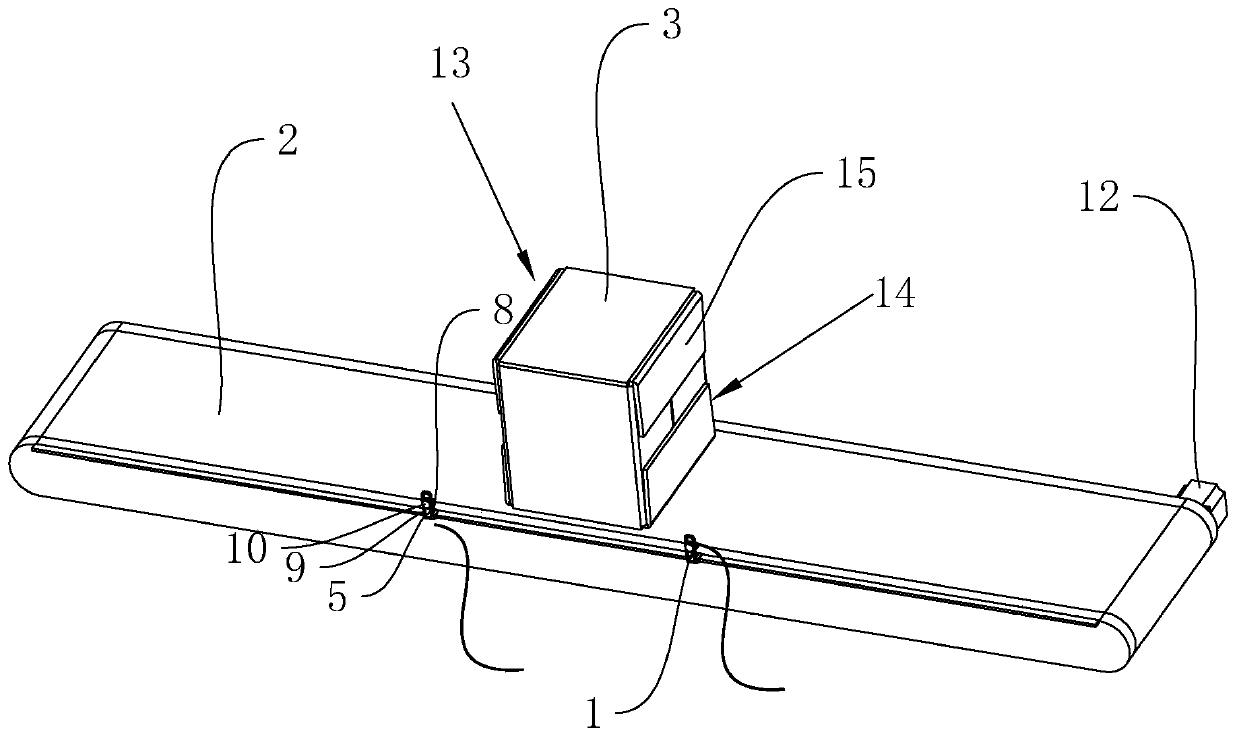

Intelligent tension detection device

InactiveCN110057670AEasy to install and detectGood stabilityMaterial strength using tensile/compressive forcesBall screwMechanical engineering

The invention discloses an intelligent tension detection device. Due to arrangement of an installation cavity, a ball screw, a screw nut, a positive and negative rotation motor, a movable frame, a connection block, a sliding rail and a sliding block, lifting adjustment of the movable frame can be realized; installation detection is conveniently carried out; furthermore, the stability of a liftingand adjusting process is better; movable adjustment of a first sliding block in a first sliding rail can be realized; movable adjustment of a second sliding block in a second sliding rail can be realized; an upper clamping head and a lower clamping head are conveniently corrected; due to arrangement of a first buffer part and a second buffer area, buffer protection on the first sliding block and the second sliding block can be realized; the use effect of the device can be prolonged; due to arrangement of a tension sensor and a position sensor, the tension and the displacement of the upper clamping head can be detected; automatic detection on the data can be realized; due to arrangement of a first installation groove, a first installation block, a second installation groove and a second installation block, the upper clamping head and the lower clamping head can be installed and disassembled rapidly; and the process is convenient and rapid.

Owner:赖海东

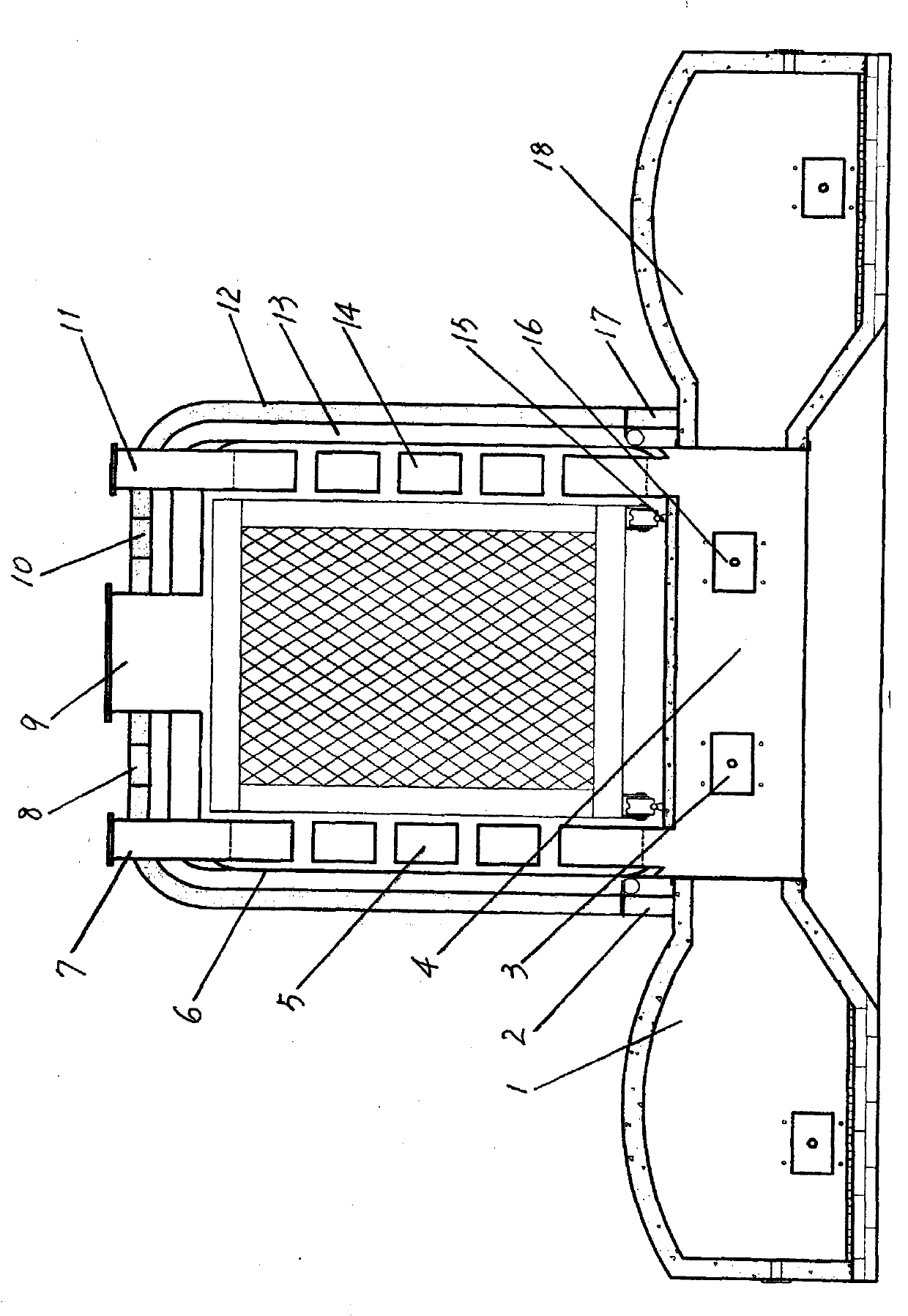

Dual temperature tunnel type waste rubber cracking furnace

InactiveCN101768460AQuality improvementNot easy to leakProductsReagentsWaste rubberProcess engineering

The invention discloses a dual temperature tunnel type waste rubber cracking furnace. The furnace is a fixed cuboid tunnel furnace, the bottom of the furnace is provided with a flat-barrel hot air passage covering the bottom of a furnace body, two sides at one end of the outside of the furnace body are provided with a combustion furnace communicated with the flat-barrel hot air passage respectively, and the other end of the flat-barrel hot air passage is provided with two hot air outlets which are communicated with coil-shaped hot air passages on the inner walls on two sides of the tunnel furnace respectively; and the bottom surface of the furnace body is provided with a skip track, a skip loaded with waste rubber raw materials can move on the skip track, and two ends of the tunnel furnace are provided with a furnace door respectively. The dual temperature tunnel type waste rubber cracking furnace has the advantages of simple structure, easy manufacture, convenient operation, short production period, high production efficiency, good safety performance and mechanized operation; because the raw materials in the furnace are static, the pyrolyzed oil has good quality and contains little impurity; the main furnace is a fixed device and avoids leaking smoke from two ends compared with a rotary cracking furnace, so the furnace is more environment-friendly; and simultaneously, the furnace can be provided with detection and monitoring instruments conveniently, and is favorable for electric control operations.

Owner:SHANGQIU RUIXIN GENERAL EQUIP MFG

Horizontal test equipment for oil pump

The invention relates to horizontal test equipment for an oil pump. The horizontal test equipment comprises a rack, a clamp system, a power system, a pipeline system and a detection system, wherein the power system is connected with the clamp system and transmits torque to the clamp system; the oil pump is mounted on the clamp system, and the pipeline system is connected onto the oil pump; a detection system is mounted on the pipeline system and used for detection; the clamp system comprises an adjusting bracket, a drive shaft and a test board, the drive shaft penetrates through the adjusting bracket, one end of the drive shaft is connected to the power system, the other end penetrates through the test board, and a main gear is mounted at the end part, and the drive shaft is made by carbon tempered steel; the oil pump is mounted on the test board, provided with an auxiliary gear meshed with the main gear and tightly attached and sealed on the test board; oil inlet holes and oil outlet holes communicated with the oil pump are formed in the test board; and the pipeline system is connected to entrances of the oil inlet holes and the oil outlet holes respectively. The test equipment is simple in structure, convenient to test, accurate in detection performance and long in service life.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

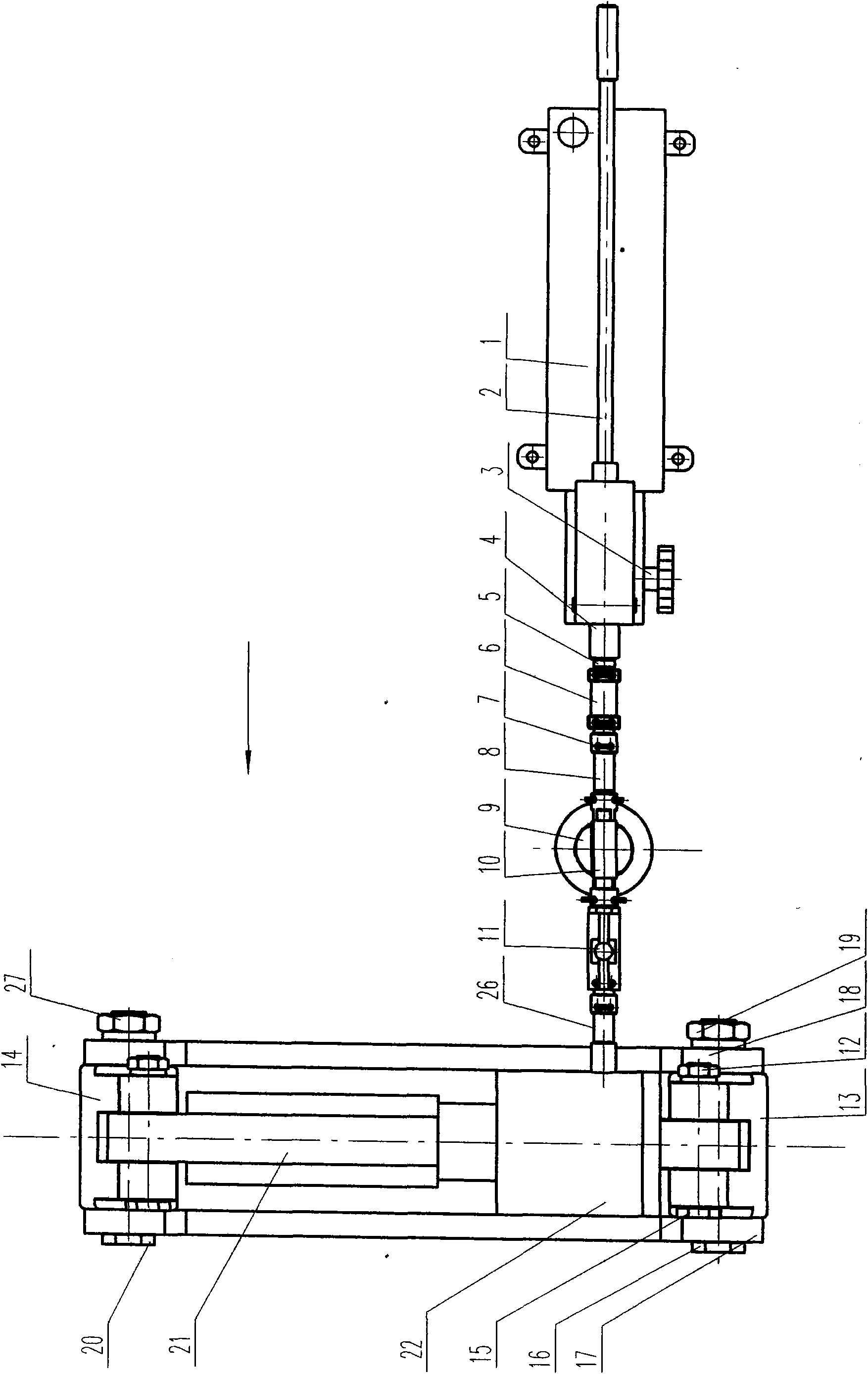

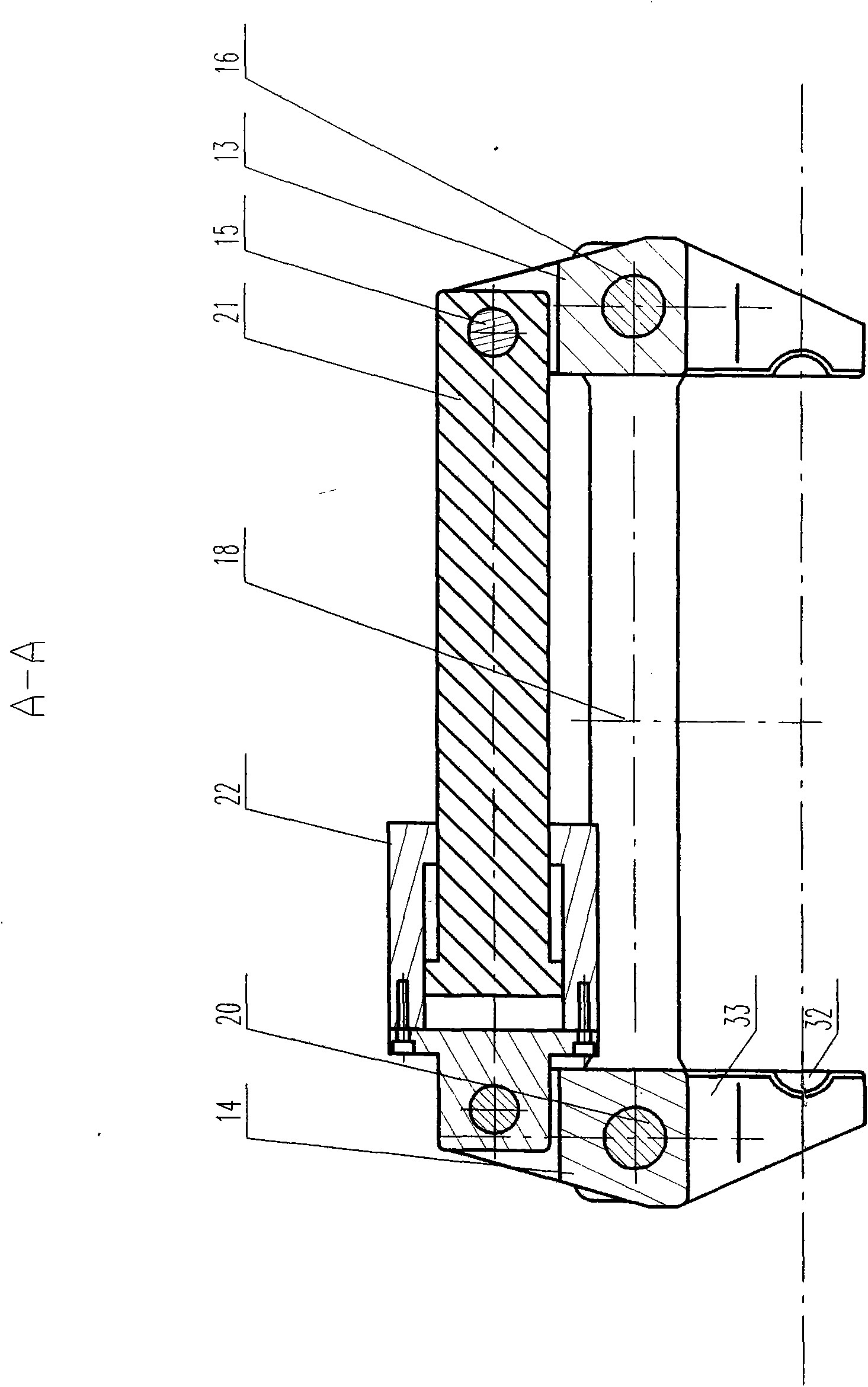

Device for measuring tension of scraper conveyer chain

The invention relates to a device for measuring the tension of a scraper conveyer chain, mainly comprising a high-pressure pump, a hand compression rod, an unloading valve, a stop valve, a tension meter, a blocking chain block, a telescopic oil cylinder and an oil cylinder piston rod. With the combination of the hydraulic drive, the tension meter and the blocking chain block of the device for measuring the tension of the scraper conveyer chain, the tension of the scraper conveyer chain under the coal mine is measured immediately on the spot, the measured pretension and the static tension are contrasted, compared and are optimized to finally determine the reasonable pretension and the reasonable static tension, the tensioning degree of the scraper conveyer chain is guided and debugged withthe pretension and the advantage and the disadvantages of tensioning state of the scraper conveyer chain are appraised with the static tension so that the scraper conveyer chain can be in the reasonable tensioning state to suffer from less accident and have long service life. The device has reasonable and advanced design, compact structure, convenient carrying, mounting and detecting and is safe,stable and reliable, thereby being very ideal.

Owner:山西煤矿机械制造股份有限公司

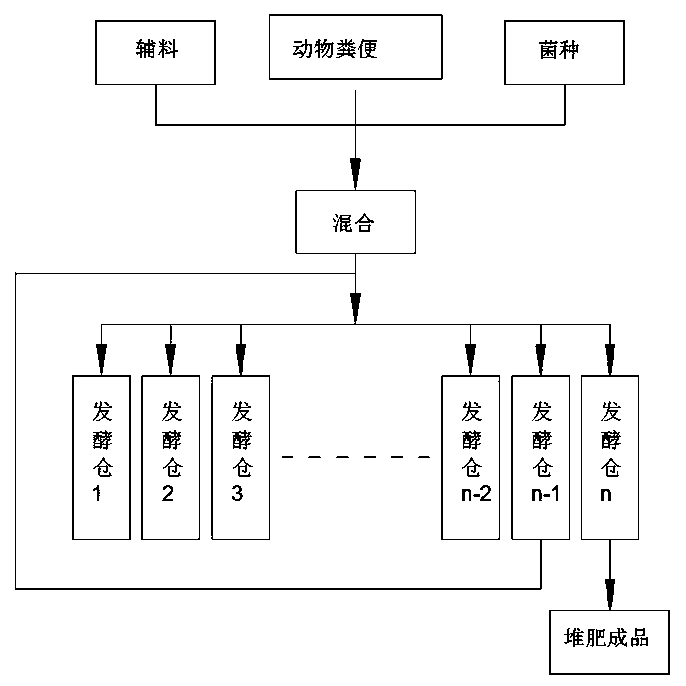

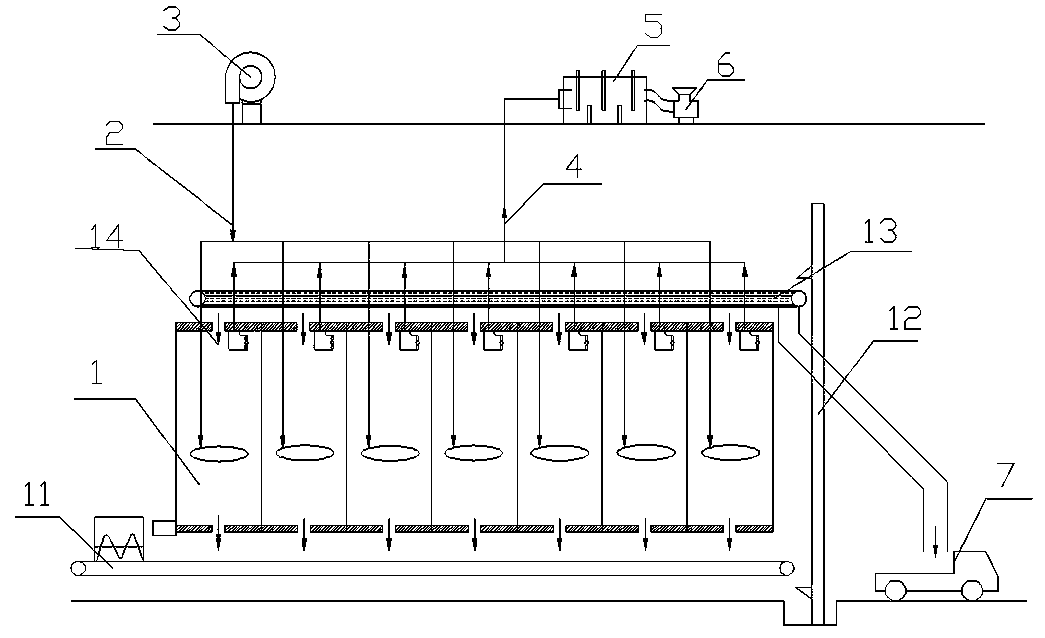

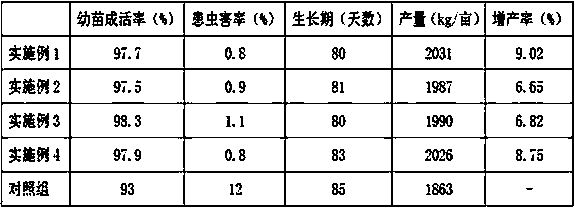

Sugarcane mud organic fertilizer with Bacillus subtilis and preparation method thereof

InactiveCN109824455AStrong abilityGood deodorantBio-organic fraction processingOrganic fertiliser preparationChemistryDecomposition

The invention discloses a sugarcane mud organic fertilizer with Bacillus subtilis and a preparation method thereof. industrial sugarcane mud is used as a main material; a biological bacterial agent, rice bran, animal waste, straws, tea cake, quick lime and a micro fertilizer are used as auxiliary materials. Bacillus subtilis used herein has a great ability to produce cellulase and lignin peroxidase and can decompose cellulose, lignin and other organics in the organic wastes, such as sugarcane mud, rice bran, straws, and tea cake; the sugarcane mud organic fertilizer with Bacillus subtilis andthe preparation method thereof have the advantages of high organics-decomposing ability, high decomposition degree, secondary aging, zero need for floor area, high automation level, and zero secondaryenvironmental pollution; fermenting equipment can run in enclosed manner, and materials under different fermenting dates are fully separated, so that fermenting speed of the organic fertilizer can beevidently increased and fermenting cycle can be shortened; no foul odor occurs, so that the quality of compost products is improved.

Owner:博白县三桦石柳生态农业开发有限责任公司 +1

Detection tool for center distance between matched and mutually perpendicular holes

InactiveCN101726233ASimple structureEasy to manufactureMechanical clearance measurementsMiddle segmentMechanical engineering

The invention discloses a detection tool for center distance between matched and mutually perpendicular holes. The detection tool comprises a positioning core shaft which is vertically arranged on a flat-plate worktable and is matched with a workpiece perpendicular hole, as well as a mandrel matched with a workpiece horizontal hole. The sum of the radius and deviation of the positioning core shaft and the middle segment of the mandrel is equal to a designed value of the center distance between matched and mutually perpendicular holes of a detected workpiece. In actual detection, the positioning core shaft and mandrel intersect, and errors of the center distance are judged according to the tangency condition of the outer walls of the two. The detection tool having the advantages of simple structure, easy manufacture and fast measurement is particularly suitable for on-line detection in mass production field.

Owner:JIANGSU GANGYANG STEERING SYST

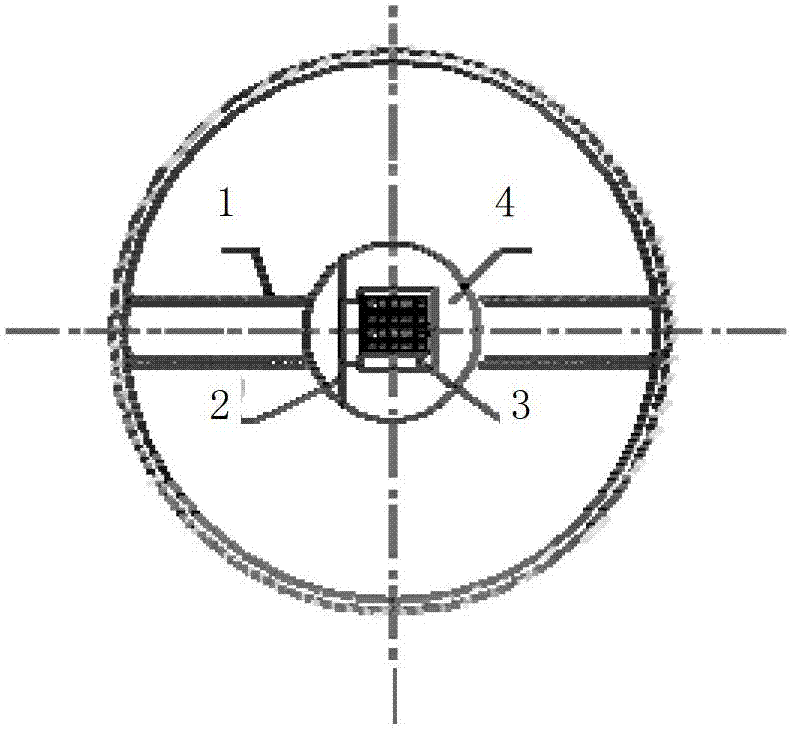

NFC (Near Field Communication) tag quality detection method and NFC detection jig

InactiveCN107271815AThe detection method is simpleIntuitive test resultsNear-field transmissionRadiofrequency circuit testingElectricityVoltmeter

The invention relates to a technology of near field communication, and particularly relates to an NFC (Near Field Communication) tag quality detection method and an NFC detection jig. The detection method comprises the steps of (1) opening a rapid fixture on the NFC detection jig, placing an NFC tag to be detected on a lower clamping plate of the NFC detection jig, enabling a bonding pad on the NFC tag to be contacted with an ejector pin arranged on the lower clamping plate, and locking the rapid fixture so as to enable an upper clamping plate to compress the NFC tag; (2) enabling a mobile phone with an NFC function to approach to the NFC tag, and observing a numerical value of a voltmeter electrically connected with the ejector pin; and (3) judging whether the numerical value of the voltmeter is within a specified range or not, and if so, judging the quality of the NFC tag to be qualified. The NFC tag quality detection method is simple and visual in test result, can realize quantization for test data and enables testing for the NFC tag to more conform to specification and standardization.

Owner:ZHONGSHAN TIANJIAN ELECTROACOUSTIC

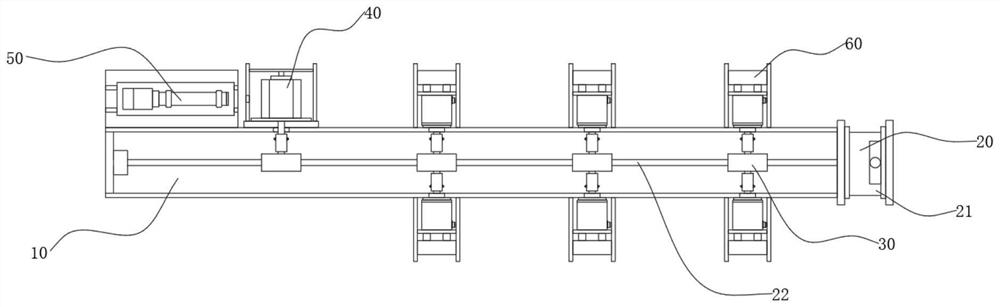

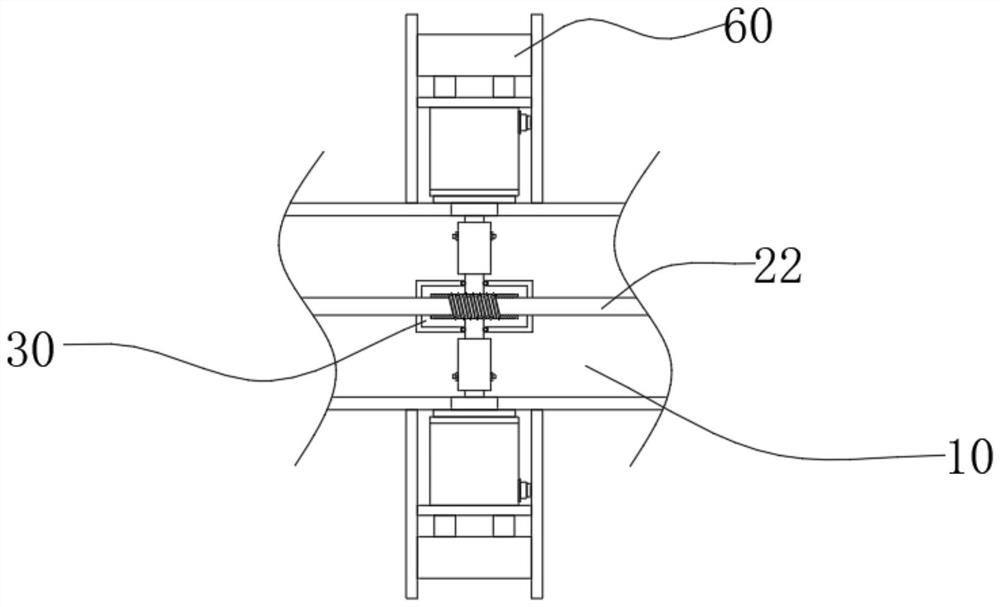

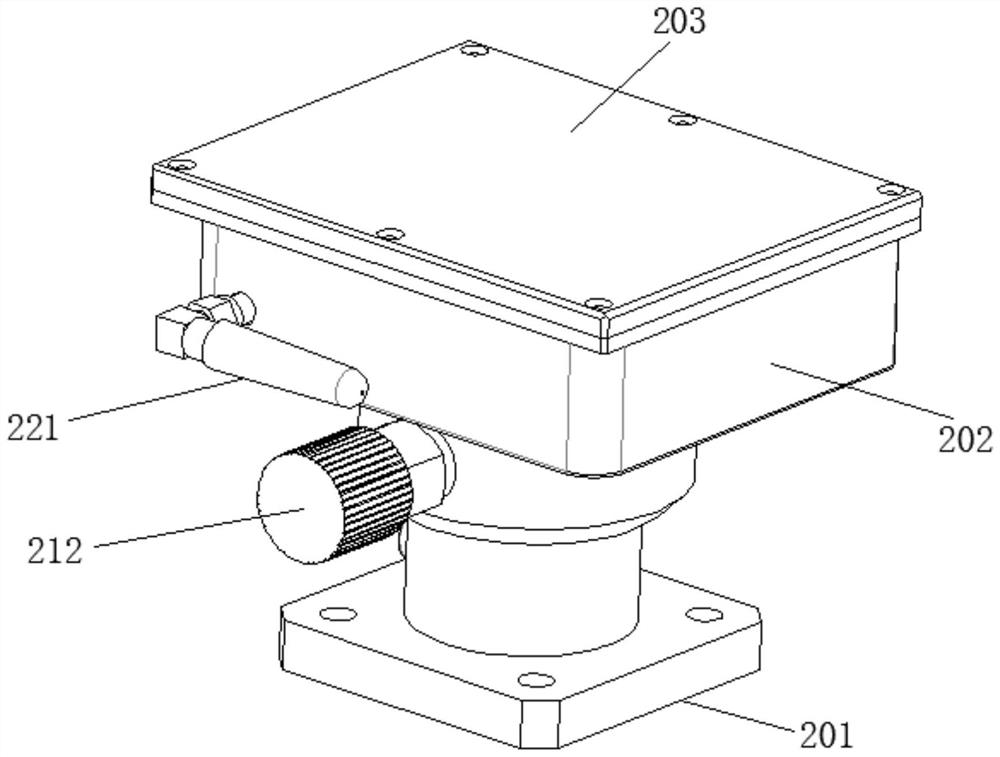

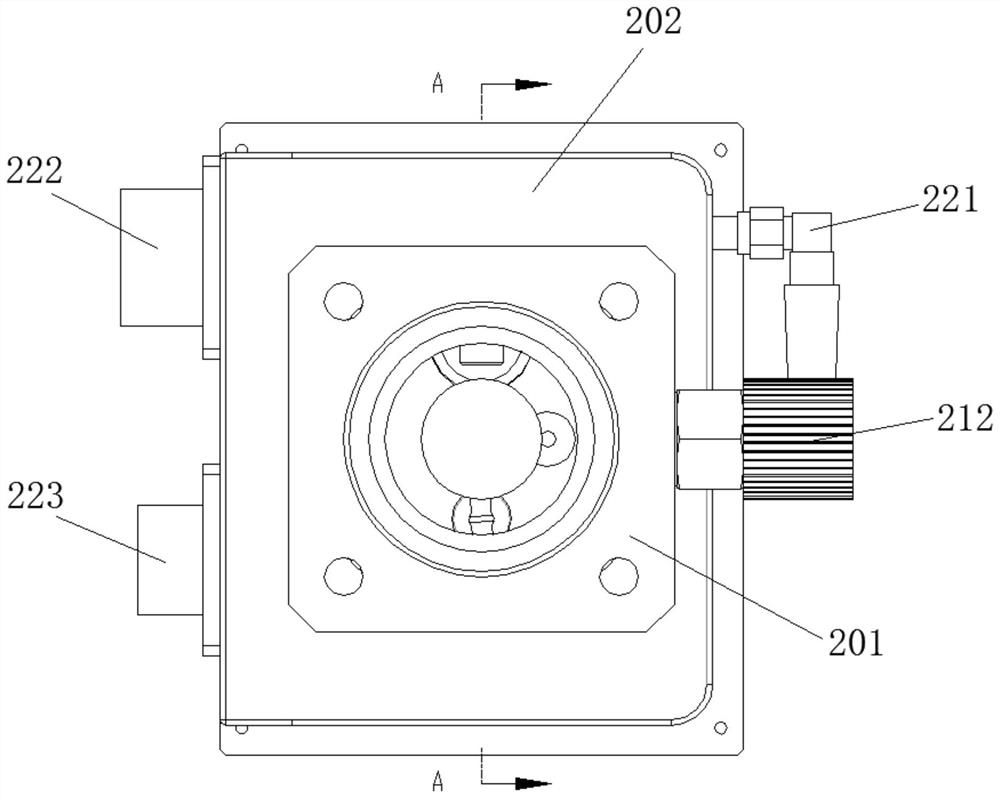

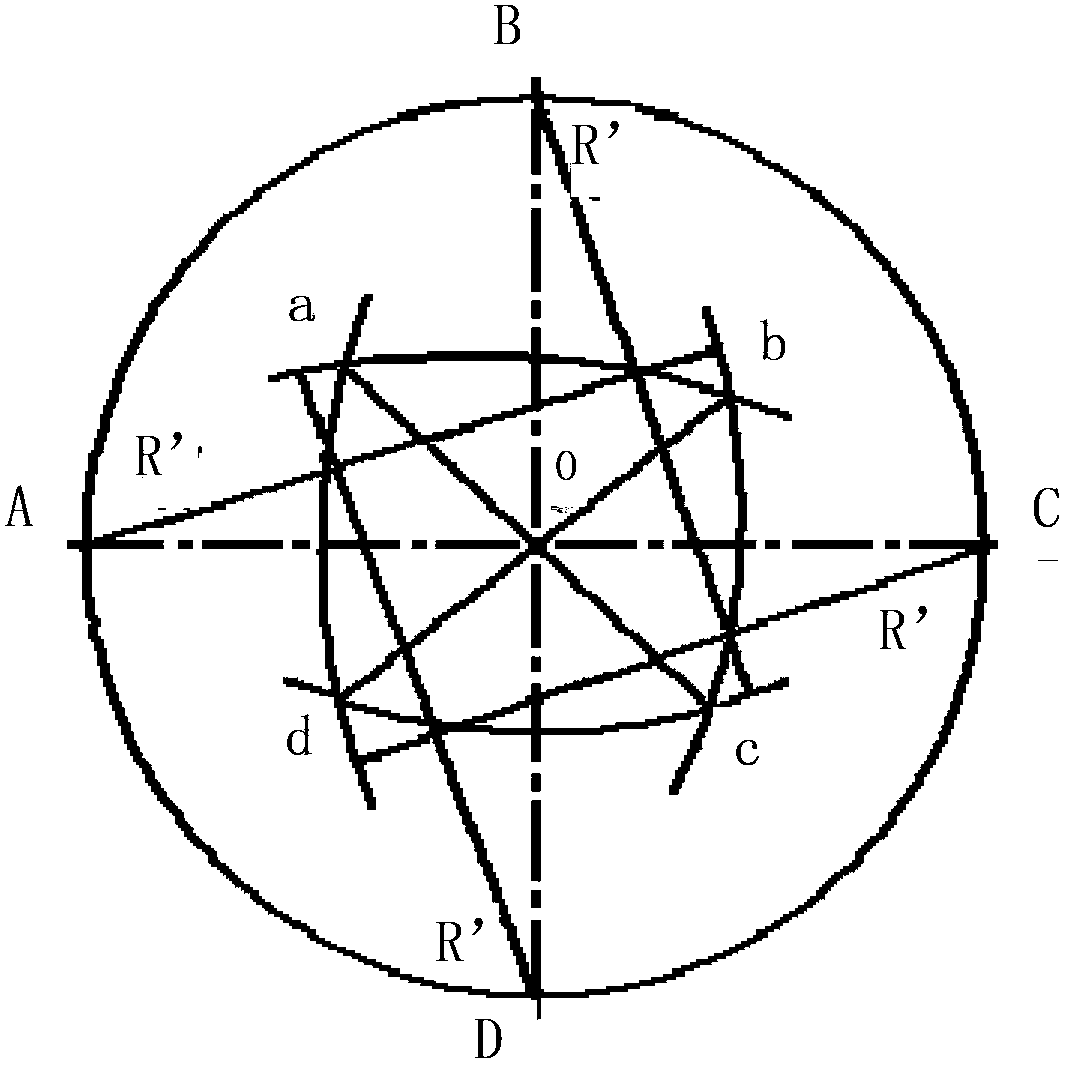

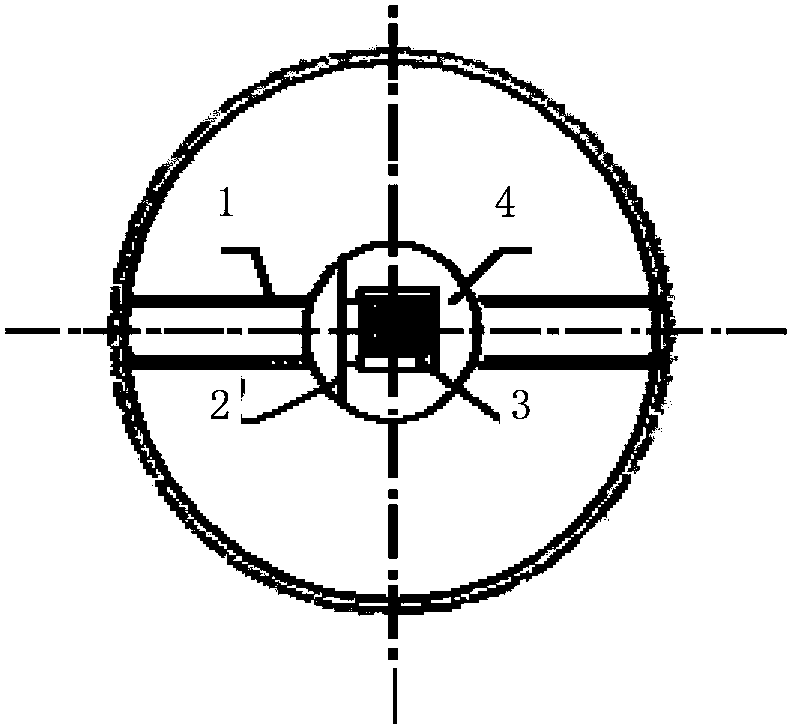

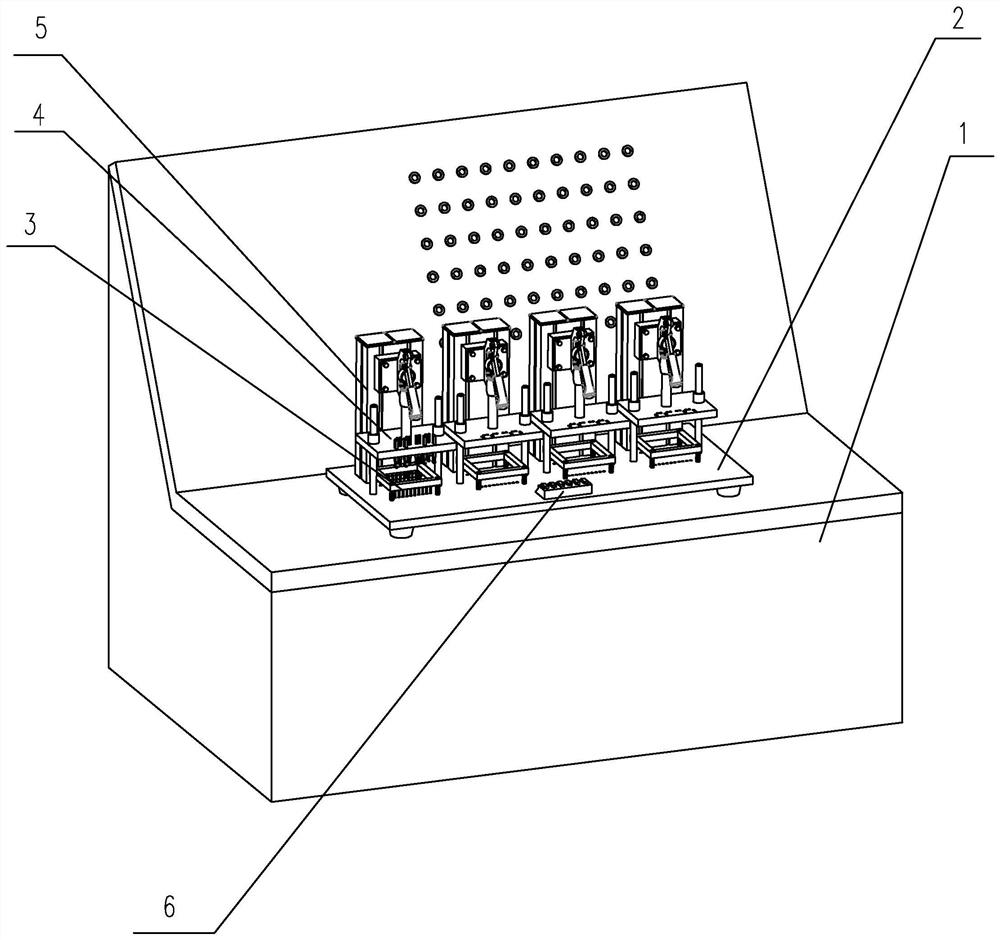

Detection device and method for rotary encoder

PendingCN114370892AImprove detection efficiencyEasy to install and detectInstrumentsControl theoryMechanical engineering

The invention relates to the technical field of rotary encoder detection, and discloses a rotary encoder detection device and method.The rotary encoder detection device comprises a detection table, detection points are symmetrically arranged on the two sides of the detection table, a driving assembly is installed at one end of the detection table, and the driving assembly comprises a tight rotary table; an output shaft of the tight rotary table is fixedly connected with a driving rod; at least two transmission assemblies located on the same horizontal line are arranged in the detection table. The plurality of groups of symmetrical detection points are arranged on the detection table, and the plurality of groups of detection points are connected with the driving assembly through the transmission assembly, so that the driving assembly can synchronously drive the shafts of the encoders on the plurality of groups of detection points to rotate through the transmission assembly at the same time, the plurality of encoders can be detected at the same time through one-time rotation, and one-by-one calibration and detection are not needed; in addition, the shaft of the encoder can be rapidly connected with the transmission assembly through the coupler, and detection and installation of the encoder are greatly facilitated.

Owner:上海融贯机电设备有限公司

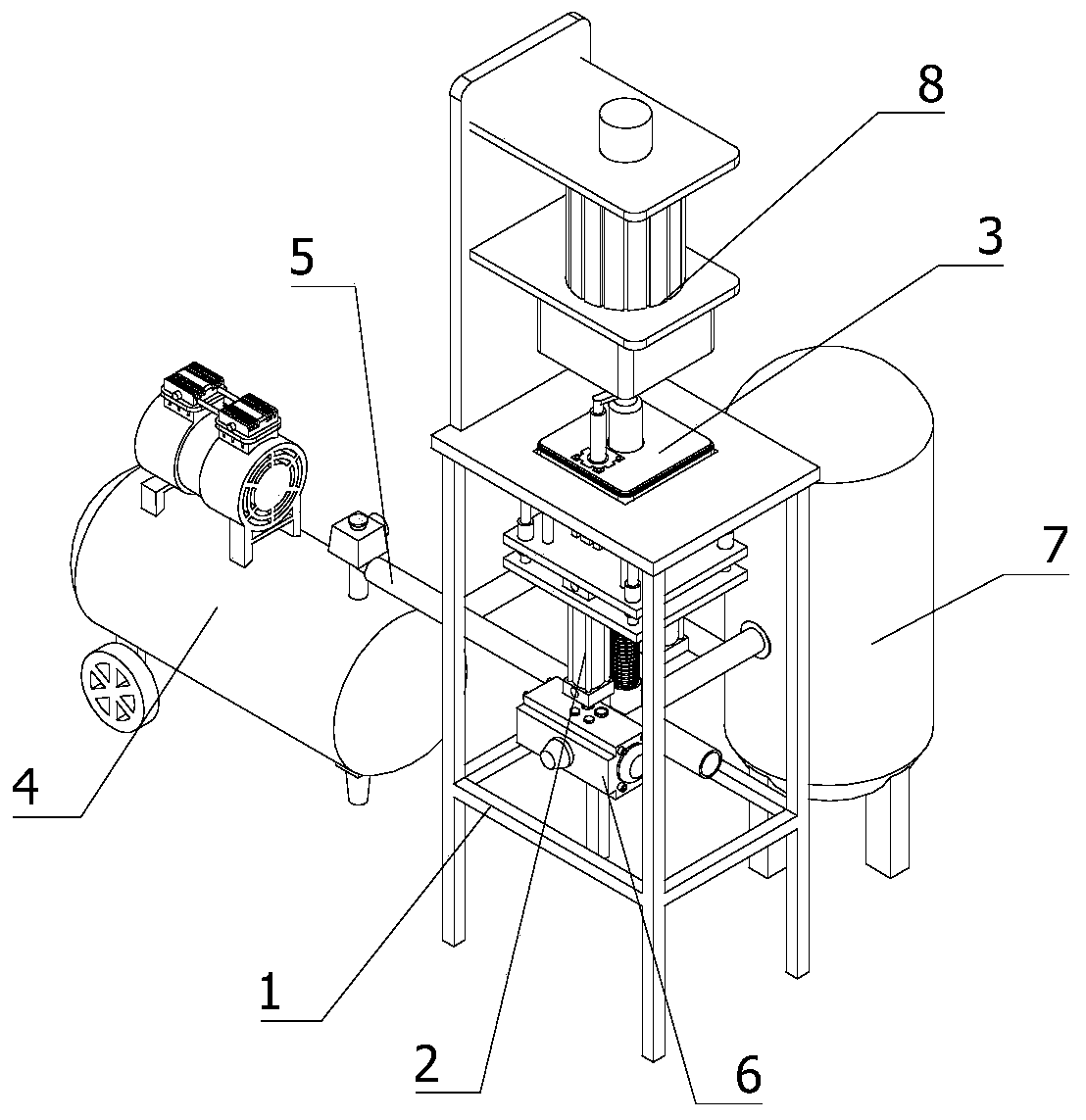

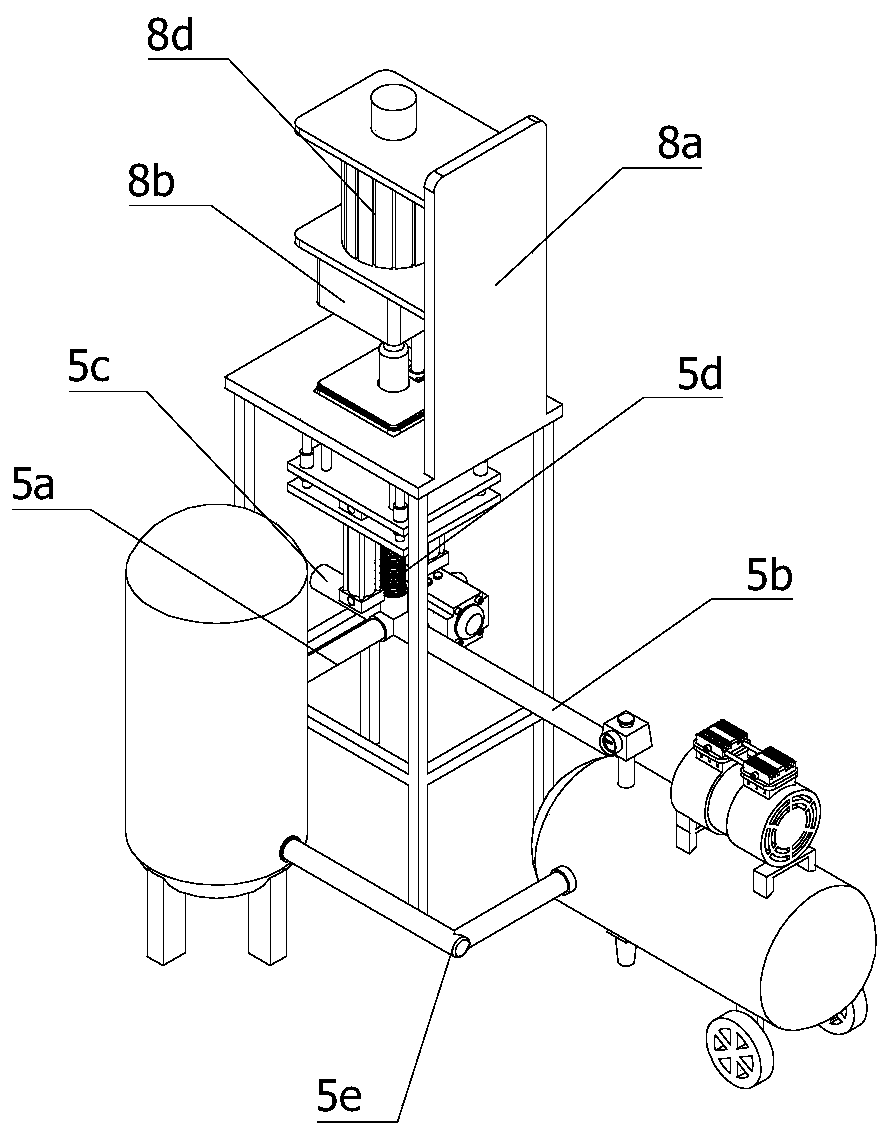

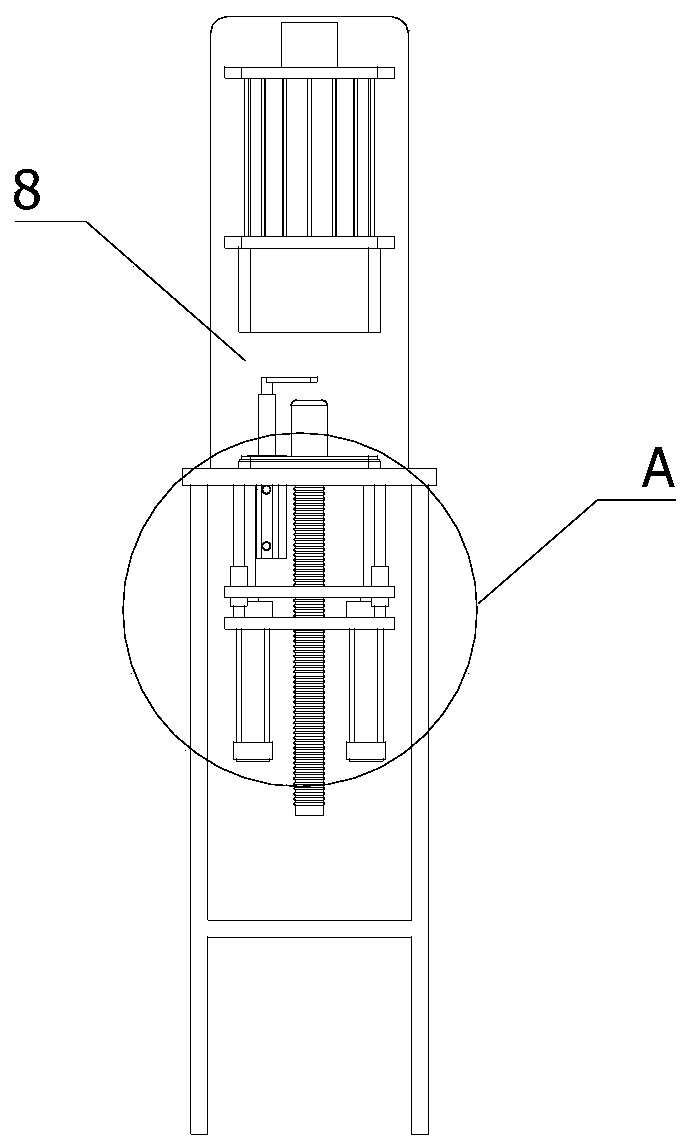

Dry-type air tightness detection machine for automobile filter

InactiveCN111579164AEasy to install and detectImprove work efficiencyDetection of fluid at leakage pointAir pumpControl theory

The invention relates to the technical field of filter detection and particularly relates to a dry-type airtightness detector for an automobile filter. The detector comprises an operation table, a jacking device, a fixed sealing device, an air pump, a pipeline system, a four-way electromagnetic valve, an air tank, a micro-pressure detection device and a controller, wherein the micro-pressure detection device and the jacking device are both arranged on the operation table, the fixed sealing device is connected with a working end of the jacking device, the pipeline system comprises a first communicating pipe, a second communicating pipe, a third communicating pipe, a corrugated communicating pipe and a connecting pipe, one end of each communicating pipe is communicated with a working end ofthe four-way electromagnetic valve, the other end of the first communicating pipe communicates with a gas tank gas outlet, the other end of the corrugated communicating pipe penetrates through the jacking device to be communicated with an air outlet end of the fixed sealing device, and two ends of the connecting pipe are communicated with an air outlet of an air pump and an air inlet of an air tank respectively. The device can recycle detection gas, and working efficiency is high.

Owner:丽水市莲都区毅荣凯盛模具厂

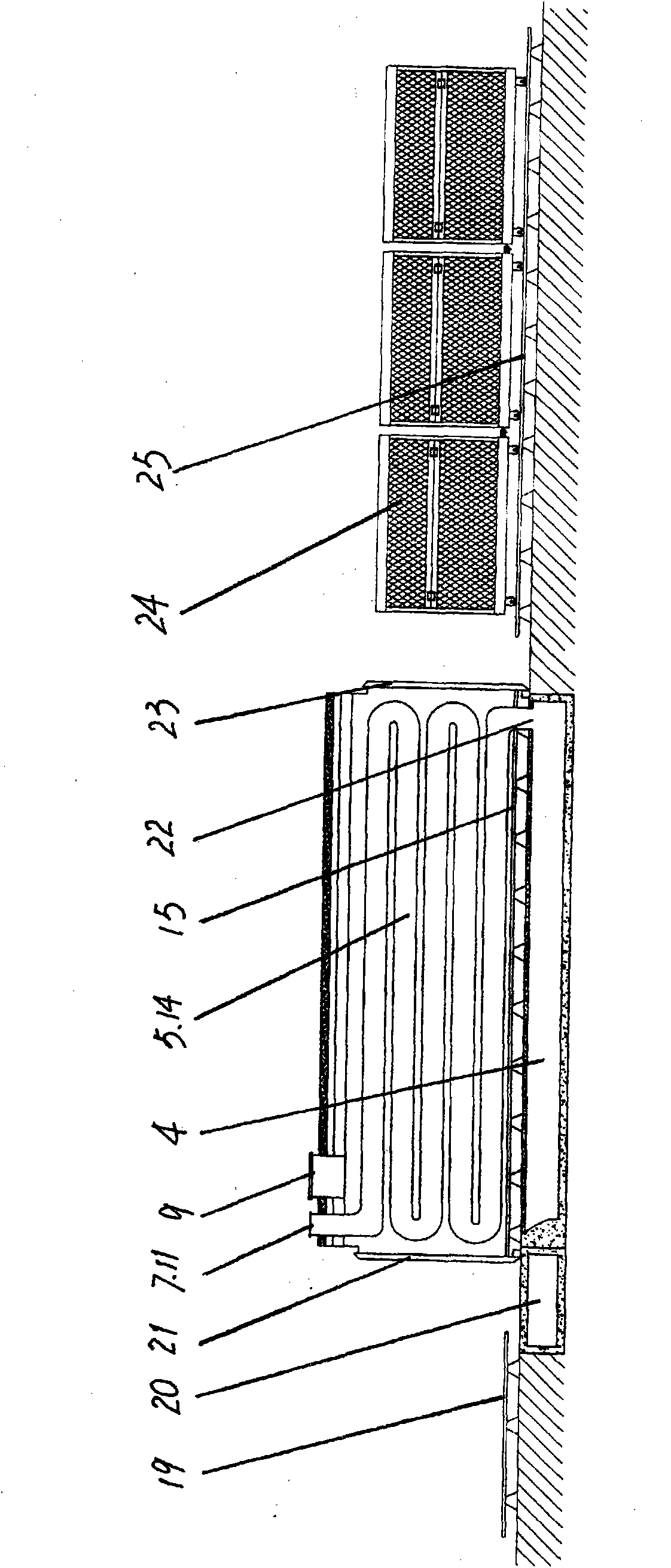

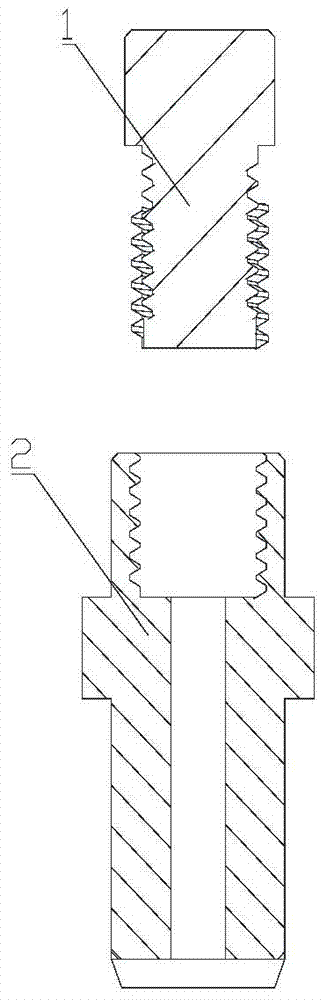

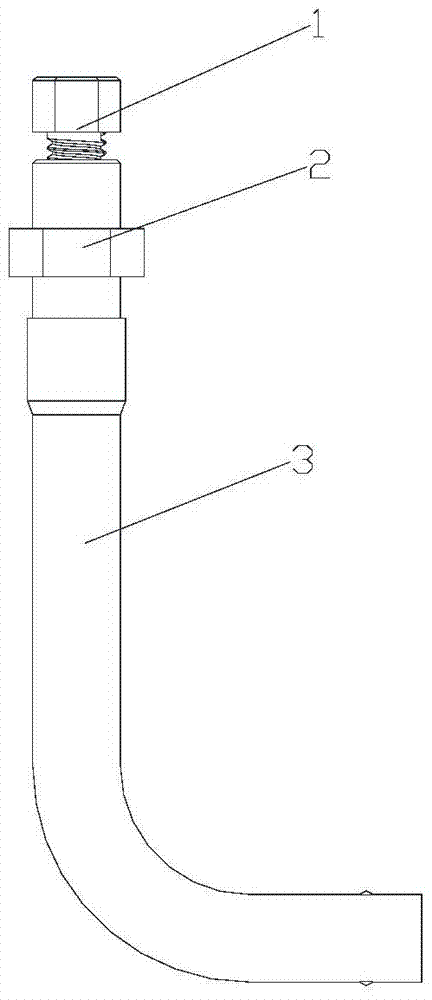

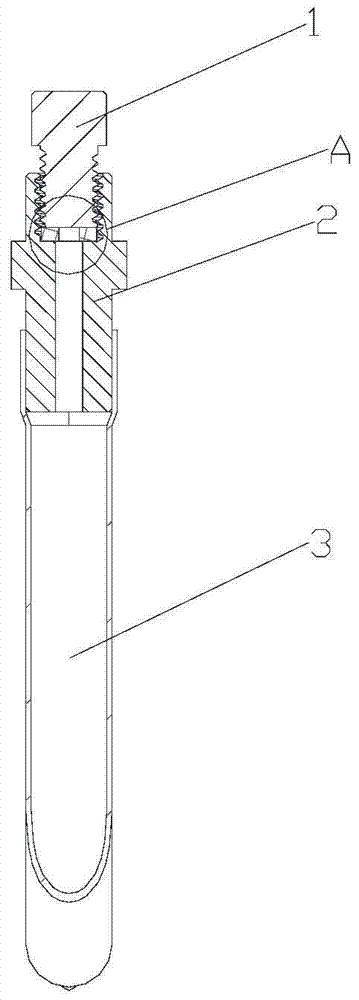

Fusible bolt structure and installation method thereof, air conditioner provided with the fusible bolt structure

ActiveCN104930655BGuaranteed tightnessDoes not affect normal detection testSpace heating and ventilation safety systemsLighting and heating apparatusFusible plugEngineering

The invention relates to the technical field of air conditioners, and discloses a fusible plug structure, a mounting method thereof and an air conditioner with the fusible plug structure. The fusible plug structure comprises a fusible plug body and a fusible plug seat, one end of the fusible plug seat is hermetically connected with the fusible plug body, and the other end of the fusible plug seat is hermetically connected with a copper pipe. By the aid of the structure, the fusible plug body is completely and effectively connected with the fusible plug seat, one copper pipe is added and can be directly welded on a part to be mounted in assembled, so that the fusible plug body is not easily damaged, normal detection tests of products cannot be affected, assembly efficiency is improved, the fusible plug seat, the fusible plug body and the copper pipe are hermetically connected, and sealing performance is ensured. The mounting method of the fusible plug structure includes the steps: firstly, hermetically connecting one end of the copper pipe with one end of the fusible plug seat; secondly, hermetically connecting the fusible plug body with the other end of the fusible plug seat; finally, connecting the other end of the copper pipe with the part to be mounted. The mounting method overcomes the shortcoming that detection is performed after gumming between the fusible plug body and the fusible plug seat is dried up in the prior art.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

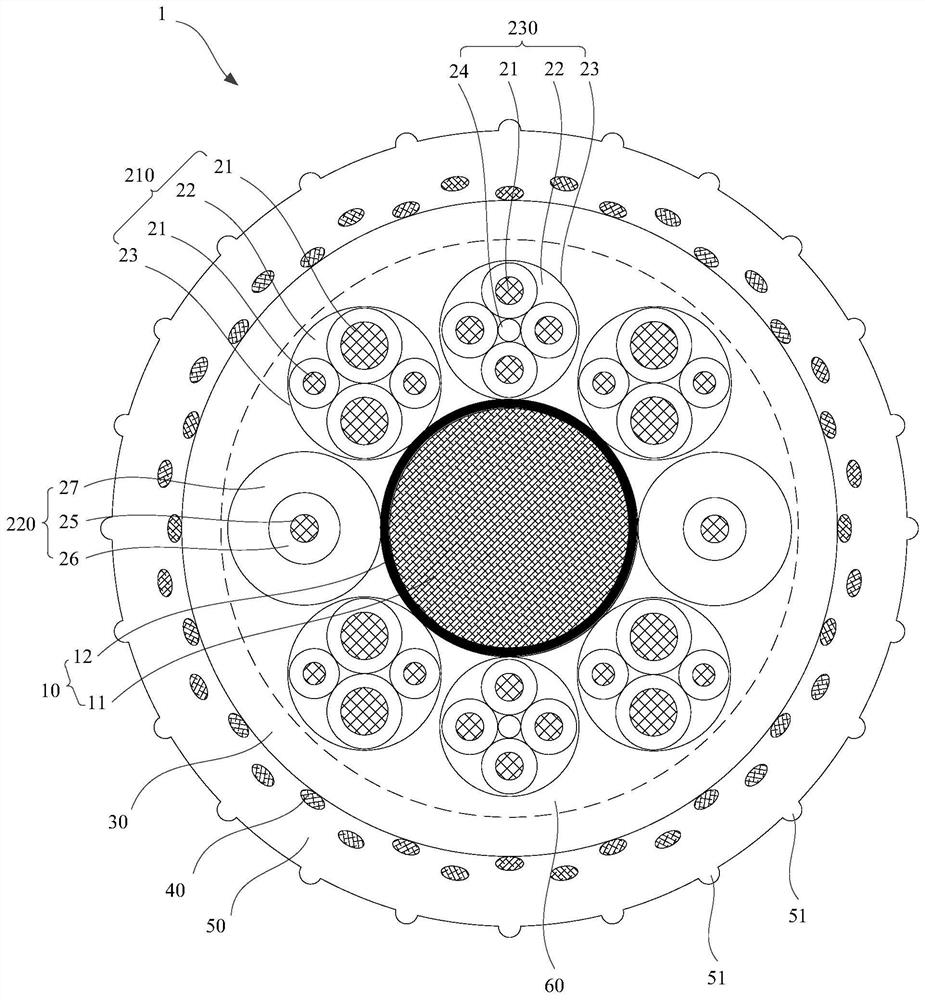

Marine towing cable

PendingCN112735655AExtended service lifeEasy to useClimate change adaptationSubmarine cablesTowingFiber

The invention provides a marine towing cable, which comprises a force bearing unit, a plurality of wire core units, a first protective layer, a fiber layer and a second protective layer which are sequentially arranged from inside to outside, and the plurality of wire core units are distributed at intervals in the circumferential direction of the force bearing unit; and a first waterproof layer is filled between the first protective layer and the force bearing unit, and the first waterproof layer is fixedly connected with the first protective layer. The marine towing cable provided by the invention is relatively good in waterproof performance.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

A machine tool spindle and tool airtight testing equipment

ActiveCN112589532BReasonable structural designSave spaceMeasurement/indication equipmentsMaintainance and safety accessoriesManufacturing technologyEngineering

The invention relates to the technical field of machine tool manufacturing, and discloses a machine tool spindle and tool airtightness testing device, which includes a device body, a pneumatic mechanism is arranged on both sides of the device body, a first controller is arranged on the top of the pneumatic mechanism, and a first controller is arranged on the top of the device body. There is a buzzer, a vent hole is set on one side of the buzzer, a second controller is set on the top of the main body of the equipment, an air-tight detection valve is set on one side of the second controller, and a pressure gauge is set on the surface of the air-tight detection valve. A main shaft is arranged inside, an arbor is arranged at one end of the main shaft, a tool is arranged at one end of the arbor, a taper shank is arranged at the other end of the arbor, and a taper hole is arranged at one end of the main shaft. This kind of machine tool spindle and tool airtightness detection equipment, by setting the machine tool spindle and tool airtightness detection system, prevents the impurities attached to the tool in advance, avoiding the processing of the workpiece when the tool and the spindle are not well matched, and the processing of the workpiece The quality and the life of the spindle have been greatly improved.

Owner:SHENZHEN SUFENG TECH

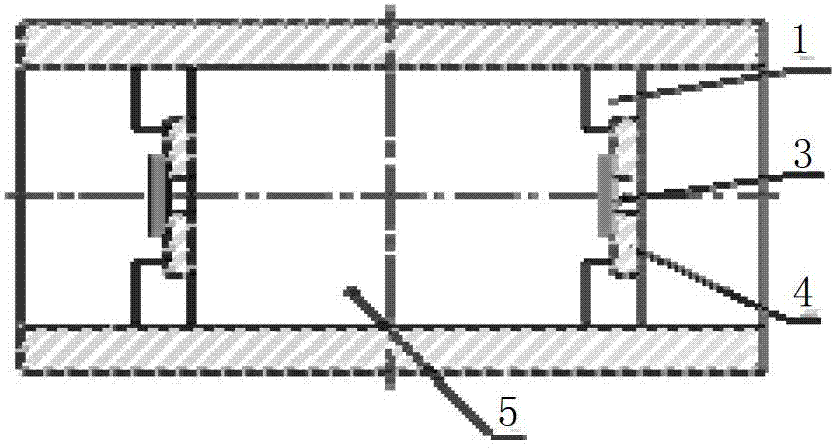

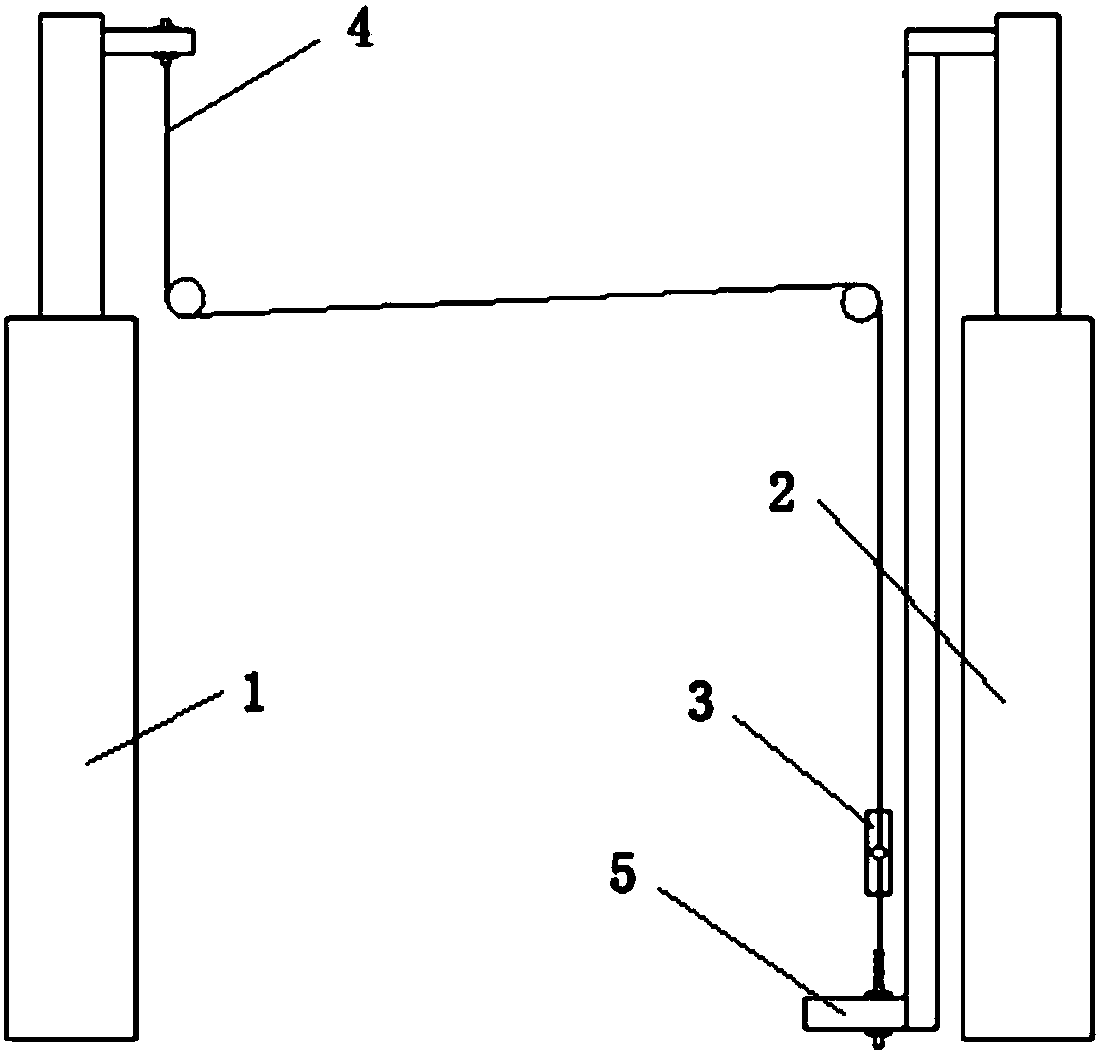

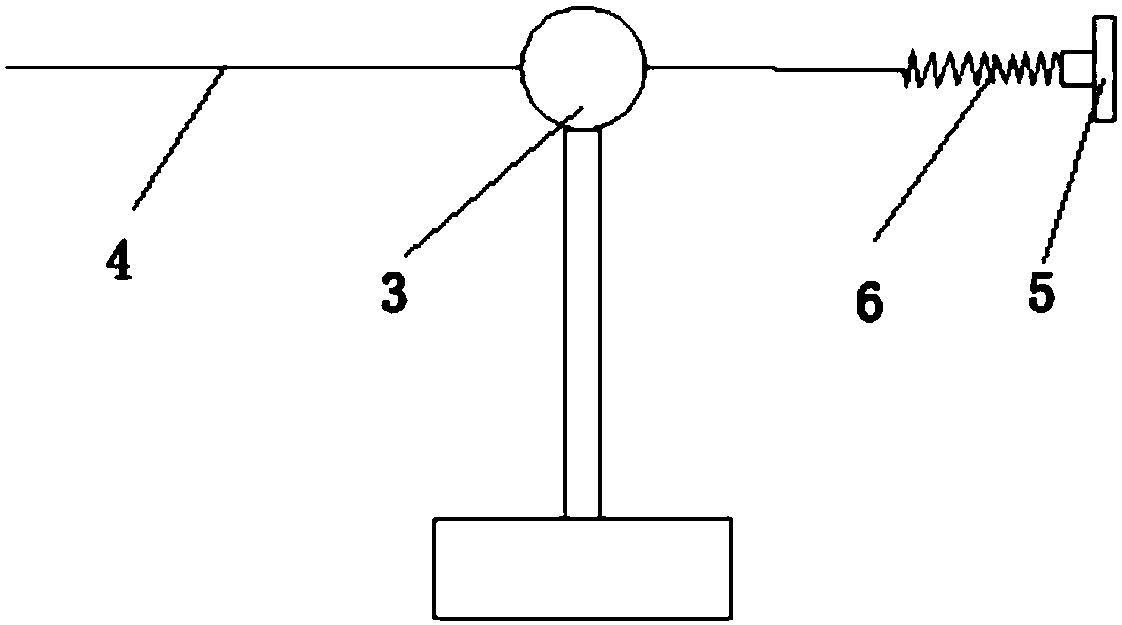

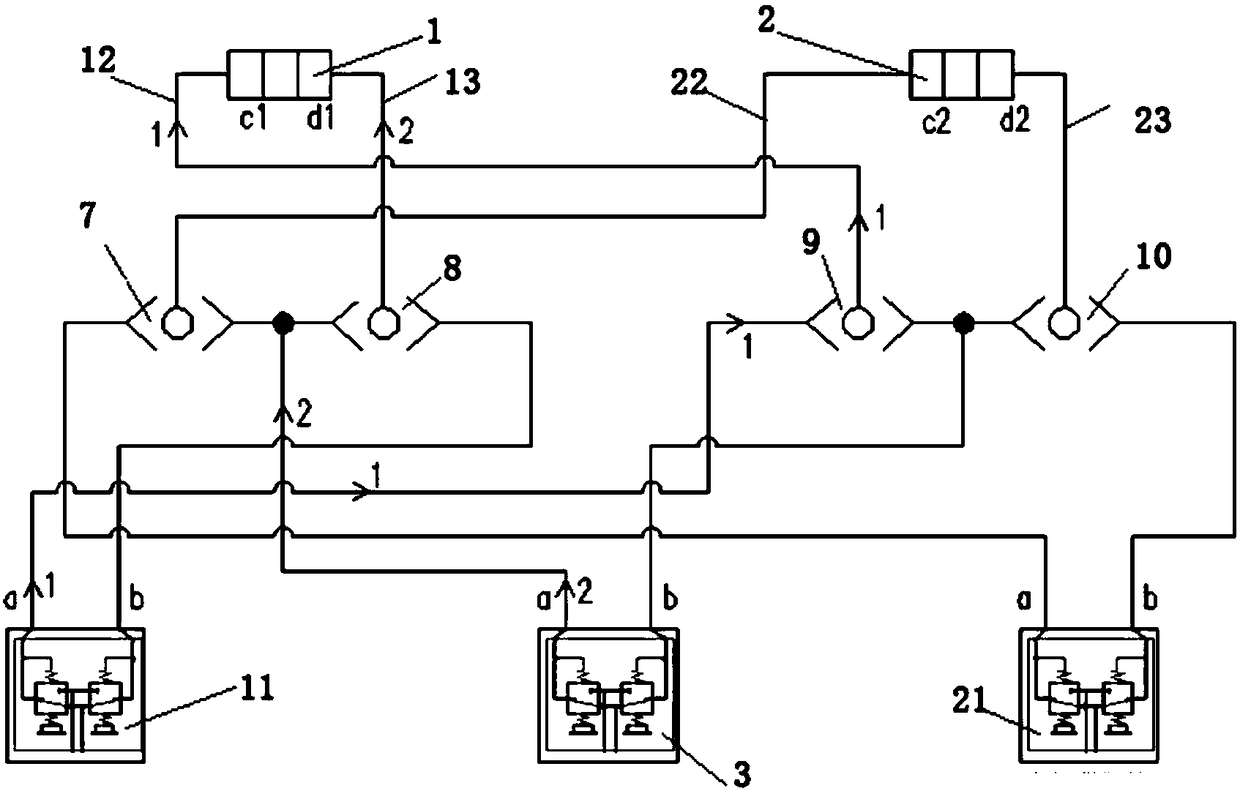

Double-hydraulic-oil-cylinder automatic synchronizing system

A double-hydraulic-oil-cylinder automatic synchronizing system comprises a first hydraulic oil cylinder, a second hydraulic oil cylinder and a feedback device, wherein a piston rod of the first hydraulic oil cylinder and a piston rod of the second hydraulic oil cylinder move in the same direction, the feedback device is used for detecting the difference of the stretching lengths of the piston rodof the first hydraulic oil cylinder and the piston rod of the second hydraulic oil cylinder during synchronous movement, the feedback device guides feedback compensation oil into a piloted oil way tocontrol a rodless cavity of the hydraulic oil cylinder with the large piston rod stretching length, and the synchronous action of the two hydraulic oil cylinders is achieved by reducing the stretchingspeed of the piston rod of the hydraulic oil cylinder. The double-hydraulic-oil-cylinder automatic synchronizing system is low in cost, reliable in control, convenient to install and detect and capable of achieving the effect of automatic synchronization of the double hydraulic oil cylinders.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

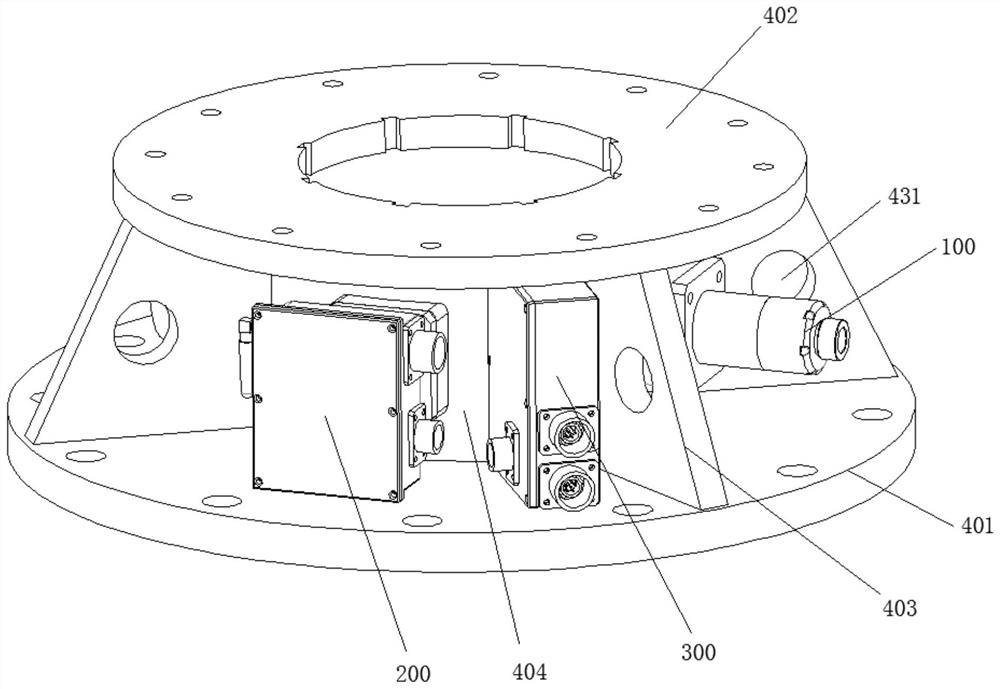

All-in-one sensing device for monitoring transformer bushing tap

PendingCN114755544ARealize remote monitoringFirmly connectedTesting dielectric strengthThermometer applicationsTransformerControl theory

The invention provides an all-in-one sensing device for monitoring an end screen of a transformer bushing, and the device comprises an end screen lead device which is connected with a grounding wire of the bushing through an installation support and leads out the grounding wire; the sensor assembly is arranged on the mounting bracket, is connected with the oil taking opening of the sleeve and is used for detecting and uploading the temperature, the pressure, the partial discharge current and the hydrogen content of the sleeve; the power supply module is arranged on the mounting bracket, takes electricity through coil induction and supplies power to the sensor assembly; the output end of the end screen lead wire device is connected with the power supply module, and the output end of the power supply module is connected with the sensor assembly. Pressure, temperature, hydrogen content, dielectric loss, UHF and HFCT signals of a transformer bushing are acquired, coil induction power taking is performed through the power module, an end screen lead wire device leads out an end screen lead-out grounding wire and sends the end screen lead-out grounding wire to the power module for detection and power taking, the end screen lead-out grounding wire is converted into voltage and current required by a sensor assembly through the power module, installation and detection are convenient, and the detection efficiency is improved. Maintenance is reduced, and the service life is prolonged.

Owner:ELECTRIC POWER SCI RES INST OF STATE GRID XINJIANG ELECTRIC POWER +2

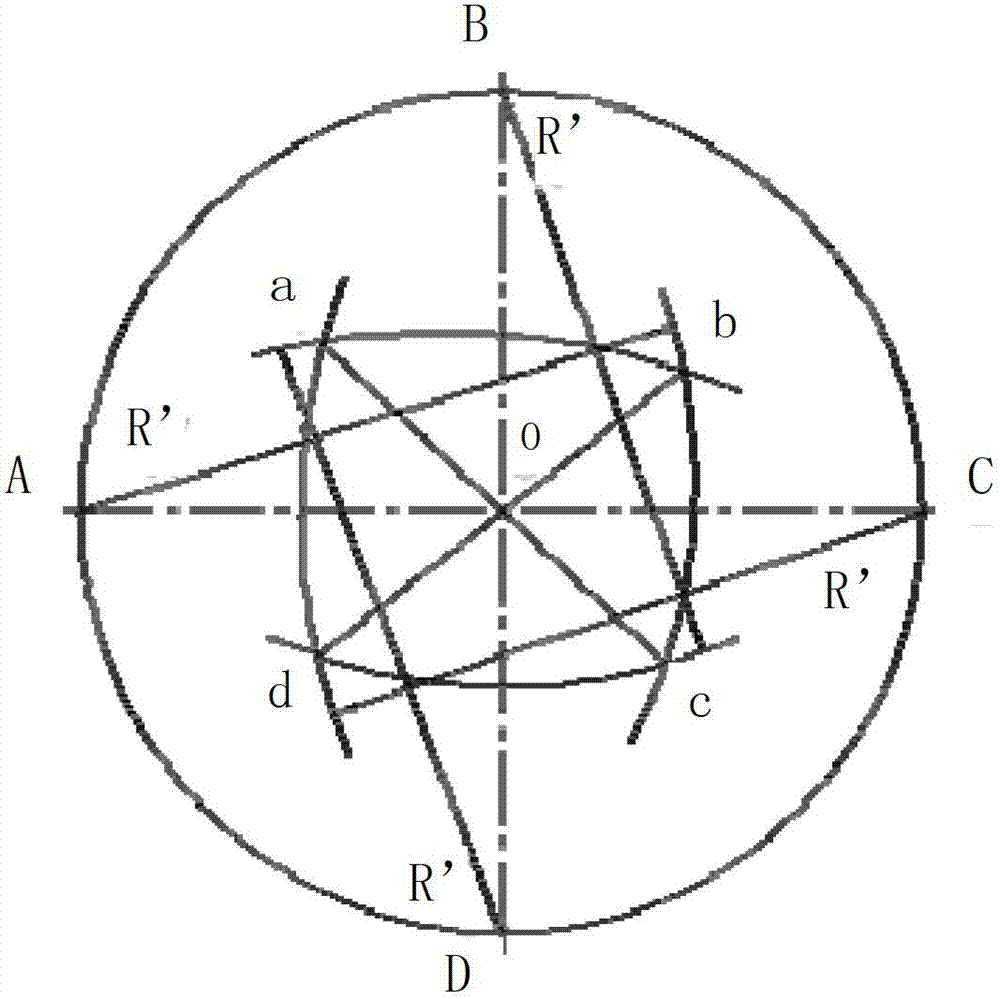

Method for assembling rotary kiln

ActiveCN102706139BEasy, quick and accurate installationEasy to install and detectRotary drum furnacesLaser beamsMechanical engineering

The invention relates to a method for assembling a rotary kiln. The method for assembling the rotary kiln includes steps: respectively marking out end face center points on two end faces of each section of a barrel of the rotary kiln pertinently; erecting a laser emitting device which emits laser beams according to the technique inclination of the rotary kiln; adjusting relative positions of the laser emitting device and a preset section so as to enable the laser beams to shoot the center points of the two end faces of the preset section provided with a transmission gear to establish a laser datum line; sequentially adjusting positions of the other sections except the preset section according to the distances from the other sections to the laser emitting device from near to far so that distances from the shooting position of the laser datum line on each end face to the center point of the end face in an X-direction and a Y-direction are within a preset error range; and fixedly connecting the sections. By the aid of the technical scheme of the method for assembling the rotary kiln, the rotary kiln can be conveniently and rapidly assembled, measuring accuracy can be improved, deviation is avoided to the greatest extent, and design requirements of the rotary kiln are met.

Owner:中色十二冶金建设有限公司

Horizontal testing equipment for oil pump

ActiveCN104153983BEasy to testSimple structurePump testingPortable liftingDrive shaftPetroleum engineering

The invention relates to horizontal testing equipment for an oil pump. The horizontal testing equipment comprises a rack, a clamp system, a power system, a pipeline system and a detection system, the power system is connected with and transmits torque to the clamp system, the oil pump is mounted on the clamp system, the pipeline system is connected on the oil pump, the detection system is mounted on the pipeline system for detection, the clamp system comprises an adjusting support, a transmission shaft and a testing plate, the transmission shaft penetrates the adjusting support, one end of the transmission shaft is connected to the power system while the other end of the same penetrates the testing plate, and a main gear is mounted at the other end of the transmission shaft; the oil pump is mounted on the testing plate, an auxiliary gear is mounted on the oil pump, the main gear is meshed with the auxiliary gear to form a gear member which is made by carbon-tempered steel, the oil pump is close to and sealed on the testing plate, an oil incoming hole and an oil outgoing hole which are communicated to the oil pump are formed in the testing plate, and the pipeline system is connected on inlets of the oil incoming hole and the oil outgoing hole respectively. The horizontal testing equipment is simple in structure, convenient in testing, accurate in testing performance and long in service life.

Owner:JIANGSU CHANGHUI COMPLETE EQUIP

Petal Friction Turning Device for Touch Conveyor Belt Tear Detection Equipment

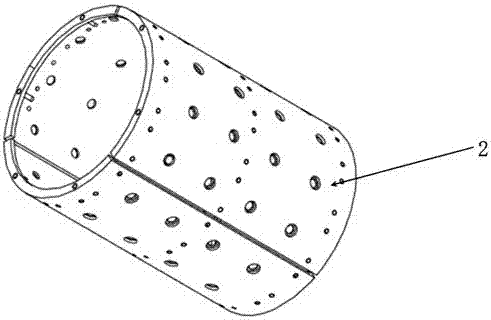

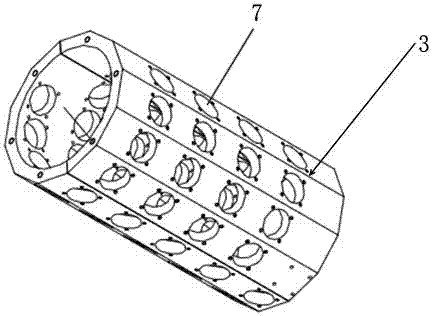

ActiveCN105173612BCompact structureEasy to disassembleControl devices for conveyorsBarrel ShapedEngineering

The petal-type friction rotating device used for the touch-type conveyor belt tear detection equipment is provided with an inner shell and an outer shell sleeved on the inner shell. The two ends of the outer shell are respectively connected to the inner shell to form a rotating body. , the rotating body is sleeved on the fixed shaft, the outer shell is a cylindrical structure spliced by multiple petal structures, a cavity for placing detection equipment is formed between the outer shell and the inner shell, and the outer shell Corresponding installation holes are provided on the body and the inner casing, and the detection equipment passes through the installation holes of the outer casing to detect the rotation of the object under test. The casing can be used to install detection equipment, which can be detected with the rotation of the object to be detected.

Owner:LUOYANG TST FLAW DETECTION TECH

Horizontal type test equipment for oil pump

ActiveCN104121180BEasy to testSimple structurePump testingPositive-displacement liquid enginesTest performanceDrive shaft

The invention provides a horizontal type test equipment for an oil pump, and belongs to the technical field of test equipment. The horizontal type test equipment for the oil pump solves the problem that test performance of existing test equipment is not accurate enough. The horizontal type test equipment for the oil pump comprises a rack, a clamp system, a power system, a pipeline system and a detection system, the power system is connected to the clamp system and transmits torque to the clamp system, the oil pump is mounted on the clamp system, the pipeline system is connected to the oil pump, the detection system is mounted on the pipeline system and carries out detection, the clamp system comprises an adjusting support, a transmission shaft and a test plate, the transmission shaft penetrates through the adjusting support, one end of the transmission shaft is connected to the power system, the other end of the transmission shaft is provided with a main gear, an auxiliary gear is mounted on the oil pump, the main gear is meshed with the auxiliary gear, the oil pump is attached to the test plate in a sealing mode, an oil inlet and an oil outlet are formed in the test plate, and the pipeline system is connected to the oil inlet and the oil outlet respectively. The horizontal type test equipment for the oil pump has the advantages of being accurate in testing and good in stability.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

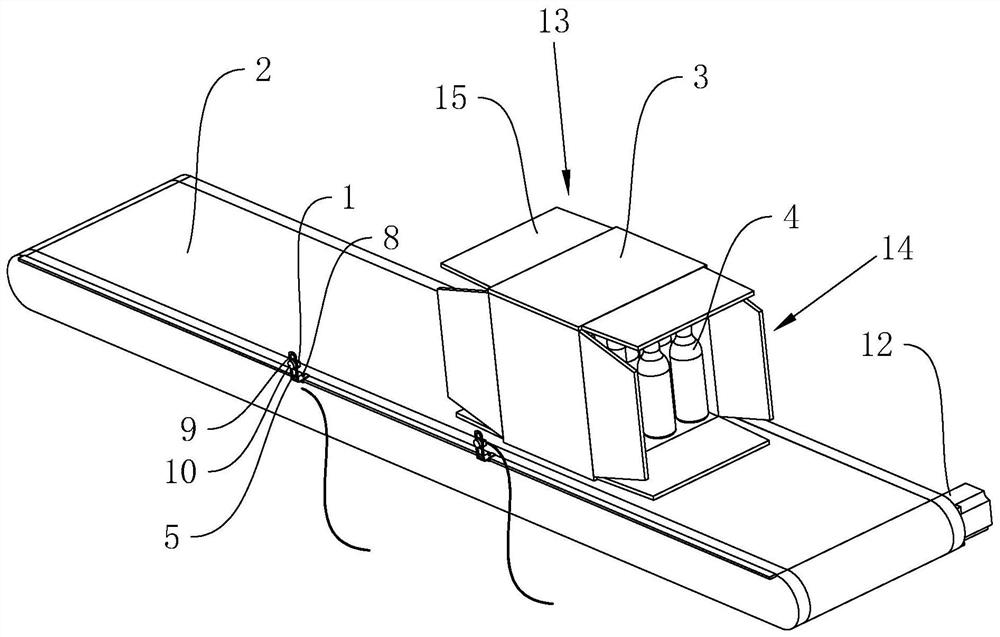

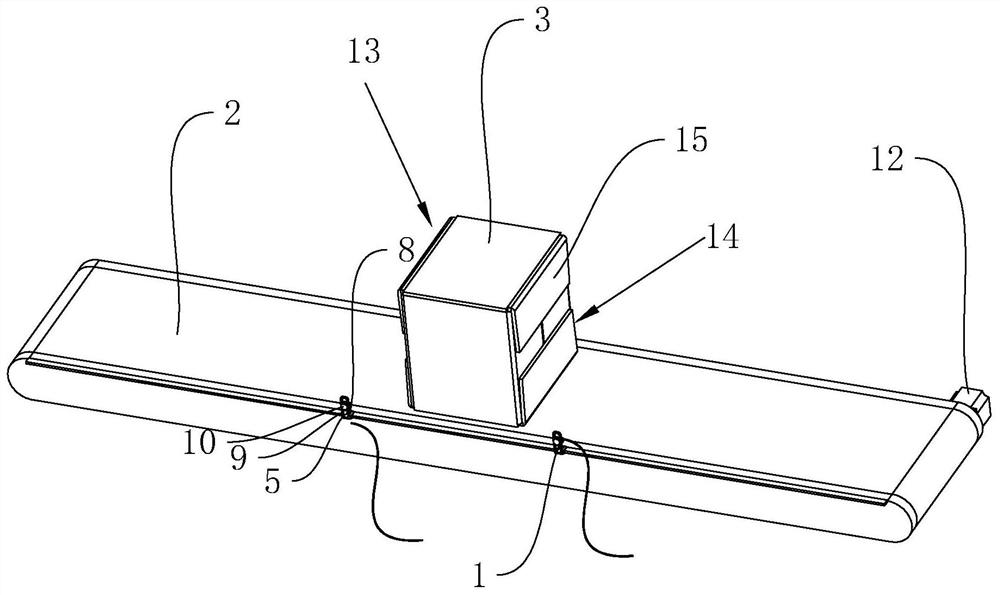

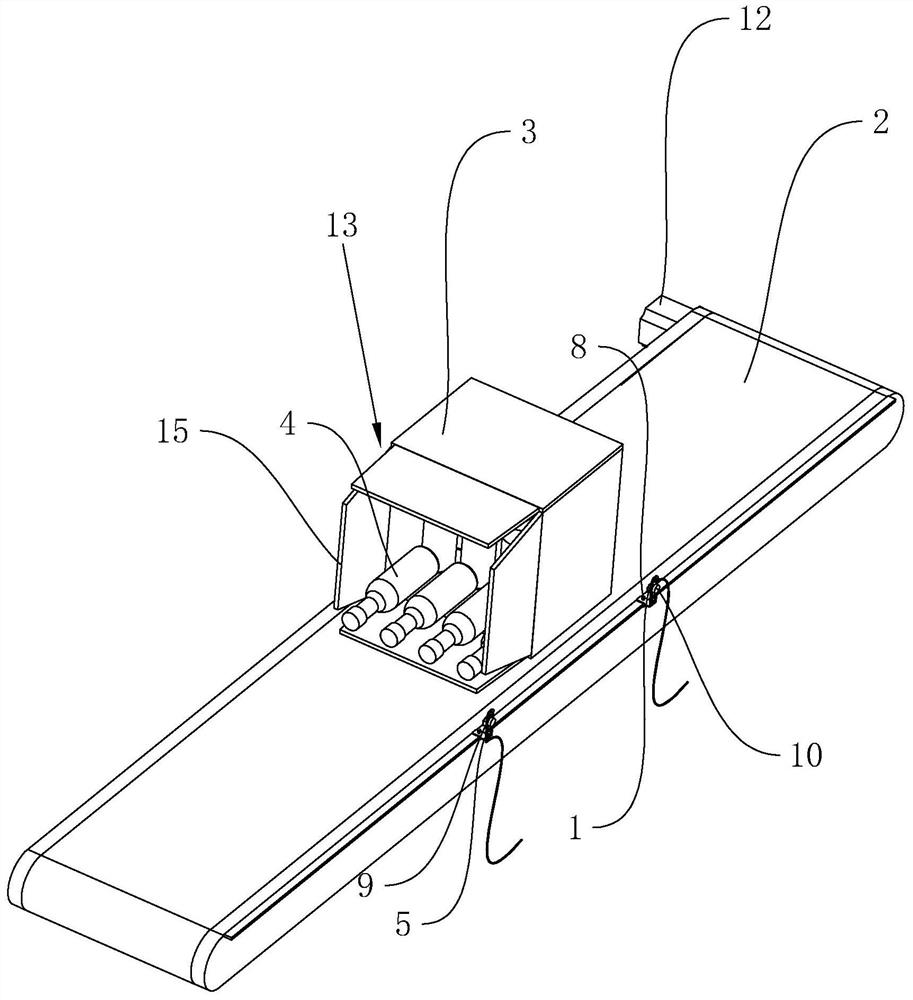

Packing and bottle protection system

ActiveCN110902048BGuaranteed to proceed normallyIncrease productivityPackaging automatic controlPackaging bottlesControl signalBottle

Owner:李锦记(广州)食品有限公司

Overhaul platform for routine tests of transformer substation

The invention relates to an overhaul platform for routine tests of a transformer substation. An upper transverse fixing frame and a lower transverse fixing frame are welded to the upper end and the lower end of a vertical fixing frame respectively, a supporting plate and a climbing ladder are arranged on the lower transverse fixing frame, the supporting plate is arranged on the two sides of the climbing ladder, a sliding connecting plate is arranged behind the supporting plate, and a rear supporting block and a front supporting block are arranged on the upper portion of the supporting plate. Asliding connecting block is further arranged behind the sliding connecting plate and arranged on a pull-up belt, one end of the pull-up belt is arranged on a belt wheel of a pull-up motor, the otherend of the pull-up belt is arranged in a rotating box, the pull-up motor is arranged on a fixing plate of a lower transverse fixing frame, and a rear baffle is arranged between the upper transverse fixing frame and the lower transverse fixing frame. A rectangular hole is formed in the rear baffle, a sliding connecting block moving up and down is arranged in the rectangular hole, fixed sliding blocks are arranged on the two sides of the rear portion of the supporting plate, fixed sliding rails are arranged on the two sides of the rear baffle, and the fixed sliding blocks are matched with the fixed sliding rails; and the overhaul platform has the advantages of being reasonable in structure, high in stability and convenient to detect and install.

Owner:JIYUAN POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

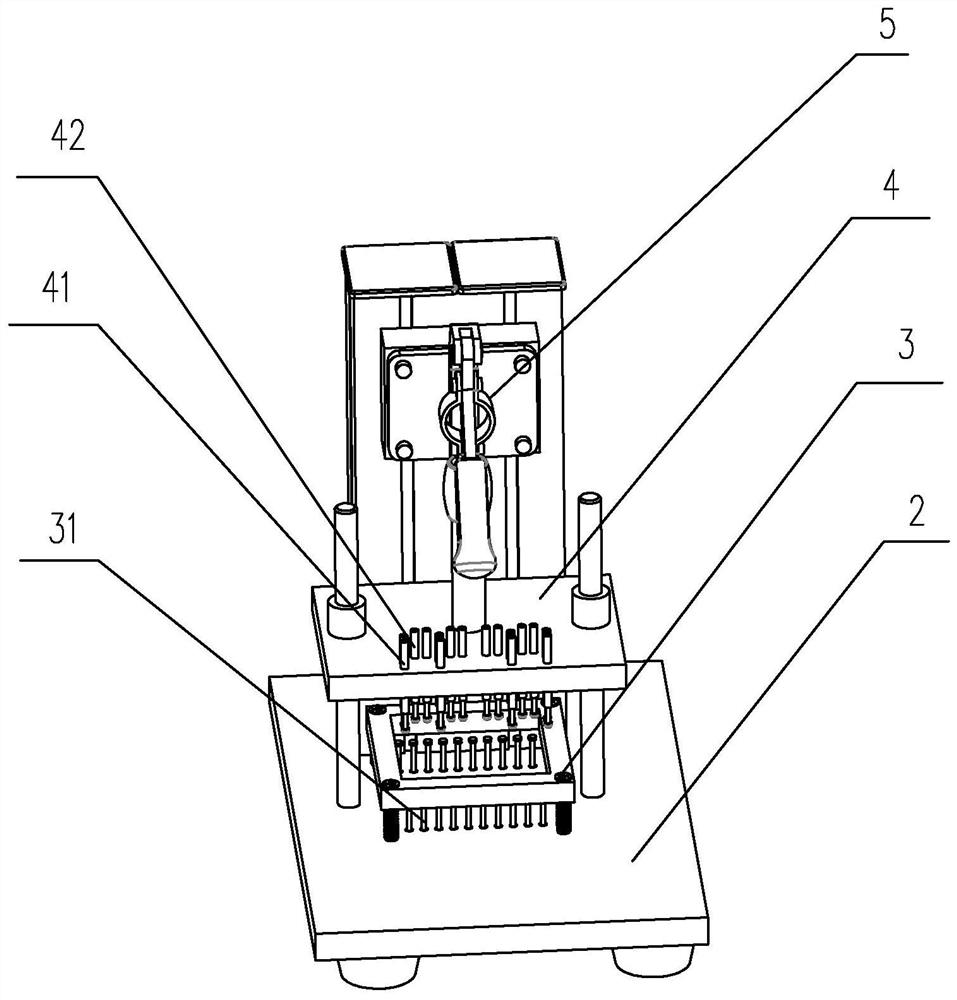

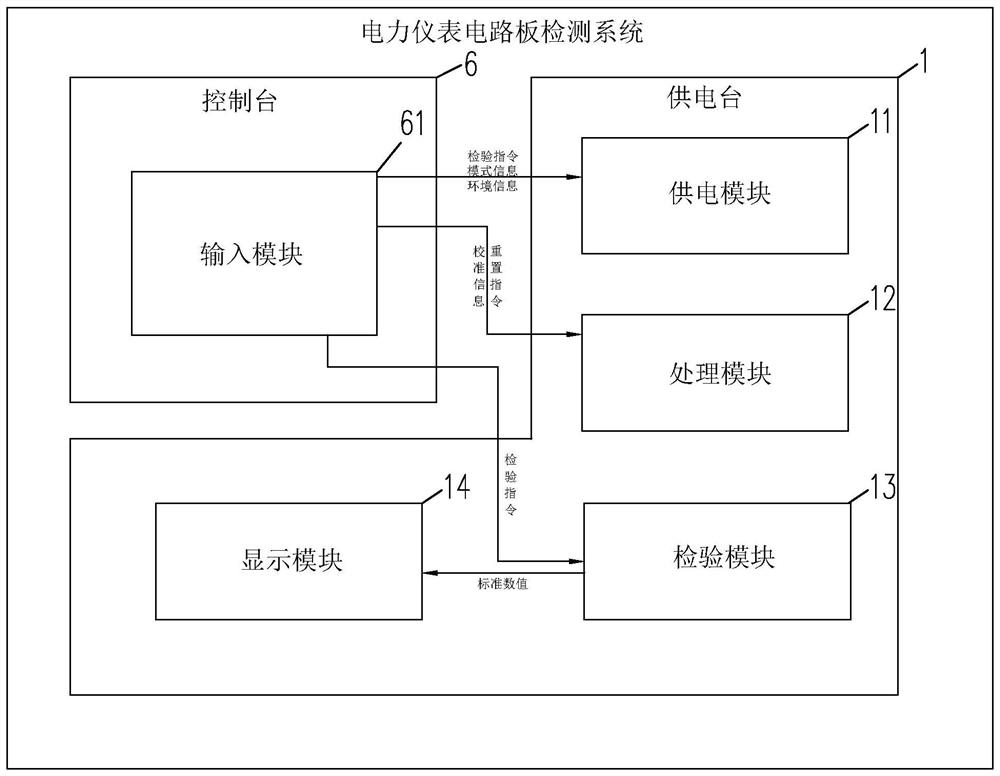

Electric power instrument circuit board detection device

PendingCN112595950ASimple structureEasy to implementPrinted circuit testingMechanical engineeringControl theory

The invention discloses an electric power instrument circuit board detection device and detection system. The device comprises an operation support which is provided with a pedestal and an abutting seat, wherein the operation support is provided with a plurality of detection slots in an inserted manner, the detection slots are provided with first probes in an inserted manner, the abutting seat isdisposed on the operation support in a sliding manner, a rapid clamp is arranged on the operation support, a first detection station and a second detection station are arranged on the abutting seat, and the first detection station and the second detection station comprise a plurality of second probes. The detection system comprises a power supply station and a control console, wherein the controlconsole is used for inputting environment information and mode information and sending the mode information and the environment information to a power supply module; and the power supply station is used for receiving the mode information and the environment information and working. The circuit board of the electric power instrument can be effectively detected, and the structure is simple and easyto realize.

Owner:永诺电气有限公司

Boxing and bottle falling protection system

ActiveCN110902048AGuaranteed to proceed normallyIncrease productivityPackaging automatic controlPackaging bottlesControl signalCarton

The invention relates to the field of packaging machinery, aims to provide a boxing and bottle falling protection system. The system is characterized by comprising an indication unit which plays a warning role and detection elements which output electric signals when being shielded, the system further comprises a paper box, output ends of the detection elements are electrically connected with an input end of the indication unit, the two detection elements are installed on the same side of a conveying device, a distance between the two detection elements is larger than the length of the paper box and smaller than the sum of the length of the paper box and the height of a bottle, when the paper box is conveyed to pass through the first detection element, the first detection element outputs acontrol signal enabling a wrapping machine to work, only when bottles in the paper box lie down to shield the second detection element, the second detection element outputs a control signal enablingthe indication unit to work. The device is advantaged in that the device is suitable for monitoring the bottle falling phenomenon when the paper box is folded.

Owner:李锦记(广州)食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com