Fusible bolt structure and installation method thereof, air conditioner provided with the fusible bolt structure

An installation method and technology of fusible bolts, which are applied to safety valves, valve devices, heating methods, etc., can solve the problems of unreliable sealing, inconvenient installation and inspection of fusible bolt structures, etc., to ensure sealing performance, convenient installation and inspection, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

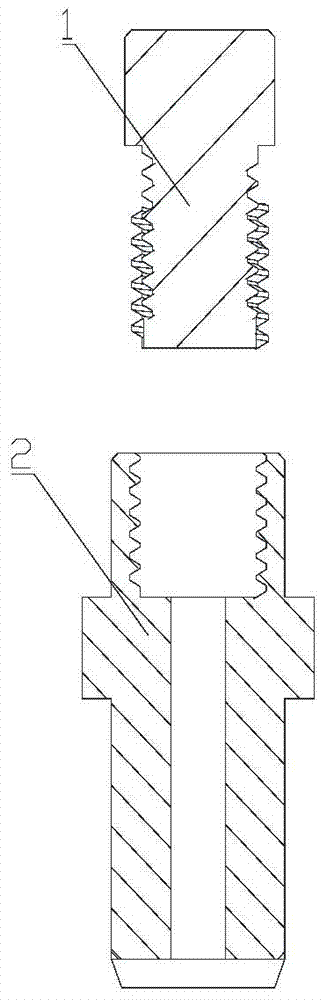

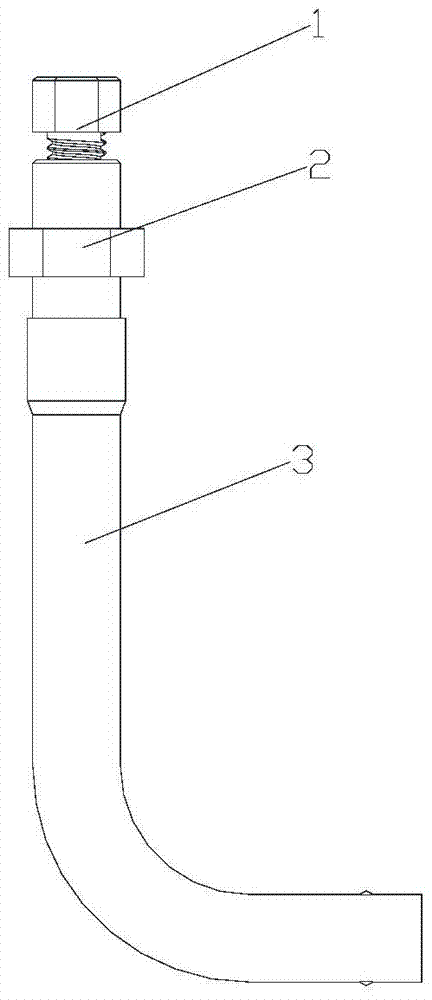

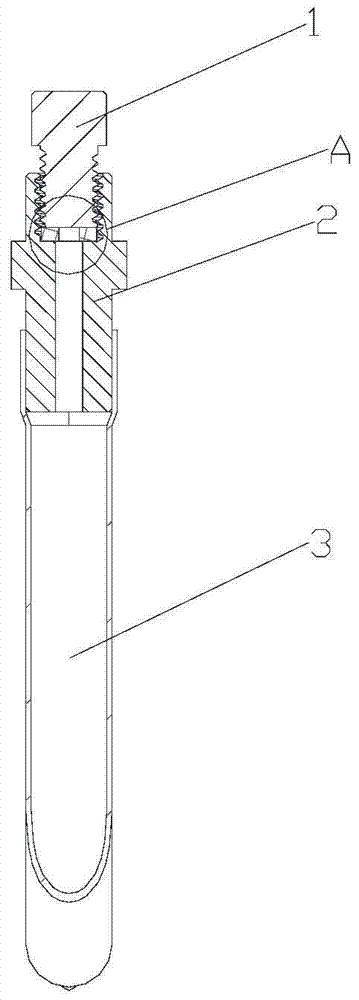

[0034] like figure 2 and image 3 As shown, a fusible plug structure provided by Embodiment 1 of the present invention includes a fusible plug body 1 , a fusible plug seat 2 and a copper pipe 3 . One end of the fusible bolt seat 2 is sealed and connected with the fusible bolt body 1, preferably the fusible bolt seat 2 and the fusible bolt body 1 are threaded, such as image 3 As shown, one end of the fusible bolt seat 2 in the first embodiment is provided with a threaded hole, and the fusible bolt body 1 is provided with an external thread, and the external thread of the fusible bolt body 1 is mated with the threaded hole of the fusible bolt seat 2, When the fusible bolt body 1 is screwed into the fusible bolt seat 2, glue can be applied or a raw material tape can be added to ensure the tightness of the fusible bolt structure in this embodiment. It should be noted that the airtight connection between the fusible bolt body 1 and the fusible bolt seat 2 is not limited to the ...

Embodiment 2

[0045] Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be described again. The difference is that the fusible bolt structure provided in Embodiment 2 is applied to the pressure vessel 6, such as Image 6 As shown, the copper tube 3 of the present embodiment 2 is a linear copper tube 31, one end of the linear copper tube 31 is sealed and connected to the fusible plug seat 2, and the other end of the linear copper tube 31 is connected to the pressure vessel 6, and the linear copper tube 31 is connected to the pressure vessel 6. The other end of the copper pipe 31 is directly welded to the pressure vessel 6 .

[0046]It should be noted that the shape of the copper pipe 3 is not limited to L-shape or straight-shape, and may be other shapes.

[0047] In summary, the fusible bolt structure provided by the present invention and the air conditioner provided with the fusible bolt structure fully connect the fusible bolt body 1 and the fusible bolt seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com