Double-hydraulic-oil-cylinder automatic synchronizing system

A hydraulic cylinder and automatic synchronization technology, which is applied in the direction of fluid pressure actuators, servo motors, mechanical equipment, etc., can solve the problems of complex installation, high cost, and precision regardless of cost, and achieve convenient installation and detection, reliable control, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

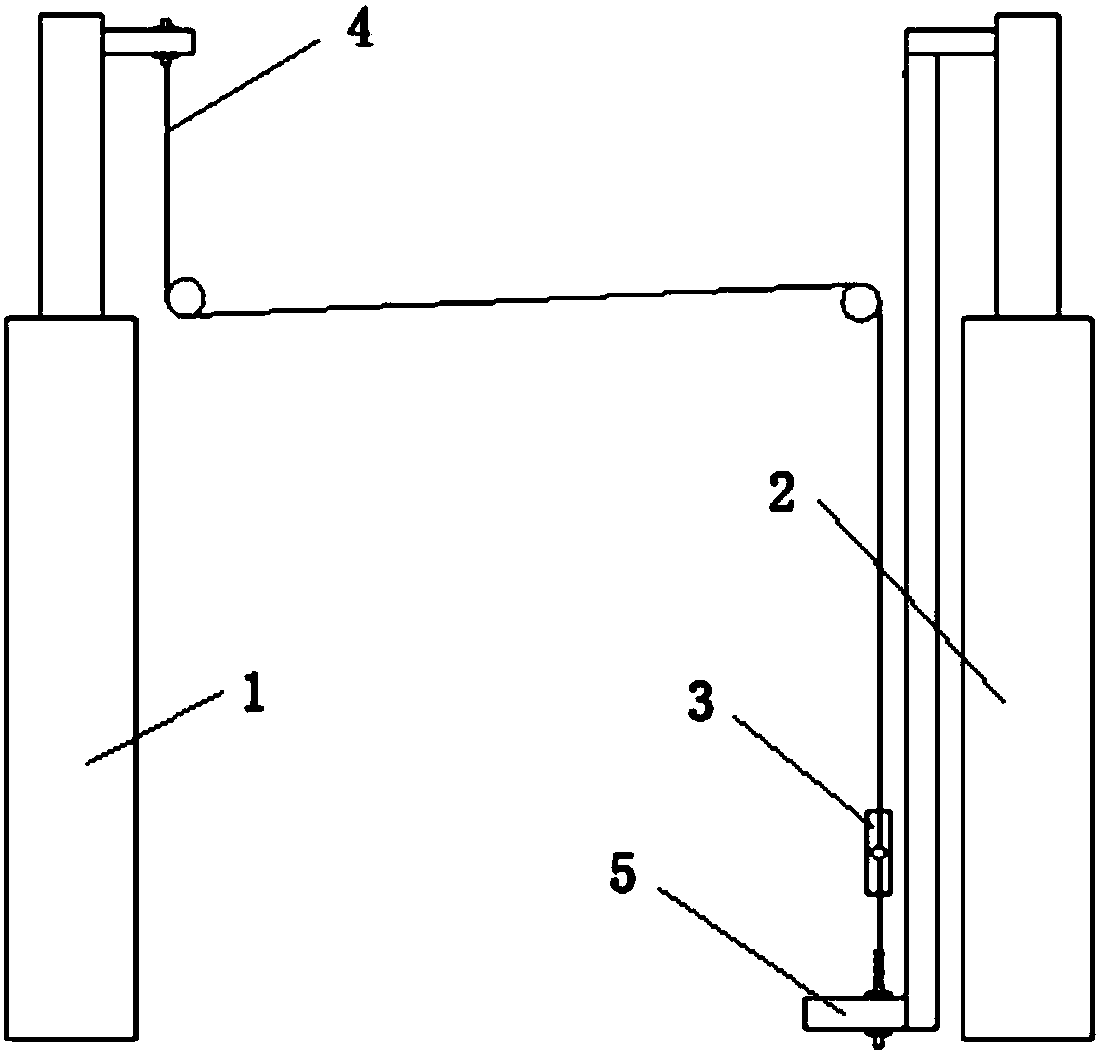

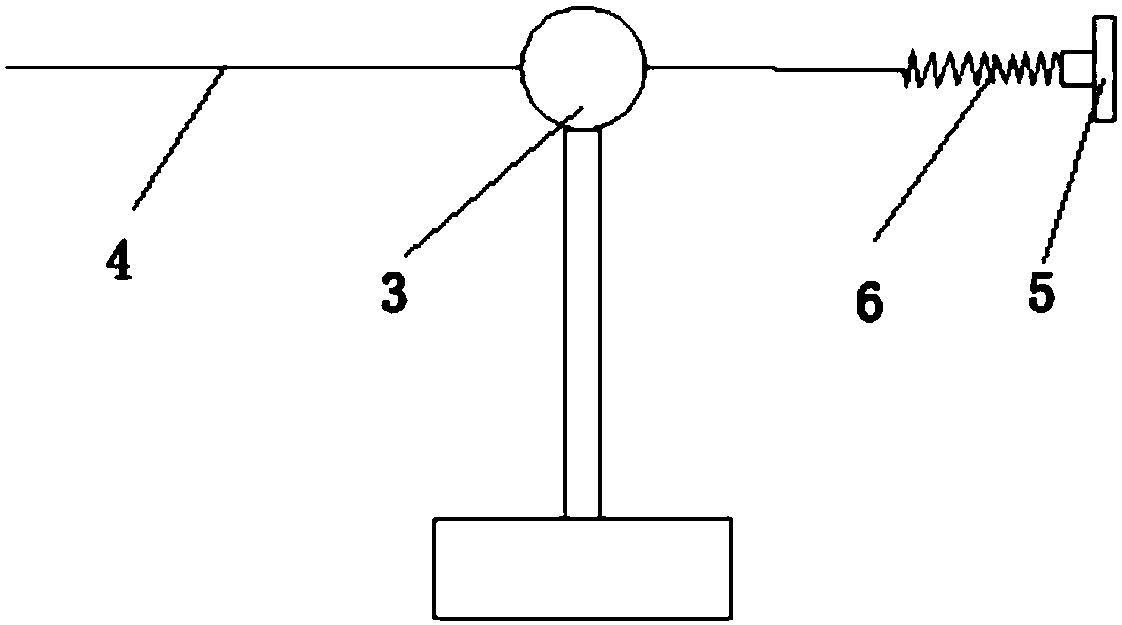

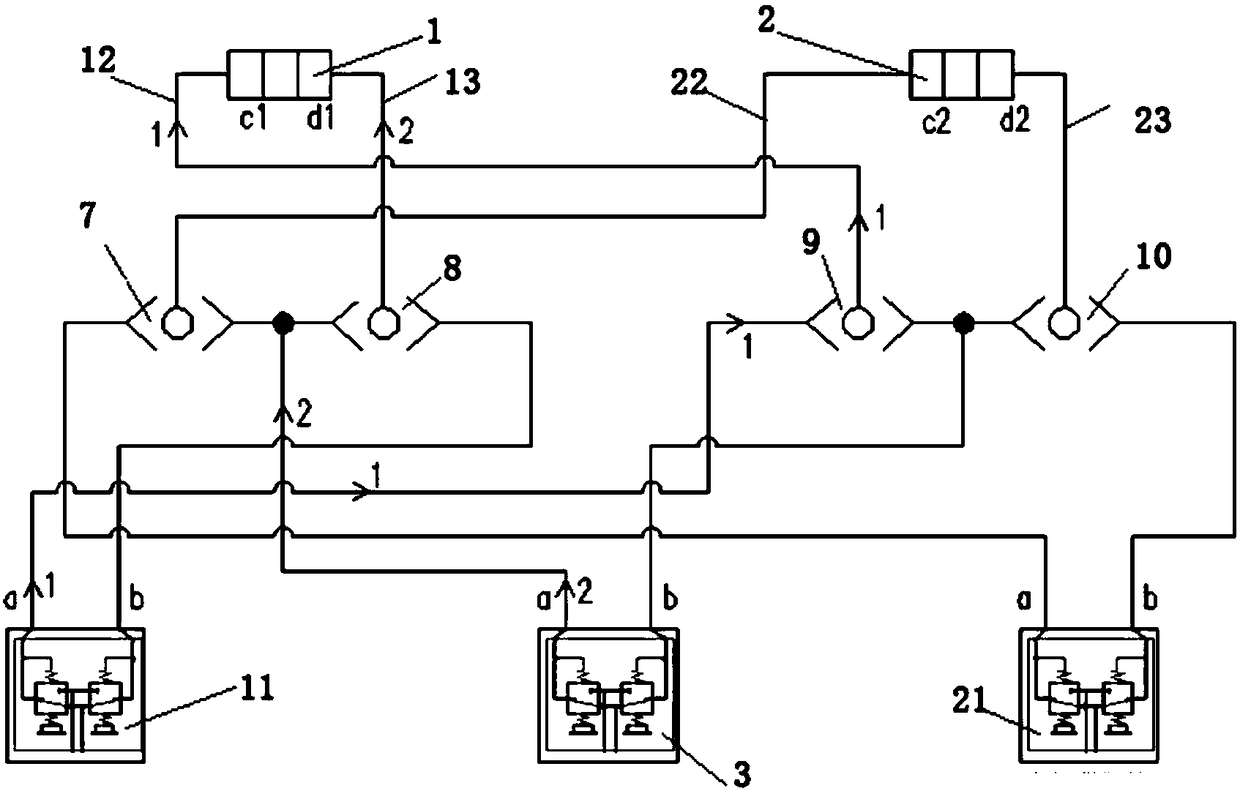

[0022] Such as Figures 1 to 3 As shown, a double hydraulic cylinder automatic synchronization system, including: the first hydraulic cylinder 1, the second hydraulic cylinder 2 with the piston rods moving in the same direction, and the piston rod used to detect the synchronization of the first hydraulic cylinder piston rod and the second hydraulic cylinder piston rod Feedback handle 3 that stretches out the difference in length during movement; the first hydraulic cylinder 1 is stretched and retracted by the first cylinder operating handle 11 through the control valve, and the second hydraulic cylinder 2 is stretched by the second cylinder operating handle 21 through the control valve .

[0023] The piston rod of the first hydraulic cylinder 1 is connected to the feedback handle 3 through the first connection device, the piston rod of the second hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com