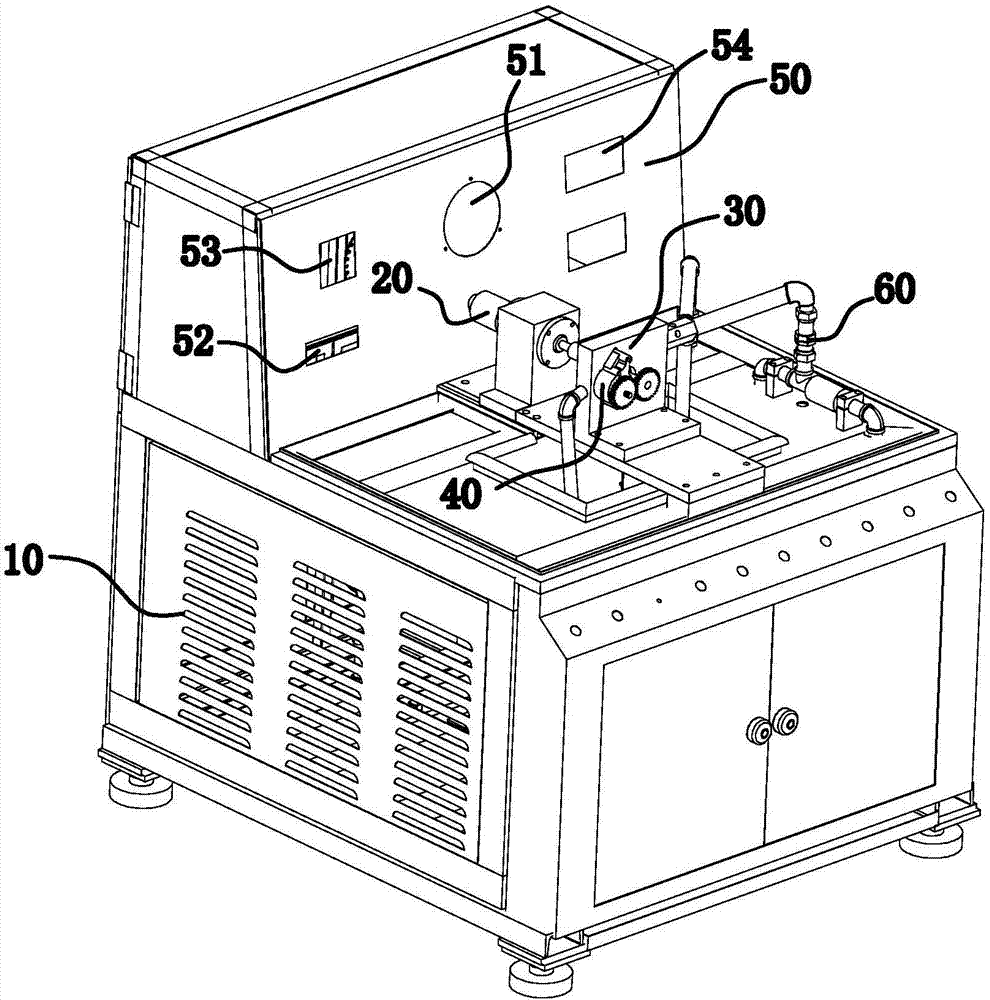

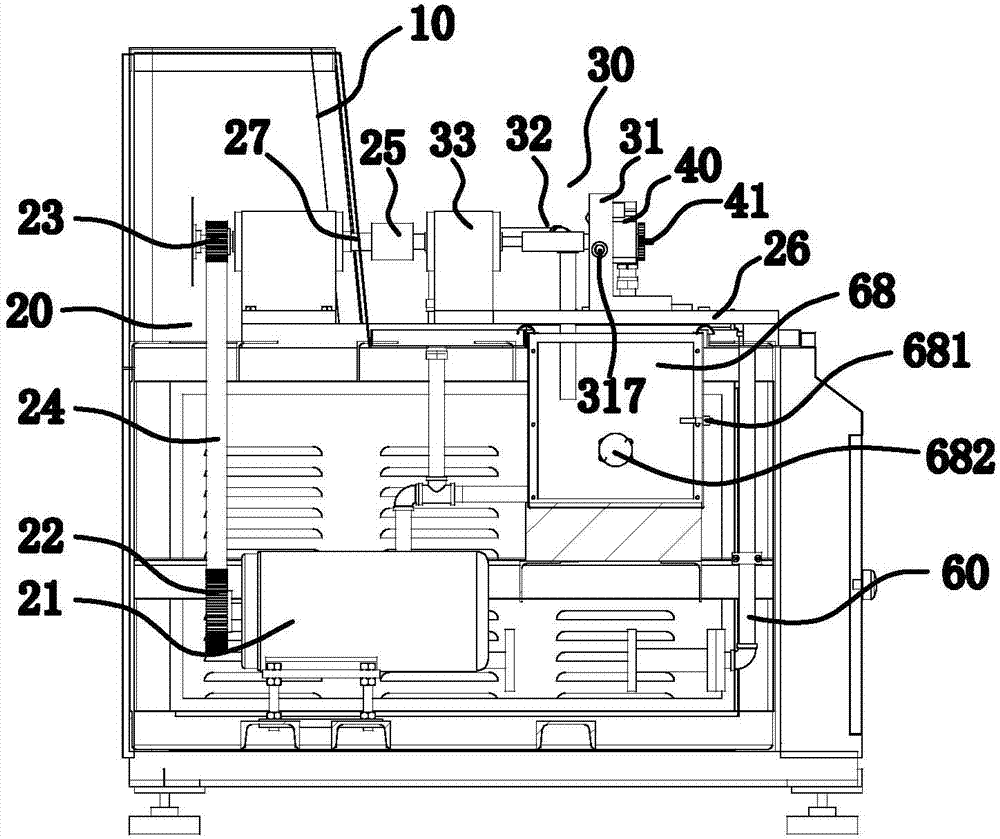

Horizontal testing equipment for oil pump

A technology for testing equipment and oil pumps, applied in pump testing, mechanical equipment, heat treatment equipment, etc., can solve the problems of inaccurate test performance and inability to effectively reflect the working conditions of the oil pump, and achieve convenient testing, good strength, and improved cutting processing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

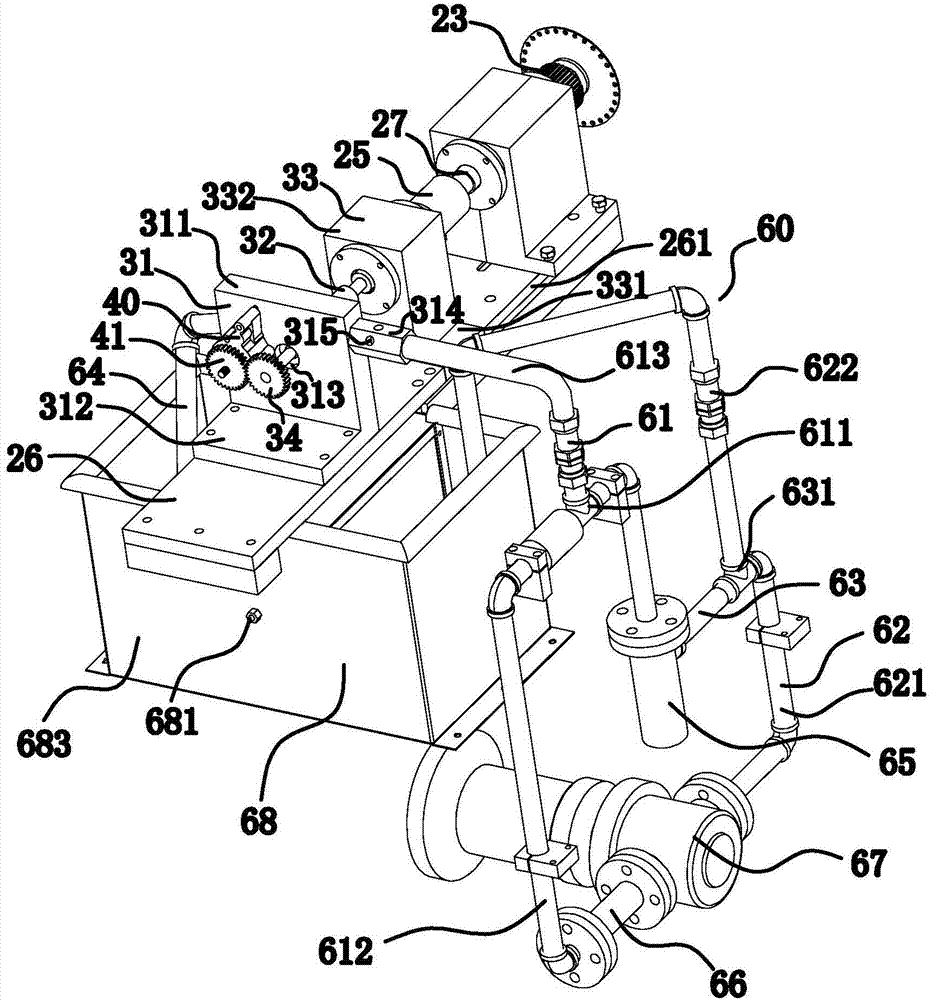

[0071] Forging: Weigh the raw materials according to the composition and weight percentages of the gear parts in the horizontal test equipment of the oil pump in Example 1 of Table 1, and forge them into main gear and auxiliary gear blanks respectively;

[0072] Normalization treatment and rough machining: the above-mentioned forged main gear and pinion gear blanks are first heated to 900°C for normalization treatment, and then a large amount of margin is removed, and the holes and end faces on the main gear and pinion gear blanks are preliminarily processed. forming;

[0073] Quenching and tempering treatment: heat the rough-processed main gear and auxiliary gear to 830°C for quenching and tempering treatment;

[0074] Finishing: finish the main gear and auxiliary gear after quenching and tempering treatment, and then send them to the machining center for drilling and tapping;

[0075] Heat treatment: High-frequency quenching is carried out on the finished main gear and auxi...

Embodiment 2

[0077] Forging: Weigh the raw materials according to the composition and weight percentages of the gear parts described in Table 1, Example 2, and the oil pump horizontal test equipment, and forge them into main gear and auxiliary gear blanks respectively;

[0078] Normalization treatment and rough machining: heat the above-mentioned forged main gear and auxiliary gear blanks to 880°C for normalization treatment, then remove a large amount of surplus, and preliminarily process the holes and end faces of the main gear and auxiliary gear blanks. forming;

[0079] Quenching and tempering treatment: heat the rough-processed main gear and auxiliary gear to 840°C for quenching and tempering treatment;

[0080] Finishing: finish the main gear and auxiliary gear after quenching and tempering treatment, and then send them to the machining center for drilling and tapping;

[0081] Heat treatment: High-frequency quenching is carried out on the finished main gear and auxiliary gear at 82...

Embodiment 3

[0083] Forging: Weigh the raw materials according to the composition and weight percentages of the gear parts described in Table 1, Example 3, and the oil pump horizontal test equipment, and forge them into main gear and auxiliary gear blanks respectively;

[0084] Normalization treatment and rough machining: heat the above-mentioned forged main gear and pinion gear blanks to 920°C for normalization treatment, then remove a large amount of surplus, and preliminarily process the holes and end faces of the main gear and pinion gear blanks. forming;

[0085] Quenching and tempering treatment: heat the rough-processed main gear and auxiliary gear to 820°C for quenching and tempering treatment;

[0086] Finishing: finish the main gear and auxiliary gear after quenching and tempering treatment, and then send them to the machining center for drilling and tapping;

[0087] Heat treatment: High-frequency quenching is carried out on the finished main gear and auxiliary gear at 860°C an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com