Petal Friction Turning Device for Touch Conveyor Belt Tear Detection Equipment

A technology for testing equipment and rotating devices, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of general products without suitable structures, and achieve enhanced load, improved utilization, and simple and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

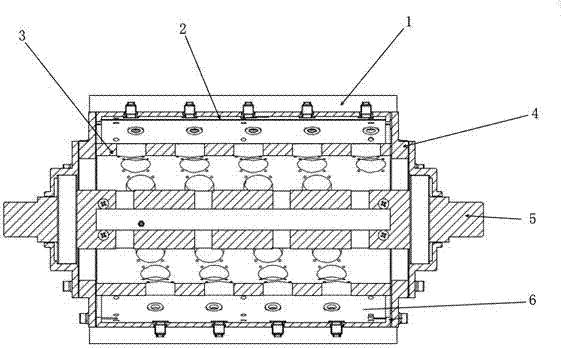

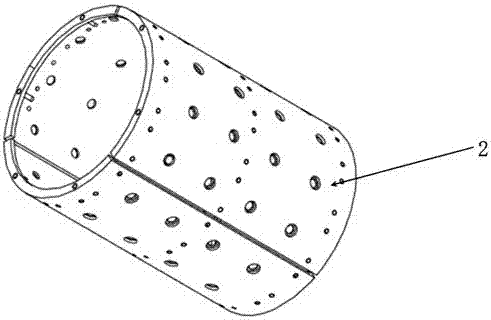

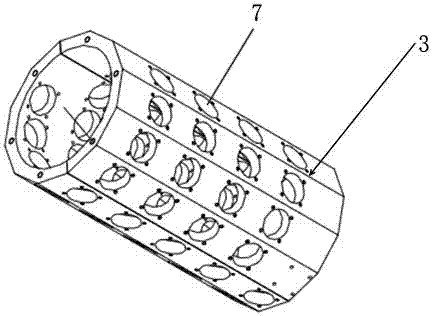

[0023] As shown in the figure, the petal-type friction rotating device used for the touch-type conveyor belt tear detection equipment includes an inner shell, an outer shell, a fixed shaft and a friction plate; there are a series of spiral-shaped installation holes on the inner shell and the outer shell ( To ensure uninterrupted contact with the surface of the detected object when rotating), the mounting hole is used to install the detection equipment, the detection equipment is under the pressure of the measured object during detection, and realizes expansion and contraction in the installation hole, and the contact with the sensor is realized through expansion and contraction.

[0024] In order to facilitate the processing, the outer casing is set as a three-lobe type. There are connecting holes at both ends of each outer casing flap. The three outer casing flaps are connected to the inner casing by the connecting end cover through the connecting position to form a rotating bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com