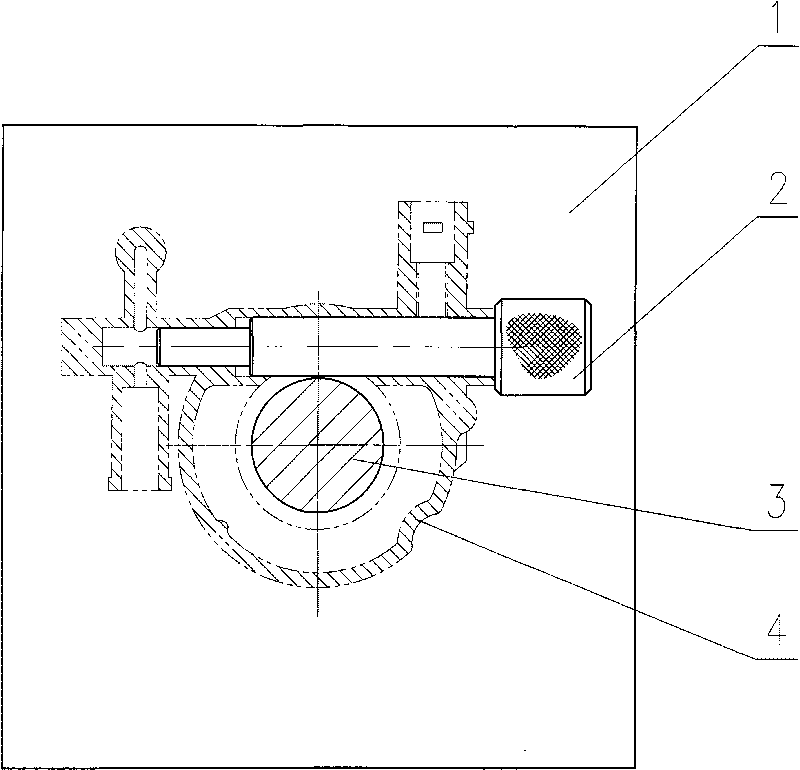

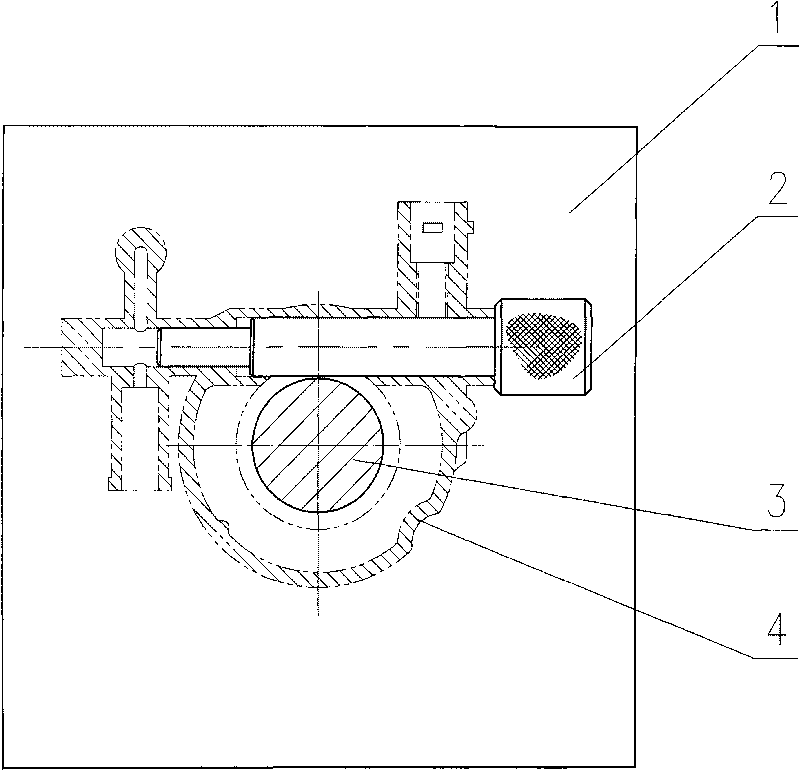

Detection tool for center distance between matched and mutually perpendicular holes

A technology of mutual perpendicularity and center distance, applied in the direction of mechanical clearance measurement, etc., can solve the problems of complicated inspection tool installation, high inspection cost, low efficiency, etc., and achieve the effect of easy inspection and installation, simple structure and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

[0013] The paired and mutually perpendicular hole center distance inspection tool shown in the accompanying drawing includes a positioning mandrel 3 standing on a flat workbench 1 and matching with the vertical hole of the workpiece 4, and a mandrel 2 matching with the horizontal hole of the workpiece 4 . The positioning mandrel 3 is tangent to the outer wall of the middle section of the mandrel 2 . This embodiment is a test tool for the center distance of the pump body of the motorcycle oil pump, in which the shaft section of the positioning mandrel 3 with an outer diameter of Φ21.4mm cooperates with the hole at the vertical position of the oil pump to determine the position of the oil pump on the flat workbench 1, and then Insert the matched mandrel 2 from the horizontal hole on the right side of the oil pump, locate the mandrel 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com