Sugarcane mud organic fertilizer with Bacillus subtilis and preparation method thereof

A technology of Bacillus subtilis and sugarcane filter mud, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, etc., can solve the problems of large impact on the surrounding environment, long production cycle, slow water volatilization, etc., and shorten the fermentation period. cycle, increase the fermentation speed, and have obvious deodorizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

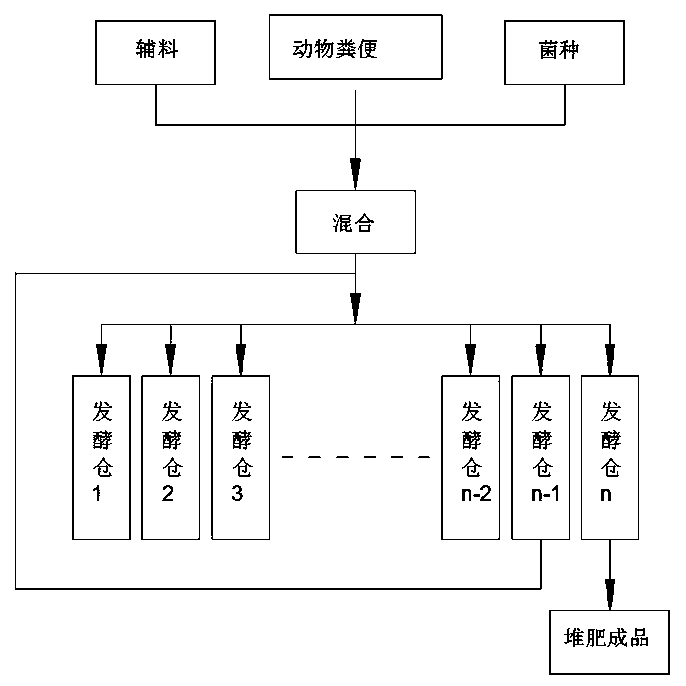

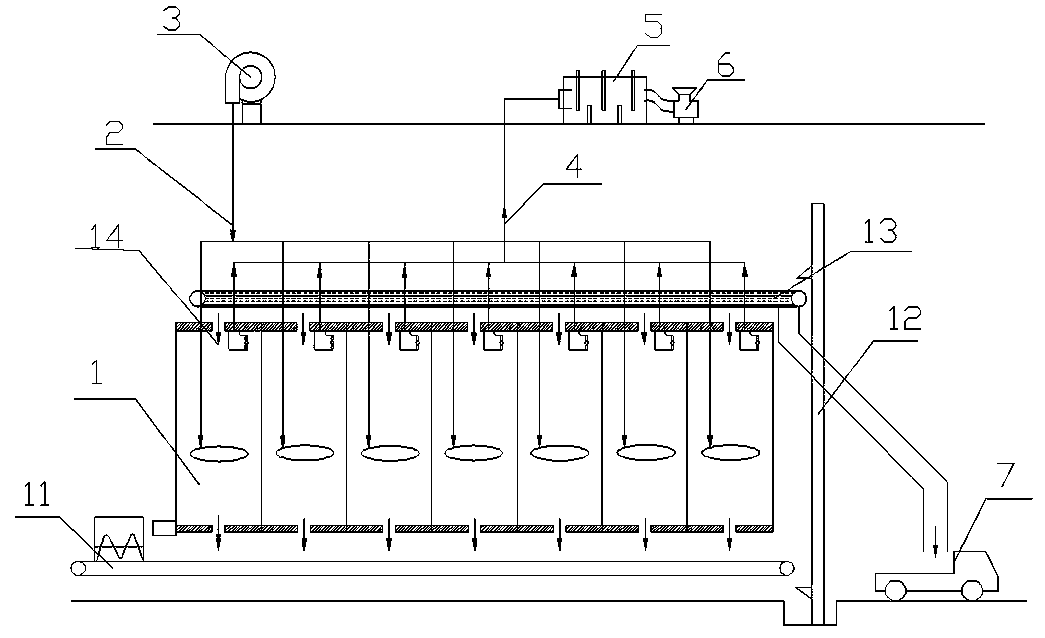

Method used

Image

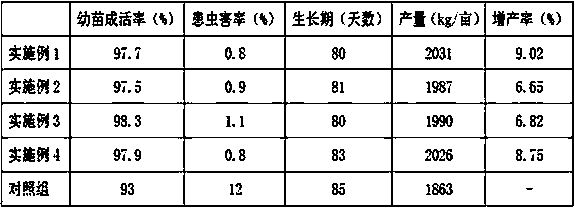

Examples

Embodiment 1

[0052] The organic fertilizer comprises the following raw materials in parts by weight: 200 parts of sugarcane filter mud; 5 parts of biological bacteria agent; 180 parts of rice bran; 80 parts of animal manure; 120 parts of straw; 30 parts of tea dregs; 3 parts of quicklime;

[0053] The biological agent is a mixture of Bacillus subtilis LTBS01, Bacillus licheniformis and Bacillus megaterium in a weight ratio of 5:1:1; both Bacillus licheniformis and Bacillus megaterium are purchased from the Institute of Microbiology, Guangxi Academy of Agricultural Sciences;

[0054] The sugarcane filter mud is the filter mud of the process of producing sucrose by sulfurous acid method;

[0055] The animal manure is a mixture of pig manure and cow manure;

[0056] The straw is corn straw;

[0057] The micro-fertilizer is manganese sulfate, ferrous sulfate, zinc sulfate, sodium tetraborate, copper sulfate, ammonium molybdate, and the weight ratio is 5:2:1:0.5:0.1:0.01.

[0058] Described o...

Embodiment 2

[0066] The organic fertilizer comprises the following raw materials in parts by weight: 220 parts of sugarcane filter mud; 7 parts of biological bacteria agent; 190 parts of rice bran; 90 parts of animal manure; 130 parts of straw; 40 parts of tea dregs; 4 parts of quicklime;

[0067] The biological agent is a mixture of Bacillus subtilis LTBS01, Bacillus licheniformis and Bacillus megaterium in a weight ratio of 5:1:1; both Bacillus licheniformis and Bacillus megaterium are purchased from the market;

[0068] The sugarcane filter mud is the filter mud of the process of producing sucrose by carbonation;

[0069] The animal manure is a mixture of pig manure, cow manure and human manure;

[0070] The straw is a mixture of corn straw and wheat straw;

[0071] The micro-fertilizer is manganese sulfate, ferrous sulfate, zinc sulfate, sodium tetraborate, copper sulfate, ammonium molybdate, and the weight ratio is 5:2:1:0.5:0.1:0.01.

[0072] Described organic fertilizer, its prepa...

Embodiment 3

[0080] The organic fertilizer comprises the following raw materials in parts by weight: 240 parts of sugarcane filter mud; 8 parts of biological bacteria agent; 200 parts of rice bran; 100 parts of animal manure; 140 parts of straw; 45 parts of tea dregs; 5 parts of quicklime;

[0081] The biological agent is a mixture of Bacillus subtilis LTBS01, Bacillus licheniformis and Bacillus megaterium in a weight ratio of 5:1:1; both Bacillus licheniformis and Bacillus megaterium are purchased from the Institute of Microbiology, Guangxi Academy of Agricultural Sciences;

[0082] The sugarcane filter mud is the filter mud of the process of producing sucrose by sulfurous acid method;

[0083] The animal manure is a mixture of chicken manure and duck manure;

[0084]The straw is a mixture of rice straw and soybean straw;

[0085] The micro-fertilizer is manganese sulfate, ferrous sulfate, zinc sulfate, sodium tetraborate, copper sulfate, ammonium molybdate, and the weight ratio is 5:2:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com