Packing and bottle protection system

A protection system and bottle pouring technology, applied in packaging protection, packaging bottles, packaging, etc., can solve the problems of affecting production efficiency, long processing time, and time-consuming, and achieve the effects of convenient operation, improved production efficiency, and easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

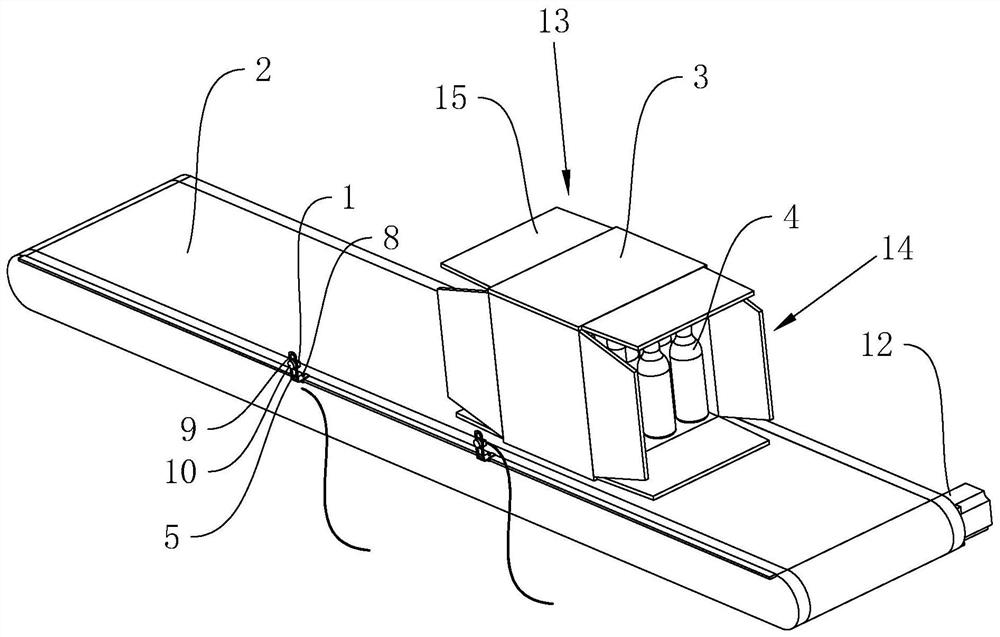

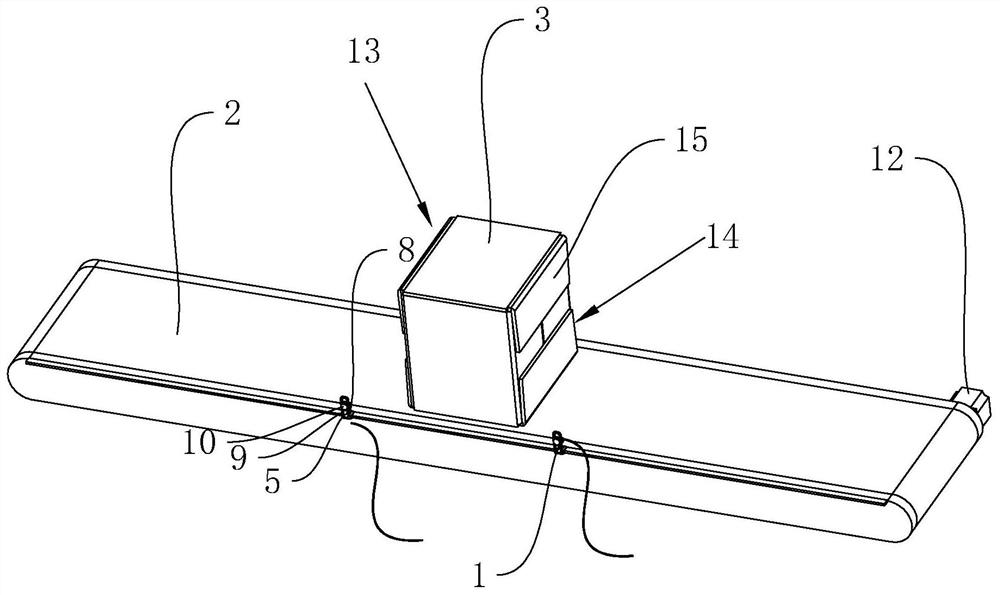

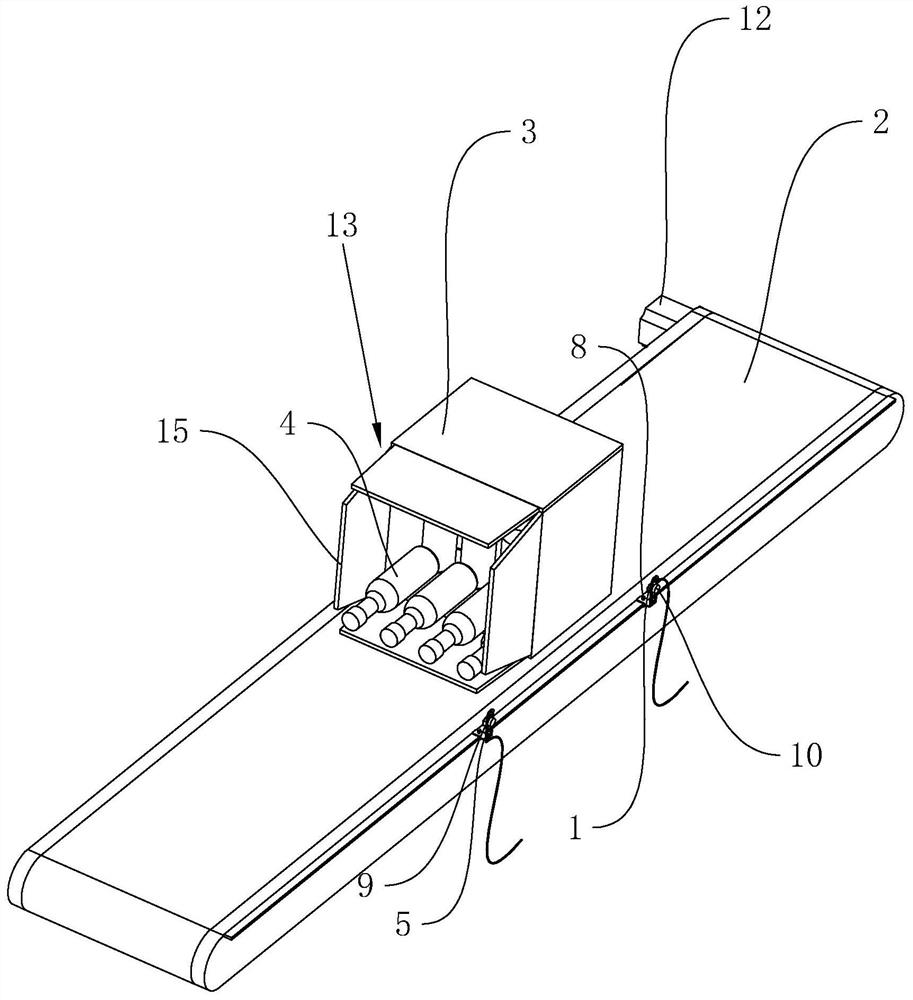

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] refer to figure 1 , is the protection system for packing and falling bottles disclosed by the present invention, comprising a detection element 1 that outputs an electrical signal when blocked, and the detection element 1 is an NT6-GB322 photoelectric eye produced by Guangzhou Fangxiang Electromechanical Equipment Co., Ltd.

[0043] It also includes a carton 3 in which the front flap 13 and the rear flap 14 are stacked by four trapezoidal surfaces 15 respectively. The angle between the waist of the two trapezoidal surfaces 15 and the bottom is 60 degrees.

[0044] There are two detection elements 1 and they are installed on the same side of the conveyor 2 respectively. The distance between the two detection elements 1 is greater than the length of the carton 3 and less than the sum of the length of the carton 3 and the height of the bottle 4 .

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com