Method for integrally fixing and installing foundation bolts with large diameter

A technology of anchor bolts and installation methods, which is applied in construction, infrastructure engineering, etc., can solve the problems of long construction period, poor bolt installation accuracy, and unguaranteed quality, so as to improve installation quality, ensure installation accuracy, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

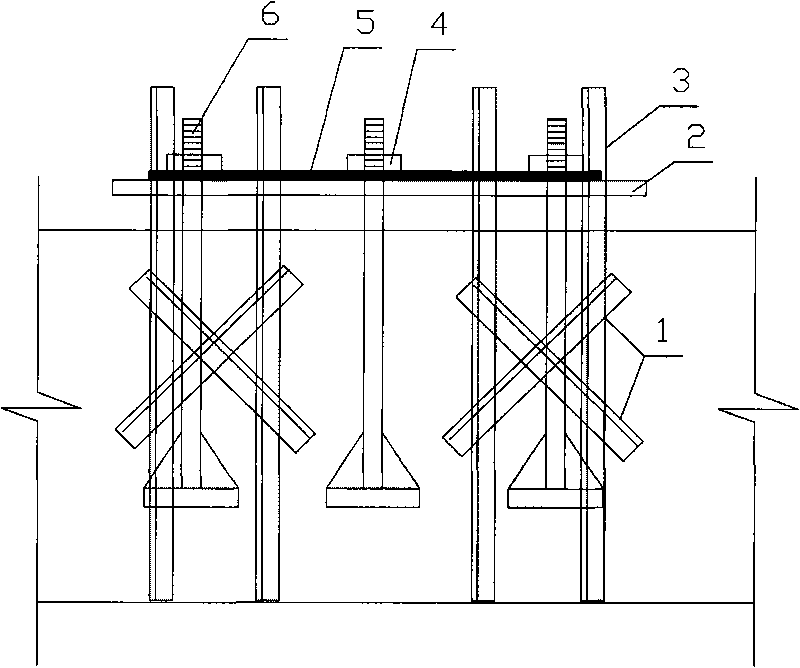

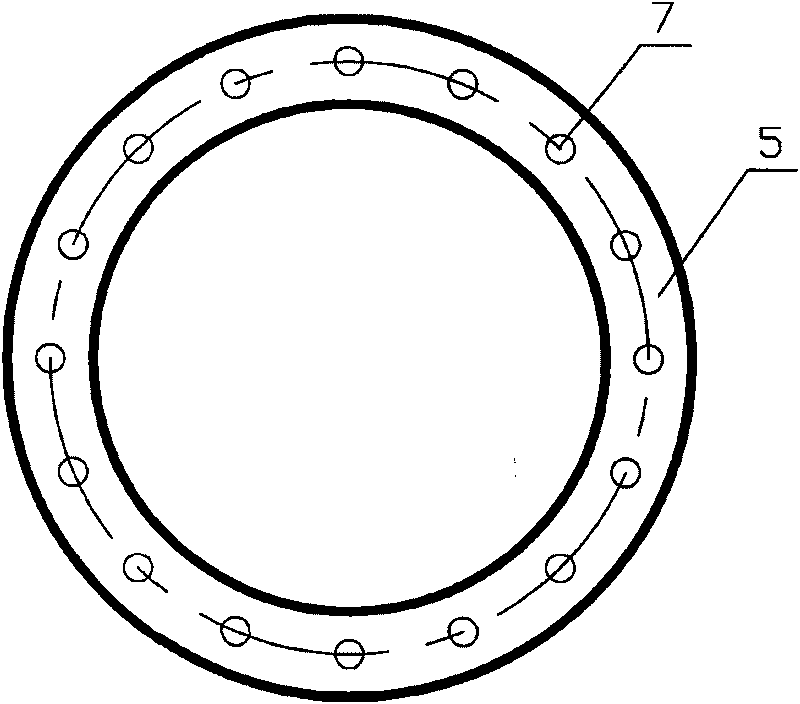

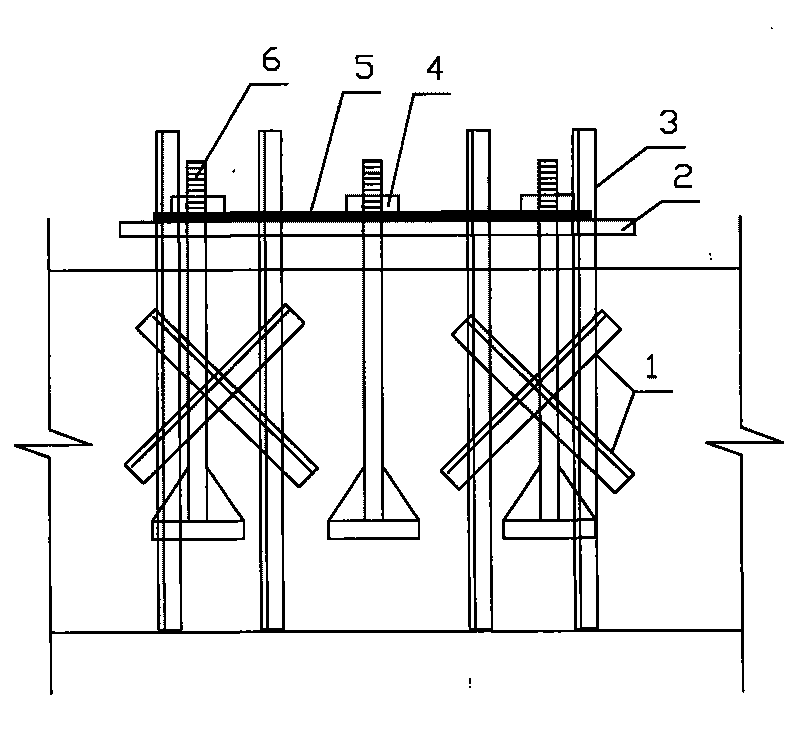

[0010] see Figure 1 ~ Figure 2 , a method for integrally fixing and installing large-diameter anchor bolts in the present invention:

[0011] 1. The pre-embedded 16 large-diameter anchor bolts 6 (hereinafter referred to as bolts) form a circle. According to the radius of the circle and the specifications of the bolts, make a 20mm thick 300mm wide inner diameter of 2000mm and an inner arc length of 392.5mm by lofting. There are 16 pieces of arc-shaped bolt supporting steel plate blocks (hereinafter referred to as supporting steel plate blocks) in total; the number of supporting steel plate blocks can be determined according to their weight;

[0012] 2. According to the size of the loft, group the above 16 supporting steel plates into pieces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com