Water-based resin sand for stone-like coating and preparation method of water-based resin sand

A technology of water-based resin and real stone paint, applied in the direction of coating, can solve the problems of water-based resin sand preparation method of real stone paint, lack of acid and alkali resistance, etc., to reduce the surface energy of the coating, the product is beautiful, and the implementation cost is low. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

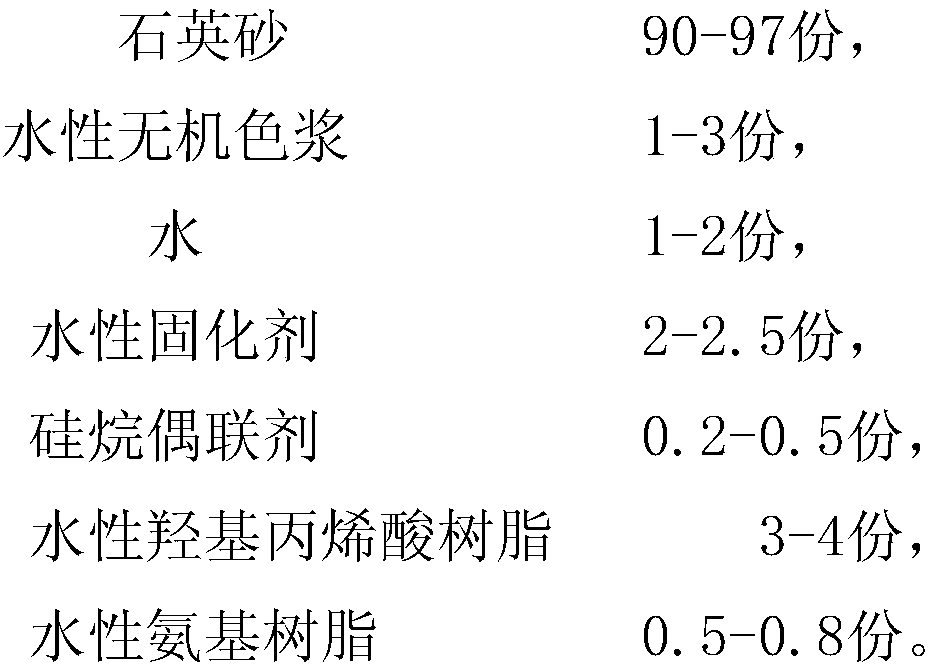

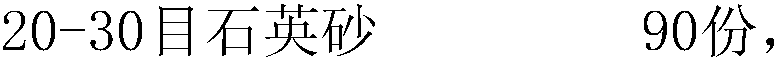

[0027] A kind of water-based resin sand for real stone paint of the present invention, said water-based resin sand for real stone paint comprises the following components in parts by mass:

[0028]

[0029]

[0030] The water-based hydroxyacrylic resin is the high-gloss hydroxyacrylic dispersion A2033 of Wanhua Chemical.

[0031] Described waterborne amino resin is Cytec 303. The silane coupling agent is an aqueous silane coupling agent. The described water-based silane coupling agent is A-1100 American United Carbon. The water-based inorganic color paste is Clariant's color paste series.

[0032] The preparation method of water-based resin sand for genuine stone paint of the present invention comprises the following steps:

[0033] (1) Each component is weighed according to the stated parts by mass, the water-based hydroxyacrylic resin and the water-based amino resin are mixed first, then water is added, and stirred for 5 minutes at a speed of 500r / min;

[0034] (2)...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is:

[0039] A kind of water-based resin sand for real stone paint of the present invention, said water-based resin sand for real stone paint comprises the following components in parts by mass:

[0040]

[0041]

[0042] The water-based hydroxyacrylic resin is the high-gloss hydroxyacrylic dispersion A2033 of Wanhua Chemical.

[0043] The water-based amino resin is a combination of fully etherified amino resin Taiwan Changchun MR603 and Cytec 303.

[0044] The preparation method of water-based resin sand for genuine stone paint of the present invention comprises the following steps:

[0045] (1) Each component is weighed according to the stated parts by mass, the water-based hydroxyacrylic resin and the water-based amino resin are mixed first, then water is added, and stirred for 5 minutes at a speed of 500r / min;

[0046] (2) The silane coupling agent is added to the mixed solution of step (1), and stirred at...

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 1 is:

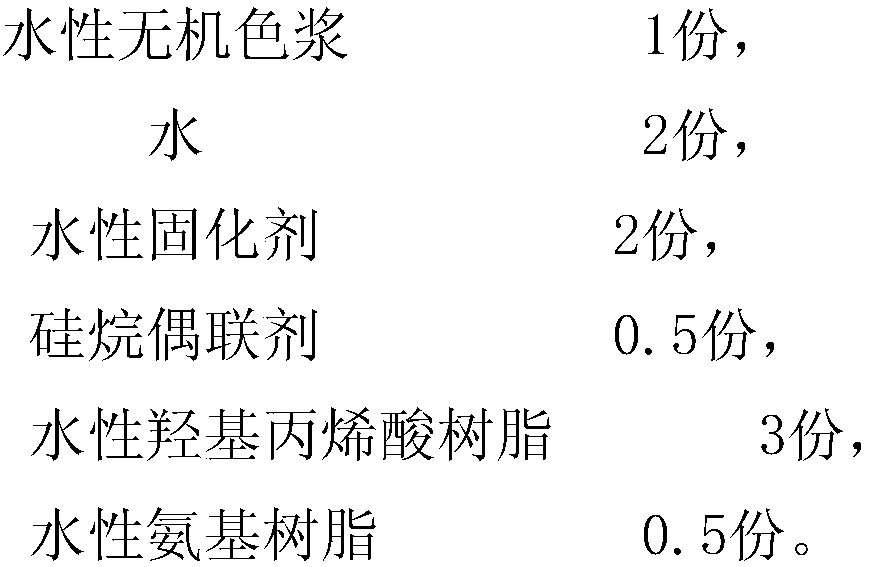

[0051] A kind of water-based resin sand for real stone paint of the present invention, said water-based resin sand for real stone paint comprises the following components in parts by mass:

[0052]

[0053]

[0054] The water-based amino resin is fully etherified amino resin Taiwan Changchun MR603.

[0055] The preparation method of water-based resin sand for genuine stone paint of the present invention comprises the following steps:

[0056] (1) Each component is weighed according to the stated parts by mass, the water-based hydroxyacrylic resin and the water-based amino resin are mixed first, then water is added, and stirred for 5 minutes at a speed of 500r / min;

[0057] (2) The silane coupling agent is added to the mixed solution of step (1), and stirred at a speed of 500r / min for 3 minutes for subsequent use;

[0058] (3) Stir the quartz sand at a rate of 200r / min, then add the mixed solution prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com