Pipe fitting punch die based on flexible slide block

A technology for punching and pipe fittings, which is applied in the direction of piercing tools, manufacturing tools, metal processing equipment, etc., can solve the problems of pipe damage, difficulty in picking, poor punching quality, etc., to facilitate picking, reduce processing costs, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

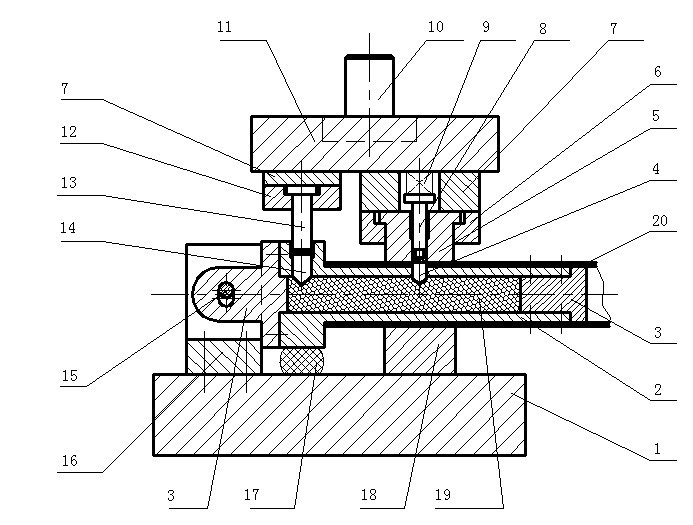

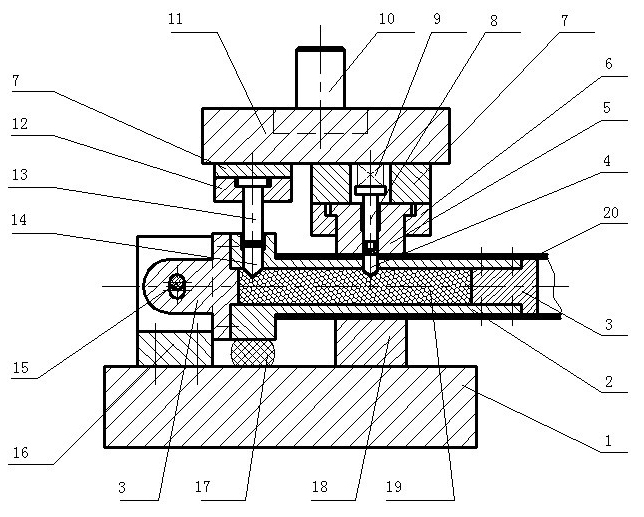

[0014] see figure 1 , shows a pipe punching die based on a flexible slider in the present invention, which includes a lower die base 1 and an upper die base 11. On the upper mold base 11; the positioning tube 2 is rotatably arranged on the lower mold base 1 with a pin 15, and is connected to the lower mold base 1 by a support base 16 in the figure, and can rotate within a certain range around the pin 15; on the positioning tube 2 In the inner cavity of the inner cavity, solid particles 19 are provided; the solid particles 19 are closed in the inner cavity of the positioning tube 2 through the plugs 3 at both ends; One end of the die 4 is located between the gaps of the solid particles 19, and the other end acts on the pipe to be punched 20 as a punching punch when punching. The concave mold 5 provided with the inner hole corresponds to the position of the punch 4, and several concave molds 5 can be partially connected to the upper mold base 11 and partially connected to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com