Resin-sealing method and resin-sealing apparatus for electronic components

A technology of resin encapsulation device and electronic component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

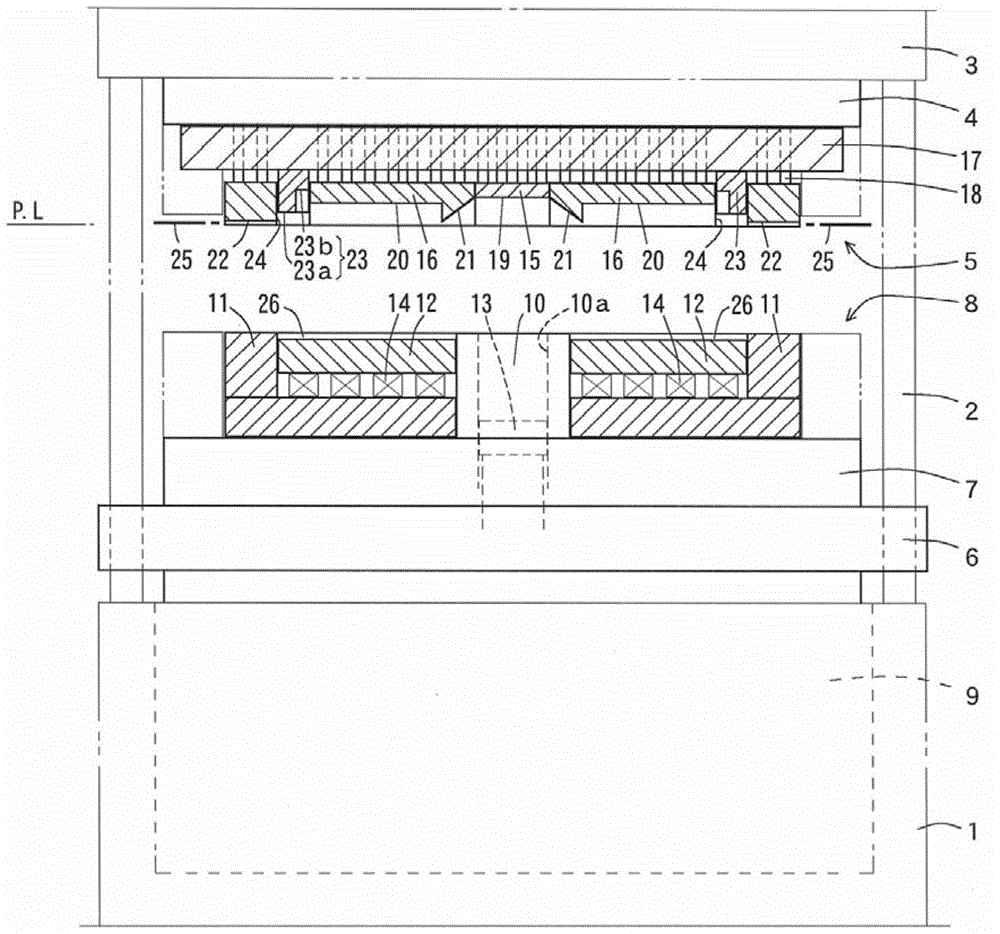

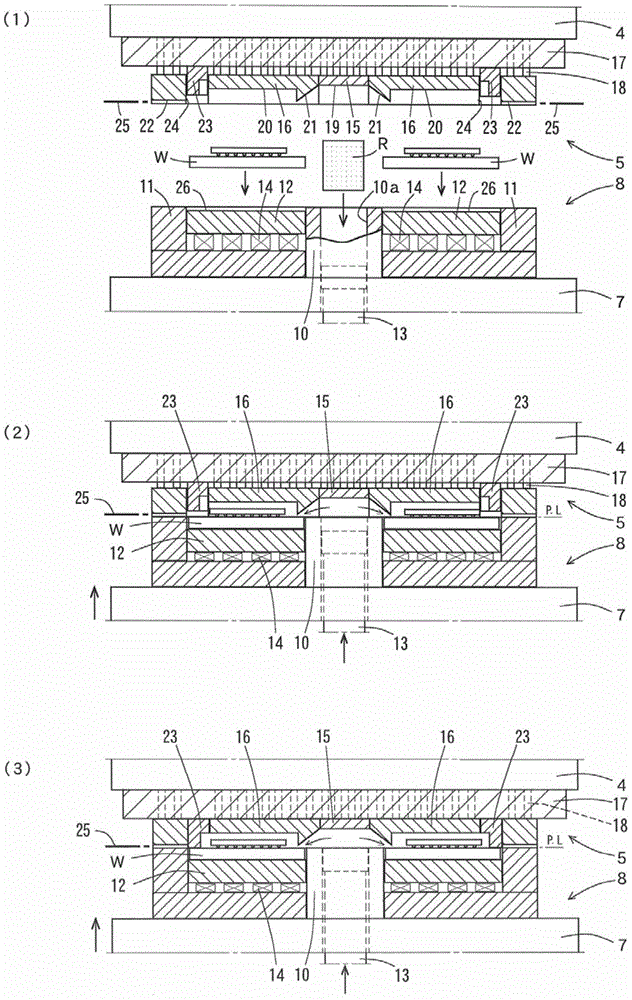

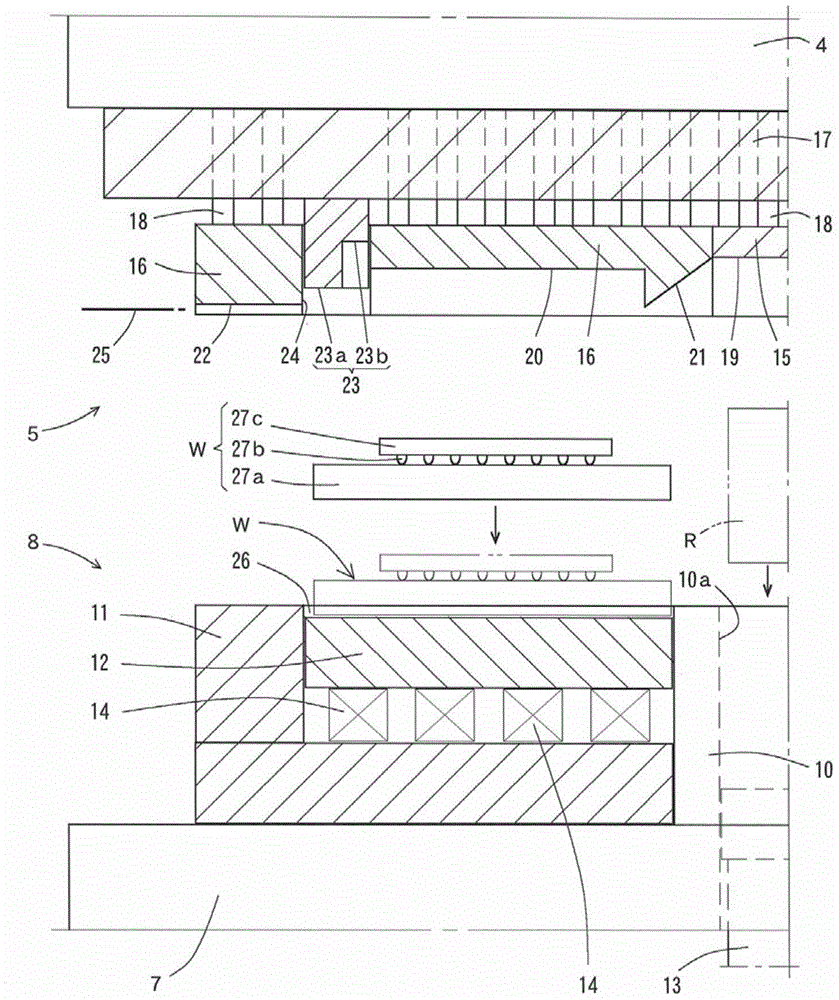

[0057] Below, based on figure 1 The illustrated embodiment illustrates the present invention.

[0058] figure 1 The overall structure of an embodiment of the resin sealing device according to the present invention using a so-called transfer molding unit is schematically shown.

[0059] The resin packaging device is provided with: a base 1 of the device; a tie rod 2 installed on the base 1 in an upright state; a fixing plate 3 mounted on the upper end of the tie rod 2; an upper template 4 mounted on the lower part of the fixing plate 3; resin The upper mold 5 (fixed mold) for forming is installed at the lower part of the upper mold plate 4; the movable plate 6 is embedded and installed in the tie rod 2 at the position below the upper mold 5; the lower mold plate 7 is installed on the movable plate 6 The upper part; the lower mold 8 (movable mold) for resin molding is installed on the upper part of the lower mold plate 7; and the mold opening and closing mechanism 9, etc., are set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com