High-efficiency energy-saving submicron bubble aeration oxygenating device

A high-efficiency, energy-saving, ultra-micron technology, applied in the direction of water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of large water body vibration, fast rising speed, low oxygenation efficiency, etc., to promote The effects of cleaning, inhibiting the reproduction of harmful microorganisms, and energy-saving treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

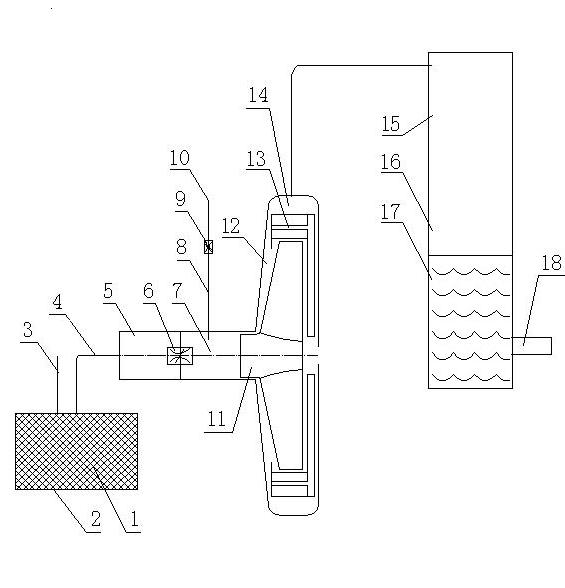

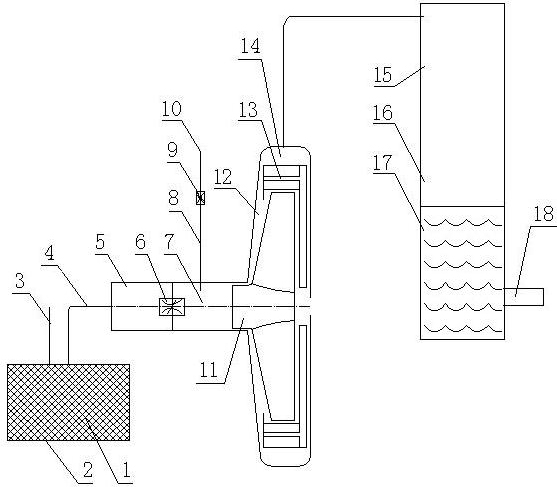

[0014] The present invention will be further described to specific embodiment below in conjunction with accompanying drawing:

[0015] 1. The working environment of the high-efficiency and energy-saving ultra-micron bubble aeration and oxygenation device proposed by the present invention is sewage treatment, and the sewage contains a large amount of suspended matter. It is necessary to prevent large suspended particles from entering the equipment to ensure long-term stable operation of the filter. The sewage is filtered by the filter 1 and enters the backwashable filter 2. When the sewage passes through the filter, the suspended solids are blocked outside the filter 1 and cannot enter the equipment. After a long period of use, the suction filter will inevitably block the suspended matter outside the filter screen. In order to avoid the filter screen being blocked by suspended matter, this design uses a special pump for backwashing with a large flow rate, and connects a backwas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com