Automatic vehicle brake plate painting equipment

A technology of automatic painting and brake pads, which is applied in painting booths, spraying devices, etc., can solve the problems of reduced production efficiency, uneven painting, environmental pollution, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

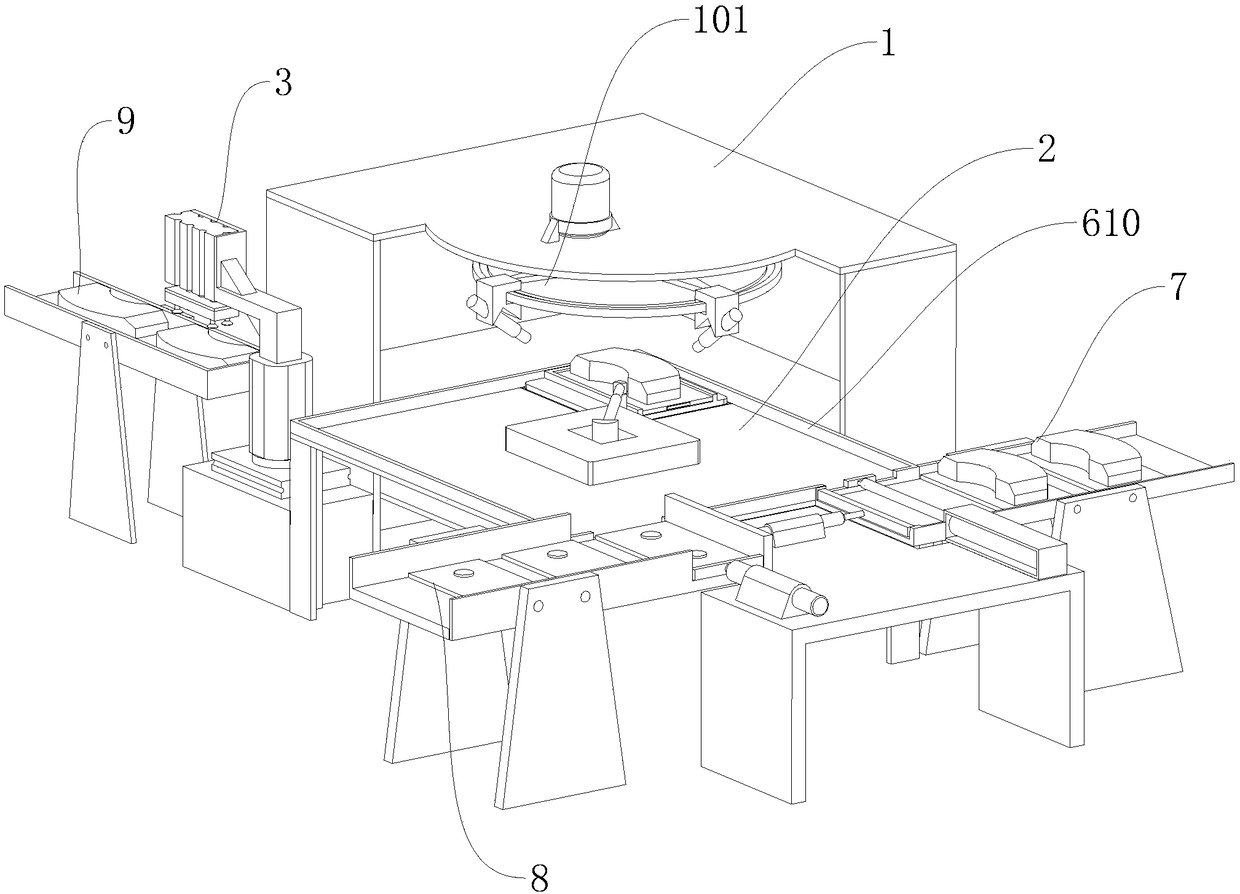

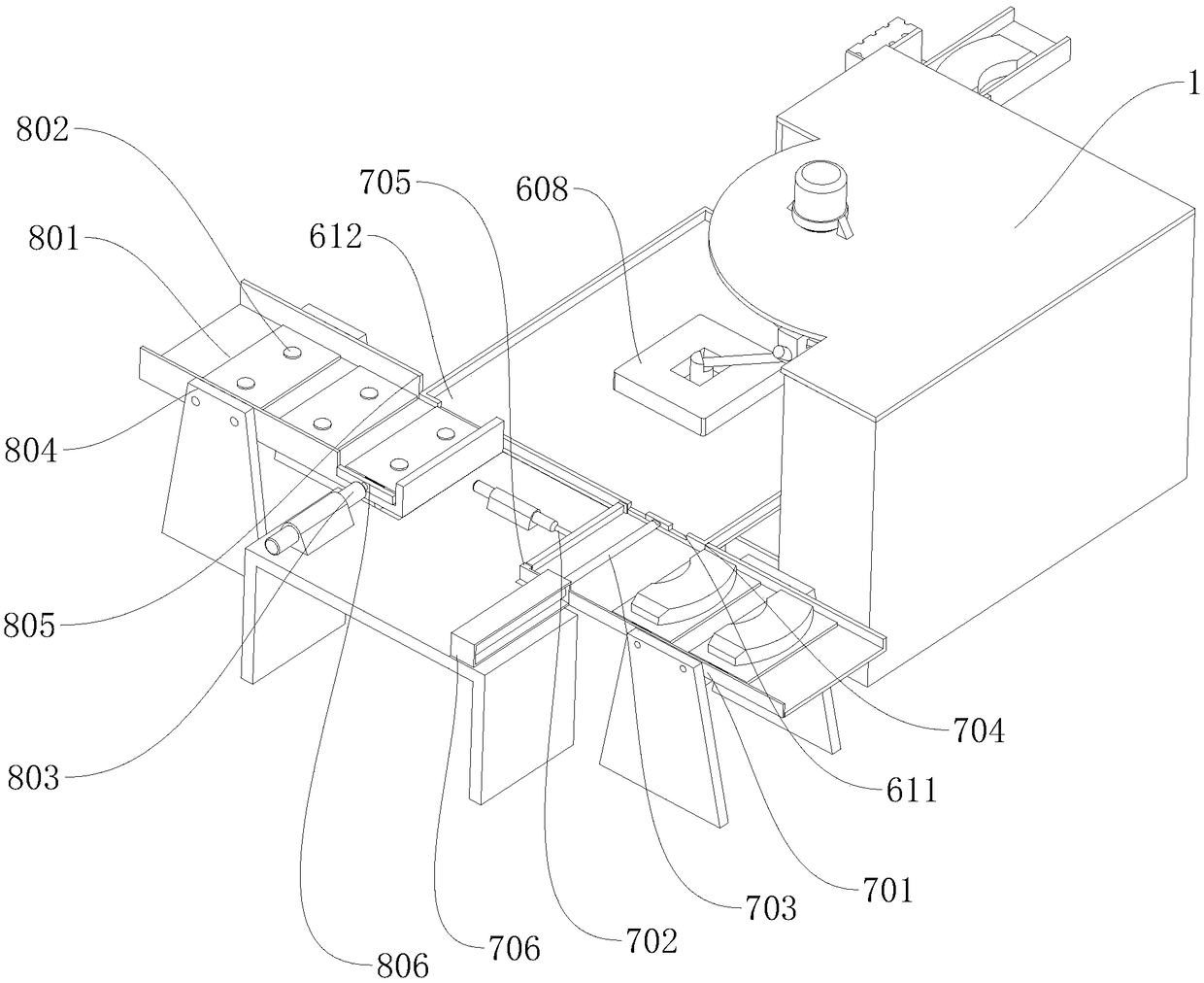

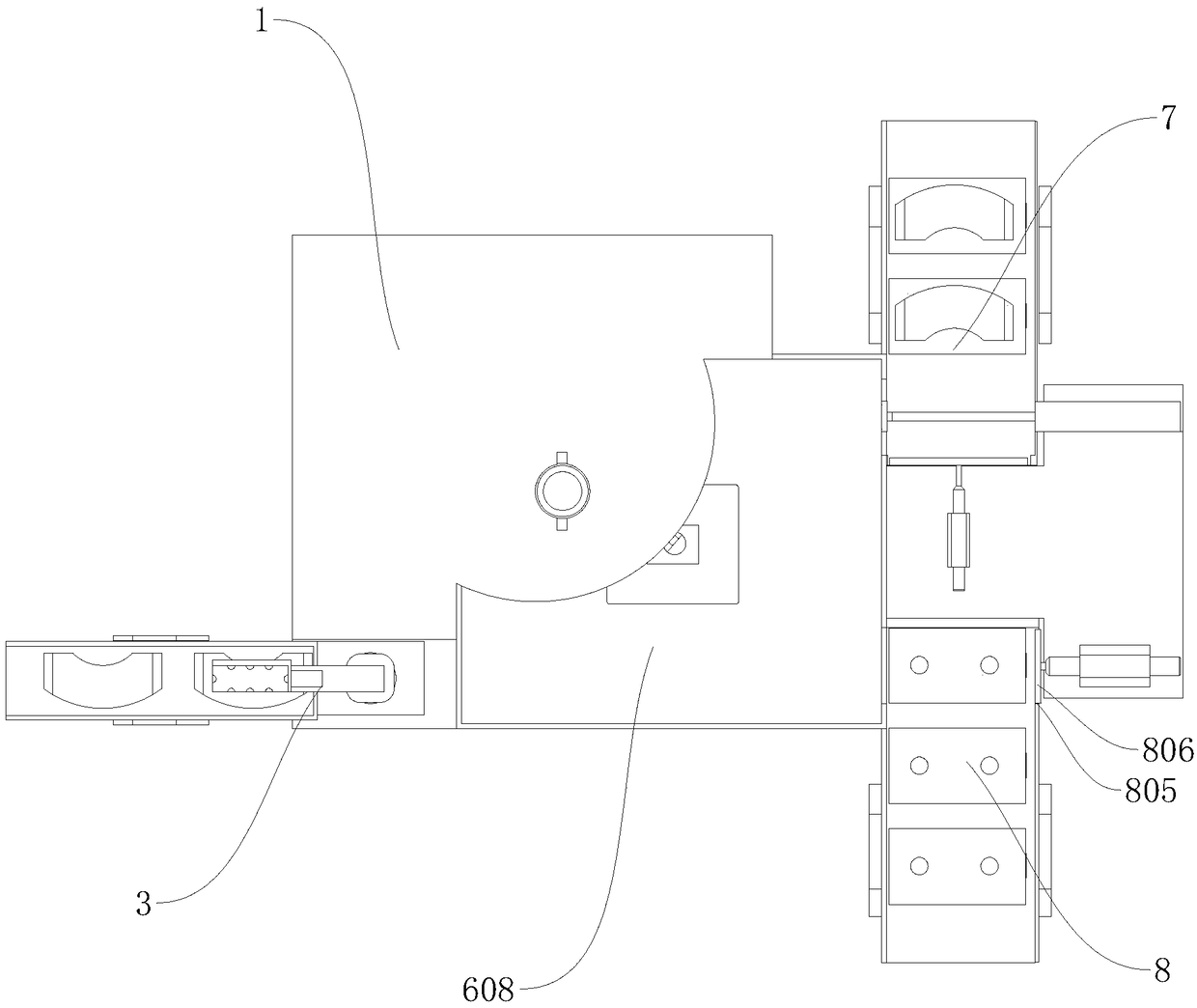

[0027] refer to Figure 1 to Figure 9The shown automatic painting equipment for automobile brake pads includes a feeding assembly, a painting booth 1, a lifting assembly 5, a carrying fixture 6, a blanking assembly 7 and a filling mechanism 8, and the painting booth 1 includes a workbench 2 and a rotating painting booth. Assembly 101, the rotary painting assembly 101 is located above the workbench 2, and the carrying jig 6 is arranged on the top of the workbench 2 through the rail moving mechanism 608. The rail moving mechanism 608 includes a telescopic rod 607 capable of rotating in the horizontal plane and a load-bearing jig 6 Fitting the moving limit frame 610, the telescopic rod 607 is set horizontally, and one end of the telescopic rod 607 is connected to the top edge of the carrying jig 6 through a vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com