Automatic single-station glaze spraying device and method

A single-station, glaze-spraying technology, used in spraying devices, devices for applying liquid to surfaces, spraying booths, etc., can solve the problems of polluting the factory workshop environment, short service life of the chain, inconvenient replacement and maintenance, etc., to improve the operation. Effects of environment, short kinematic chain, and fast action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in combination with specific embodiments.

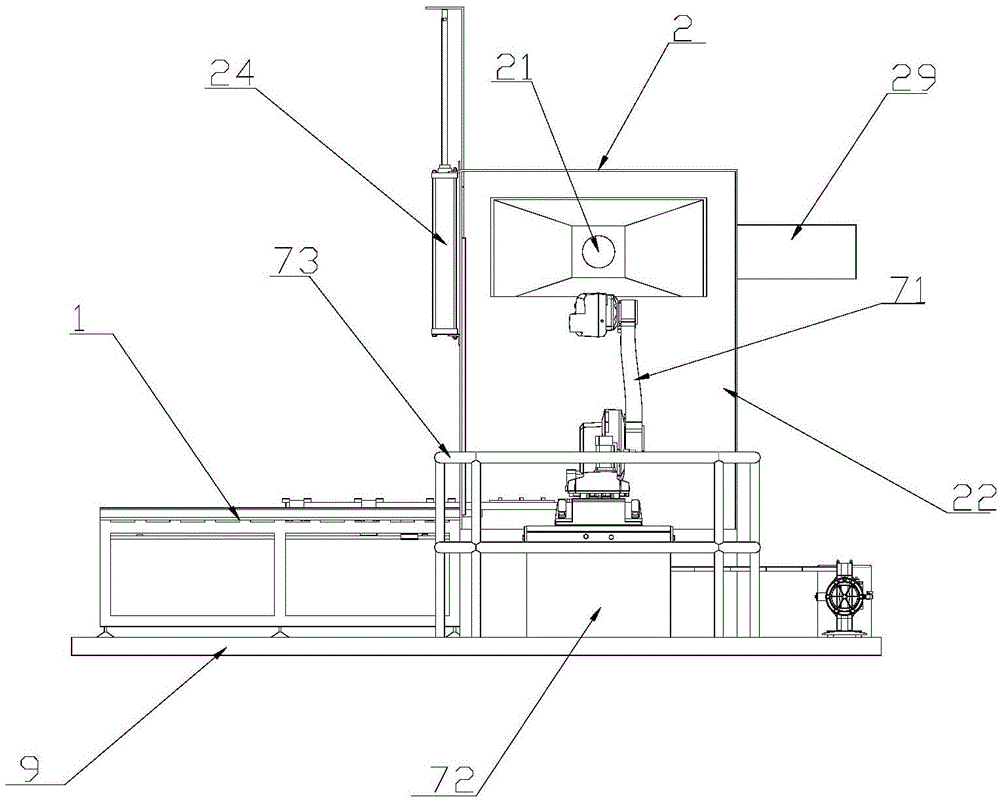

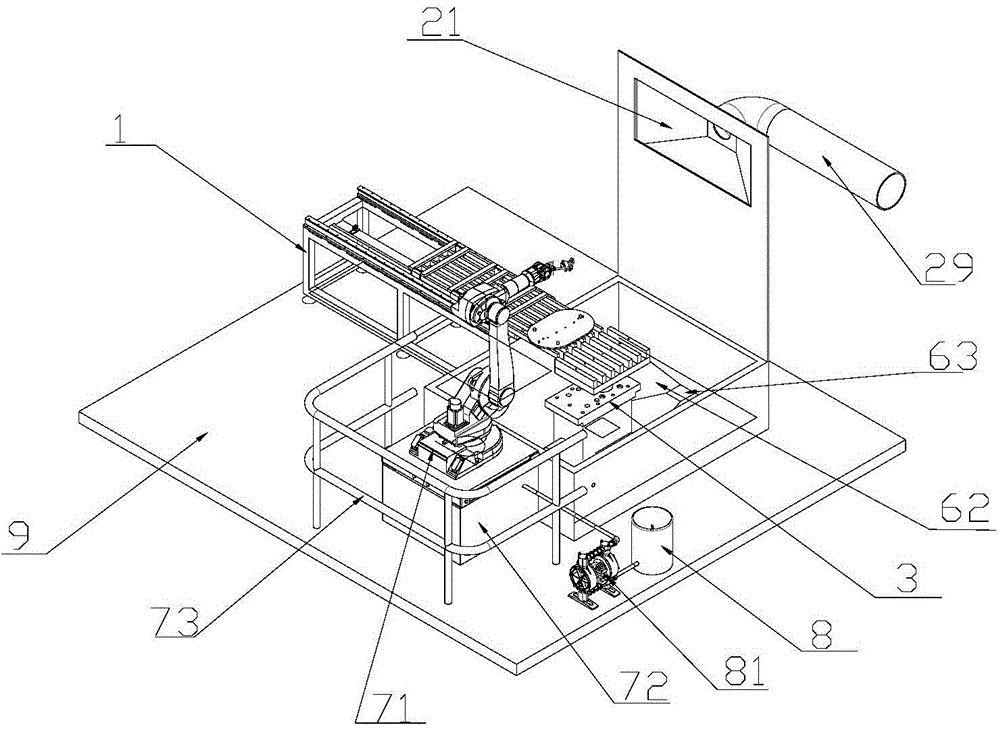

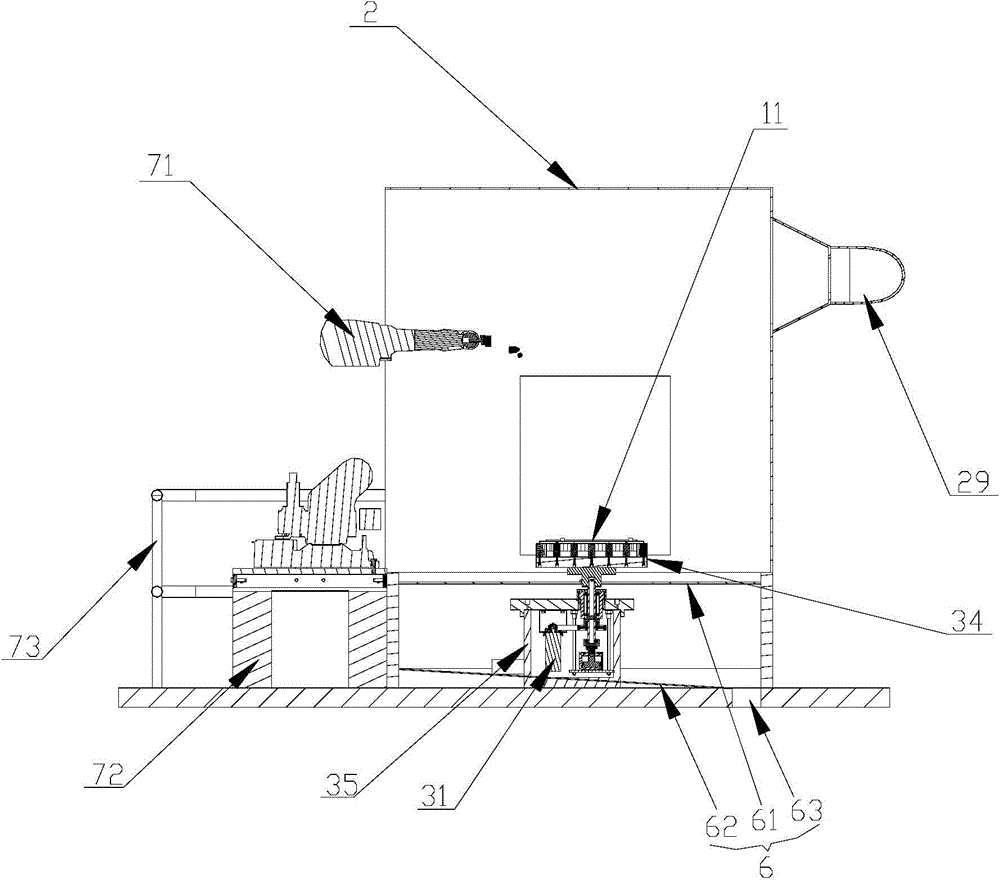

[0047] Please refer to Figure 1-Figure 3 As shown, a single-station automatic glaze spraying device, which includes: feeding mechanism 1, spray booth 2, working turntable 3, damping mechanism 4, positioning mechanism 5, glaze recovery mechanism 6, robot components, glaze reserve pressure box 8. Diaphragm pump 81 and spray booth base 9.

[0048] The spray booth 2 is a semi-closed structure installed on the spray booth base 9, and it is made up of two sides, a top surface and a rear end surface. The mouth is used to place the robot body 71. On the rear end face of the spray booth 2 opposite to the open opening 22, there is an air exhaust port 21 connected to the exhaust air passage 29, through which the air intake 21 is used to extract air in the spray booth 2, and then the glaze diffused in the spray booth will be drawn by the exhaust air passage 29. The material is draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com