Special hoisting device for hollow cylindrical piece

A lifting device and cylinder technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of increasing workload and cost, reducing production efficiency, etc., and achieve the effect of convenient operation, simple structure and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

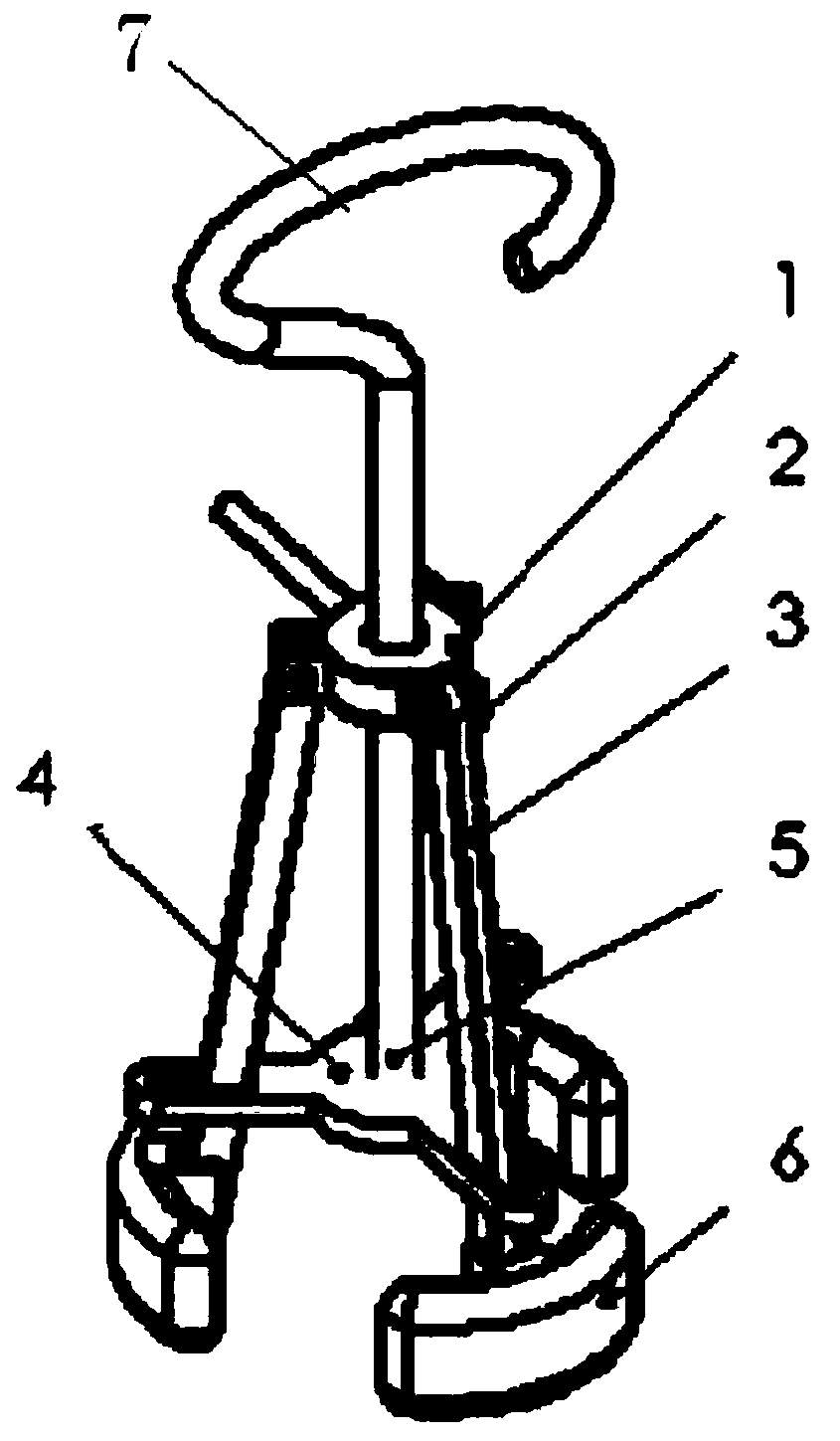

Embodiment 1

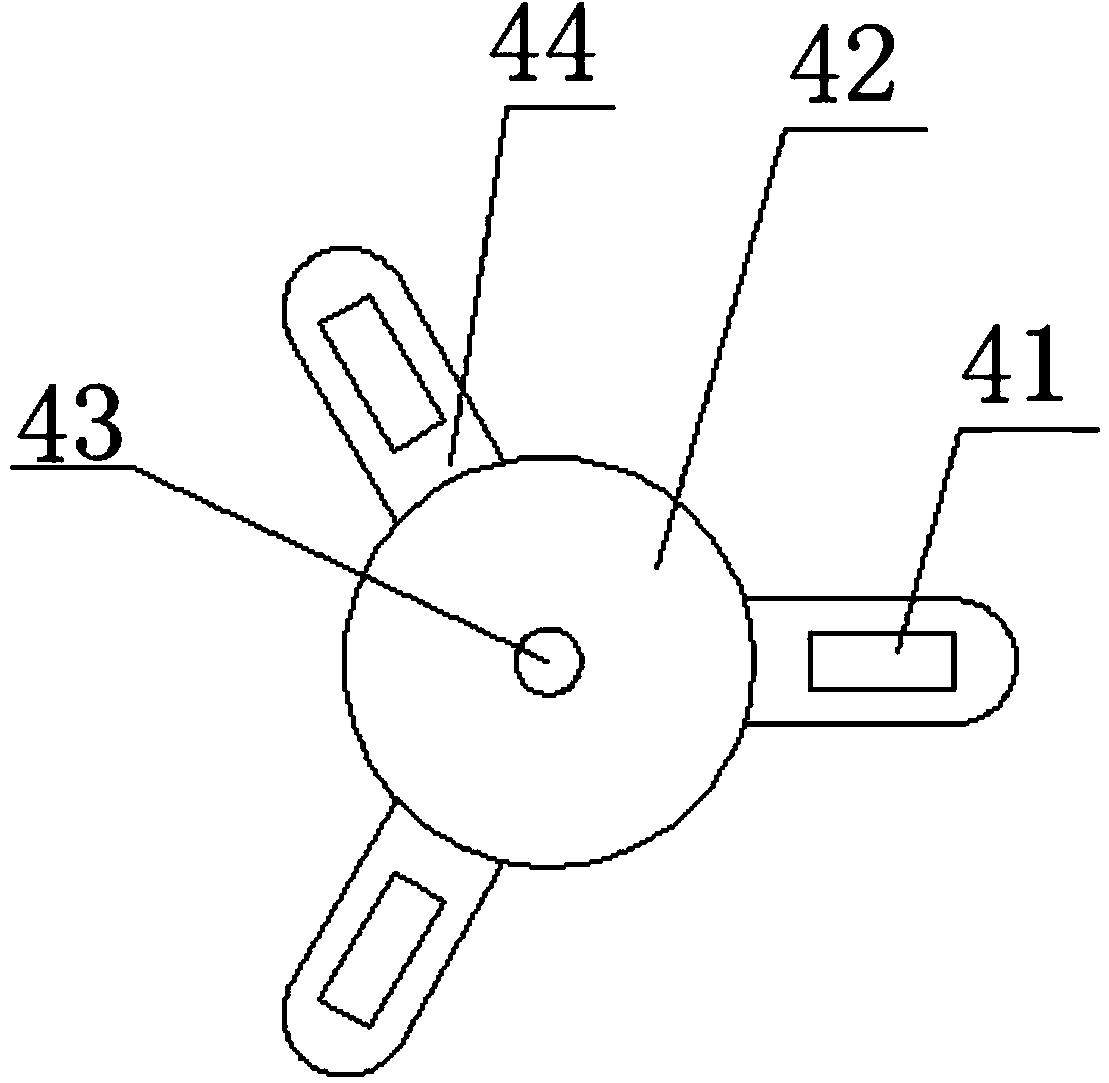

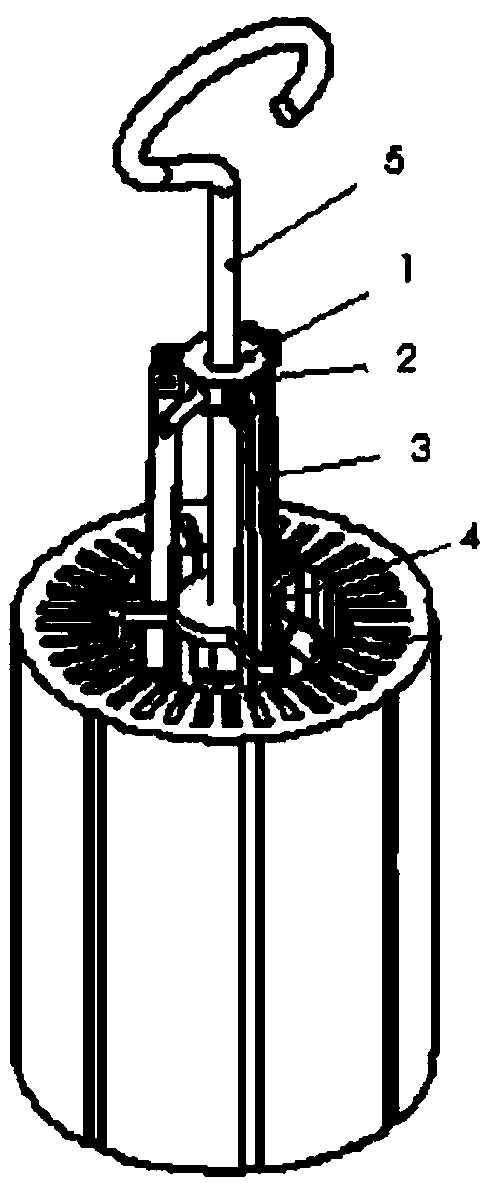

[0030] Use the lifting device with three claw rods 3. When using it, hold the fixed ring 1, push the handle 5 down to fold the claw rods 3, and put the lifting device into the middle of the motor stator with silicon steel sheets stacked together. In the hole, the outer side of the claw pad 6 is wrapped with a nylon layer. When the handle 5 is lifted up, it pulls the support plate 4 up, and the support plate 4 pushes the three claw bars 3 to the outside through the square groove 41 to form a fan. Unfold, make the claw pad 6 close to the inner diameter of the workpiece, and use friction to make the lifting device and the workpiece more and more tight. When the friction force is greater than the mass of the workpiece, the workpiece is lifted and moved to the required place. After use, move the handle 5 to the Lower the top, make the claw bar 3 draw in, just can take out the lifting device from the workpiece.

Embodiment 2

[0032] Use the lifting device with 5 claw rods 3, hold the fixed ring 1 when in use, push the handle 5 down to make the claw rods 3 close up, put the lifting device into the middle hole of the coil of the large motor, and its claws The outer side of the pad 6 is covered with a silicone layer. When the handle 5 is lifted up, it pulls the support plate 4 up, and the support plate 4 pushes the five claw rods 3 to fan out to the outside through the square groove 41, so that the claw pad 6 Close to the inner diameter of the workpiece, use friction to make the lifting device and the workpiece more and more tight, when the friction force is greater than the mass of the workpiece, use the hook of the crane to hook the hook-shaped handshake part 7 to lift the workpiece and move it to the required place. After the use is completed, the handle 5 is pushed downwards, so that the claw bar 3 is drawn in, and the lifting device can be taken out from the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com