Double-station rotation type gimbal hot plate welding machine

A hot plate welding machine and rotary technology, which is applied in the field of double-station rotary balance ring hot plate welding machine, can solve the problems of affecting machine performance, low efficiency, and shortening the service life of the machine, so as to improve production and processing efficiency and reduce Switching frequency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

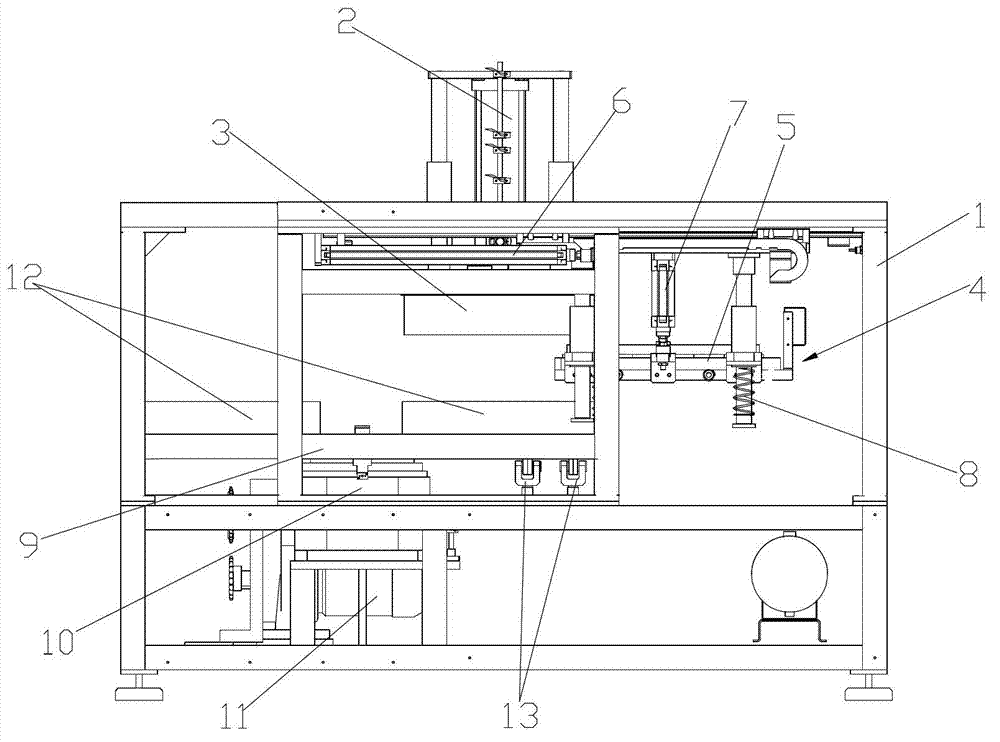

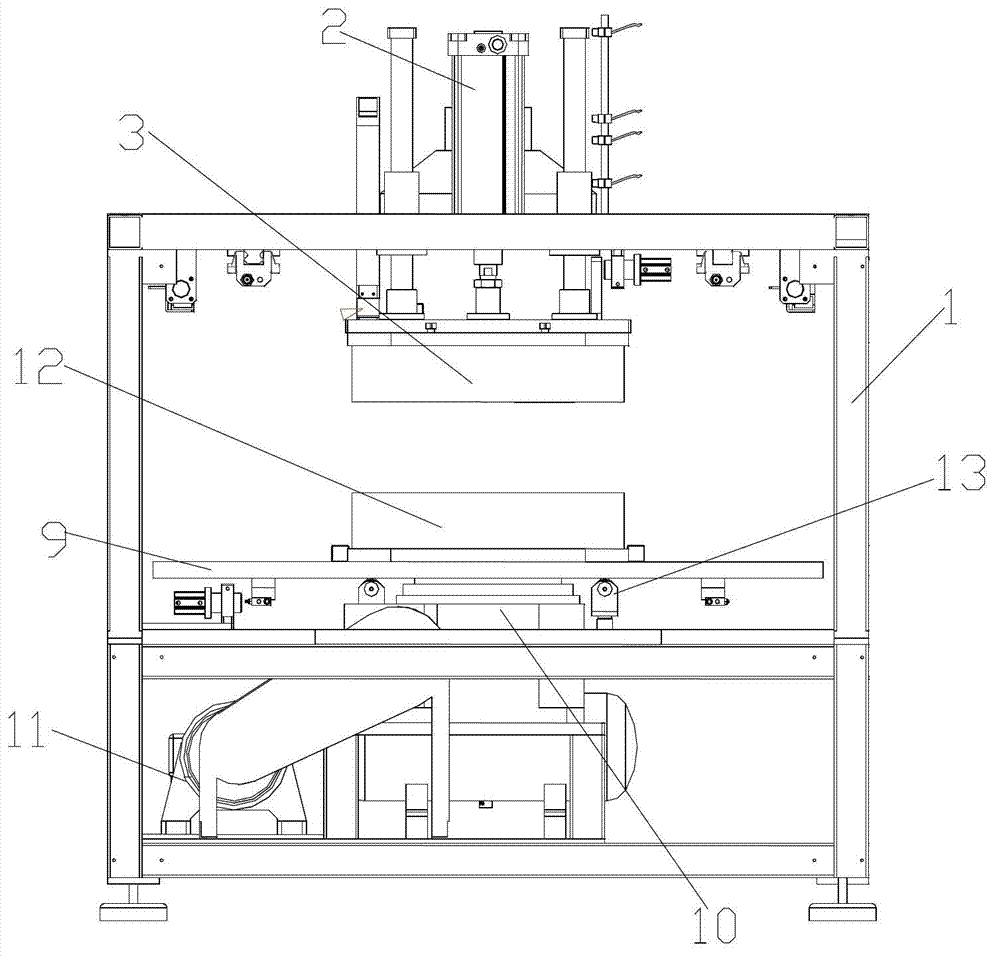

[0014] attached figure 1 , 2 It is a dual-station rotary balance ring hot plate welding machine according to the present invention, which includes a frame 1, a main cylinder 2 is arranged on the top of the frame 1, and the main cylinder 2 is vertically arranged on the frame 1, and its piston The end extends downwards and is connected with an upper mold clamp 3, which controls the lifting of the upper mold clamp 3; the upper mold clamp 3 is disc-shaped; a thermal mold transfer device 4, which includes a square thermal template 5 and The horizontal cylinder 6 that controls the horizontal movement of the hot template 5, the piston end of the horizontal cylinder 6 is connected to the hot mold transfer device 4, and the hot template 5 is provided with a telescopic cylinder 7 for controlling the lifting of the hot template 5; the hot template 5 A spring 8 is also provided below to prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com