TPU (Thermoplastic Polyurethane Elastomer) material and preparation method thereof

A raw material, diisocyanate technology, applied in the field of TPU material and its preparation, can solve the problems of insufficient mechanical properties, wear resistance and rigidity, cannot be reused, low operation efficiency, etc., achieve excellent mechanical properties, reduce high cost, resist Low wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

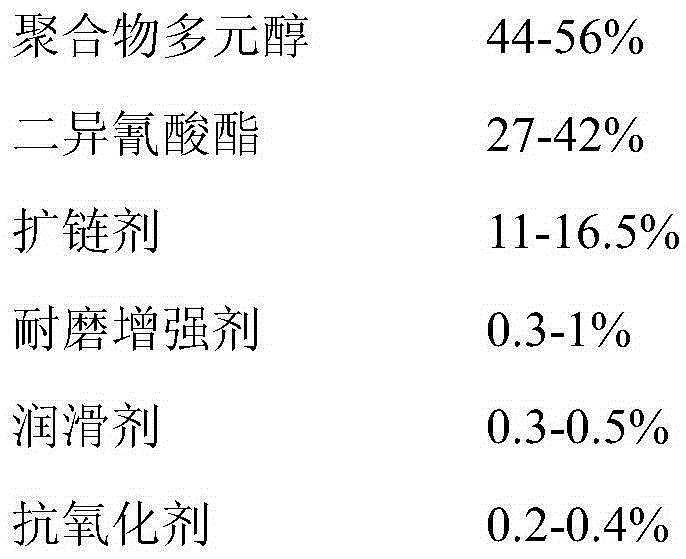

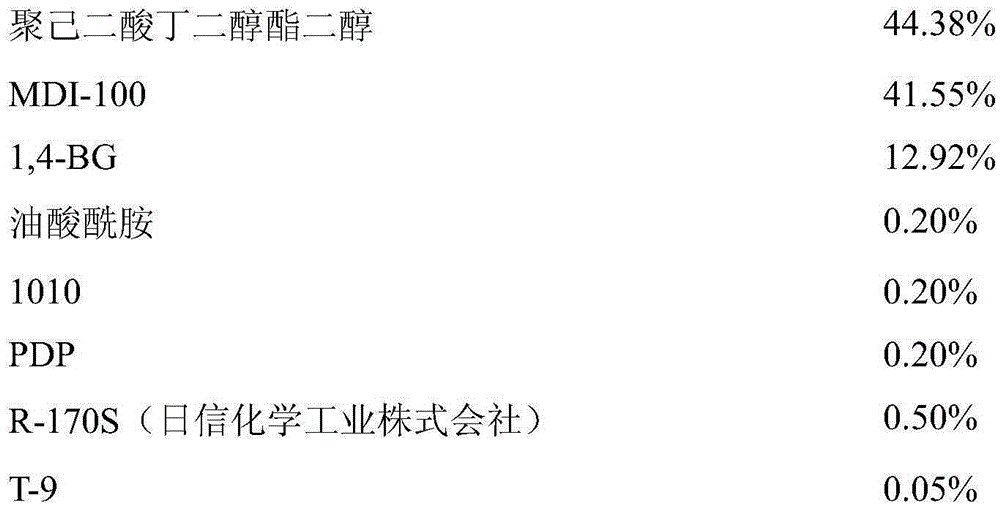

[0025] Raw material composition is as follows, by weight percentage:

[0026]

[0027] Preparation process: Weigh the raw materials of each component according to the weight percentage, and add the accurately weighed polybutylene adipate diol, oleic acid amide, 1010, PDP, R-170S and catalyst to the In reactor A, set the temperature at 100°C; place MDI-100 in reactor B, set the temperature at 60°C; place 1,4-BG in reactor C, set the temperature at 45°C; The temperature of the reactor is stable. Through the metering and filling system, the raw material components in the A / B / C reactor are mixed and injected into the feeding port of the twin-screw reactor through the high-speed rotating mixing head. The speed of the mixing head is set at 5000rpm / min, and the extrusion The temperature of the machine is 150-200°C, and the screw speed is set at 220rpm / min, so that the mixed material is uniformly reacted and plasticized in the twin-screw barrel, and is cut into oval particles with ...

Embodiment 2

[0029] Raw material composition is as follows, by weight percentage:

[0030]

[0031] Preparation process: Weigh the raw materials of each component by weight percentage, and accurately weigh polybutylene adipate diol, oleic acid amide, bisethylene stearic acid amide, 1010, PDP, SI-69 and catalyst Add it into A reactor equipped with mechanical stirring and thermometer, set the temperature at 100°C; place MDI-100 in B reactor, set the temperature at 60°C; place 1,4-BG in C reactor, The set temperature is 45°C; when the temperature of each reactor is stable, the raw material components in the A / B / C reactor are mixed and injected into the feeding port of the twin-screw reactor through the high-speed rotating mixing head through the metering perfusion system, and the speed of the mixing head is set 5000rpm / min, set extruder temperature to 145-200°C, set screw speed to 220rpm / min, so that the mixed material can be uniformly reacted and plasticized in the twin-screw barrel, and ...

Embodiment 3

[0033] Raw material composition is as follows, by weight percentage:

[0034]

[0035] Preparation process: Weigh the raw materials of each component by weight percentage, and accurately weigh polybutylene adipate diol, oleic acid amide, stearic acid amide, 1010, PDAP, R-170S, E-2203 and The catalyst is added to the A reactor equipped with mechanical stirring and thermometer, and the set temperature is 100°C; the MDI-100 is placed in the B reactor, and the set temperature is 60°C; the HQEE is placed in the C reactor, and the set temperature is 105°C; when the temperature of each reactor is stable, the raw material components in the A / B / C reactors are mixed and injected into the feeding port of the twin-screw reactor through the high-speed rotating mixing head through the metering perfusion system, and the speed of the mixing head is set at 5500rpm / min, set the temperature of the extruder to 145-195°C, set the screw speed to 220rpm / min, so that the mixed material can be uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com