Graphene sheet paint spraying and drying device

A drying device and graphene technology, applied in spraying devices, devices for coating liquid on the surface, pre-treatment of the surface, etc., can solve the problems of difficult painting at the clamping place, damage to the paint surface, and formation of defects, so as to avoid dead ends , improve production and processing efficiency, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

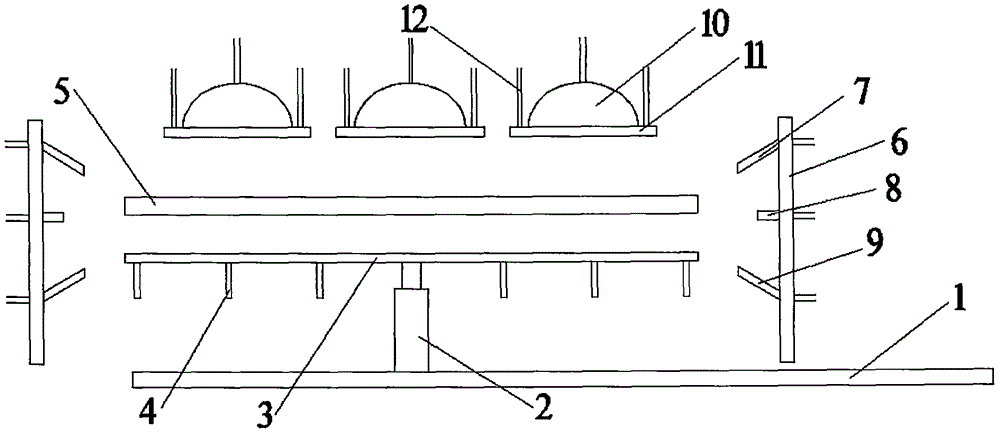

[0015] like figure 1 As shown, a kind of graphene sheet paint spraying and drying device of the present embodiment comprises a slide rail 1, a placement table 3, a paint spray rack 6 and a vacuum suction cup 10, and a telescopic support rod 2 is installed in the slideway of the slide rail 1, and the The upper end of the telescopic support rod 2 is fixedly connected to the bottom center of the placing table 3, and the drying port with a rounded table body structure is uniformly opened on the placing table 3, and the first hot air connected to the drying port is provided under the placing table 3 Tube 4, graphene plate 5 is placed on the placement platform 3, and the two sides of the placement platform 3 are symmetrically provided with paint spraying racks 6, and the paint spraying rack 6 is provided with upper paint spray nozzles 7 and middle paint spray nozzles 8 at intervals from top to bottom With the lower paint spray nozzle 9, the upper paint spray nozzle 7 is aimed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com