Processing technique of Cui Ya tea

A processing technology, the technology of green buds, applied in the field of processing technology of green bud tea, can solve the problems of flatness, flatness, lack of straightness, large differences in color, aroma and taste, and unstable performance, achieving good stability and reducing dosage. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

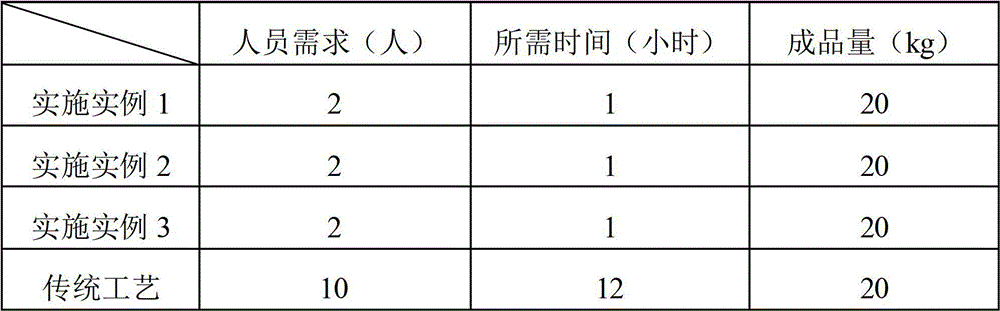

Examples

Embodiment 1

[0020] (1) Fresh leaves: Pick the tender shoot spring tea of Meijiang moss tea in Guizhou Province by cutting off the single bud by manual fingernails, and separate the attached water leaves and non-attached water leaves.

[0021] (2), Levels 1, 2 and 3 are stacked separately without crowding or pressing.

[0022] ①, first-level length: 1≤length≤1.5cm

[0023] ②, secondary length: 1.5

[0024] ③, three-level length: 2

[0025] (3) Withering: Spread the fresh leaves on the withering tank with a thickness of 3cm. The withering time depends on whether there is attached water or no attached water. It is 5 hours for leaves with water and 3 hours for leaves without water, and the wind speed is assisted by a blower.

[0026] (4) Finishing: Use a 6csT-40 drum continuous finishing machine for finishing, the pot temperature at the inlet is 150°C, the pot temperature at the exit is 120°C, and the rotating speed is 57r / min. Set the time for the withered leave...

Embodiment 2

[0035] (1) Fresh leaves: Pick the tender shoot summer tea of Meijiang moss tea in Guizhou Province by hand-cutting single-bud nails, and separate the attached water leaves and non-attached water leaves.

[0036] (2), Levels 1, 2 and 3 are stacked separately without crowding or pressing.

[0037] ①, first-level length: 1≤length≤1.5cm

[0038] ②, secondary length: 1.5

[0039] ③, three-level length: 2

[0040] (3) Withering: Spread the fresh leaves on the withering tank with a thickness of 4cm. The withering time depends on whether there is attached water or no attached water. Generally, it is 6.5 hours with water leaves and 4 hours without water leaves, and the wind speed is assisted by a blower.

[0041] (4) Finishing: Use a 6csT-40 drum continuous finishing machine to complete the process. The pot temperature at the entrance is 175°C, the pot temperature at the exit is 135°C, and the rotating speed is 57r / min. Set the time for the withered leaves...

Embodiment 3

[0050] (1) Fresh leaves: Pick the tender autumn tea leaves of Meijiang fine-bred moss tea in Guizhou Province by hand-cutting single-bud fingernails, and separate the attached water leaves and non-attached water leaves.

[0051] (2), Levels 1, 2 and 3 are stacked separately without crowding or pressing.

[0052] ①, first-level length: 1≤length≤1.5cm

[0053] ②, secondary length: 1.5

[0054] ③, three-level length: 2

[0055] (3) Withering: Spread the fresh leaves on the withering trough with a thickness of 5cm. The withering time depends on whether there is attached water or not. Generally, it takes 8 hours for leaves with water and 5 hours for leaves without water. Use a blower to assist the wind speed.

[0056] (4) Finishing: Use a 6csT-40 drum continuous finishing machine to complete the process. The pot temperature at the inlet is 200°C, the pot temperature at the exit is 150°C, and the rotating speed is 57r / min. Set the time for the withered lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com