Multi-mechanical-arm collaborative offline programming method based on RoboDK

An off-line programming, robotic arm technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as obvious engineering transformation efficiency, lack of collaborative control schemes, and poor operation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

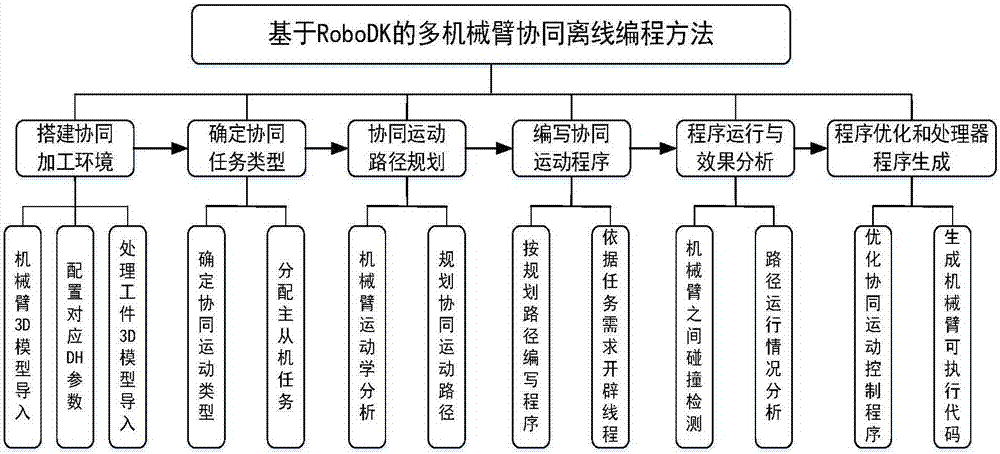

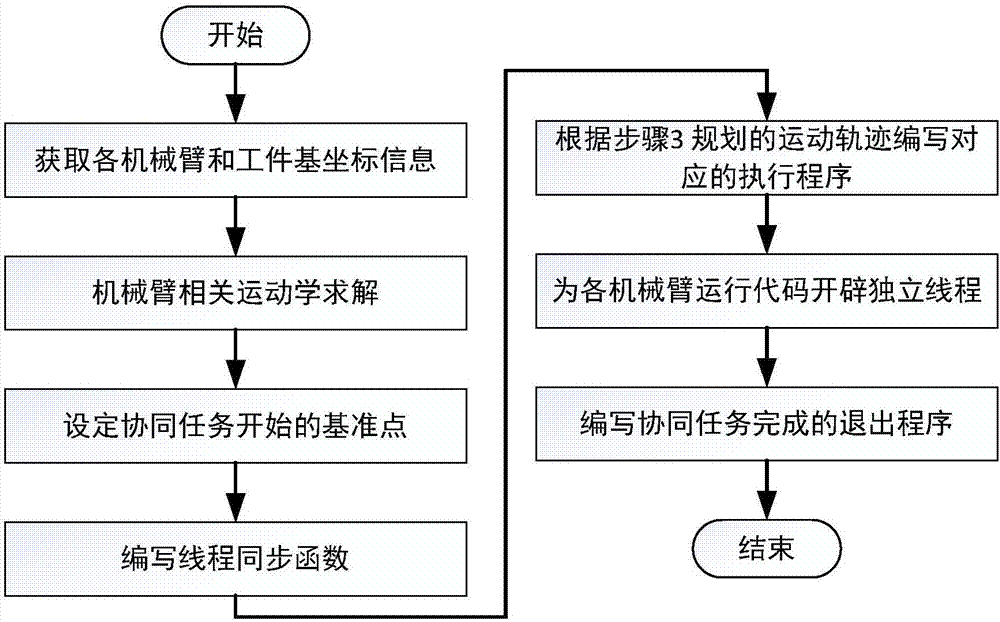

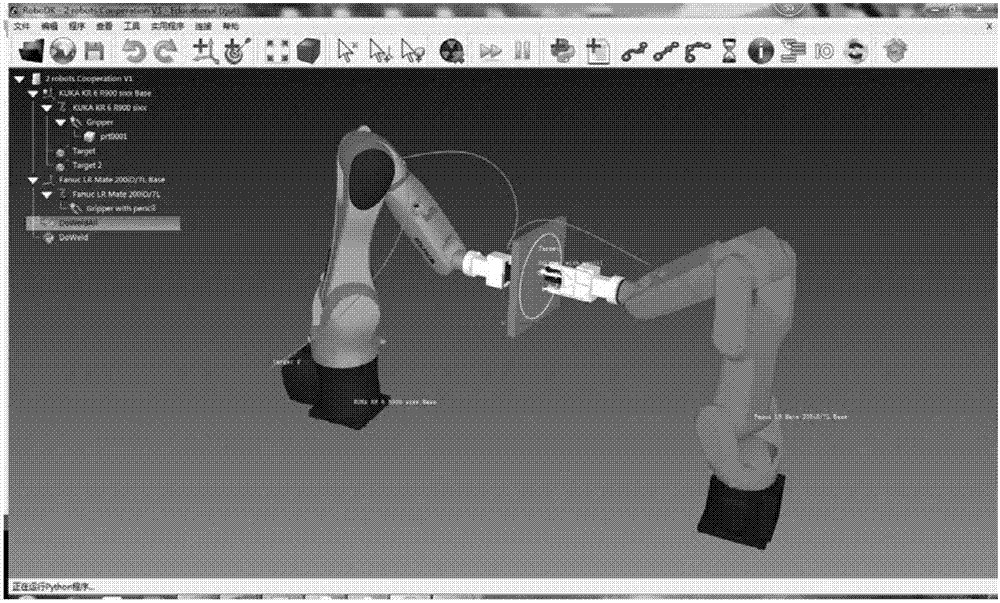

[0054] The present invention aims at the imperfection and lack of function of the current multi-manipulator collaborative offline programming method, and considers the urgent need of the manufacturing industry 2025 to improve the processing ability of industrial robots. Based on the RoboDK platform and combined with its secondary developed API function, a relatively The perfect collaborative off-line programming method for manipulators improves the efficiency of off-line programming development for collaborative control and greatly enhances the strength of manipulators in the field of production and processing. The present invention first imports the 3D models of the robotic arm, end effector, and processed workpiece into the RoboDK visualization interface, configures the DH parameters of the robotic arm to establish a complete robotic arm simulation model, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com