Full-automatic robot-assisted machining production line

A robot-assisted and fully automatic technology, applied in metal processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of difficult large-scale parts processing and production, high labor intensity of workers, and low degree of automation, so as to reduce Labor intensity and labor cost, improve machining efficiency, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

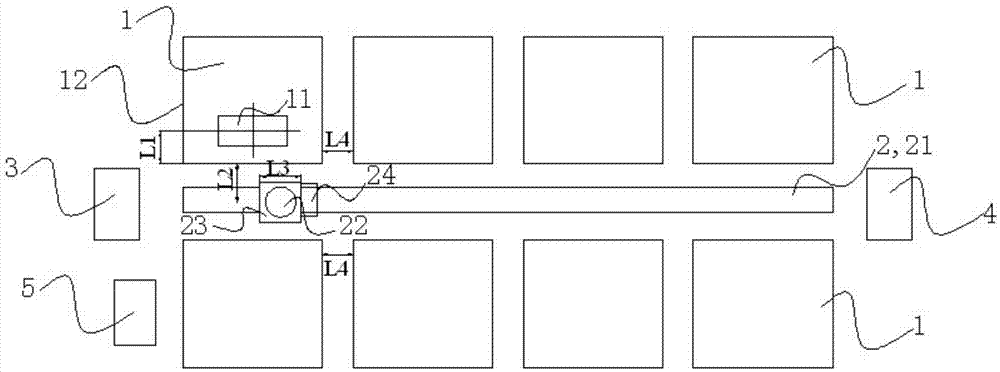

[0021] See figure 1 , the present invention comprises a plurality of CNC machine tools 1, robot auxiliary devices 2 and robot control boxes 5; The two ends of the device 2 are respectively provided with a feeding table 3 and a feeding table 4 . The robot auxiliary device 2 comprises a robot sliding guide rail 21 and a robot 22 positioned on the sliding guide rail 21. The robot 22 is slidingly connected with the sliding guide rail 21 through a robot base 23. The front portion of the robot base 23 is also provided with an accompanying material platform 24, which can The CNC machine tool 1 is loaded and unloaded at any time. The robot 22 is rotatably connected with the robot base 23, and can rotate 360° around the robot base 23. The robot 22 also includes a robot arm, which is scalable and expands the range of motion of the robot 22. One or two double grippers can be installed on the robot arm according to actual needs.

[0022] There are 2-10 CNC machine tools 1 in each row o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com