Numerical control punching machine tool

A technology of CNC punching and machine tools, applied in the direction of punching tools, metal processing equipment, feeding devices, etc., can solve the problems of high processing cost and low processing efficiency, and achieve the goal of improving production and processing efficiency, reducing labor costs and processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

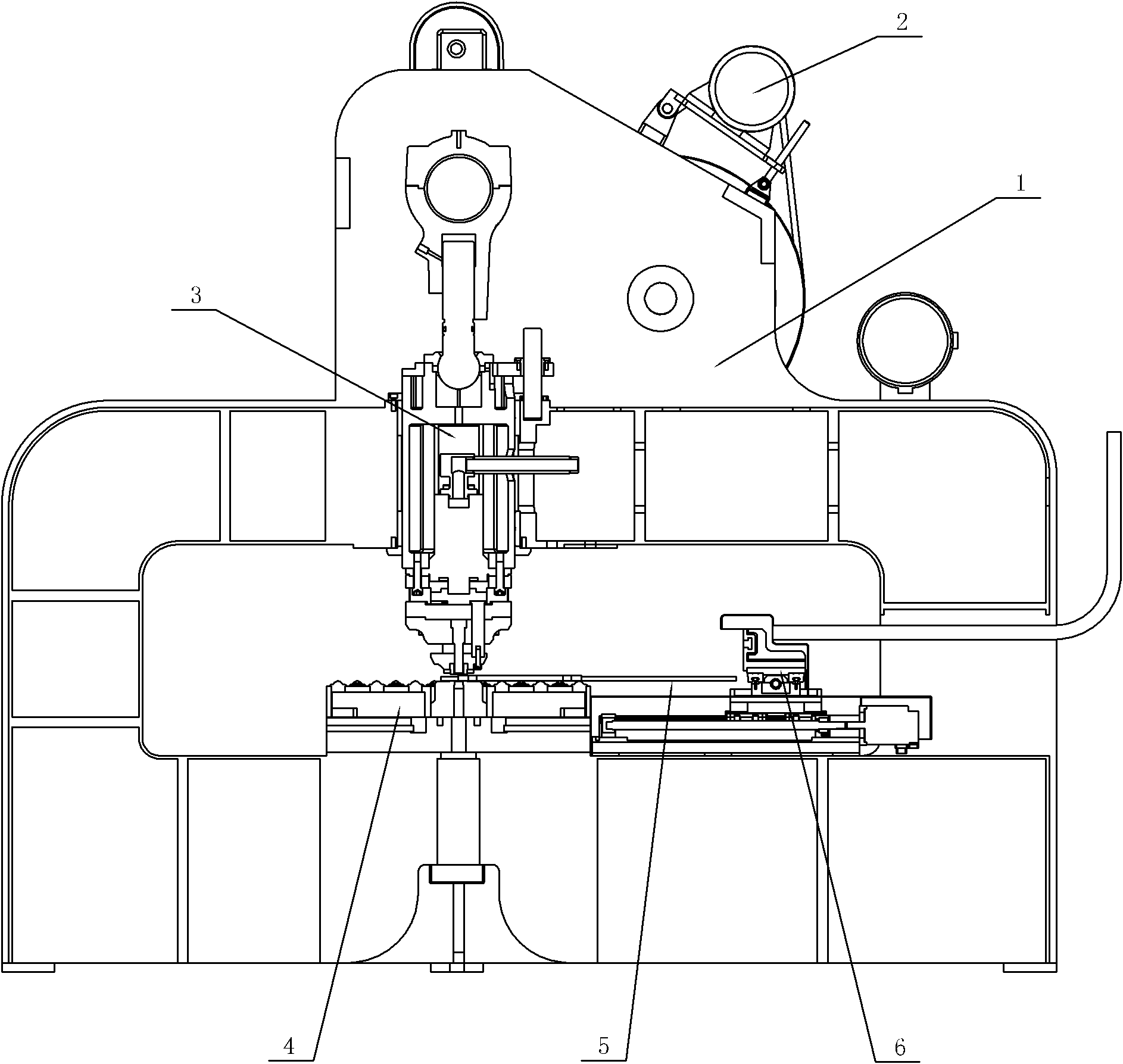

[0025] like figure 1 A numerically controlled punching machine tool shown includes a gantry-type body 1, on which a punch mechanism 3 for punching and a power transmission mechanism for providing punching power to the punch mechanism 3 are provided. 2. The feeding mechanism 6 for clamping and transferring the small thick plate 5 and the material platform mechanism 4 located below the punch mechanism 3 for placing the small thick plate 5 . The fuselage breaks the conventional press fuselage structure design and adopts a gantry-type fuselage structure, which has high structural precision and good deformation resistance, which can better ensure the punching accuracy of the mold and improve the service life of the mold.

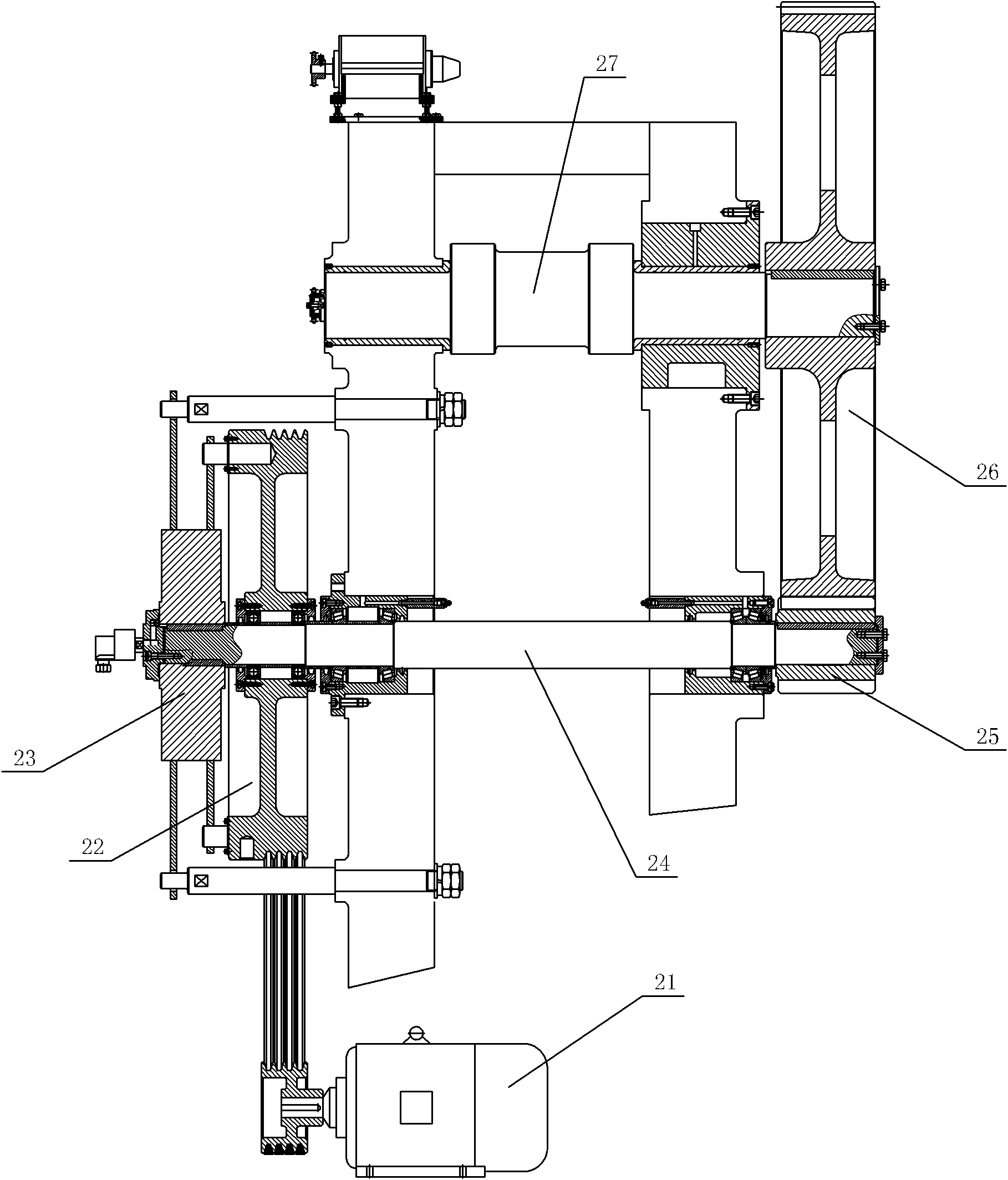

[0026] like figure 2 The power transmission mechanism 2 shown includes a motor 21 installed on the fuselage 1, the motor 21 is connected with a flywheel 22, and the flywheel 22 is connected with a transmission shaft 24 through a clutch 23, and the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com