Automobile tire rapid maintenance and correction device

An automobile tire and fast technology, applied in tire installation, wheel assembly and disassembly equipment, wheels, etc., can solve the problem of automobile tires being unable to be automated, and achieve the effect of tire maintenance and correction, automatic handling, and labor intensity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

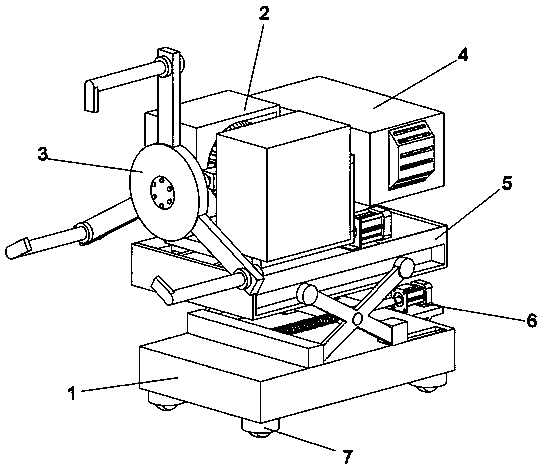

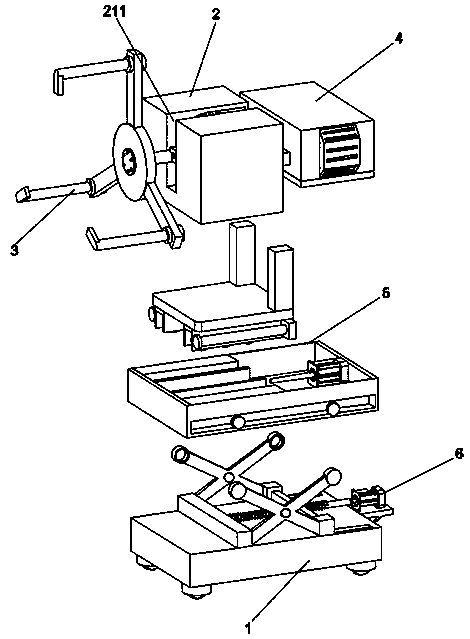

[0044] A rapid repair and correction device for automobile tires, including a mobile base 1, characterized in that it also includes:

[0045] Lifting component 6, the lifting component 6 is arranged on the upper surface of the mobile base 1, and the lifting component 6 is used for lifting the Y-axis rotation mechanism 2, the tire clamping component 3, the power output mechanism 4 and the Z-axis adjustment mechanism 5;

[0046] The Z-axis adjustment mechanism 5, the Z-axis adjustment mechanism 5 is arranged above the lifting assembly 6, and the Z-axis adjustment mechanism 5 is used to adjust the positions of the Y-axis rotation mechanism 2, the tire clamping assembly 3 and the power output mechanism 4 in the Z-axis direction;

[0047] Y-axis rotation mechanism 2, Y-axis rotation mechanism 2 is arranged on the top of Z-axis adjustment mechanism 5, and Y-axis rotation mechanism 2 is used to rotate the position of tire clamping assembly 3 in the Y-axis direction, and adjust tire cl...

Embodiment 2

[0053] Embodiment 2: the difference based on Embodiment 1 is;

[0054] Lifting assembly 6 includes: motor mounting frame 600, decelerating motor 601, T-shaped screw rod 602, linear bearing rod 603, screw rod connecting block 604, cross plate 605, pin shaft 606, reinforcing rod 607, guide groove 608 and lifting bracket 609;

[0055] The rear end of the mobile base 1 is fixedly provided with a motor mounting frame 600, and the top surface of the motor mounting frame 600 is fixedly mounted with a geared motor 601. The outer thread is connected with a screw connection block 604, and the rear end of the top surface of the mobile base 1 is symmetrically provided with two guide grooves 608, and a linear bearing rod 603 is fixedly arranged in the guide groove 608, and the two ends of the screw connection block 604 are connected with two straight lines respectively. The bearing rod 603 is socketed, and the middle part of the top surface of the mobile base 1 is also fixedly provided wi...

Embodiment 3

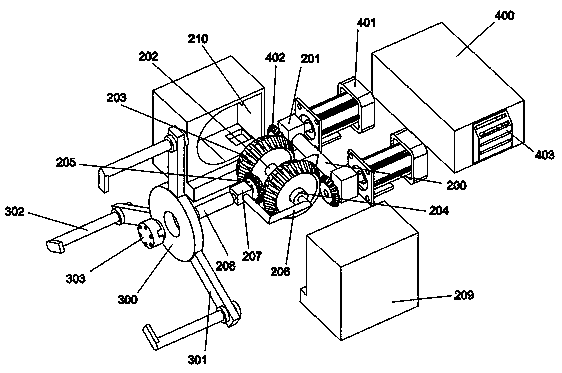

[0058] Embodiment 3: the difference based on embodiment 1 and 2 is;

[0059] The Z-axis adjustment mechanism 5 includes: an installation box 500, a rotating block 501, a cylinder 502, a slide groove 503, a strip groove 504 and a limit groove 505;

[0060] The outer sides of the left and right ends of the installation box 500 are symmetrically provided with two rotating blocks 501, the inner ends of the rotating blocks 501 are slidingly connected with the side surfaces of the installation box 500, and the outer sides of the rotating blocks 501 are rotationally connected with the inner sides of the upper ends of the reinforcing rods 607. After the installation of the box body 500 A cylinder 502 is fixedly installed on the inner wall of the end, and a strip groove 504 is provided in the middle position of the installation box 500, and two slide grooves 503 are symmetrically opened on the left and right sides of the strip groove 504 in the installation box 500. A limiting groove 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com