Intelligent carrying device

An intelligent handling and station technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of large positioning processing errors, affecting product quality, affecting the service life of line pipes, etc., achieving high positioning accuracy and improving product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

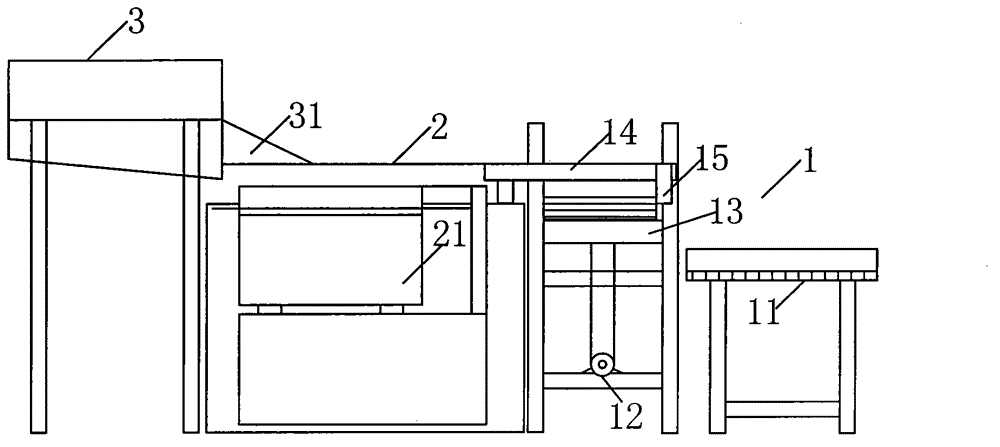

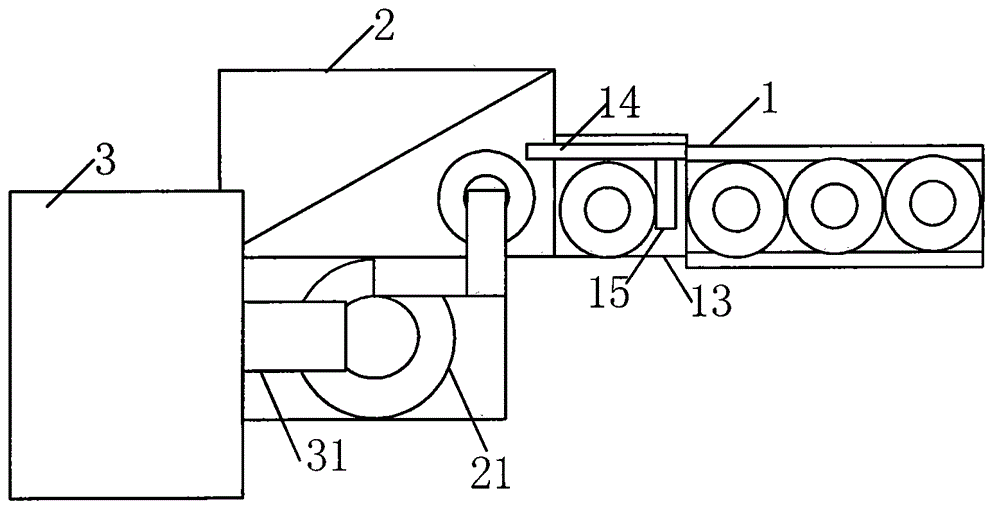

[0011] like figure 1 and 2 As shown, it is a structural schematic diagram of an intelligent handling device, including: a first station 1, a second station 2, and a third station 3. The first station 1 includes a belt line 11, a servo motor 12, a lifting Pallet 13, rodless cylinder 14, shift fork 15; the second station 2 includes a vibrating feeding tray 21; the third station 3 includes a stock box 31; the servo motor 12 drives the lifting tray 13 through a belt Lifting, the rodless cylinder 14 drives the shift fork 15 to move, pushing the workpiece to the second station 2, and the vibrating feeding plate 21 sends the wall tube to the middle of the workpiece.

[0012] An intelligent handling device provided by the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com