Displacement mechanical arm with vision system

A vision system and robotic arm technology, applied in the field of shifting robotic arms, can solve the problems of very high installation space requirements, large robotic arms, and low safety factor, so as to reduce labor intensity of workers, small size, and improve use safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

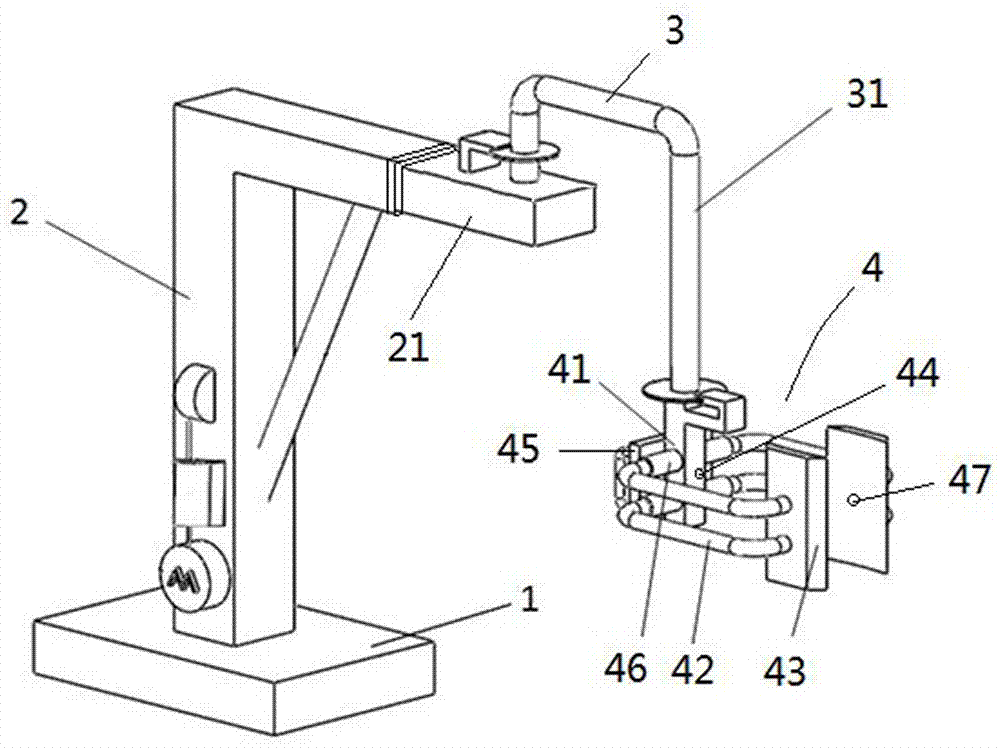

[0021] A kind of displacement mechanical arm with visual system of the present invention, such as figure 1 As shown, it includes a control module, a base 1, a support 2, a transport main shaft 3 and a transport clamping device 4, and the end of the support 2 is provided with a horizontal telescopic device 21 and is connected to the transport main shaft 3 through the horizontal telescopic device 21. The end of the transport spindle 3 is provided with a vertical telescopic device 31 and is connected to the transport clamping device 4 through the vertical telescopic device 31; the transport clamp 4 includes a rotating shaft 41 and a pair of clamping arms 42 arranged on the rotating shaft 41 , a pair of suction cups 43, a visual device 44 and an operating panel 45; the pair of clamp arms 42 are connected with an opening and closing drive system 46, and the pair of suction cups 43 are connected with a grabbing drive system; the surface of the pair of suction cups 43 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com