Heavy load intelligent carrying traveling crane

A technology of intelligent handling and track beams, which is applied in cranes, traveling mechanisms, transportation and packaging, etc., can solve the problems of low positioning accuracy of flexible lifting, increase the problem of precise positioning and lifting shaking, ingenious design, simple and reliable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

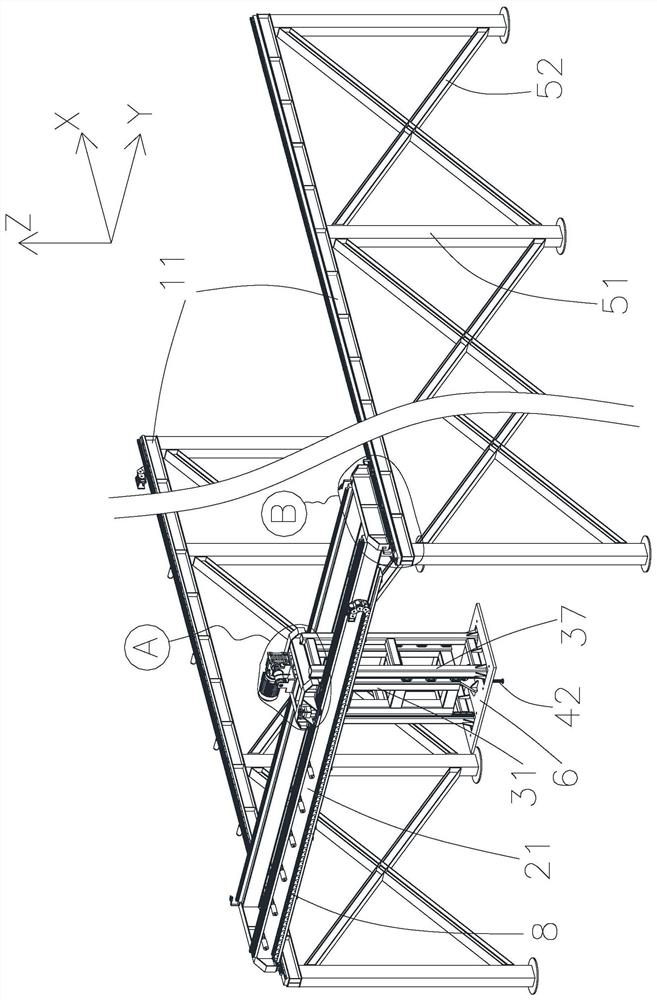

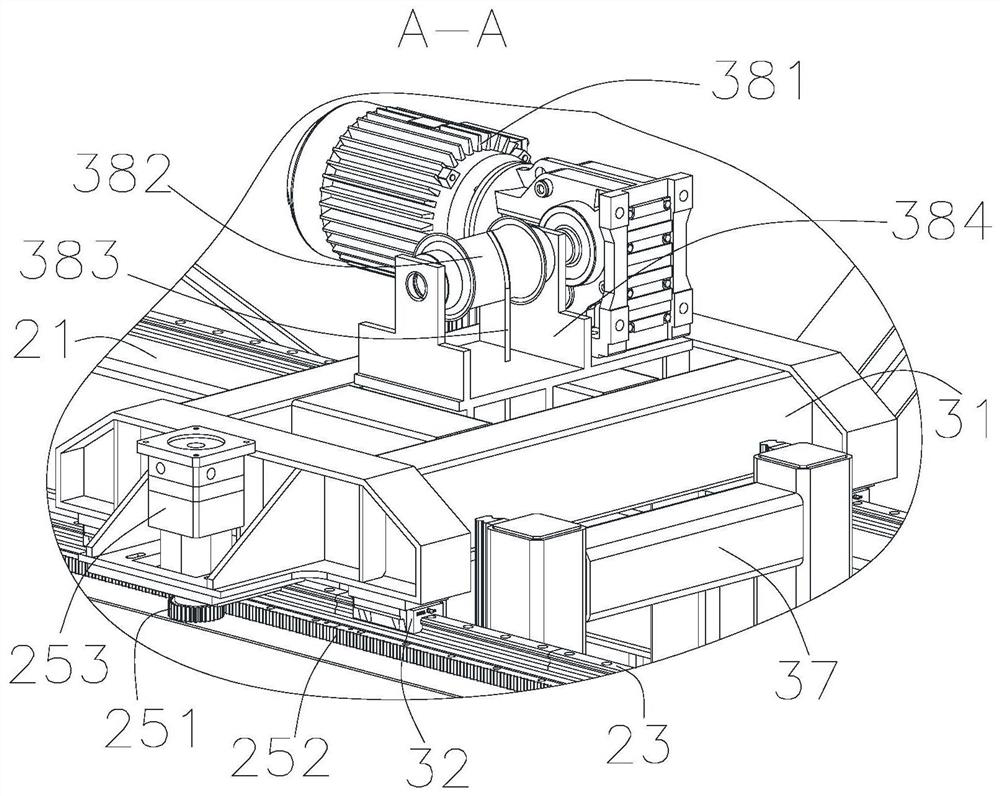

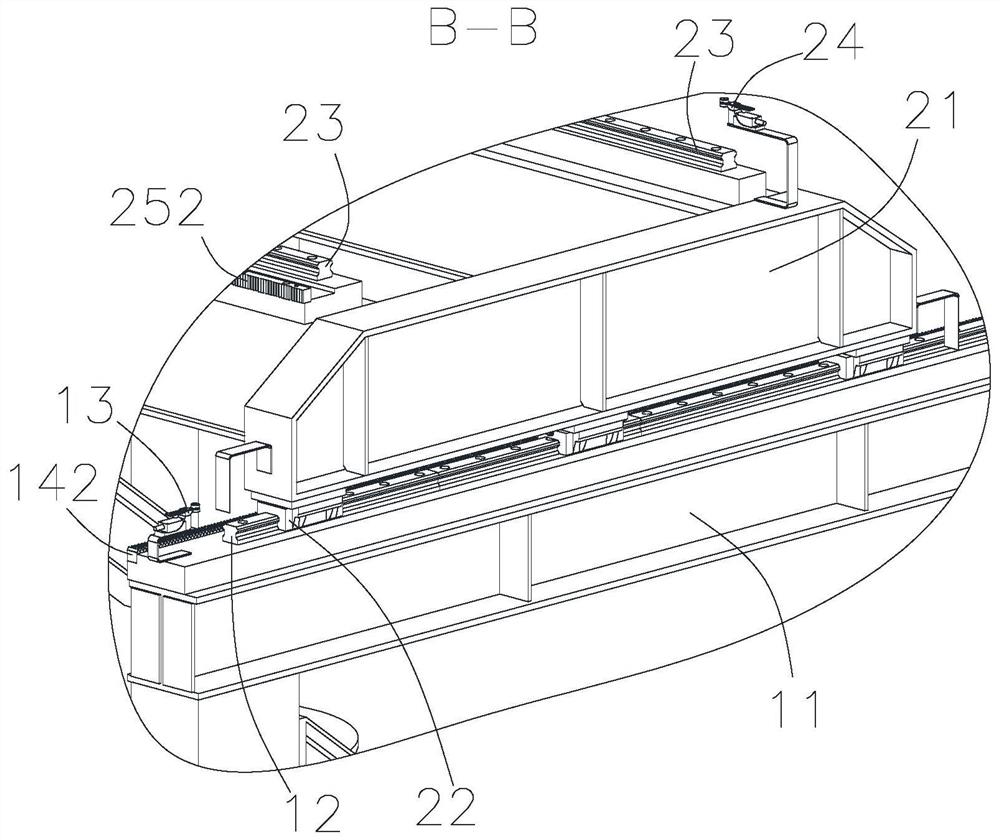

[0035] Such as Figure 1-12 As shown, a heavy-duty intelligent transport vehicle includes X-direction track beams 11, Y-direction track beams 21 and Z-direction track beams 31 perpendicular to each other, and the Z direction faces the vertical direction. The X-direction track beams 11 are composed of several Supported by uprights 51, the uprights 51 are fixedly connected to the X-direction track beam 11 through bolts, and several uprights 51 are arranged in sequence along the length direction of the X-direction track beam 11, and tie bars 52 are intersected between adjacent uprights 51, The tie bars 52 are fixedly connected to the column 51 through bolts, the Y-direction track beam 21 is driven by the first drive mechanism to move along the X-direction track beam 11, and the Z-direction track beam 31 is driven by the second drive mechanism to move along the Y-direction track beam 21 to move, the Z-direction track beam 31 is slidably provided with a lift frame 37, and the lift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com