Battery module grasping finger and battery module assembling robot with same

A technology for battery modules and clamping claws, which is applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of low assembly efficiency, high labor intensity, safety and reliability to be improved, etc., to improve assembly efficiency, Reduce labor intensity, realize the effect of automatic handling and automatic assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

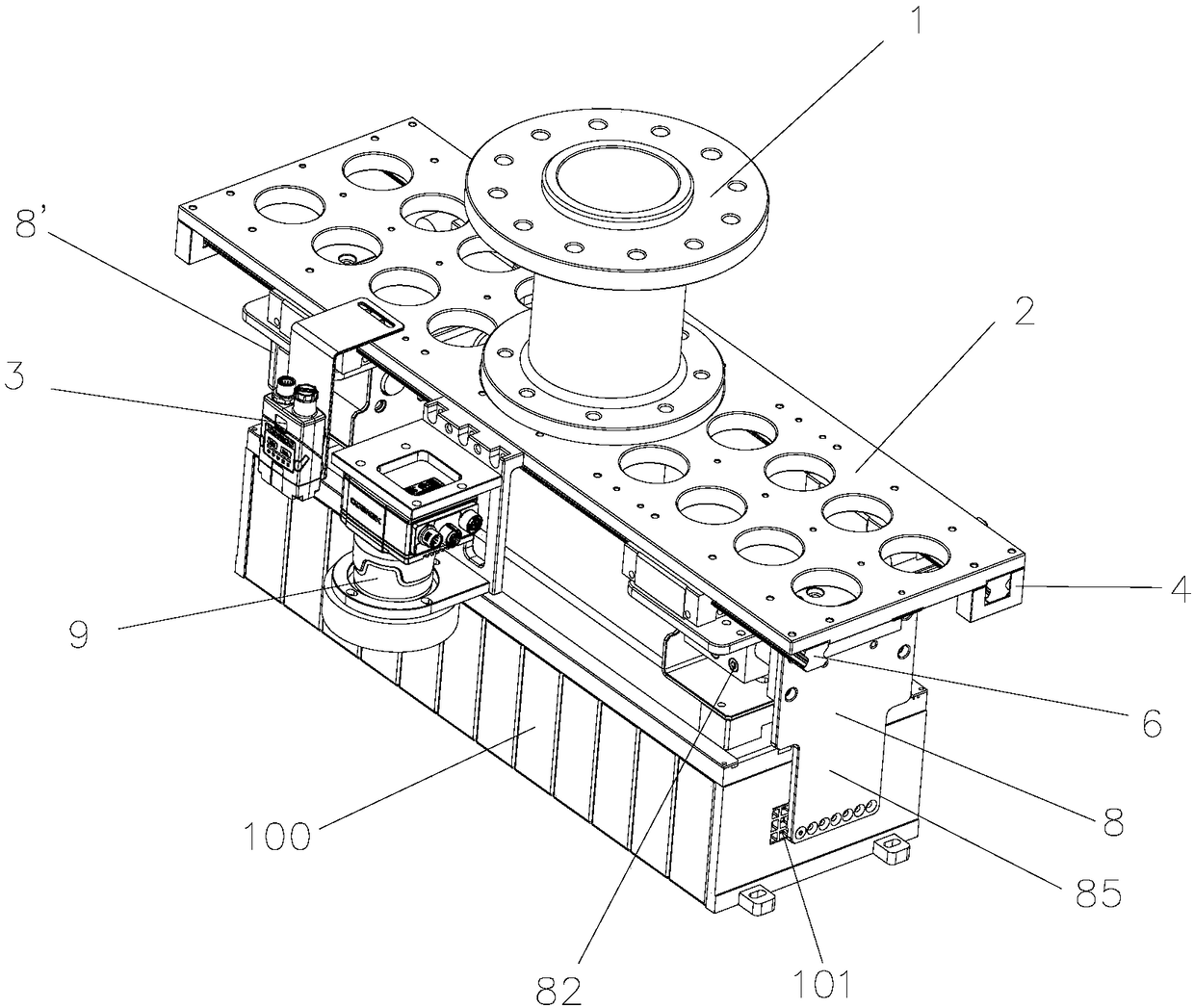

[0037] The first aspect of the present invention provides a battery module clamping gripper, which is used to clamp the side of the battery module 100 (such as a lithium battery for vehicles), such as the end plates on both sides, so as to carry the battery module 100 And automatic assembly, such as performing operations such as assembly into boxes.

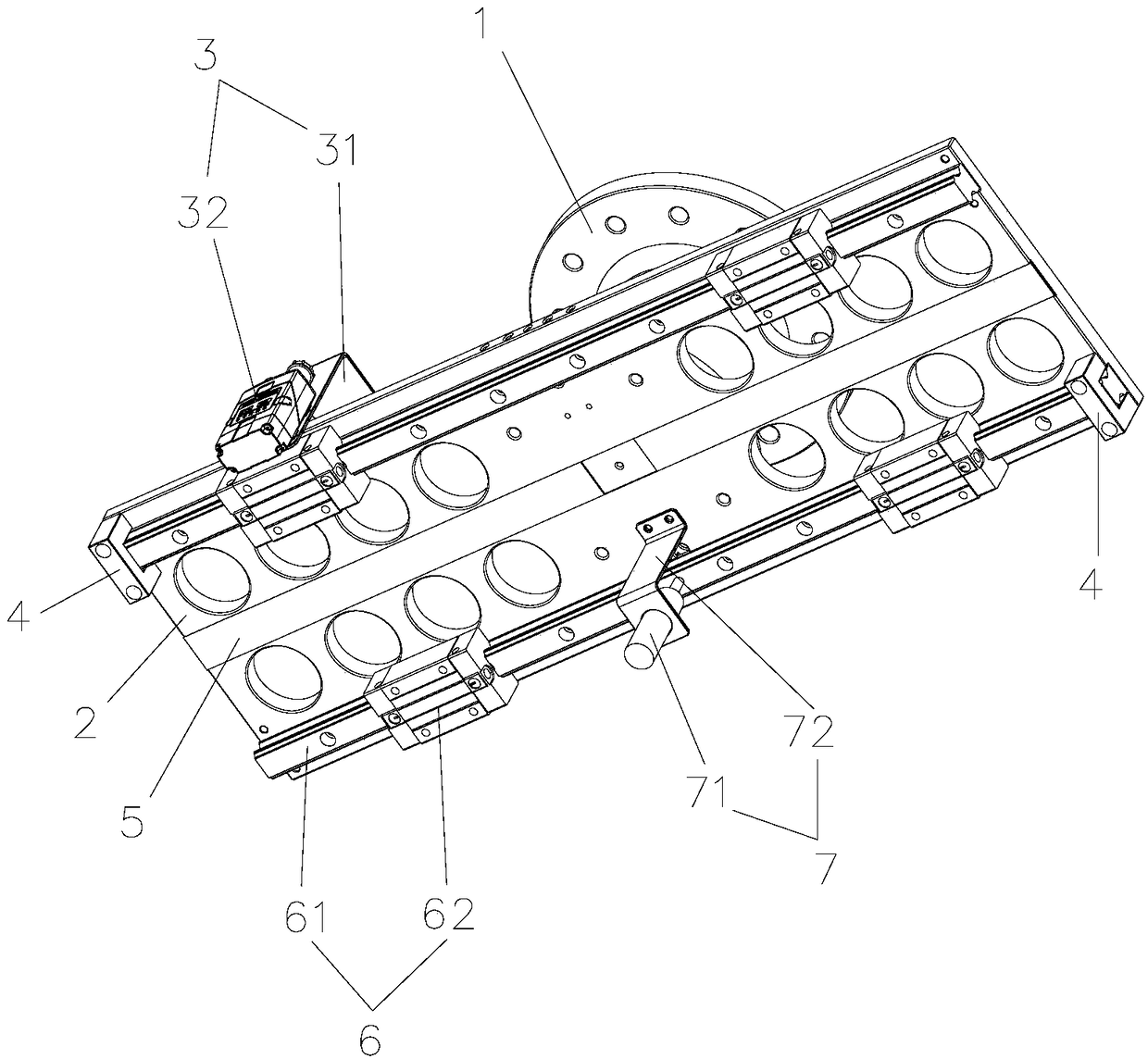

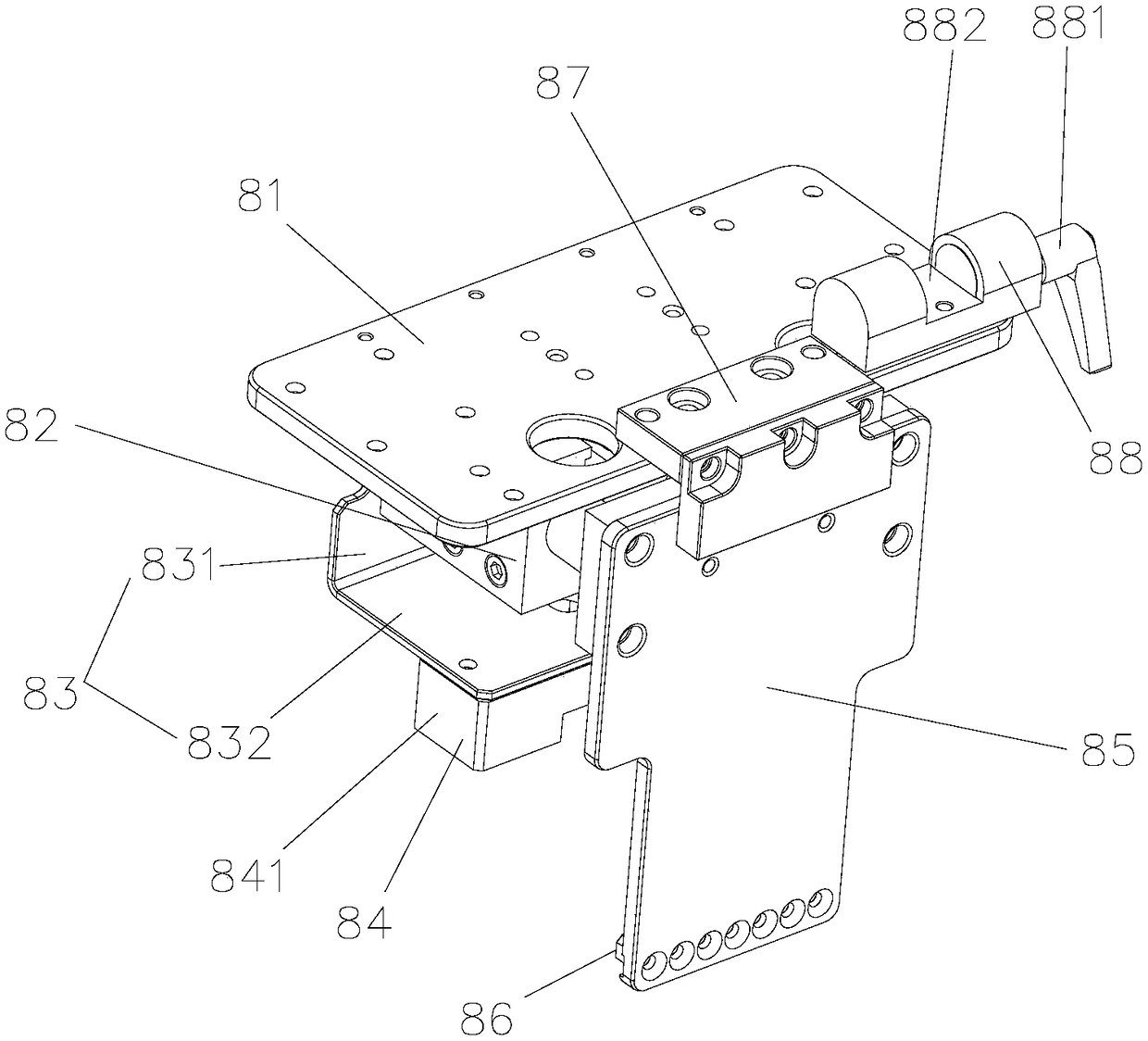

[0038] Such as figure 1 As shown, the battery module clamping claw includes a base plate 2, a first clamping component 8 and a second clamping component 8', and the first clamping component 8 and the second clamping component 8' are mutually Relatively installed below the base plate 2, the first clamping assembly 8 and the second clamping assembly 8' both include a clamping part 85 and a driving part 82 (for details, refer to image 3 ), the driving part 82 is used to drive the clamping part 85 to move so as to perform the clamping operation. That is, when the clamping portions 85 of the two clamping assemblies move toward each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com