Intelligent carrying vehicle system adopting screw rod for jacking

An intelligent pallet truck and lead screw technology, applied in the field of warehousing, can solve the problems of low efficiency, high labor cost and low degree of automation, and achieve the effect of avoiding collision and realizing automatic handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

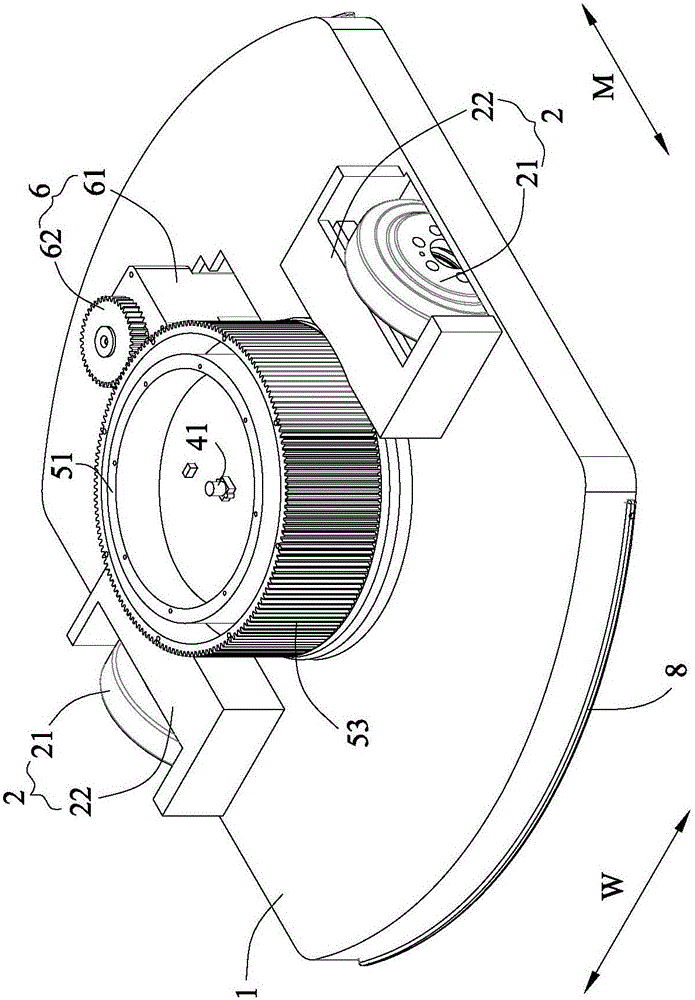

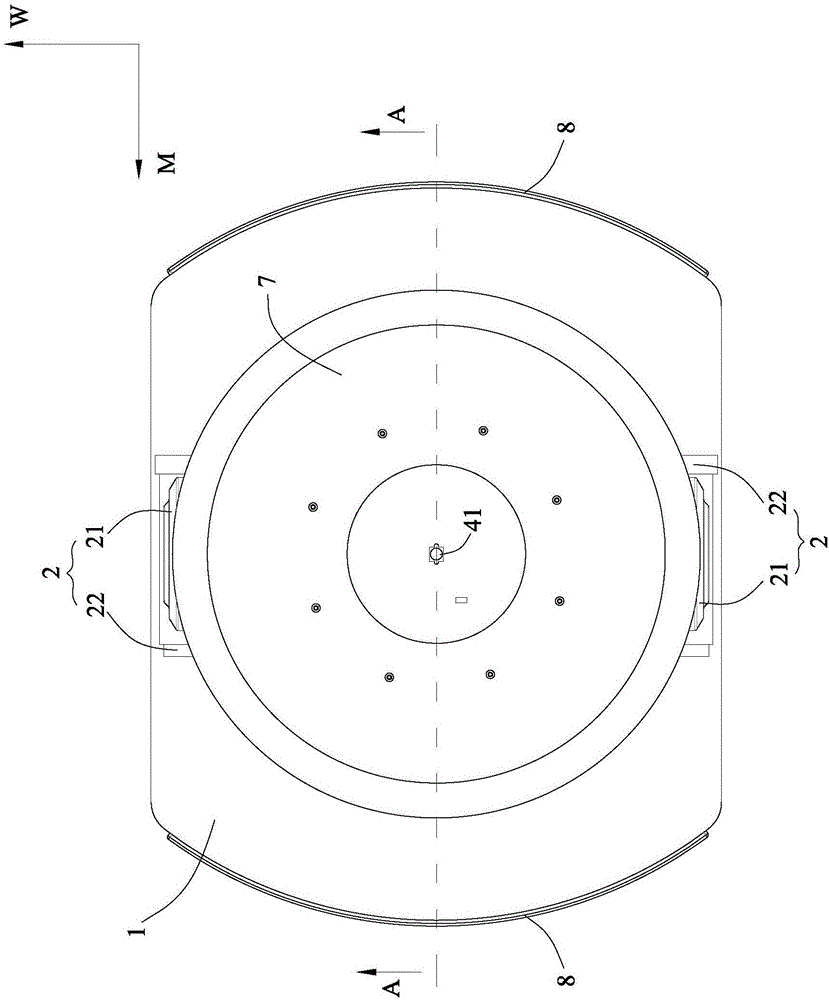

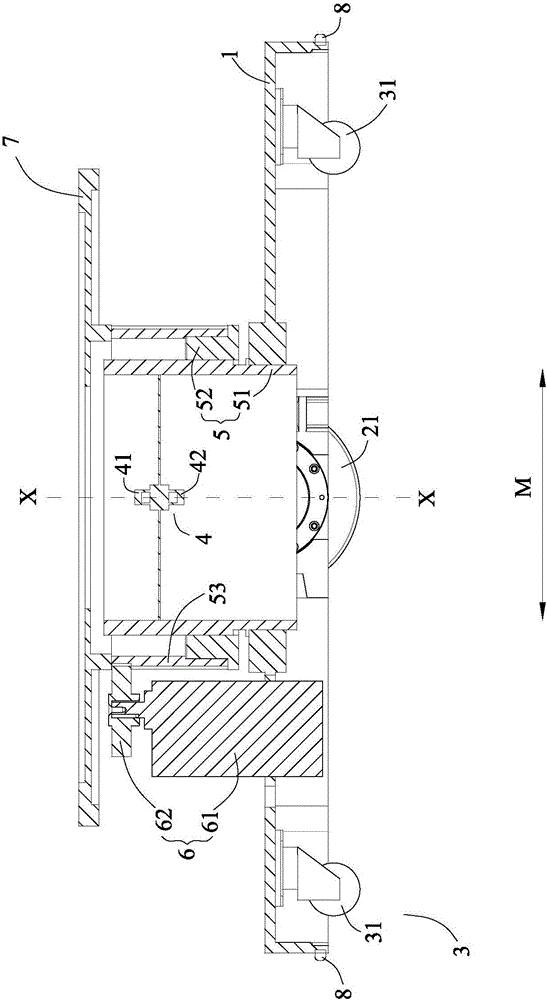

[0029] The intelligent transport vehicle system that adopts screw jacking according to the present invention will be described in detail below with reference to the accompanying drawings.

[0030] refer to Figure 1 to Figure 8 , according to the present invention, the intelligent transport vehicle system that adopts screw jacking includes: a vehicle body 1; a first driving mechanism 2 for driving the vehicle body 1 and changing the moving direction of the vehicle body 1; an auxiliary support mechanism 3 for the vehicle body 1 provides auxiliary support; the guiding mechanism 4 identifies the traveling path of the vehicle body 1 and the position of the object to be transported; the screw transmission mechanism 5 is arranged on the vehicle body 1; the second driving mechanism 6 drives the screw transmission mechanism 5 to rotate; And the tray 7 is fixed on the lead screw transmission mechanism 5, and can move up and down with the rotation of the lead screw transmission mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com